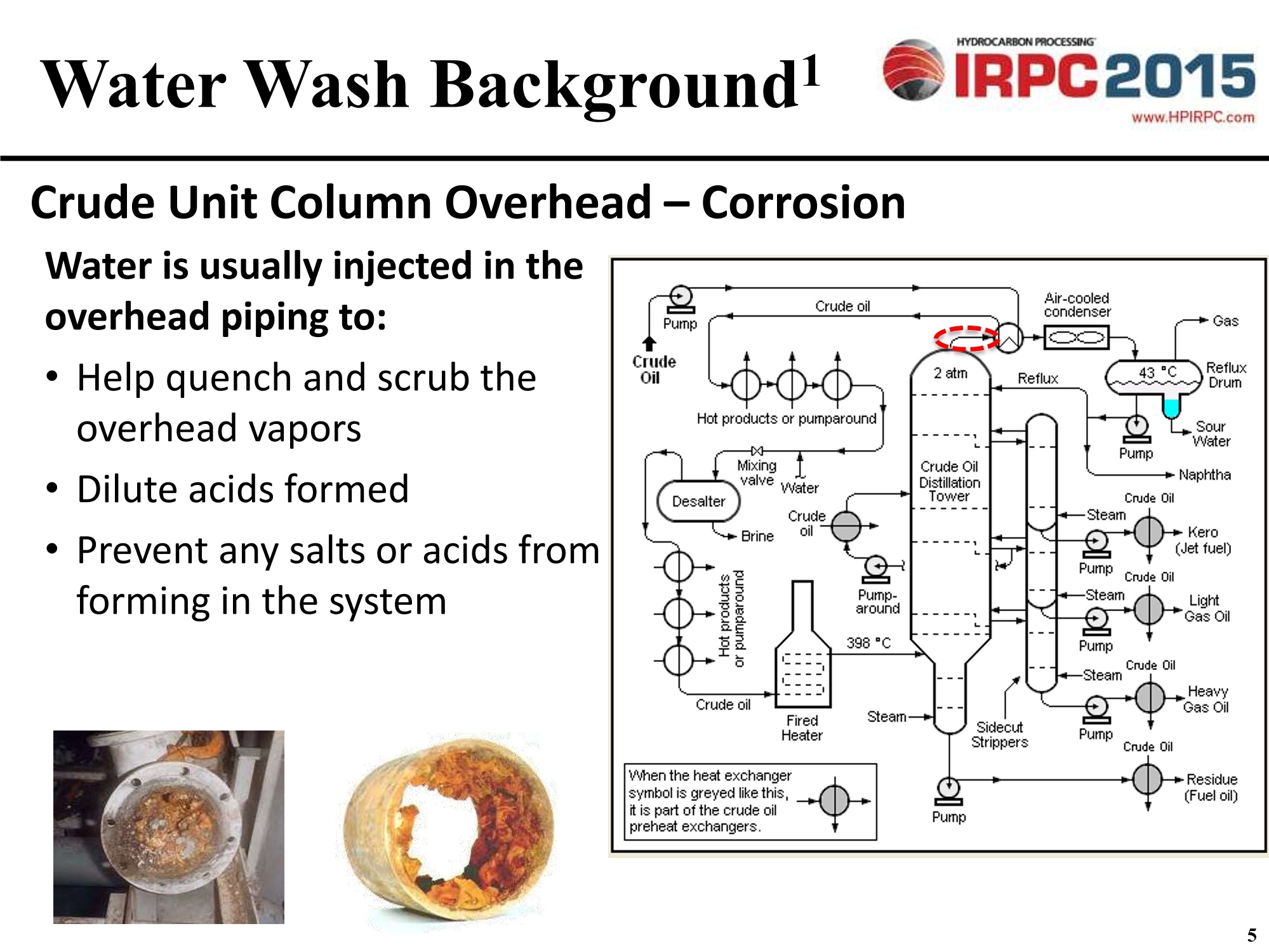

Crude Unit Column Overhead – Corrosion

Water is usually injected in the

overhead piping to:

