动态颗粒成像分析(DIPA)越来越多地被用作表征基于蛋白质的药物中的亚可见微粒的方法。 许多这类配方,特别是预填充的注射器,其含有用于润滑的硅油液滴。 当计算颗粒浓度,特别是在2μm至10μm尺寸范围内时,总希望能够消除硅油液滴对总颗粒数的影响。

方案详情

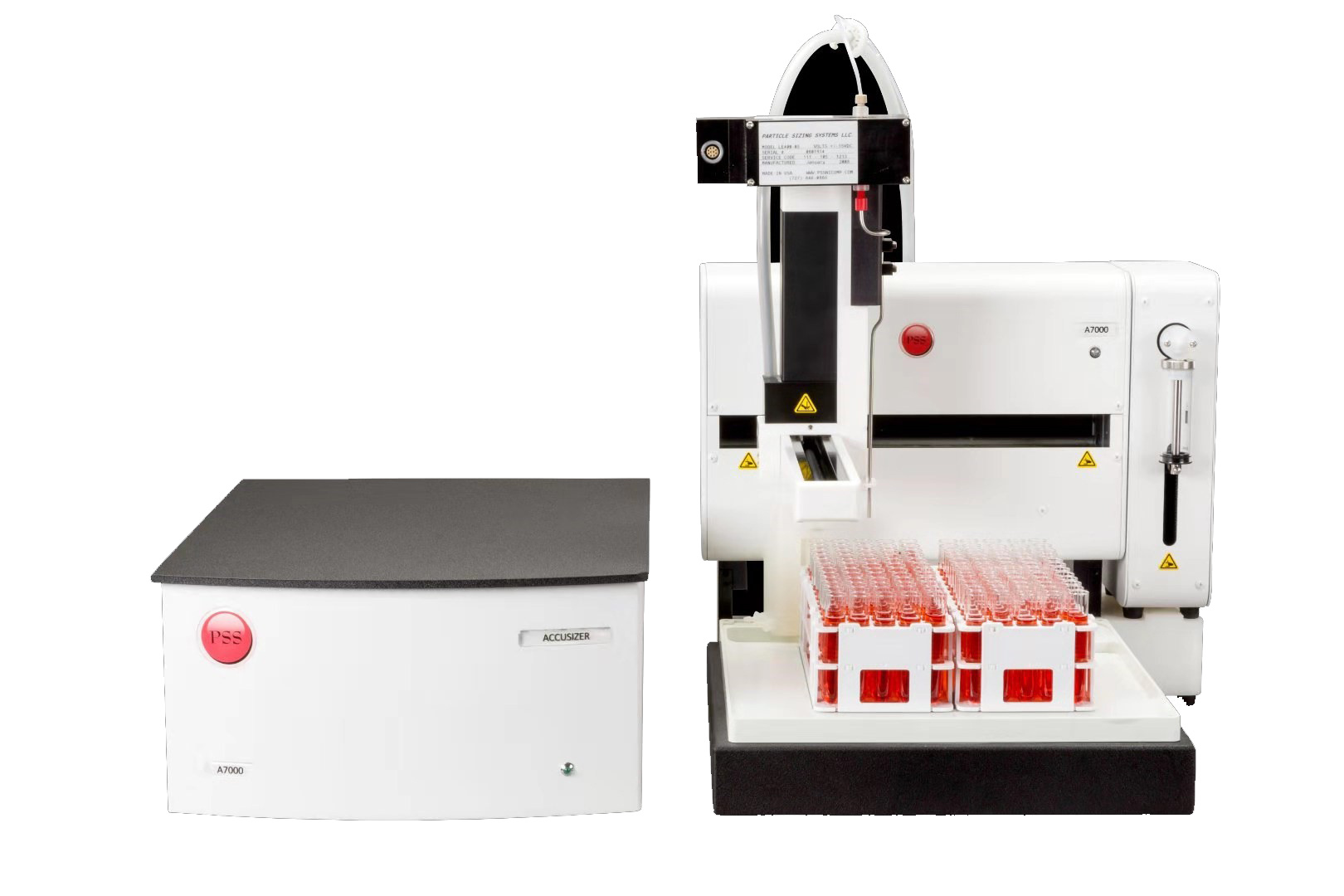

A Comparison of Methods for Quantifying Silicone Droplets in BiologicsUsing Dynamic Imaging Particle Analysis A Polyclonal IgG sample was obtained (Courtesy University of Colorado) which hadbeen stressed via agitation. This sample was first run in a FlowCAM°DIPA instrumentunmodified to get a baseline reading for particle load and to verify repeatability of thedata sets, as shown in Figure 3. The sample was then silicone infused by pulling it intoand ejecting it out of a siliconized syringe ten times prior to being run through theFlowCAM DIPA instrument again. Figure 4 shows the particle size distributions forfive runs of the sample after being silicone infused, again showing good repeatability.Note also the large increase in overall particle load, caused by adding the silicone andthe additional stressing due to the multiple trips through the syringe prior to the runsis. Figure 3: Five replicate runs of original Polyclonal IgG prior to being infused with silicone. Figure 4: Five replicate runs of Polyclonal IgG after silicone infusion. At this point, an enhanced development version of the FlowCAM VisualSpreadsheetsoftware was used to “hand-classify”each of four runs of the protein/silicone mix. Theprocedure used was to view every particle image in the data set, and have the operatorthen append a particle “Type (known)”to each particle's spreadsheet information as anadditional data field. Figure 5 shows a screen capture of this procedure. For the reasonsnoted above, this was only done for the data set>2um in size, which cut the number ofparticles to be appended by about half since the largest size bin is the 1-2um one. Evenwith this reduction in data, it left an average of 2,500 particles to be hand-classified,-ywhich takes considerable time. Results For the hand classification, four particle types were created:“protein"aggregate,"silicone"droplet,“combination"and“unknown". The unknown had to be createdbecause, even at 2um and larger, there will still be some particles that just cannotbe classified, even by a human (Figure 6 shows some examples). The “combination"category consists of both multiple silicone droplets stuck together (forming a different shape than singlets) andpredominantly silicon droplet(s)embedded into protein aggregates(Figure 7 shows some examples). Thisis not an uncommon occurrence ,and was probably exacerbated by themultiple runs through the syringe (anarea suggested for future modificationin this continuing research). The most commonly used filtercriterion for separating siliconedroplets from protein aggregatedis aspect ratio (width/length). Thisis because the silicone droplets areusually perfectly spherical in shapeversus the amorphous shape qualityof the protein aggregates. However,aspect