方案详情

文

采用LaVision的Davis 8.3.0软件平台,IagerHS4M高速相机,以及LDY300高重频激光器,构成一套时间分辨粒子成像测速系统(TR-PIV),并利用该系统对低速非常规蒸汽流流场进行了实验测量和理论分析。

方案详情

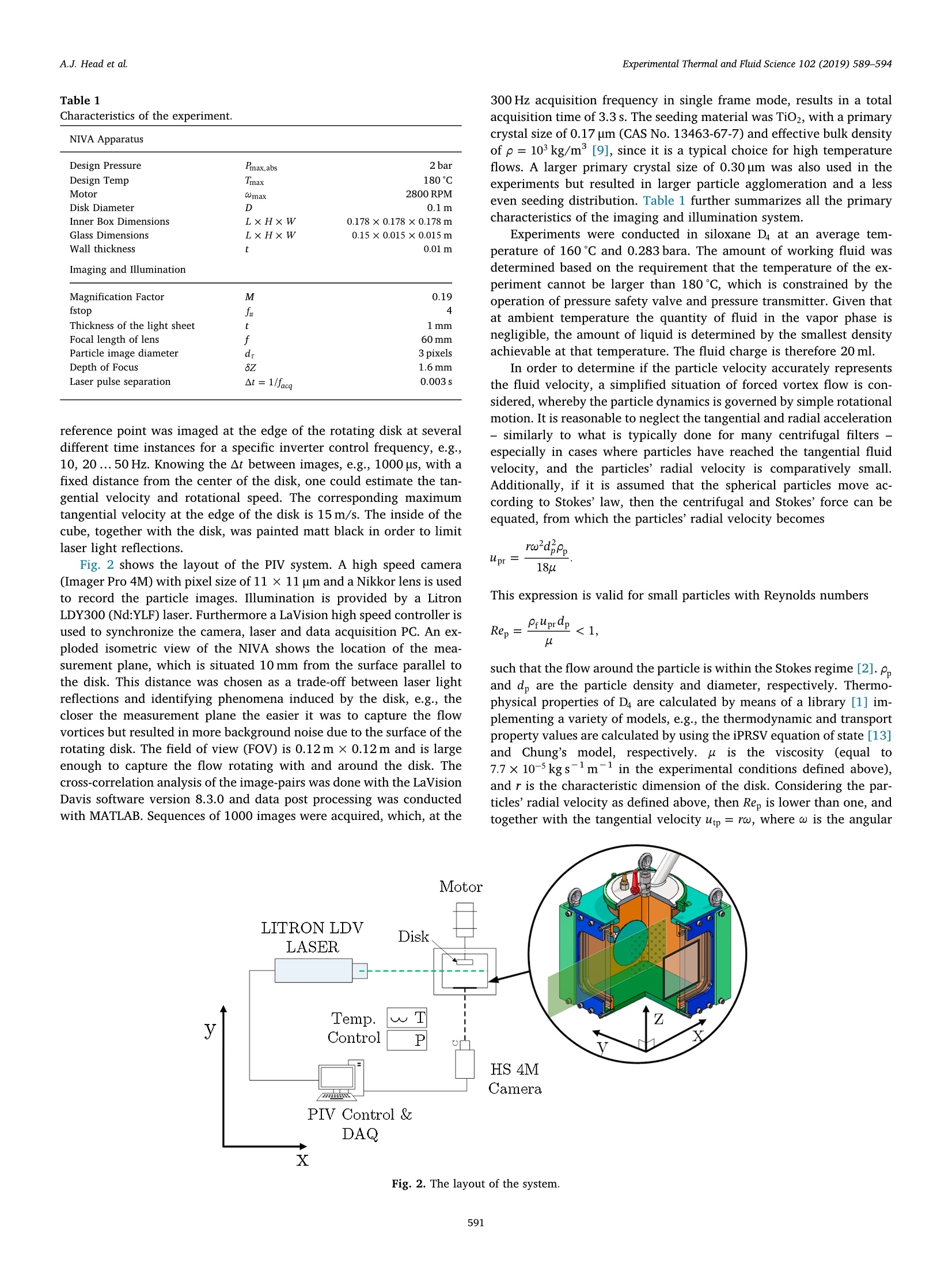

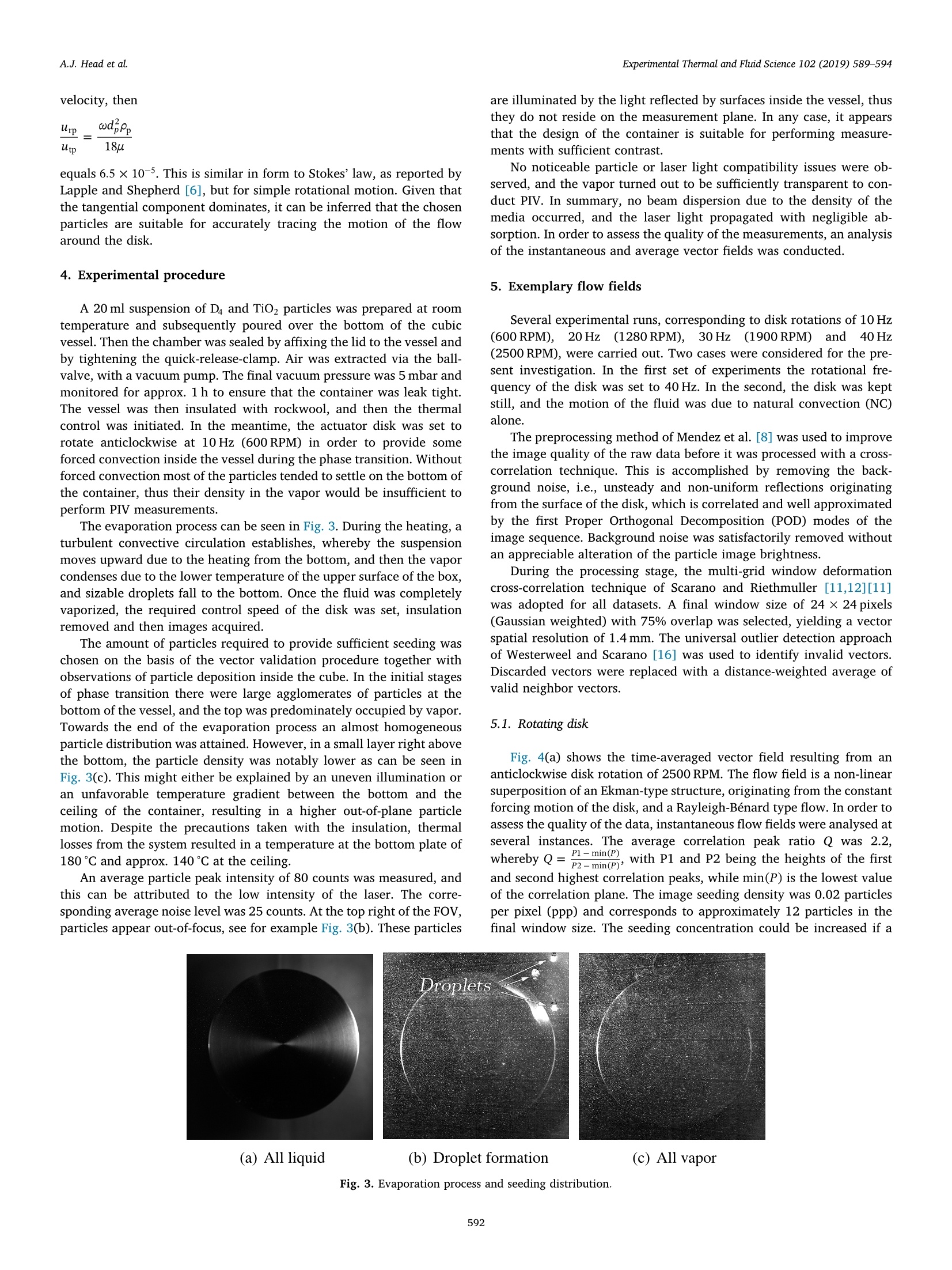

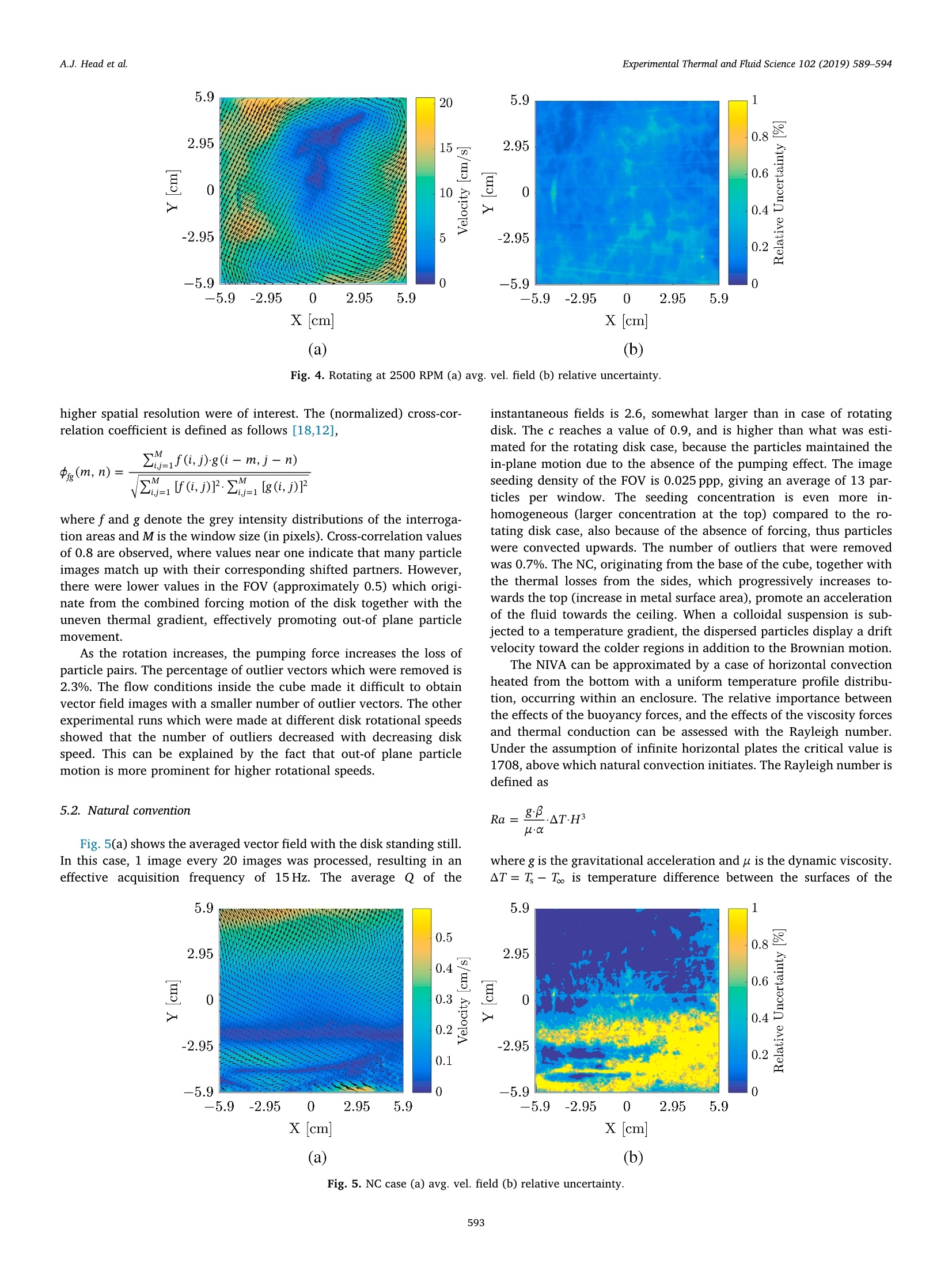

Experimental Thermal and Fluid Science 102 (2019) 589-594Contents lists available at ScienceDirect A.J. Head et al.Experimental Thermal and Fluid Science 102 (2019) 589-594 Experimental Thermal and Fluid Science journal homepage: www.elsevier.com/locate/etfs Feasibility of particle image velocimetry for low-speed unconventionalvapor flows A.J. Head, M. Novara, M. Gallo, F. Schrijer, P. Colonna * “Propulsion & Power, Aerospace Engineering, Delft University of Technology, Kluyverweg 1, 2629 HS, Delft, The Netherlands"Aerodynamics, Aerospace Engineering, Delft University of Technology, Kluyverweg 2, 2629 HS, Delft, The Netherlands‘Aeronautical Engineering, Inholland University of Applied Sciences, Rotterdamseweg 141, 2628AL Delft, The Netherlands “Institute of Aerodynamics and Flow Technology, DLR, Gottingen, Germany ARTICLEINFO ABSTRAC T Keywords:Siloxane fluidsLow speed rotating organic vapor flowParticle image velocimetrySeeding technique This work assesses the feasibility of the planar PIV technique to study the characteristics of a siloxane vapor D4.Titanium dioxide (TiO2) seeding particles were used to track the motion around a rotating disk in a low speedflow. Vector fields of natural convection (NC) and a superposition of NC and rotating flow were selected asexemplary cases. The particles were capable of tracing the flow since the calculated Stokes number St is6.5×10-5. The quality of the experimental data is assessed by means of particle seeding density and particleimage Signal to Noise ratio (S/N). The final results are deemed acceptable for an accurate assessment of the flowfield. Rejected outliers are below 2.3% and the relative uncertainties corresponding to the average velocity fieldsare below 1%. 1. Introduction Organic compounds are used as working fluids in many power andrefrigeration applications, such as organic Rankine cycle (ORC) andsupercritical carbon dioxide power systems, vapor compression cyclesystems, and in other chemical, and transport processes. In many ofthese processes, flows occur in the non-ideal compressible fluid dy-namic (NICFD) regime at high relative pressure and temperature [4].The fluid dynamic design of machinery operating in these conditionsnecessitates validated CFD codes. Validation can be performed only ifaccurate experimental information covering a representative range ofconditions is available. Particle image velocimetry (PIV) is arguably theexperimental technique of choice for providing these data. Some initialattempts of using PIV in this type of flows are documented in [10,14].The investigation described here aims at addressing some of the issuesrelated to utilizing PIV in high-temperature organic vapors moving atlow speed. This work serves also as a precursor study before performingPIV in transonic and supersonic flows of organic fluids in a newly builtexperimental facility [5]. 2. Optical properties and particle compatibility PIV measurements require a transparent fluid, i.e., laser light ab-sorption should be insignificant. In addition, ideally, the index of refraction should remain constant, such that aero-optical aberrationsare minimal [3]. The refractive index n and the extinction coefficient kcharacterize how light propagates through a medium. With regards tomembers of the siloxane family, e.g., MM and D4, these parameters arenot available for the vapor state because measurements of reflectance,transmittance or ellipsometric parameters are not documented. How-ever, the refractive index can be estimated from measurements of themolar refractivity together with the Lorentz-Lorenz formula and the molar volume .