• Help quench and scrub the

overhead vapors

• Dilute acids formed

• Prevent any salts or acids from

forming in the system

方案详情

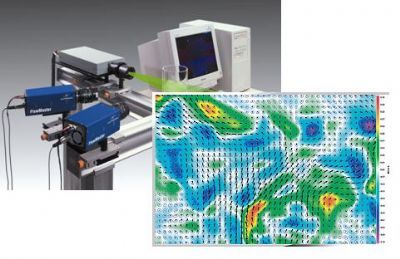

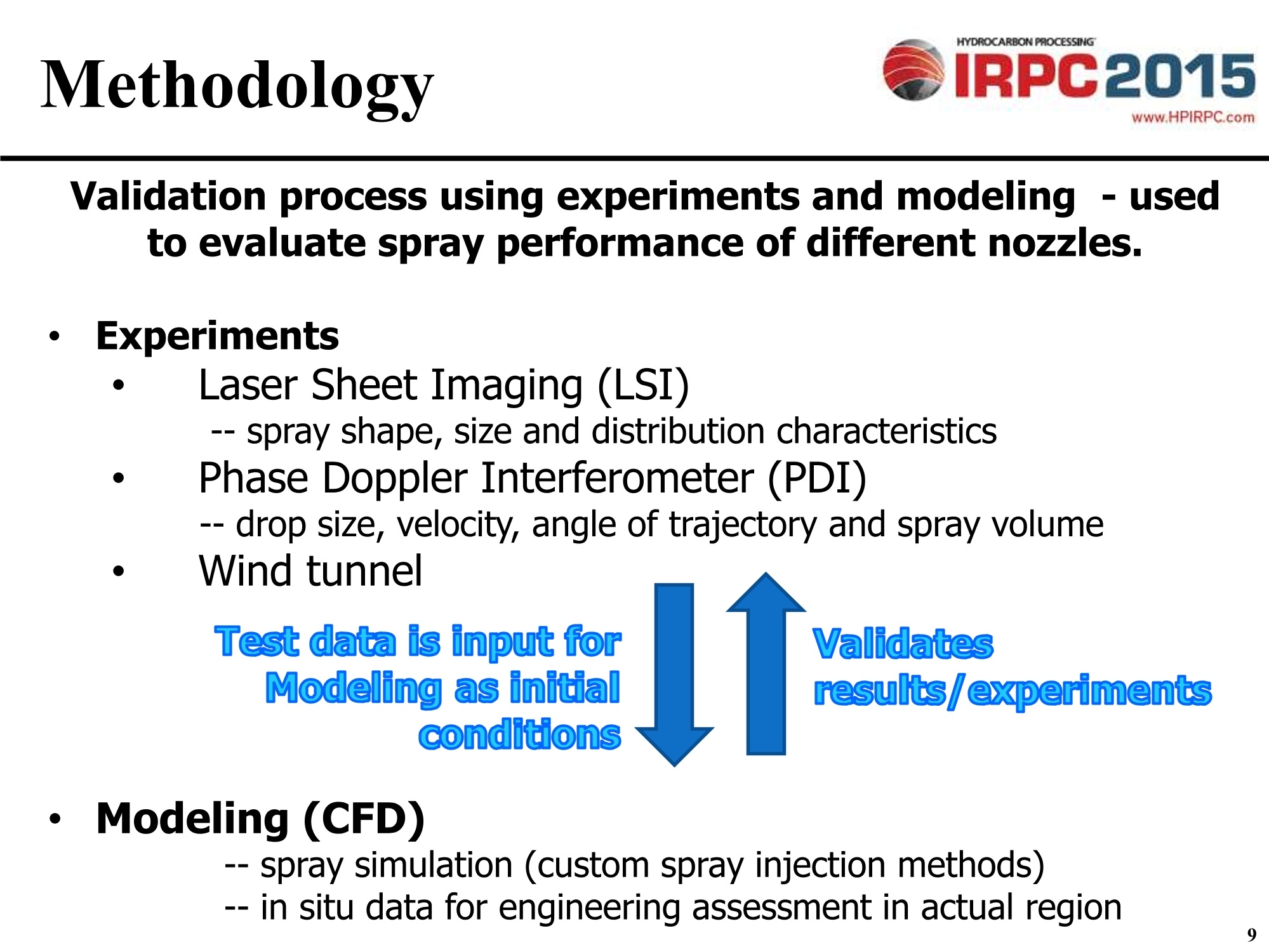

