方案详情

文

对制药行业连续生产的灵感来自某客户联系我们寻求保障制药辅料的精确剂量。该客户计划投资一套连续制药生产设备。

方案详情

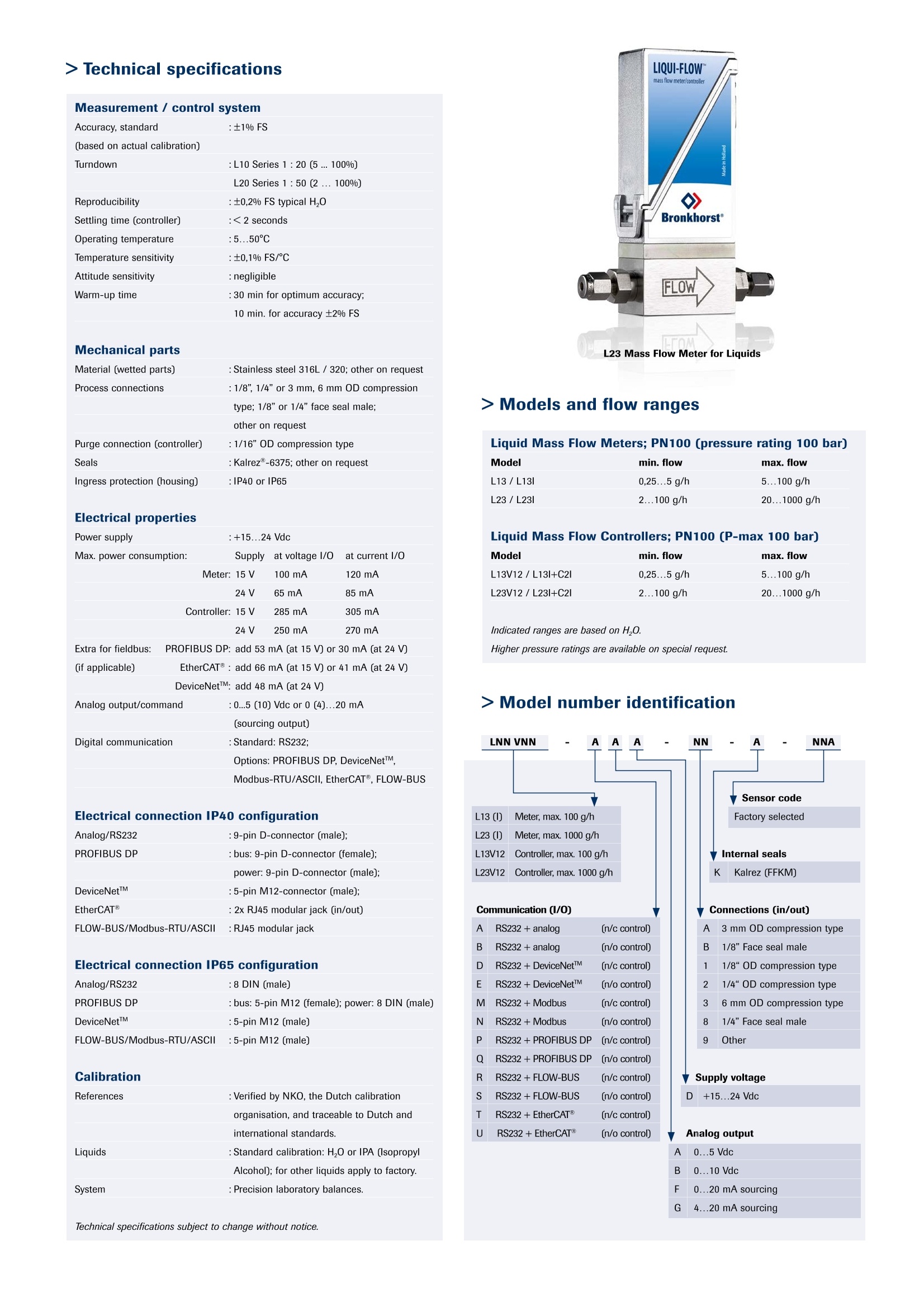

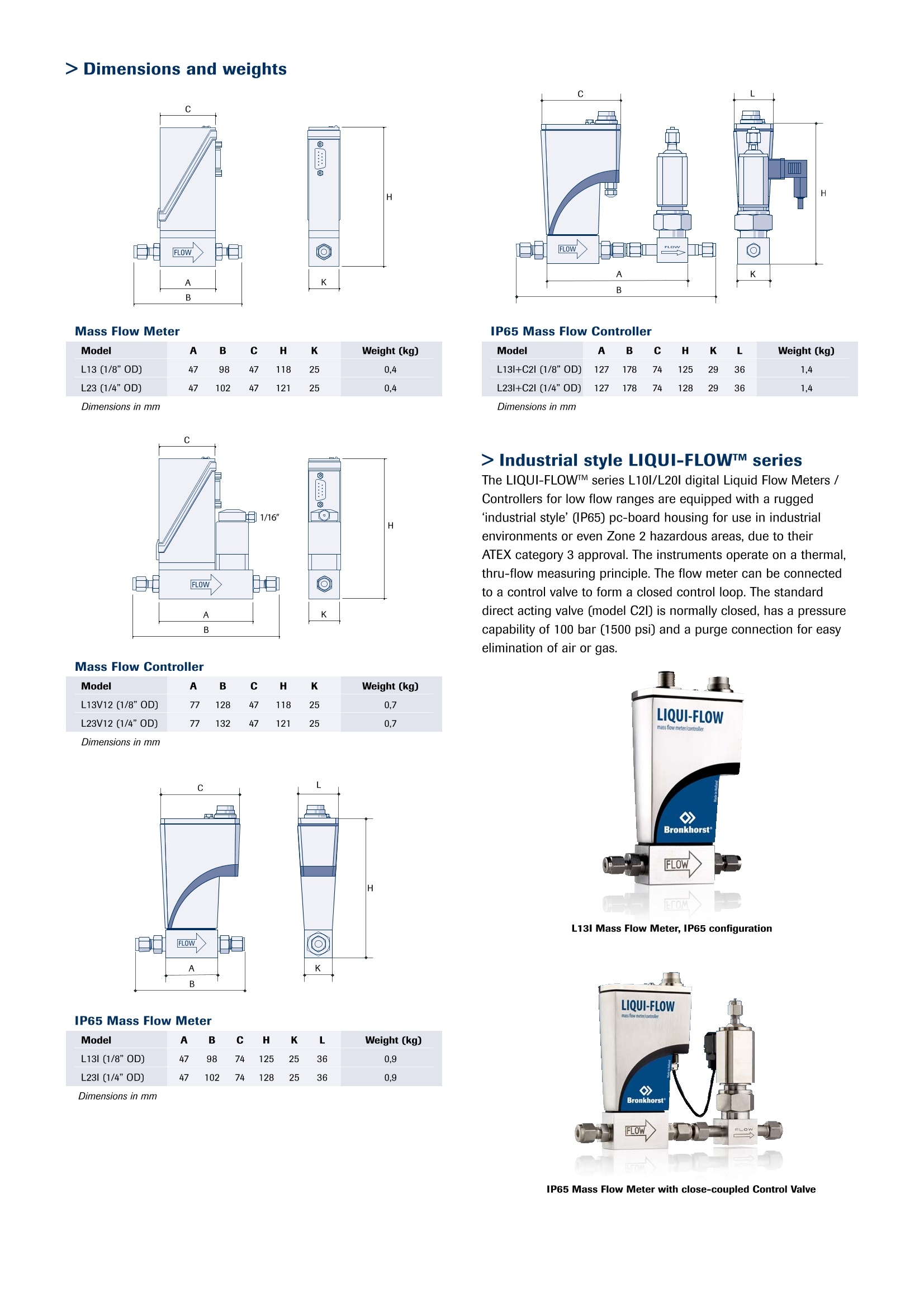

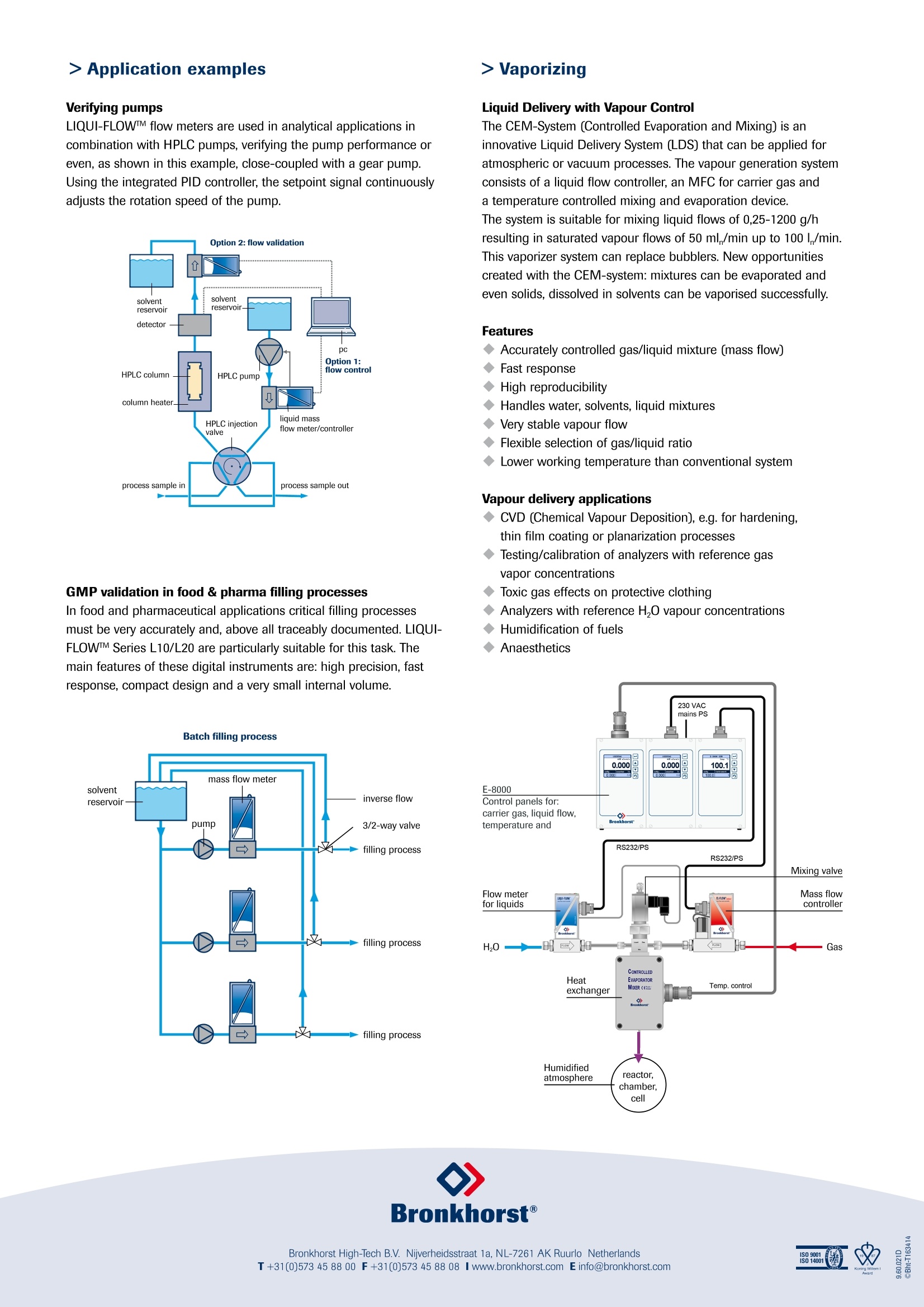

T +31(0)573 45 88 00 F +31(0)573 45 88 08 I www.bronkhorst.com E info@bronkhorst.com LIQU-FLOWIM Series L10 / L20 Digital Mass Flow Meters / Controllers for Liquids > Introduction Bronkhorst High-Tech B.V., the European market leader in thermalMass Flow Meters/Controllers and Electronic Pressure Controllers,has many years experience in designing and manufacturing preciseand reliable measurement and control devices. With a wide rangeof instruments, Bronkhorst offers innovative solutions for manydifferent applications in many different markets. The instruments aremade to customers' specification, in various styles, suitable for usein laboratory, industrial environment, hazardous areas, semiconductorprocessing or analytical equipment. >LIQUI-FLOWTM series L10 / L20 Bronkhorst has been the pioneer in the field of micro to low flowliquid metering instruments based on a thermal measuring principle.The digital LIQUI-FLOWTM Mass Flow Meter was designed to coverthe range between 5 and 1000 g/h (Full Scale) in a compactinstrument with a fast response. The Flow Meter is basically astainless steel tube without any moving parts or built-in obstructions.The heater/sensor assembly is arranged around the tube and, byfollowing the anemometric principle: a constant difference intemperature (AT) is created and the energy required to maintainthe AT is dependent of the mass flow rate. Due to the benefits ofthe unique patented sensor, the fluid will be warmed to a maximumof 5℃, thereby making the L10/L20 series suitable for fluids withlow boiling points. > Liquid flow control Flow control is achieved by integrating a control valve onto thebody of the Liquid Flow Meter, or by mounting it as a separatecomponent [in IP65 configuration). This control valve has a purgeconnection on top of the sleeve that enables easy elimination of airor gas when starting up the system. The electronic control functionforms part of the normal circuitry in the liquid flow meter, so theneed for an external controller is eliminated. > Multi-Bus technology Bronkhorst developed their latest digital instruments according tothe “multi-bus” principle. The basic pc-board on the instrumentcontains all of the general functions needed for measurement and control. It has analog I/O-signals and also an RS23 connection asa standard feature. In addition there is the possibility of integrating aninterface board with DeviceNetTM, PROFIBUS DP, Modbus, EtherCATor FLOW-BUS protocol. > General LIQUI-FLOWTM features ◆fast and accurate measuring signal ●iinsensitive to mounting position ◆ very small internal volume ◆ suitable for liquids with low boiling points ◆ for laboratory and OEM applications ◆also available for industrial applications, with IP65 housing,ATEX Cat.3, Zone 2 > Digital features ◆D[eviceNet M, PROFIBUS DP, Modbus-RTU/ASCII, EtherCATor FLOW-BUS slave ◆ RS232 interface ◆ alarm and counter functions >Fields of application ◆SSemiconductor industry ◆ HPLC applications Chemical industry Food & Pharmaceutical industry ◆ Analytical laboratories > Dimensions and weights Model A B C H K Weight (kg) L13 (1/8”OD) 47 98 47 118 25 0,4 L23 (1/4”OD) 47 102 47 121 25 0,4 Mass Flow Controller IP65 Mass Flow Meter Model A B C H K L Weight (kg) L13I (1/8"OD) 47 98 74 125 25 36 0,9 L23I (1/4”OD) 47 102 74 128 25 36 0,9 Dimensions in mm Model A B C H K L Weight (kg) L13I+C2I (1/8”OD) 127 178 74 125 29 36 1,4 L23I+C2I (1/4”OD) 127 178 74 128 29 36 1,4 > Industrial style LIQUI-FLOWTM series The LIQUI-FLOWTM series L10I/L20I digital Liquid Flow Meters /Controllers for low flow ranges are equipped with a rugged‘industrial style'(IP65) pc-board housing for use in industrialenvironments or even Zone 2 hazardous areas, due to theirATEX category 3 approval. The instruments operate on a thermal,thru-flow measuring principle. The flow meter can be connectedto a control valve to form a closed control loop. The standarddirect acting valve (model C2l) is normally closed, has a pressurecapability of 100 bar (1500 psi) and a purge connection for easyelimination of air or gas. L13I Mass Flow Meter,IP65 configuration IP65 Mass Flow Meter with close-coupled Control Valve > Application examples Verifying pumps LIQUI-FLOWIM flow meters are used in analytical applications incombination