=Nm _MN PThis results in an explicit equation relating the refractive index tothe density of the medium, namely ( h t t ps://doi.org/ 1 0.1016/j.expthermflusci . 2018.10.028 ) ( Received 17 April 2018;Received in revised f orm 22 October 2018; A c cepted 24 October 20 1 8 ) ( 0894-1777/C 2018 The Aut h ors.Publ i shed by Else v ier Inc . Th i s is a n open access article under the CC BY-NC-ND license ) where N is Avogadro’s number, N is the number of molecules per unitvolume, and As= is the specific refractivity, with M being the molar mass. If measure-ments of the molecular refractivity are unavailable then A may be es-timated by the concept of additivity of bond refractions and by simplifiedmethods given by Warrick[15]. The A for D4 is calculated as74.5 cm³mol-1 which results in a similar index of refraction value ifcompared to that of air at low density; namely, ~1 and therefore noadditional difficulties are expected with respect to PIV measurements.However, for high speed organic flows the density variations are largerand can change by two orders of magnitude over a short distance [5],imposing up to a 7% variation in the refractive index over the expan-sion path. In this case, the apparent shift (normal or lateral) or blurring(smearing) of the particle image could change substantially [2], andmeasures should be taken to ensure an appropriate depth of focus isselected. Absorption spectra have not been reported for organosiliconcompounds in the vapor state and thus the extinction coefficient cannotbe estimated. However, provided that the medium is sufficientlytransparent for the particles to scatter enough light, then the particleimage signal to noise (S/N) ratio, i.e., the ratio between the particlepeak intensity and the image noise level, will be large enough to per-form PIV measurements. If the medium is D4, this condition is satisfiedand results are discussed in Sections 4 and 5. Particles for PIV experiments should be preferably inexpensive, non-toxic, non-corrosive, non-abrasive, non-volatile, and chemically inert.Commonly used seeding materials for high temperature flows are drymetal oxide powders, e.g., Aluminum Dioxide AlzOs or TitaniumDioxide TiO2, and Silica spheres SiO2. However, dispersing the solidparticles uniformly in a hot gas flow is challenging. Especially if theflow to be studied is formed by organic molecules, since it must not becontaminated by, e.g., water or air, as this would affect its thermalstability [7]. The introduction of solid particles by atomization of asuspension is the most viable possibility for the envisaged experiments[2]. 3. The non-intrusive vapor analyser (NIVA) PIV experiments were performed in the NIVA: organic vapour isenclosed in a vessel with optical access, and a rotating disk providesfluid motion. Fig. 1 shows the back-side view of the NIVA together withthe control hardware. The setup characteristics and design specifica-tions are listed in Table 1. A stainless-steal (SS) cube with two borosilicate (Borofloat 33)windows is positioned on top of a heating plate (max. power 2.2kW).The set-point temperature is controlled by a relay and a thermocouplewhich is located inside the bottom flange. The temperature at the topflange can be monitored with an additional thermocouple and readout Nomenclature M molar mass [kg mol] A molar refractivity [cmmol-1] angular velocity [rad sec] Vm molar volume [m’mol-1] p density [kg m3] dp particle diameter [m] pr(m,n) (normalized) cross-correlation coefficient[-] Upr particles'radial velocity [m s-] u viscosity [kgs-m-] Rep