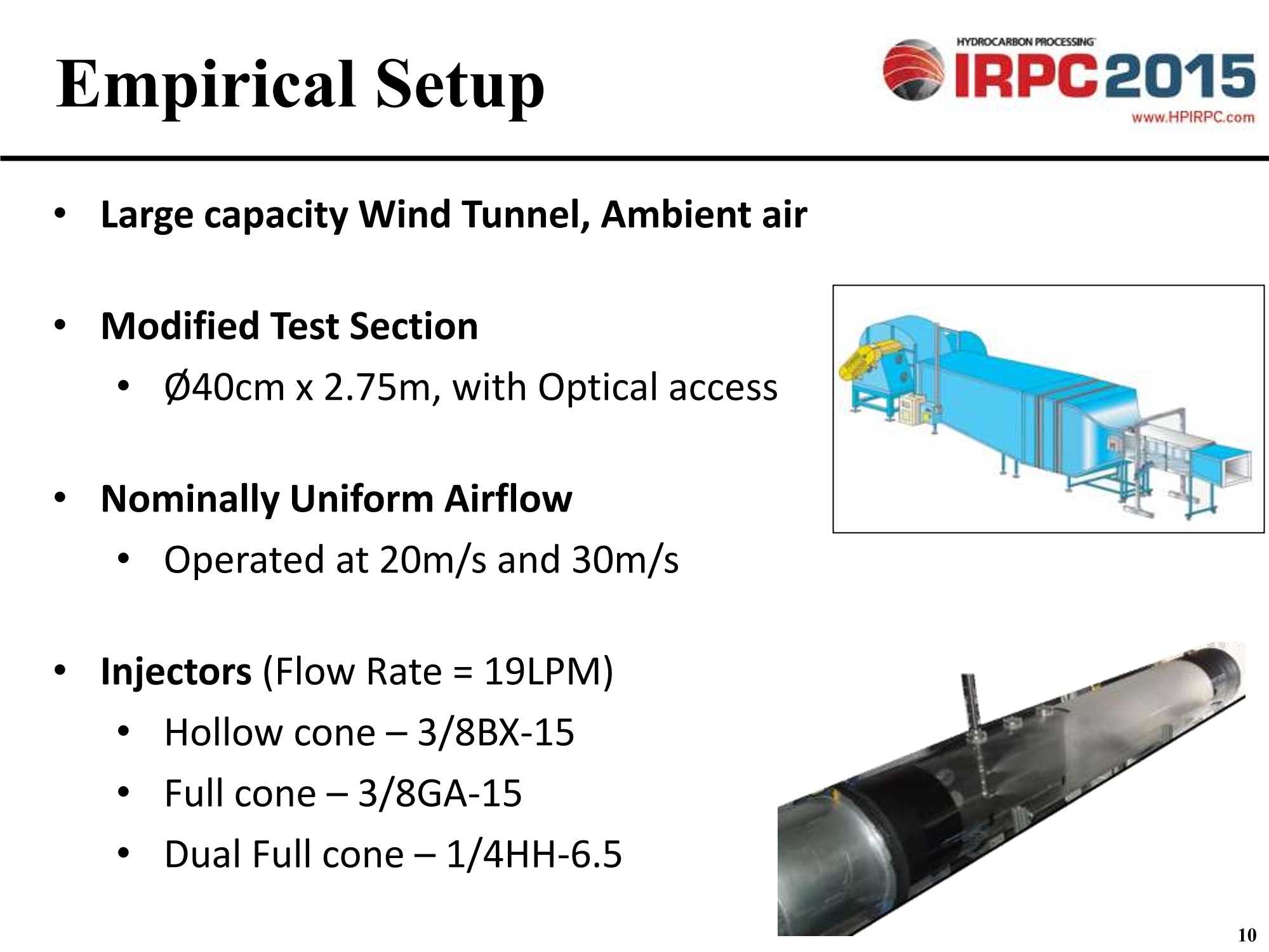

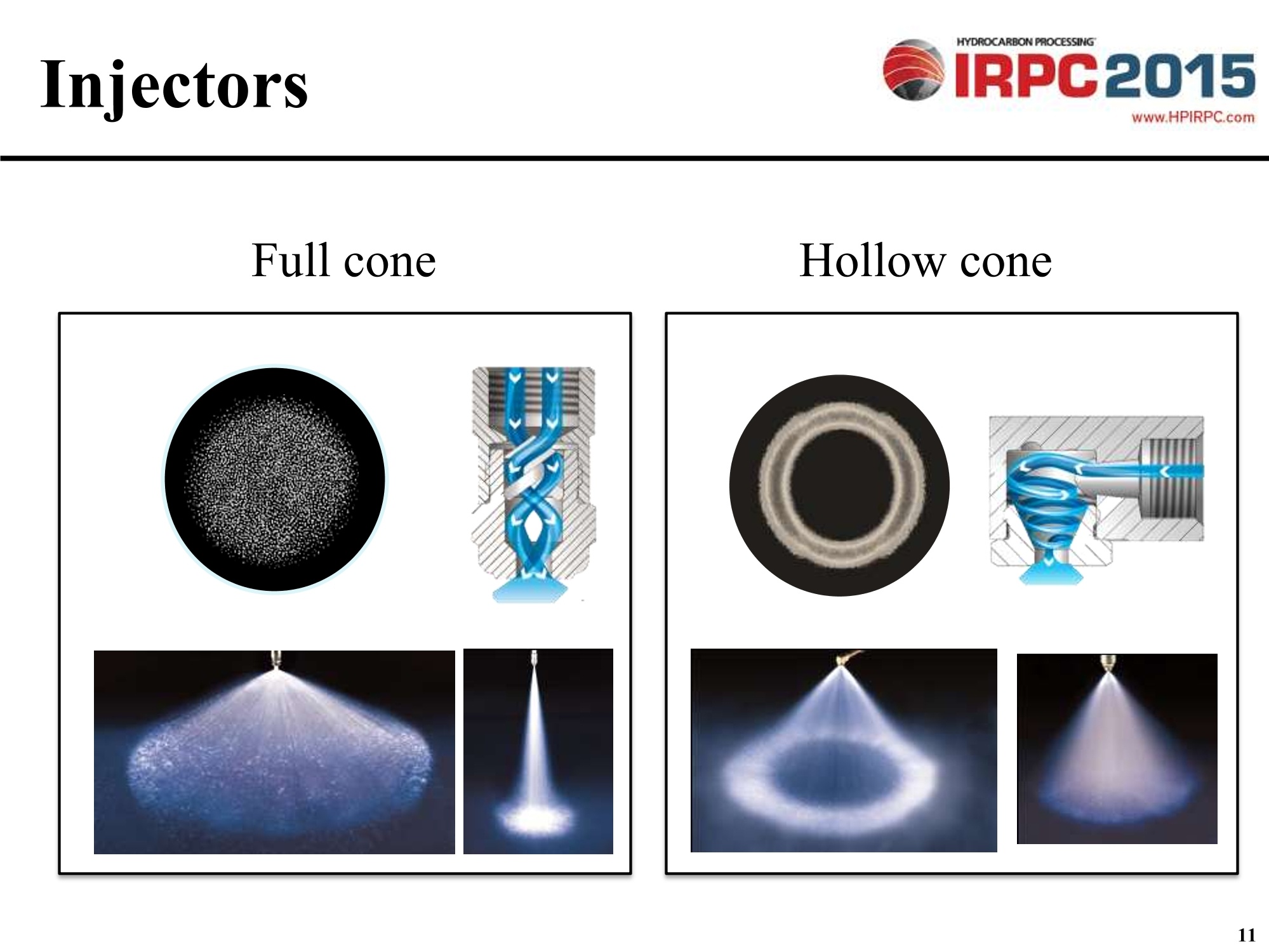