with HPLC pumps, verifying the pump performance oreven, as shown in this example, close-coupled with a gear pump.Using the integrated PID controller, the setpoint signal continuouslyadjusts the rotation speed of the pump. GMP validation in food & pharma filling processes In food and pharmaceutical applications critical filling processesmust be very accurately and, above all traceably documented. LIQUI-FLOWIM Series L10/L20 are particularly suitable for this task. Themain features of these digital instruments are: high precision, fastresponse, compact design and a very small internal volume. Bronkhorst High-Tech B.V. Nijverheidsstraat 1a, NL-7261 AK Ruurlo Netherlands Liquid Delivery with Vapour Control The CEM-System (Controlled Evaporation and Mixing) is aninnovative Liquid Delivery System (LDS] that can be applied foratmospheric or vacuum processes. The vapour generation systemconsists of a liquid flow controller,an MFC for carrier gas anda temperature controlled mixing and evaporation device.The system is suitable for mixing liquid flows of 0,25-1200 g/hresulting in saturated vapour flows of 50 ml,/min up to 100 l,/min.This vaporizer system can replace bubblers. New opportunitiescreated with the CEM-system: mixtures can be evaporated andeven solids, dissolved in solvents can be vaporised successfully. Features ◆ Accurately controlled gas/liquid mixture (mass flow) ◆ Fast response ◆ High reproducibility ◆ Handles water, solvents, liquid mixtures ◆ Very stable vapour