ratio is a relatively crudemeasurement, and, even though the . Figure 7: Typical examples of Particles hand-classified as"Combination". Oriqinal size on left,zoomed 8X on riqht Various different measurements of particle circularity are available in the VisualSpreadsheet software, but one that is particularly effective for detecting siliconedroplets is "Circularity (Hu)". Hu Circularity has been shown to produce better resultsfor circularity than other measures when looking at particles with boundary defects,i.e. when the perimeter of the circle is not perfect. This is exactly what occurs whensilicon droplets are imaged with very few pixels, therefore at the limits of the optical/sensor system (see Figure 1). Once again, different thresholds for Circularity (Hu) weretried, with a value Circularity(Hu) >0.95 producing the best results, an increase of42% more silicone drops found over the best results using an aspect ratio filter. The previous filters discussed are what is called “value filters", meaning that a rangeof values for a certain particle measurement are defined, and then all particles are . Sharma, D.K., Oma, P, & Krishnan, S, (2009). Silicone Microdroplets in Protein Formulations-Detection and Enumeration. Pharmaceutical Technologx 33 (4), 74-79. 2Strehl, R., Rombach-Riegraf, V., Diez, M., Egodage, K., Bluemel, M., & Kouloy, A.V. (2011). DiscriminationBetween Silicone Oil Droplets and Protein Aggregates in Biopharmaceuticals: A Novel Multiparametric Image Filtete!for Sub-visible Particles in Microflow Imaging Analysis. Pharm Res 29(2)594-602.MunFiriess, W.,NWiVint icro-fow imaging andnd 3.. Weinbuch, D.. Zolls, S. Wiggenhorn, M nter, G., & Hawe, A. (2013).Micro-floresonant mass measurement (Archimedes)--complementary methods to quantitatively differentiate protein particlesand silicone oil droplets. I Pharm Sci, 102 (Z),2152-21654.. Gerhardt, A.. Mcgraw. N.R., Schwartz, D.K., Bee, I.S.. Carpenter, I.E & Randolph,T.W. (2014). Protein Aggregation and Particle Formation in Prefilled Glass Syringes. JPbarm Sci, 103 (6), 1601-1612.5.. Brown, L. (2014). Can a Computer Characterize a Particle My Eve Can Not? URL http://www.particleimaging.com/can-a-computer-characterize-a-particle-my-eye-can-not/.6,Zunic, 1 Hirota&RosinPL.(2008). A Hu nvariant as a shape circularity measure. Patteri Recoonition, 43 (2 47-57. ( 7 B Brown, L. ( ( 2008). P Iarticle Image e U U n n d d e e r rstanding -A P r imer. U RL http://www.fl u idimaging.com/resource- hte C r r - w hitepapers.htm ) 动态颗粒成像分析(DIPA)越来越多地被用作表征基于蛋白质的药物中的亚可见微粒的方法。 许多这类配方,特别是预填充的注射器,其含有用于润滑的硅油液滴。 当计算颗粒浓度,特别是在2μm至10μm尺寸范围内时,总希望能够消除硅油液滴对总颗粒数的影响。

确定

还剩1页未读,是否继续阅读?

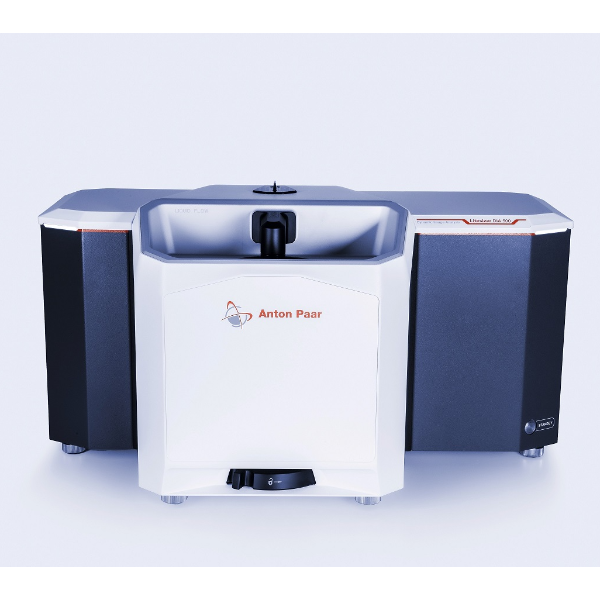

大昌华嘉科学仪器为您提供《生物制剂硅胶液滴中动态颗粒成像分析检测方案(图像粒度粒形)》,该方案主要用于其他中动态颗粒成像分析检测,参考标准--,《生物制剂硅胶液滴中动态颗粒成像分析检测方案(图像粒度粒形)》用到的仪器有流式颗粒成像分析系统FlowCam®8100、颗粒成像法+光阻法分析系统 FlowCam® + LO、纳米流式颗粒成像分析系统 FlowCam® Nano

推荐专场

相关方案

更多

该厂商其他方案

更多