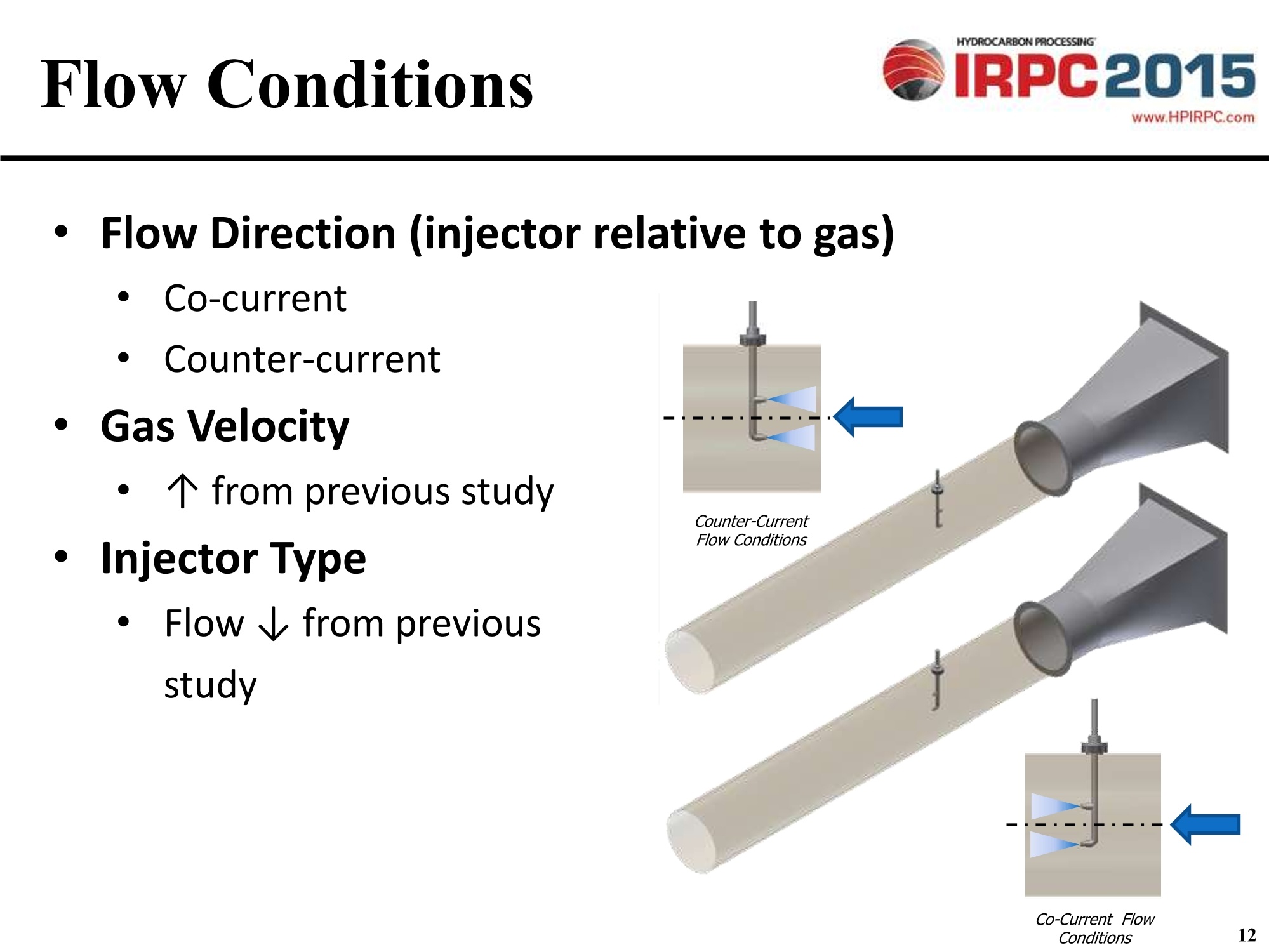

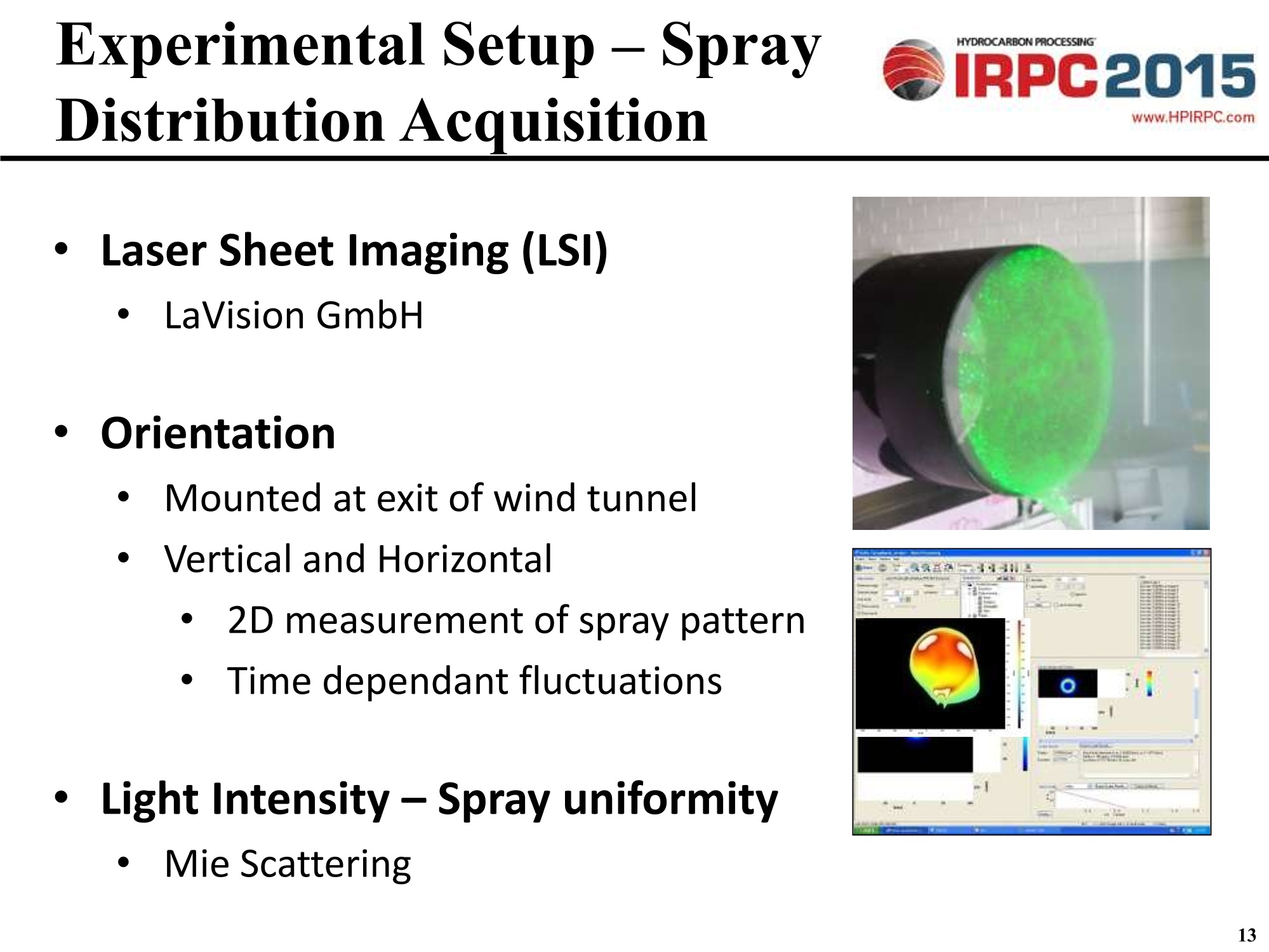

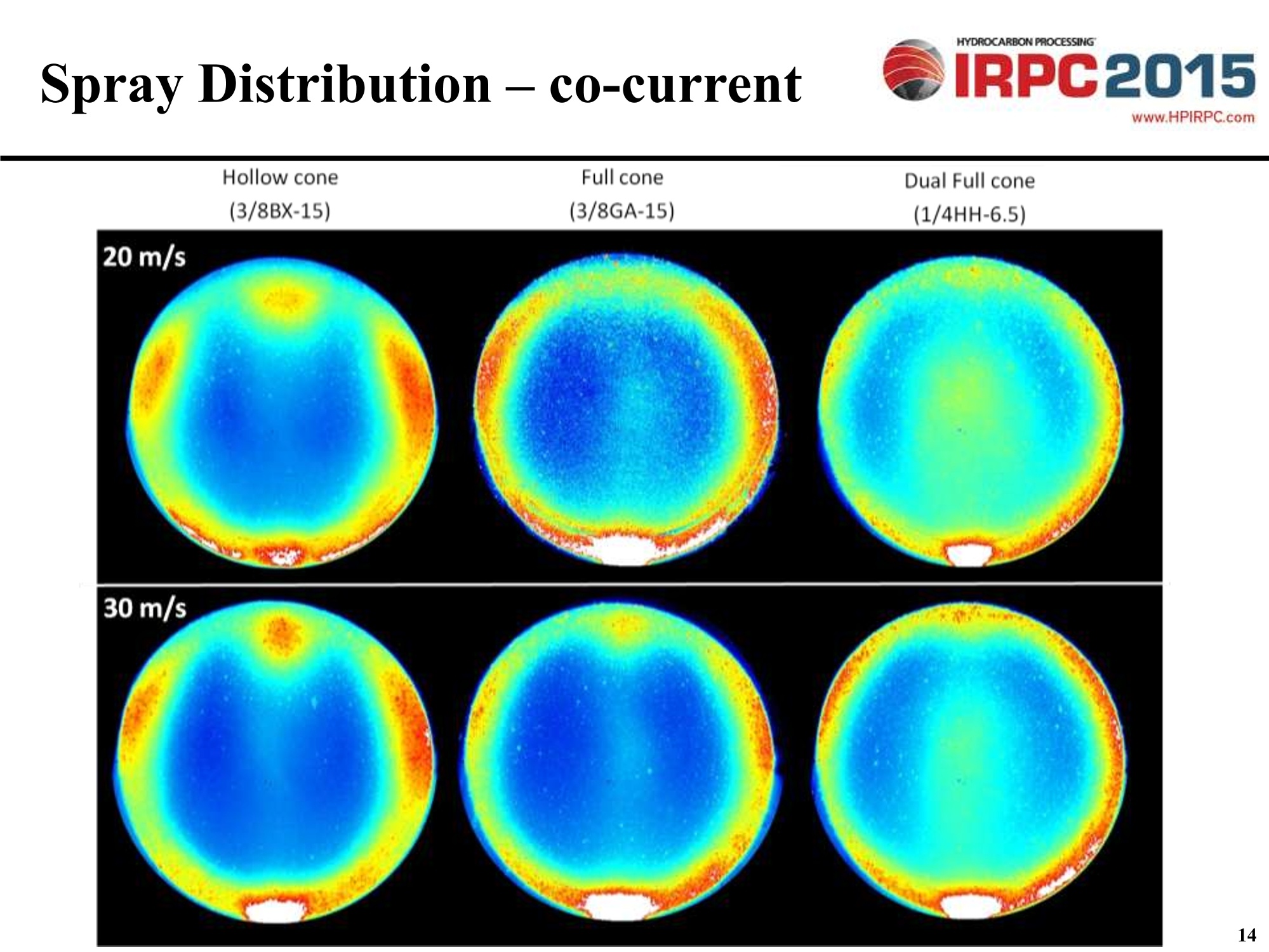

