方案详情

文

The OCA20 and the software modules SCA2 and 21 offer an easy

way to determine the surface energy of polymer surfaces. The polar

portions of the surface energy responsible for the adhesion of

coatings can be quantitatively collected by means of the contact

angle measurement. In this way, wetting and adhesion properties

can be predicted. Compared to the use of test inks to estimate the

surface free energy, the present method has the advantage of providing

a greater accuracy and let to additional information the polar

and dispersive contribution of the surface free energy, which

governs printability or adhesion. At the same time being

independent of the experimenter, thus ruling out subjective influences.

方案详情

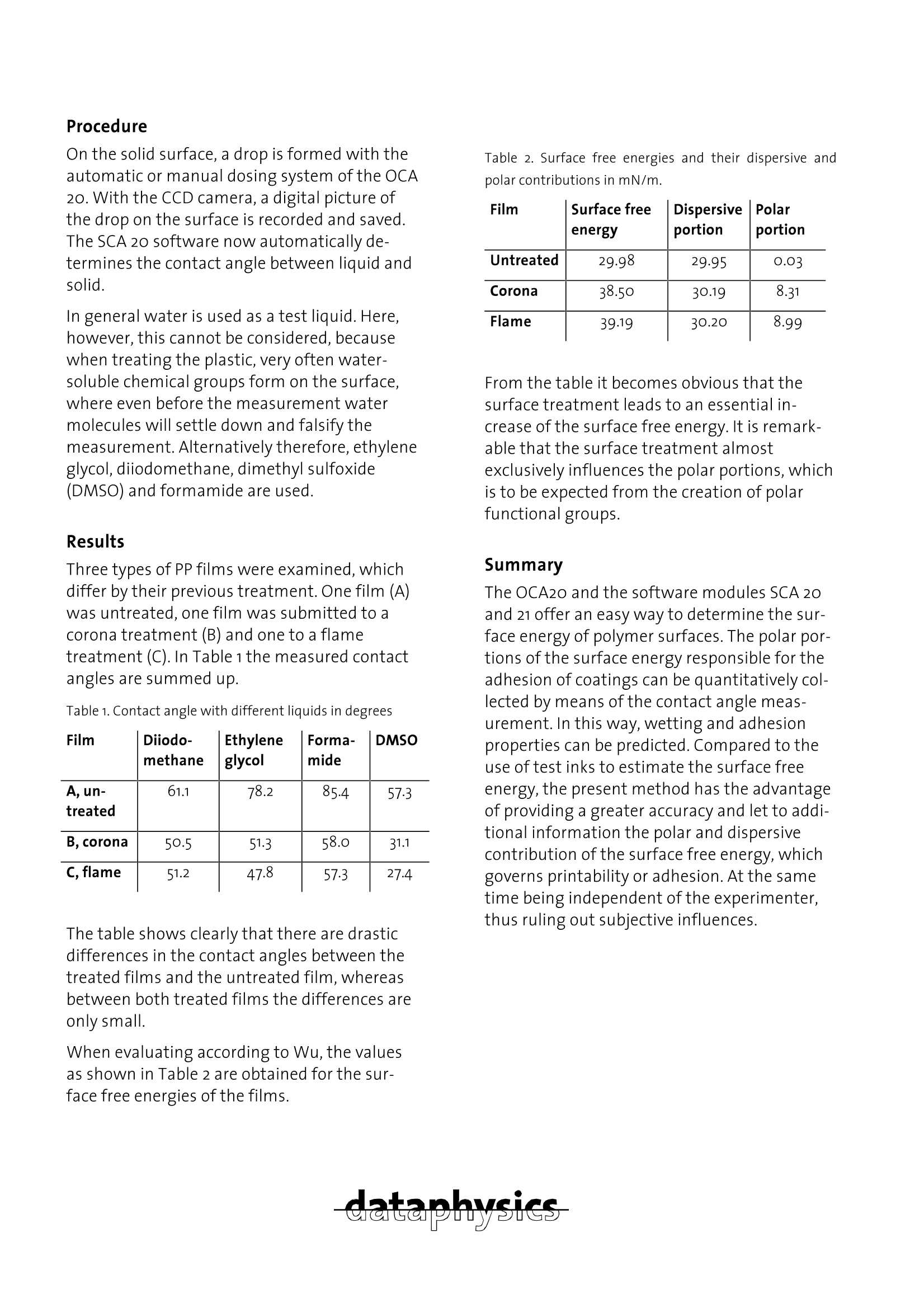

-dataphysics-dataphysics DataPhysics Instruments GmbH·RaiffeisenstraBe 34·D-70794 Filderstadtphone ++49 (o)711 770556-o· fax++49 (o)711-770556-99 e-mail info@dataphysics.de·internet http://www.dataphysics.de Application Note 4 Principle example for the determination ofwetting properties of polymer films withthe DataPhysics OCA 20. Problem The exact knowledge of the surface free energyof polymers is essential for optimizing variouscoating processes. In the contact angle meas-urement process, which enables the determi-nation of the surface free energy, the selectionof appropriate test liquids is sometimes sophis-ticated. On many industrial sectors, plastics play animportant role for the production of high-quality consumer goods. In this connection, thecoating and painting of these materials is ofparticular importance.This applies for instanceto the painting of plastic bumpers and thecoating of other injection-molded items. Inthese processes problems sometimes occurbecause the plastic surfaces have relativelypoor wetting and adhesion properties. This isdue to the relatively low surface free energy ofthese materials and the absence of polar sur-face groups. To improve the wetting properties,the plastics are generally submitted to a sur-face treatment such as for instance a plasma ora corona treatment. In this way, polar groupsare introduced on the surface, and the surfacefree energy increases. The knowledge of thesurface free energy of a treated plastic with itspolar and dispersive portions is therefore ofcrucial importance when producing coatablepolymers. With the example of polypropylene films (PPrnrfilms) a method will be introduced of measur-ing the surface free energy easily and in anoptimized way, using the contact angle meas-uring instrument OCA 20 and the softwaremodules SCA 20 and 21. Method To determine the surface free energy of apolymer with its polar and dispersive portions,the contact angle is measured with a numberoftest liquids and evaluated according to themethod of Wu. This evaluation method is inte-grated in the software and is fully automati-cally carried out by the computer. The methodrequires the use of at least two test liquids withknown surface tension and its polar and dis-persive contributions. Each additional liquidwill increase the accuracy of the estimation. For the particular case of PP films describedhere,the method according to Wu has proveduseful, because-as known from literature- ityields better reproducible results than othermethods, especially with low-energy systems. The