particle Reynolds number [-] volumetric thermal expansivity [K-] Utr particles'tangential velocity [ms-] thermal diffusivity[-] Ra Rayleigh number [-] Q average correlation peak ratio [-] n refractive index [-] NA Avogadro’s number [mol-] specific heat at constant pressure [JkgK-'] H characteristic thickness of fluid layer [m] k thermal conductivity[Wm~K-] Z compressibility factor [-] k extinction coefficient [-] device. In order to limit thermal losses, the SS cube’s exterior was in-sulated with rockwool. The interior of the cube is air-tightened bymeans of a metal lid and snap-clamp. The air can be removed from thecube through a ball-valve such that the organic vapor will not becontaminated. A sheet of Viton is used as a gasket, which, in addition,serves as insulator minimizing the thermal stresses of the windows.Since the operational temperature of the Siemens Sitran P200 pressuretransmitter must not exceed 145℃, the sensor was mounted at the endof a pipe which protrudes from the lid. This allows for monitoring thepressure inside the cube. Furthermore a safety blow-off valve is in-stalled to ensure that the maximum operating pressure cannot be ex-ceeded. A 0-50 Hz (0-2800RPM) frequency controller modulates a0.18kW electric motor, which connects to a 100 mm circular flat disk(located inside the cube and visible in the top-right of Fig. 2) via aflexible shaft coupling. The shaft is sealed with a Viton o-ring and issituated in a bearing holder. The inverter frequency and correspondingdisk rotation was checked directly using an optical approach. A NIVA Apparatus Design Pressure Pmax,abs 2bar Design Temp Tmax 180°C Motor @max 2800RPM Disk Diameter D 0.1m Inner Box Dimensions L ×H×W 0.178×0.178 ×0.178 m Glass Dimensions LXH×W 0.15 ×0.015×0.015 m Wall thickness 0.01m Imaging and Illumination Magnification Factor 0.19 fstop 4 Thickness of the light sheet 1mm Focal length of lens 60mm Particle image diameter 3 pixels Depth of Focus 1.6 mm Laser pulse separation At=1/facg 0.003s reference point was imaged at the edge of the rotating disk at severaldifferent time instances for a specific inverter control frequency, e.g.,10, 20...50 Hz. Knowing the At between images, e.g., 1000 us, with afixed distance from the center of the disk, one could estimate the tan-gential velocity and rotational speed. The corresponding maximumtangential velocity at the edge of the disk is 15 m/s. The inside of thecube, together with the disk, was painted matt black in order to limitlaser light reflections. Fig. 2 shows the layout of the PIV system. A high speed camera(Imager Pro 4M) with pixel size of 11 × 11 um and a Nikkor lens is usedto record the particle images. Illumination is provided by a LitronLDY300 (Nd:YLF) laser. Furthermore a LaVision high speed controller isused to synchronize the camera, laser and data acquisition PC. An ex-ploded isometric view of the NIVA shows the location of the mea-surement plane, which is situated 10 mm from the surface parallel tothe disk. This distance was chosen as a trade-off between laser lightreflections and identifying phenomena induced by the disk, e.g., thecloser the measurement plane the easier it was to capture the flowvortices but resulted in more background noise due to the surface of therotating disk. The field of view (FOV) is 0.12 m ×0.12 m and is largeenough to capture the flow rotating with and around the disk. Thecross-correlation analysis of the image-pairs was done with the LaVisionDavis software version 8.3.0 and data post processing was conductedwith MATLAB. Sequences of 1000 images were acquired, which, at the 300 Hz acquisition frequency in single frame mode, results in a totalacquisition time of 3.3 s. The seeding material