方案详情

文

The OCA20 offers an easy way of determining the surface energy of polymer

surfaces. For the case of serial examinations on the same, only slightly modified

materials as they often occur in industrial production, a method has been

developed which further facilitates the determination of the surface energy.

Here, the measurement of a contact angle with just one liquid is needed,

thus considerably reducing the time needed. The example of PP films,

which were submitted to different surface treatments, showed that the new

method can predict the surface energy with an accuracy of 2﹪.

方案详情

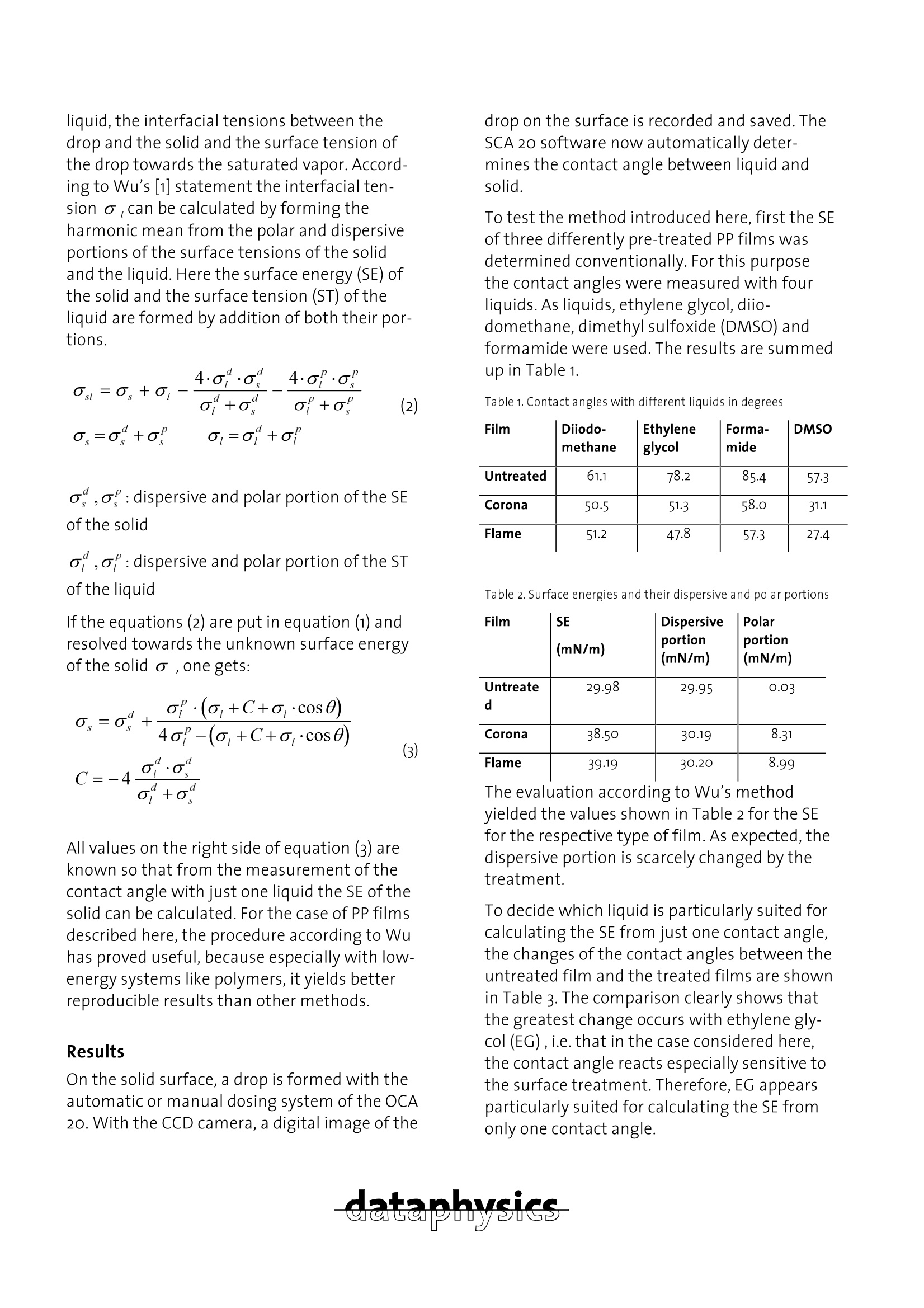

-dataphysics-dataphysics DataPhysics Instruments GmbH·RaiffeisenstraBe 34·D-70794 Filderstadtphone ++49 (o)711 770556-0·fax++49 (0)711-770556-99 e-mail info@dataphysics.de·internet http://www.dataphysics.de Application Note 6 Determination of wetting properties ofpolymer films with the DataPhysics OCA 20with just one test liquid Problem The exact knowledge of the surface energy ofpolymers is essential for optimizing variouscoating processes. Due to restrictions of timeand expenses, often a contact angle measure-ment with only one test liquid is necessary. On many industrial sectors, plastics play animportant role for the production of high-quality consumer goods. In this connection, thecoating and painting of these materials is ofparticular importance. In these processesproblems sometimes occur because the plasticsurfaces have relatively bad wetting and adhe-sion properties. This is due to the low surfacefree energy of these materials and the absenceof reactive free surface groups. To improve thewetting properties, the plastics are generallysubmitted to a surface treatment such as forinstance a flame ora corona treatment. Tocheck the success and effectivity of such atreatment, the surface energy of the plasticmaterial must be determined.The contact an-gle measurement is a simple and quantitativemethod, where usually several test liquids areused.Under certain production or laboratoryconditions,where a very quick and very simplemethod is demanded,the use of several testliquids may not be suitable. With the example of polypropylene films (PPfilms) a method will be introduced of measur- ing the surface energy, using the contact anglemeasuring instrument OCA 20 and the soft-ware module SCA 2o with just one liquid. Method Often, in one single industrial production al-ways the same types of plastic material areexamined for their wetting properties. The onlydifference between the individual samples istheir different previous treatment. This is espe-cially the case if the parameters for such pre-treatments must be optimized. If the samples to be examined are from thesame basic material, first the surface energyand its polar and dispersive portions are de-termined in the conventional wayon one of thesamples with at least two liquids. Since in gen-eral the surface treatment has no influence onthe dispersive portions of the surface energy,these may be assumed to be constant for amaterial class. This assumption is confirmed bythe measuring results. The surface energy of more samples ofthesame class can now be determined by a con-tact angle measurement with only one liquid.When a drop of liquid is formed on a surface,the resulting equilibrium of forces can be de-scribed by the interface energies of the respec-tive interfaces. Fromthe equilibrium of forces,it results for the respective surface and interfa-cial tensions (Young-Dupre equation): Where o,, oand o are the surface tensionsbetween solid and the saturated vapor of the liquid, the interfacial tensions between thedrop and the solid and the surface tension ofthe drop towards the saturated vapor. Accord-ing to Wu’s [1] statement the interfacial ten-sion o can be calculated by forming theharmonic mean from the polar and dispersiveportions of the surface tensions of the solidand the liquid. Here the surface energy (SE) ofthe solid and the surface tension (ST) of theliquid are formed by addition of both their por-tions. o,o”:dispersive and polar portion of the SEof the solid o",o": dispersive and polar portion of the STof the liquid If the