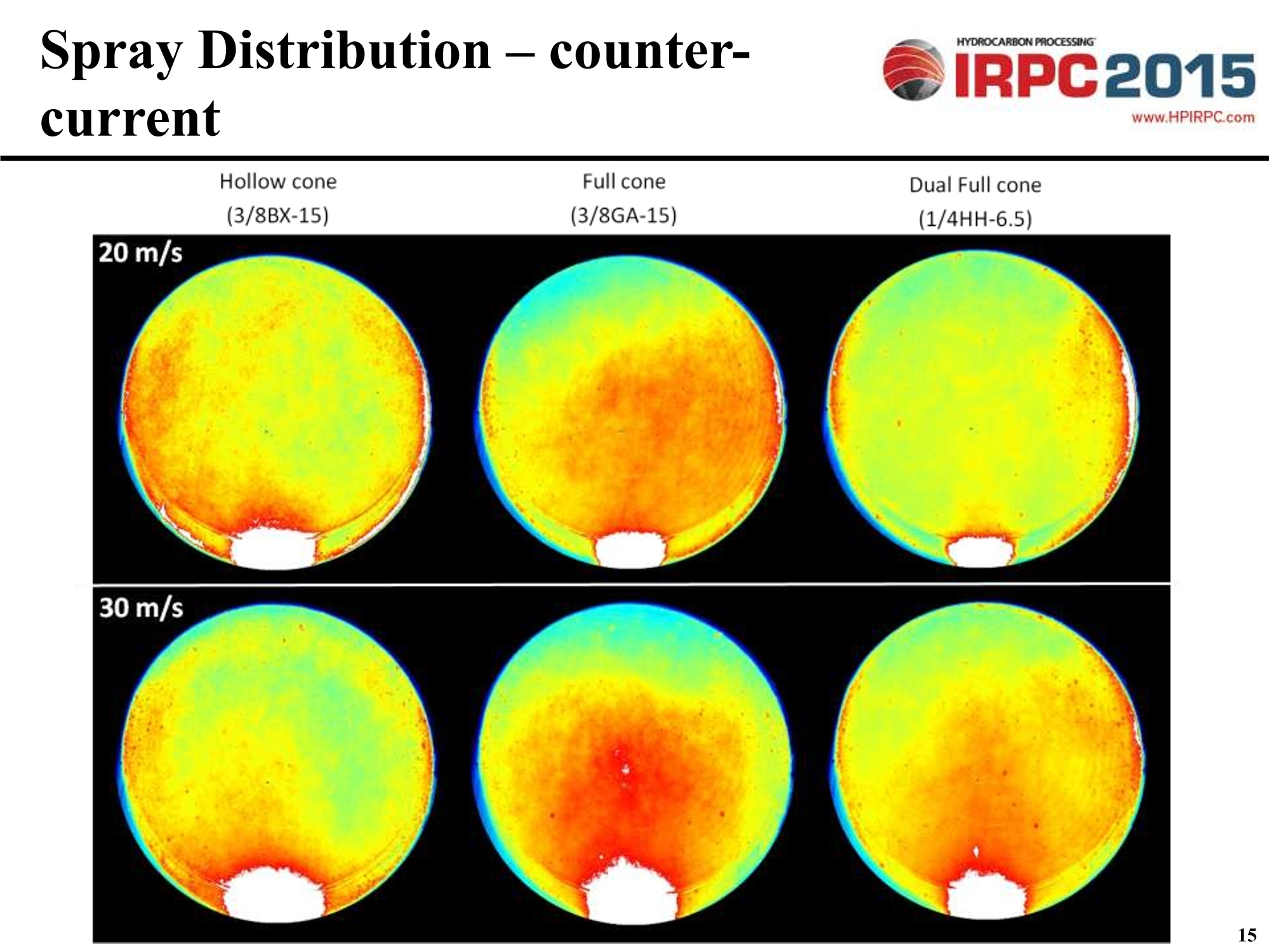

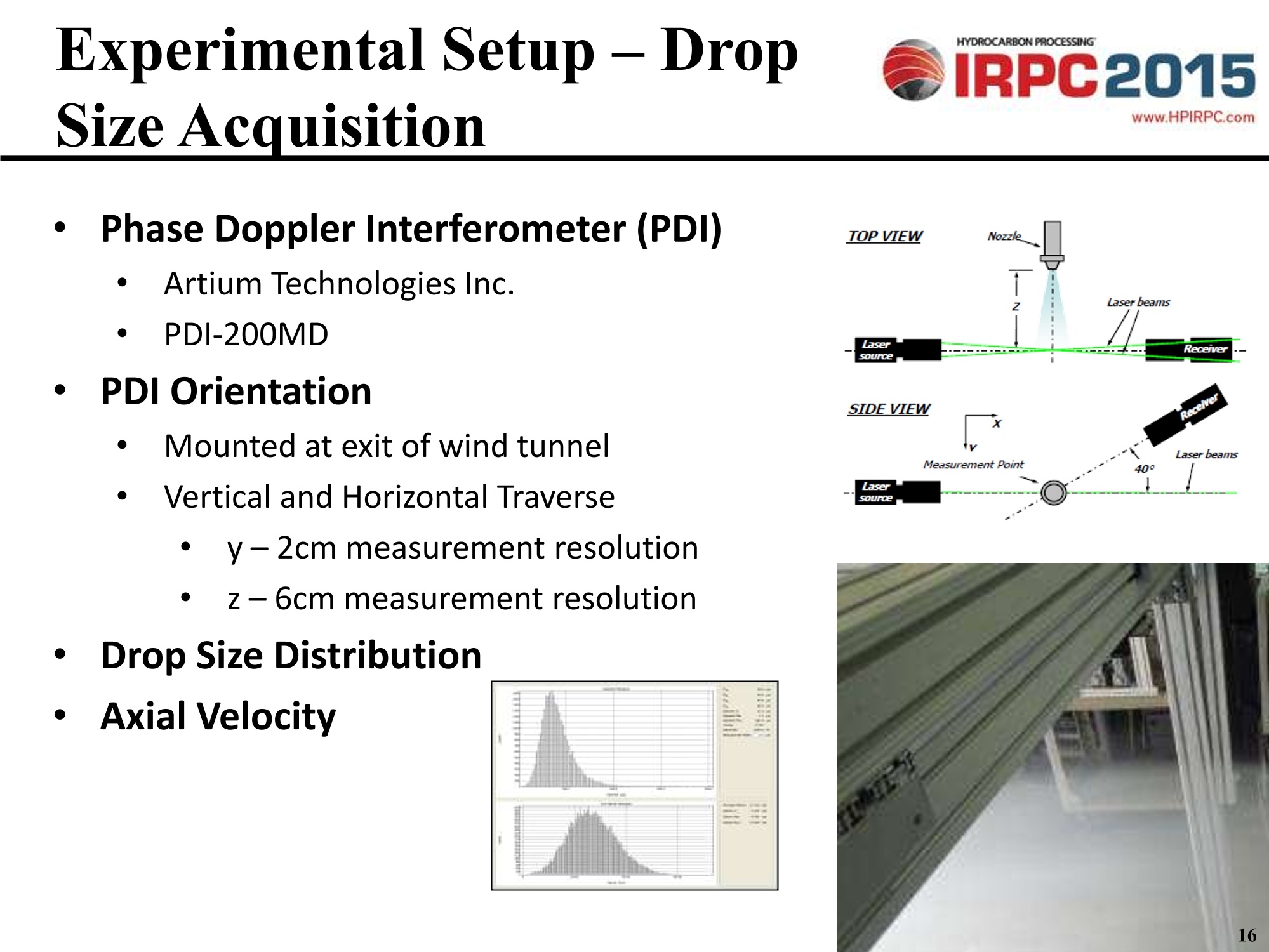