was TiO2, with a primarycrystal size of 0.17 um (CAS No. 13463-67-7) and effective bulk densityof p=103kg/m³[9], since it is a typical choice for high temperatureflows. A larger primary crystal size of 0.30 um was also used in theexperiments but resulted in larger particle agglomeration and a lesseven seeding distribution. Table 1 further summarizes all the primarycharacteristics of the imaging and illumination system. Experiments were conducted in siloxane D4 at an average tem-perature of 160℃ and 0.283 bara. The amount of working fluid wasdetermined based on the requirement that the temperature of the ex-periment cannot be larger than 180℃, which is constrained by theoperation of pressure safety valve and pressure transmitter. Given thatat ambient temperature the quantity of fluid in the vapor phase isnegligible, the amount of liquid is determined by the smallest densityachievable at that temperature. The fluid charge is therefore 20 ml. In order to determine if the particle velocity accurately representsthe fluid velocity, a simplified situation of forced vortex flow is con-sidered, whereby the particle dynamics is governed by simple rotationalmotion. It is reasonable to neglect the tangential and radial acceleration- similarly to what is typically done for many centrifugal filters -especially in cases where particles have reached the tangential fluidvelocity, and the particles’ radial velocity is comparatively small.Additionally, if it is assumed that the spherical particles move ac-cording to Stokes' law, then the centrifugal and Stokes’ force can beequated, from which the particles’radial velocity becomes rwd,Upr =18uThis expression is valid for small particles with Reynolds numbers such that the flow around the particle is within the Stokes regime[2]. and dp are the particle density and diameter, respectively. Thermo-physical properties of D4 are calculated by means of a library [1] im-plementing a variety of models, e.g., the thermodynamic and transportproperty values are calculated by using the iPRSV equation of state [13]and Chung’s model, respectively. u is the viscosity (equalto7.7×10-5kgs-m- in the experimental conditions defined above),andr is the characteristic dimension of the disk. Considering the par-ticles’radial velocity as defined above, then Re, is lower than one, andtogether with the tangential velocity utp =rw, where w is the angular Fig. 2. The layout of the system. wd, 18u equals 6.5 × 10-5. This is similar in form to Stokes'law, as reported byLapple and Shepherd [6], but for simple rotational motion. Given thatthe tangential component dominates, it can be inferred that the chosenparticles are suitable for accurately tracing the motion of the flowaround the disk. 4. Experimental procedure A 20 ml suspension of D4 and TiO2 particles was prepared at roomtemperature and subsequently poured over the bottom of the cubicvessel. Then the chamber was sealed by affixing the lid to the vessel andby tightening the quick-release-clamp. Air was extracted via the ball-valve, with a vacuum pump. The final vacuum pressure was 5 mbar andmonitored for approx. 1 h to ensure that the container was leak tight.The vessel was then insulated with rockwool, and then the thermalcontrol was initiated. In the meantime, the actuator disk was set torotate anticlockwise at 10 Hz (600 RPM) in order to provide someforced convection inside the vessel during the phase transition. Withoutforced convection most of the particles tended to settle on the bottom ofthe container, thus their density in the vapor would be insufficient toperform PIV measurements. The evaporation process can be seen in Fig. 3. During the heating, aturbulent convective circulation establishes, whereby