equations (2) are put in equation (1)andresolved towards the unknown surface energyof the solid o,one gets: All values on the right side of equation (3) areknown so that from the measurement of thecontact angle with just one liquid the SE of thesolid can be calculated. For the case of PP filmsdescribed here, the procedure according to Wuhas proved useful, because especially with low-energy systems like polymers, it yields betterreproducible results than other methods. Results On the solid surface, a drop is formed with theautomatic or manual dosing system of the OCA20. With the CCD camera, a digital image of the drop on the surface is recorded and saved. TheSCA 20 software now automatically deter-mines the contact angle between liquid andsolid. To test the method introduced here, first the SEof three differently pre-treated PP films wasdetermined conventionally. For this purposethe contact angles were measured with fourliquids. As liquids, ethylene glycol, diio-domethane, dimethyl sulfoxide (DMSO)andformamide were used. The results are summedup in Table 1. Table 1. Contact angles with different liquids in degrees Film Diiodo-methane Ethyleneglycol Forma-mide DMSO Untreated 61.1 78.2 85.4 57.3 Corona 50.5 51.3 58.0 31.1 Flame 51.2 47.8 57.3 27.4 Table 2. Surface energies and their dispersive and polar portions Film SE (mN/m) Dispersiveportion(mN/m) Polar portion (mN/m) Untreated 29.98 29.95 0.03 Corona 38.50 30.19 8.31 Flame 39.19 30.20 8.99 The evaluation according to Wu’s methodvielded the values shown in Table 2 for the SEfor the respective type of film. As expected,thedispersive portion is scarcely changed by thetreatment. To decide which liquid is particularly suited forcalculating the SE from just one contact angle,the changes of the contact angles between theuntreated film and the treated films are shownin Table 3. The comparison clearly shows thatthe greatest change occurs with ethylene gly-col (EG), i.e. that in the case considered here,the contact angle reacts especially sensitive tothe surface treatment. Therefore, EG appearsparticularly suited for calculating the SE fromonly one contact angle. Table 3. Change of the contact angle on treated films as com-pared to the untreated film in degrees Film Diiodo- methane Ethyleneglycol Forma-mide DMSO Corona 10.6 33.9 27.4 26.2 Flame 9.9 37.4 28.1 29.9 In Diagram 1 the SE calculated according toequation (3) for different contact angles withEG as a test liquid is outlined. If this model iscorrect, it should be possible to predict the cor-rect SE of the films from one contact anglewith EG. For comparison,the diagram alsoshows the SE's that were determined accordingto the conventional method. The diagramshows that there are only slight deviations ofthe exact values from the calculated curve. A more detailed comparison is given in Table 4. Table 4. Comparison of the exact and the calculated SE in mN/m Method Flame 47.8° Corona51.3 untreated 78.2°0 Exact 39.19 38.50 29.98 Model 38.58 37.58 30.90 Diff. 0.61 0.92 0.92 The summary shows that the difference be-tween the exact value and the model value ismax. o.9 mN/m, representing a deviation per-centage of only 2%. This proves that for theconsidered case of PP films with different pre-treatments it is possible to predict the SE by Diagram Surface energies as a function of the contactangle with ethylene glycol measuring just one contact angle with an ac-curacy of about 2%. Summary The OCA 20 offers an easy way of determiningthe surface energy of polymer surfaces. For thecase of serial examinations on the same, onlyslightly modified materials as they often occurin industrial production, a method has beendeveloped which further facilitates the deter-mination of the surface energy.Here, themeasurement of a contact angle with just oneliquid is needed, thus considerably reducing thetime needed. The example of PP films, whichwere submitted to different surface treat-ments,showed that the new method can pre-dict the surface energy with an accuracy of 2%. [1] Wu S., J. Adhesion, Vol. 5, (1973) 39-55.

确定

还剩1页未读,是否继续阅读?

北京东方德菲仪器有限公司为您提供《聚合物膜中润温性能检测方案(接触角测量仪)》,该方案主要用于其他中润温性能检测,参考标准--,《聚合物膜中润温性能检测方案(接触角测量仪)》用到的仪器有

相关方案

更多

该厂商其他方案

更多