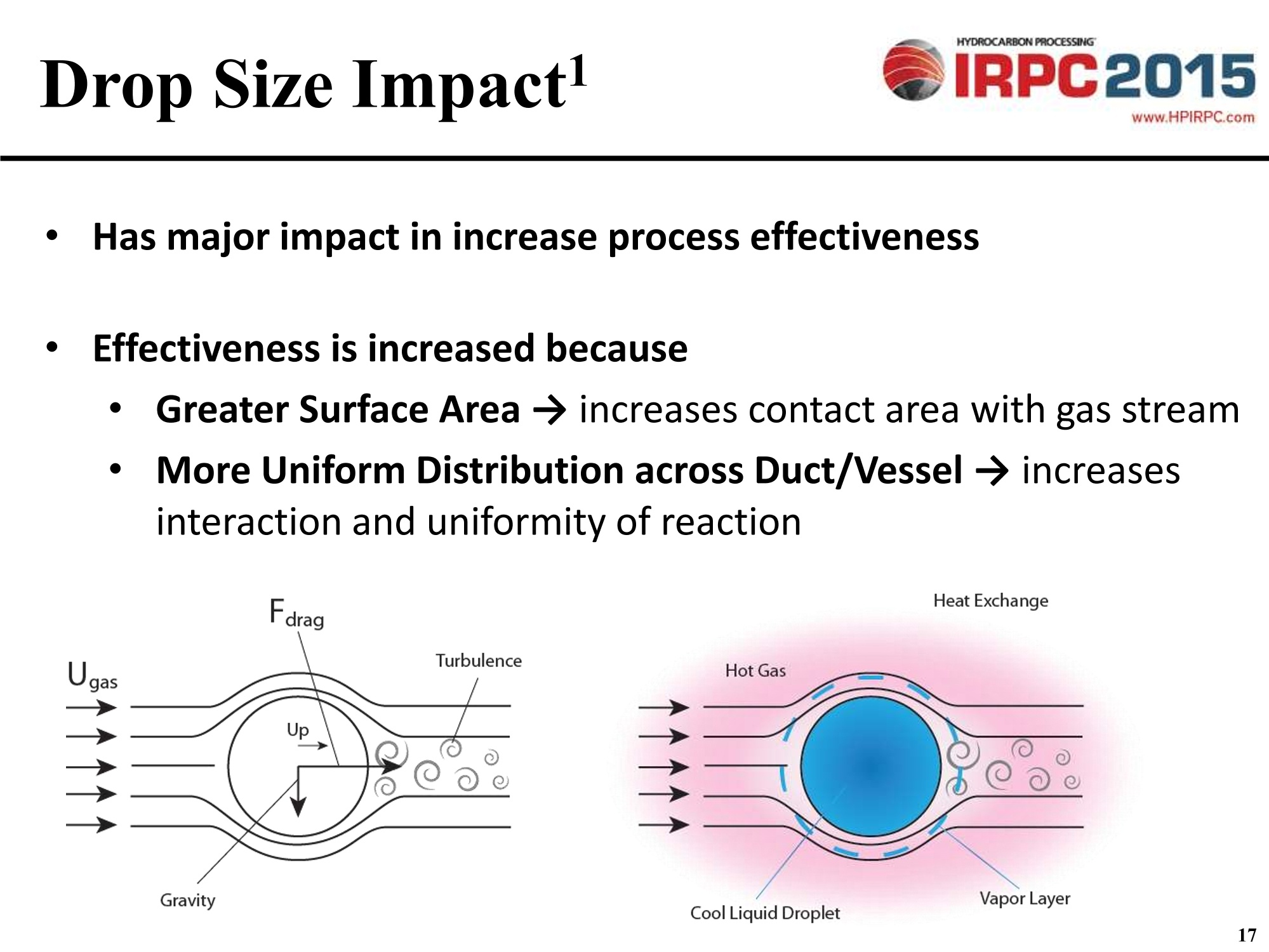

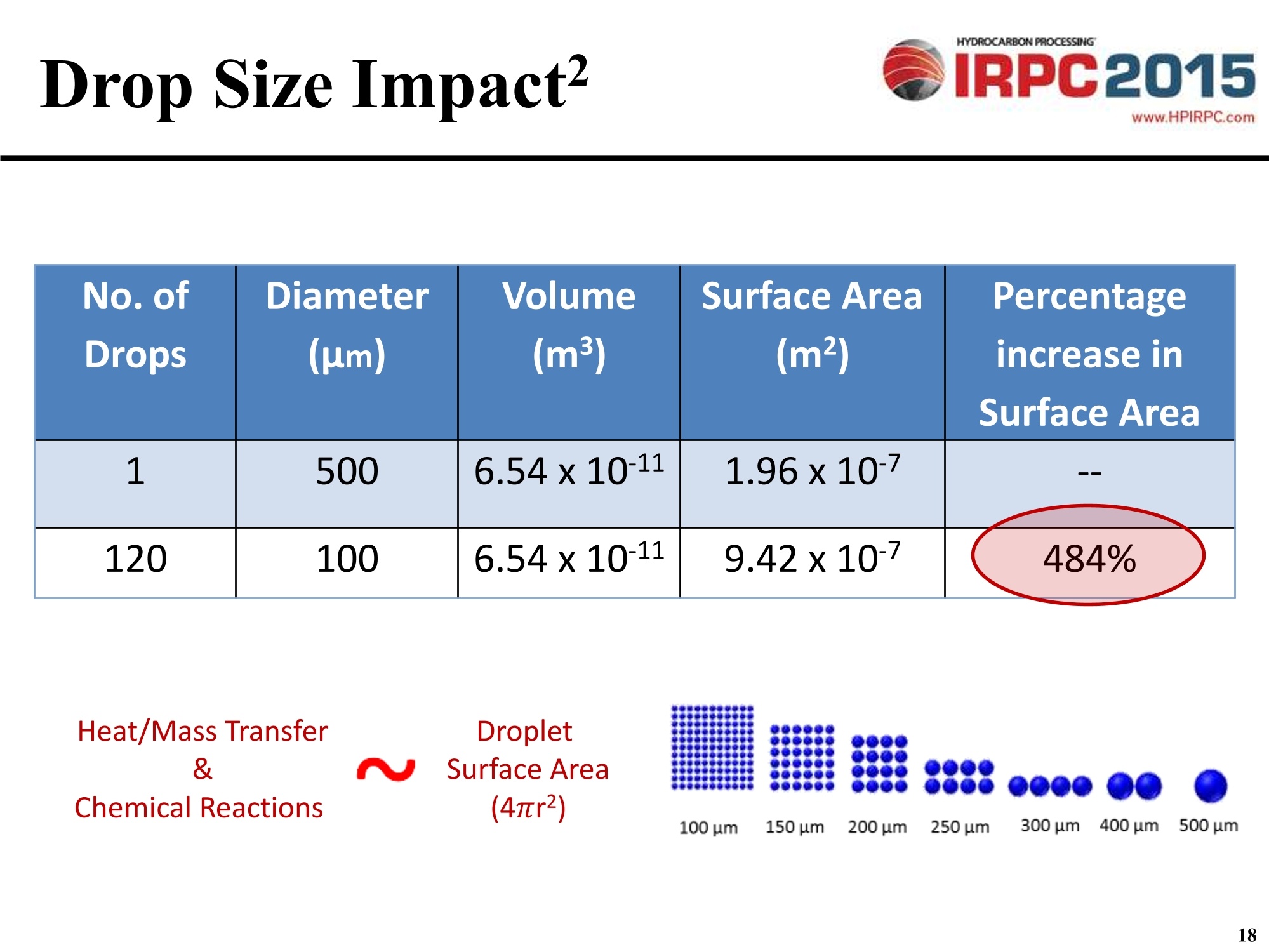

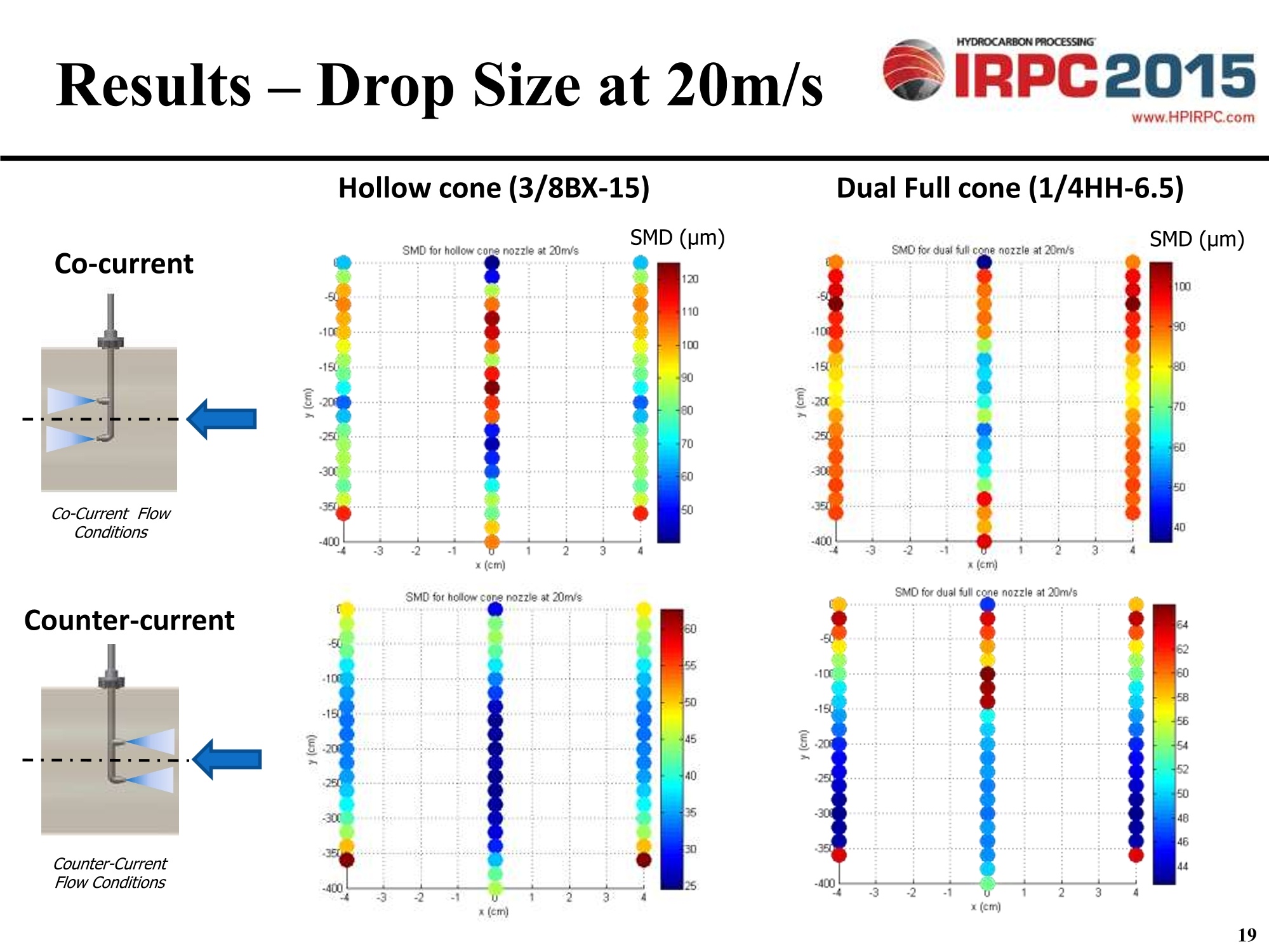