flow ◆ Flexible selection of gas/liquid ratio ◆ Lower working temperature than conventional system Vapour delivery applications ◆ CCVD (Chemical Vapour Deposition), e.g. for hardening,thin film coating or planarization processes ◆Testing/calibration of analyzers with reference gasvapor concentrations ◆ T Toxic gas effects on protective clothing ◆ Analyzers with reference H,0 vapour concentrations ◆Humidification of fuels ◆ Anaesthetics 对制药行业连续生产的灵感来自某客户联系我们寻求保障制药辅料的精确剂量。该客户计划投资一套连续制药生产设备。 批量生产工艺 传统上,大多数人类药品都是逐步批量生产,每步之间进行大量测试,以确保成品的质量和功效一致。药品生产是个高度管制的过程,政府部门需检查审批药品的生产过程和设施。2016年,美国食品与药品管理局(FDA)首次允许制造商将传统批量生产工艺转为持续生产工艺。 连续生产工艺 连续制造技术极具潜力,有可能改变未来药品的制造方式。过程分析技术(PAT)的改进使以前逐步制造过程得以自动化和精简化。现在可以在连续反应器中精确混合成分,仔细监测和控制反应速率,并实现比10年前更高的产量。 新型连续工艺系统的液体流量比传统旧批次工艺要小很多。典型的工况以千克每小时(kg/hr)的流量运行,某些领域甚至以克每小时(g/hr)或体积流量ml/h下运行。 何时采用连续制造? 新药倾向于针对小疾病,且无需大量活性药物成分。连续制药生产是新药制造的理想解决方案。 Bronkhorst提供市场上最宽广的低流量质量和体积流量计/控制器产品系列,客户选中我们为其新工艺提供最佳的流量监测/控制解决方案。 科氏MFC解决方案 客户需要灵活的工艺,能够监测和控制不同流体的流量,并内置基于压力变化或中断而自动调整的功能。此外,客户还需记录大量的实时流量数据并通过DCS系统控制。 基于连续制药生产工艺中严格的流量控制要求,我们推荐mini CORI-FLOWMFC+齿轮泵作为其理想的解决方案。 采用mini CORI-FLOW MFC的决定因素有:直接质量流量测量,不受流体特性影响可测量密度和温度可转换为体积流量高精度,极佳的重复性设计紧凑,带独立集成PID控制器,控制快速又稳定适用于较宽的流量范围带Profibus接口,可与DCS系统进行通信接液材质为耐化学腐蚀的不锈钢和哈氏合金闭环控制,可直接控制泵来改变工艺参数,实现快速响应。与IN-PRESS压力控制器配合使用时,该系统可实现工艺某些关键压力和温度的灵活控制。记录所有参数,因此提供了极好的工艺溯源性。

确定

还剩2页未读,是否继续阅读?

布琅轲锶特(上海)测量设备贸易有限公司为您提供《制药中质量流量控制检测方案(液体流量计)》,该方案主要用于化药制剂中限度检查检测,参考标准--,《制药中质量流量控制检测方案(液体流量计)》用到的仪器有mini CORI-FLOW™系列 科里奥利质量流量计/控制器

推荐专场

相关方案

更多