accuracy of the values obtained is essen-tially influenced by the test liquids selected.Onthe one hand side, an influence on the surfaceby the test liquid by partial etching or disolvingmust be ruled out. On the other hand side,thesurface tension of the test liquid must not bechanged by soluble substances possibly exist-ing on the solid surface. If one or both of thedescribed processes take place, this manifestsitself by a strong variation of the measuredcontact angles in spite of a visually homogene-ous surface, and by a poor reproducibility of theresults. Procedure On the solid surface, a drop is formed with theautomatic or manual dosing system of the OCA2o. With the CCD camera, a digital picture ofthe drop on the surface is recorded and saved.The SCA 20 software now automatically de-termines the contact angle between liquid andsolid. n general water is used as a test liquid. Here,however, this cannot be considered,becausewhen treating the plastic, very often water-soluble chemical groups form on the surface,where even before the measurement watermolecules will settle down and falsify themeasurement.Alternatively therefore,ethyleneglycol, diiodomethane, dimethyl sulfoxide(DMSO) and formamide are used. Results Three types of PP films were examined, whichdiffer by their previous treatment. One film (A)was untreated, one film was submitted to acorona treatment (B) and one to a flametreatment (C). In Table 1 the measured contactangles are summed up. Table 1. Contact angle with different liquids in degrees Film Diiodo-methane Ethyleneglycol Forma-mide DMSO A, un-treated 61.1 78.2 85.4 57.3 B,corona 50.5 51.3 58.o 31.1 C,flame 51.2 47.8 57.3 27.4 The table shows clearly that there are drasticdifferences in the contact angles between thetreated films and the untreated film,whereasbetween both treated films the differences areonly small. When evaluating according to Wu, the valuesas shown in Table 2 are obtained for the sur-face free energies of the films. Table 2. Surface free energies and their dispersive andpolar contributions in mN/m. Film Surface free energy Dispersiveportion Polar portion Untreated 29.98 29.95 0.03 Corona 38.5o 30.19 8.31 Flame 39.19 30.20 8.99 From the table it becomes obvious that thesurface treatment leads to an essential in-crease of the surface free energy. It is remark-able that the surface treatment almostexclusively influences the polar portions, whichis to be expected from the creation of polarfunctional groups. Summary The OCA20 and the software modules SCA 20and 21 offer an easy way to determine the sur-face energy of polymer surfaces.The polar por-tions of the surface energy responsible for theadhesion of coatings can be quantitatively col-lected by means of the contact angle meas-urement. In this way, wetting and adhesionproperties can be predicted.Compared to theuse of test inks to estimate the surface freeenergy,the present method has the advantageof providing a greater accuracy and let to addi-tional information the polar and dispersivecontribution of the surface free energy,whichgoverns printability or adhesion. At the sametime being independent of the experimenter,thus ruling out subjective influences.

确定

还剩1页未读,是否继续阅读?

北京东方德菲仪器有限公司为您提供《聚合物薄膜中j接触角检测方案(接触角测量仪)》,该方案主要用于其他中j接触角检测,参考标准--,《聚合物薄膜中j接触角检测方案(接触角测量仪)》用到的仪器有

相关方案

更多

该厂商其他方案

更多