the suspensionmoves upward due to the heating from the bottom, and then the vaporcondenses due to the lower temperature of the upper surface of the box,and sizable droplets fall to the bottom. Once the fluid was completelyvaporized, the required control speed of the disk was set, insulationremoved and then images acquired. The amount of particles required to provide sufficient seeding waschosen on the basis of the vector validation procedure together withobservations of particle deposition inside the cube. In the initial stagesof phase transition there were large agglomerates of particles at thebottom of the vessel, and the top was predominately occupied by vapor.Towards the end of the evaporation process an almost homogeneousparticle distribution was attained. However, in a small layer right abovethe bottom, the particle density was notably lower as can be seen inFig. 3(c). This might either be explained by an uneven illumination oran unfavorable temperature gradient between the bottom and theceiling of the container, resulting in a higher out-of-plane particlemotion. Despite the precautions taken with the insulation, thermallosses from the system resulted in a temperature at the bottom plate of180℃ and approx. 140°℃ at the ceiling. An average particle peak intensity of 80 counts was measured, andthis can be attributed to the low intensity of the laser. The corre-sponding average noise level was 25 counts. At the top right of the FOV,particles appear out-of-focus, see for example Fig. 3(b). These particles are illuminated by the light reflected by surfaces inside the vessel, thusthey do not reside on the measurement plane. In any case, it appearsthat the design of the container is suitable for performing measure-ments with sufficient contrast. No noticeable particle or laser light compatibility issues were ob-served, and the vapor turned out to be sufficiently transparent to con-duct PIV. In summary, no beam dispersion due to the density of themedia occurred, and the laser light propagated with negligible ab-sorption. In order to assess the quality of the measurements, an analysisof the instantaneous and average vector fields was conducted. 5. Exemplary flow fields Several experimental runs, corresponding to disk rotations of 10 Hz(600RPM), 20 Hz (1280RPM), 30 Hz (1900RPM) andd40 Hz(2500 RPM), were carried out. Two cases were considered for the pre-sent investigation. In the first set of experiments the rotational fre-quency of the disk was set to 40 Hz. In the second, the disk was keptstill, and the motion of the fluid was due to natural convection (NC)alone. The preprocessing method of Mendez et al. [8] was used to improvethe image quality of the raw data before it was processed with a cross-correlation technique. This is accomplished by removing the back-ground noise, i.e., unsteady and non-uniform reflections originatingfrom the surface of the disk, which is correlated and well approximatedby the first Proper Orthogonal Decomposition (POD) modes of theimage sequence. Background noise was satisfactorily removed withoutan appreciable alteration of the particle image brightness. During the processing stage, the multi-grid window deformationcross-correlation technique of Scarano and Riethmuller [11,12][11]was adopted for all datasets. A final window size of 24× 24pixels(Gaussian weighted) with 75% overlap was selected, yielding a vectorspatial resolution of 1.4 mm. The universal outlier detection approachof Westerweel and Scarano [16] was used to identify invalid vectors.Discarded vectors were replaced with a distance-weighted average ofvalid neighbor vectors. 5.1. Rotating disk Fig. 4(a) shows the time-averaged vector field resulting from ananticlockwise disk rotation of 2500 RPM. The flow field is a non-linearsuperposition of an Ekman-type structure, originating from the constantforcing motion of the disk, and a Rayleigh-Benard type flow. In order toassess the quality of the data, instantaneous flow fields were analysed atseveral instances. The average correlation peak ratio Q was 2.2,P1-min(P)whereby Q=, with P1 and PP2 being the hei2-mights of the fin(P)’rstand second highest correlation peaks, while min(P) is the lowest valueof the correlation plane. The image seeding density was 0.02 particlesper pixel (ppp) and corresponds to approximately 12 particles in thefinal window size. The seeding concentration could be increased if a (a) All liquid (b) Droplet formation (c) All vapor Fig. 3. Evaporation process and seeding distribution. Fig. 4. Rotating at 2500 RPM (a) avg. vel. field (b) relative uncertainty. higher spatial resolution were of interest. The (normalized) cross-cor-relation coefficient is defined as follows [18,12], where fand g denote the grey intensity distributions of the interroga-tion areas and M is the window size (in pixels). Cross-correlation valuesof 0.8 are observed, where values near one indicate that many particleimages match up with their corresponding shifted partners. However,there were lower values in the FOV (approximately 0.5) which origi-nate from the combined forcing motion of the disk together with theuneven thermal gradient, effectively promoting out-of plane particlemovement. As the rotation increases, the pumping force increases the loss ofparticle pairs. The percentage of outlier vectors which were removed is2.3%. The flow conditions inside the cube made it difficult to obtainvector field images with a smaller number of outlier vectors. The otherexperimental runs which were made at different disk rotational speedsshowed that the number of outliers decreased with decreasing diskspeed. This can be explained by the fact that out-of plane particlemotion is more prominent for higher rotational speeds. 5.2. Natural convention Fig.5(a) shows the averaged vector field with the disk standing still.In this case, 1 image every 20 images was processed, resulting in aneffective acquisition frequency of 15 Hz. The average Q of the 5.9 instantaneous fields is 2.6, somewhat larger than in case of rotatingdisk. The c reaches a value of 0.9, and is higher than what was esti-mated for the rotating disk case, because the particles maintained thein-plane motion due to the absence of the pumping effect. The imageseeding density of the FOV is 0.025 ppp, giving an average of 13 par-ticles per window. The seeding concentration is even more in-homogeneous (larger concentration at the top) compared to the ro-tating disk case, also because of the absence of forcing, thus particleswere convected upwards. The number of outliers that were removedwas 0.7%. The NC, originating from the base of the cube, together withthe thermal losses from the sides, which progressively increases to-wards the top (increase in metal surface area), promote an accelerationof the fluid towards the ceiling. When a colloidal suspension is sub-jected to a temperature gradient, the dispersed particles display a driftvelocity toward the colder regions in addition to the Brownian motion. The NIVA can be approximated by a case of horizontal convectionheated from the bottom with a uniform temperature profile distribu-tion, occurring within an enclosure. The relative importance betweenthe effects of the buoyancy forces, and the effects of the viscosity forcesand thermal conduction can be assessed with the Rayleigh number.Under the assumption of infinite horizontal plates the critical value is1708, above which natural convection initiates. The Rayleigh number isdefined as whereg is the gravitational acceleration and u is the dynamic viscosity.AT= Ts- T is temperature difference between the surfaces of the 5.9 Fig. 5. NC case (a) avg. vel. field (b) relative uncertainty. bottom and top plate.For an ideal gas with pressure held constant, thevolumetric thermal expansivity (i.e. relative change in volume due totemperature change), is the inverse of temperature. The properties offluid are taken at an absolute pressure P of 0.283 bara and at an averagetemperature T inside the cube, e.g., (Ts+T)/2. Therefore, for naturalconvection from a horizontal plate, given the experimental conditionsabove, β=1/T=0.00231. This assumption is validated by calculatingthe compressibility factor, for the conditions inside the cube, which results in approximately 0.98.R is the universal gas constant and M the molar mass. H is the thicknessof the fluid layer- or characteristic length of the fluid domain. For a flatplate, H is the area (of the bottom side) of the plate divided by itsperimeter H==0.0445. a is the thermal diffusivity and is de-2(w+l)fined as k C:三p.Cp and is equal to 3.7×10-6, where k is the thermal conductivity, p is thelocal density and c, is the specific heat at constant pressure. Therefore, the Rayleigh number is calculated as 3×10 which islarger than the criterion for the onset of natural convection. 5.3. Uncertainty quantification The correlation statistics approach of Wieneke [17] was used tocalculate the absolute and relative uncertainty in the displacementvector from the average vector field. Figs. 4(b) and 5(b) show thecorresponding relative uncertainty maps. The RMS uncertainties forRotating case are 0.7 Abs./px and 0.4% relative, while for the NC caseare 0.4 Abs./px and 1% relative. The RMS absolute uncertainty is lowerfor the NC case due to the lower occurrence of out-of-plane particlesmovement. Since the particle displacement is lower and the absoluteuncertainty of the particle displacement is similar for the two cases, therelative uncertainty is higher for the NC case. The relative uncertainty ishigher in the layer at the bottom of the cube, also see Fig. 5(b), becauseof the lower particle concentration. 6. Conclusions and outlook The work documented here allows to draw the following conclu-sions regarding the use ofPIV in low-speed organic vapor flows: · The D4 vapor is sufficiently transparent to conduct PIV; Evaporating the fluid together with TiO2 seeding particles allows toobtain a proper tracer distribution: an external seeder is not needed; ·A seeding density of 0.02-0.03ppp can be achieved with limitedparticle agglomeration and sufficient contrast (Q> 2.5); e Particles follow the flow with sufficient accuracy (St= 6.5×10-); · The Rayleigh number is calculated as 3 × 10° which is larger thanthe criterion for the onset of natural convection; and, · The relative uncertainty is lower than or equal to 1%. It can be inferred that PIV is feasible in low speed flows of hot or-ganic vapors. Further work will be devoted to devising a seedingstrategy that allows to perform PIV in supersonic and transonic flows inthe newly built ORCHID setup [5]. Acknowledgements The authors are grateful to H. Lakkad for his help with vectorprocessing, to A. Sciacchitano for his guidance on UQ analysis, and to S.van Herk for the realization of the NIVA. References ( [1] P. C olonna, T.P. v an der Stelt, A. Guardone, FluidProp: A program for the estima- t ion o f t hermophysical pr o perties of fluids, 2 0 12. ) ( [2] F . D urst, A . M ellin g , J . H . W hitelaw, Pr i n c iples and Practice of Las e r-DopplerAnemometry, A c ademic P r e ss, 1 981. ) [3]G.E. Elsinga, B.W. van Oudheusden, F. Scarano, Evaluation of aero-optical distor-tion effects in PIV, Exp. Fluids 39 (2) (2005) 246-256. ( [ 4] J . H arinck, A . G u a r d one, P . C olonna, T h e in f luence o f molecular c o m plexi t y on expanding f l ows o f ideal a nd dense g a ses, P h ys . F l uids 21 ( 8) (2009) 086-10 1. ) [5]A. Head, C. De Servi, E. Casati, M. Pini, P. Colonna, Preliminary design of the ( O RCHID : a facility f or st u dying non-ideal compressible f luid d ynamics a nd t estingORC e xpand e rs, A SME T ur bo Expo, GT2016-56103,2016, p. 14 . ) ( [6] C .E. L apple, C.B. S hepherd, C alculation of pa r ticle tr a jectories, Ind. E ng. Chem. 32 (5)( 1 940) 605-617 ) ( [7] C . L u d ovico, P. C olonna, T h ermal stability o f R-134a, R - 1 4 1b, R - 13 i 1, R -7 1 46, R- 1 25 a s sociated with st a inless steel as a containing mat e rial, In t . J . Re f rig. 20 (6) ( 1 9 97) 381- 3 89. ) [8] M. Mendez, M. Raiola, A. Masullo, S. Discetti, A. Ianiro, R. Theunissen, ( J . M. B uch l in, P OD-b a sed b a ckground removal for pa r ticle image ve l ocimetry, E x p. Therm. Flui d Sci. 80(2017)18 1 - 1 92 . ) [9] D1. Ragni, F. Schrijer, B.W. van Oudheusden, F. Scarano, Particle tracer responseacross shocks measured by PIV, Exp. Fluids 50 (1) (2011) 53-64. ( [ 1 0] I U . Satoshi, T . Wakana, K . Yoic hi , S . Nor ima sa, S. T oshiaki, P I V measurement of c arbon d ioxide gas-li q uid two-phase nozzle flo w, ASME Procee d ings : Sym p osium o n No n invasive Measurements in S i ngl e and M u ltiph a se Flows, 2 015. ) ( [11] F I . S carano, M .L. Riethmuller, I terative multi gri d ap pr oach i n PIV i mage processing with d iscrete window of f set, Exp. Fl u ids 26 (6) (1999) 513 - 523. ) ( [12] F . S ca r an o , M . L. R i ethmu l ler, Advances in iterative mult i g ri d P IV i m age processin g , E xp . F luids 29 ( 1) (2000) S051 -S 060. ) ( [13] T . v an der Stel t , N . R. N annan , P . C olonna , The iPRS V equation of s tate, Fluid P h ase E quili b . 330 (2012) 24 - 35 . ) [14]V. Valori, Rayleigh-Benard convection of a supercritical fluid: (PIV) and heat ( t ransfer study, [ P h D t hesis] De l ft University of Techn o logy , 201 7 . ) [15]E.L. Warrick, The application of bond refractions to organo-silicon chemistry, J.Am. Chem. Soc. 68 (12) (1946) 2455-2459. [16] J. Westerweel, F. Scarano, Universal outlier detection for PIV data, Exp. Fluids 39(6)(2005) 1096-1100. ( [17] B . W iene k e, PIV un c ertainty quantificat i on fro m corr e lat i on stat i stic s , Meas. Sci . T echnol. 26 (7)(2015). ) [18]C.E. Willert, M. Gharib, Digital particle image velocimetry, Exp. Fluids 10 (4).(1991)181-193. Available online November This work assesses the feasibility of the planar PIV technique to study the characteristics of a siloxane vapor D4. Titanium dioxide (TiO2) seeding particles were used to track the motion around a rotating disk in a low speed flow. Vector fields of natural convection (NC) and a superposition of NC and rotating flow were selected as exemplary cases. The particles were capable of tracing the flow since the calculated Stokes number St is 6.5 × 10^-5. The quality of the experimental data is assessed by means of particle seeding density and particleimage Signal to Noise ratio (S/N). The final results are deemed acceptable for an accurate assessment of the flow field. Rejected outliers are below 2.3% and the relative uncertainties corresponding to the average velocity fields are below 1%.

确定

还剩4页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《低速非常规蒸汽流中速度矢量场 PIV检测方案(CCD相机)》,该方案主要用于其他中速度矢量场 PIV检测,参考标准--,《低速非常规蒸汽流中速度矢量场 PIV检测方案(CCD相机)》用到的仪器有LaVision HighSpeedStar 高帧频相机、时间分辨粒子成像测速系统(TR-PIV)、LaVision DaVis 智能成像软件平台

推荐专场

CCD相机/影像CCD

更多

相关方案

更多

该厂商其他方案

更多