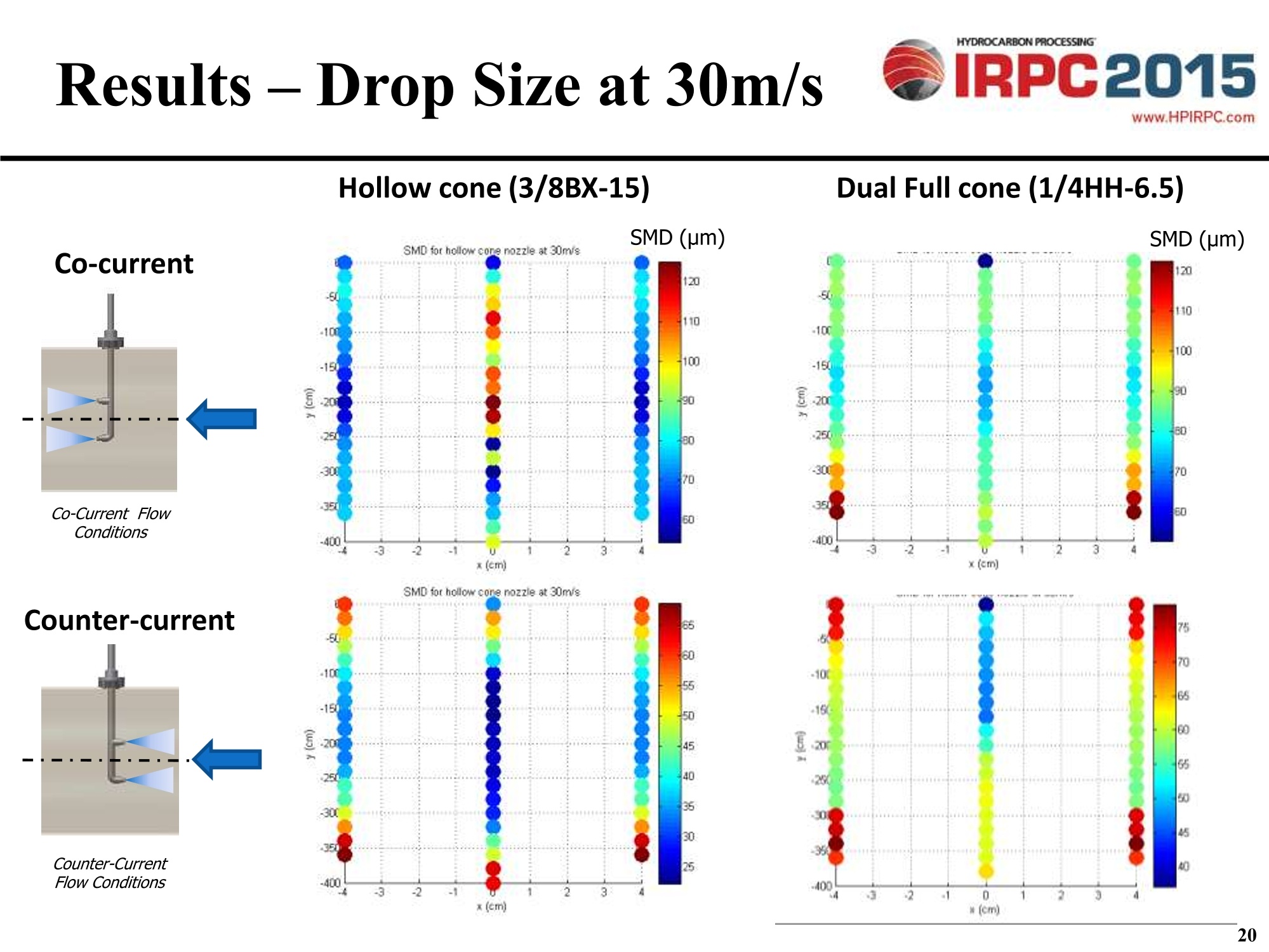

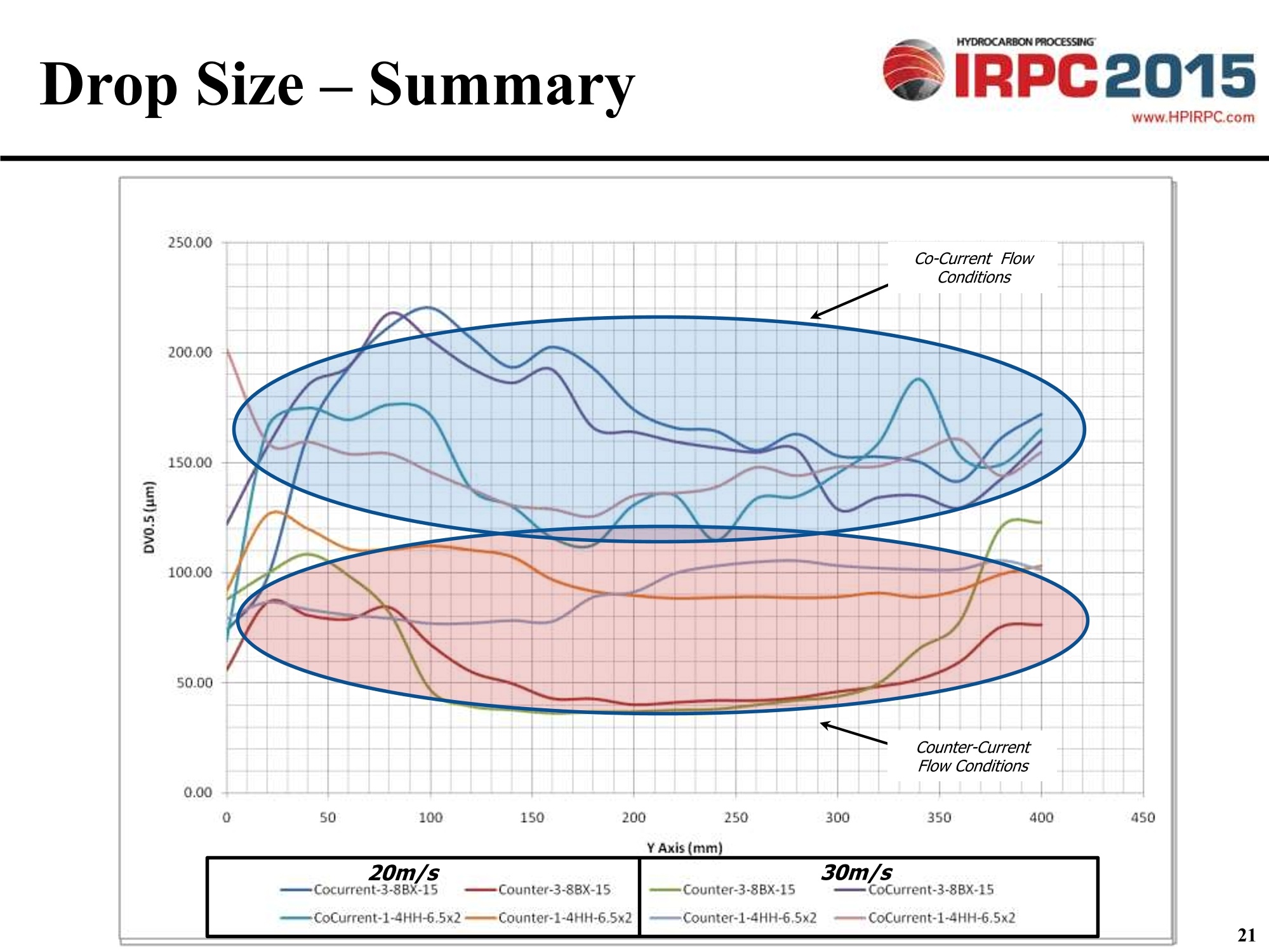

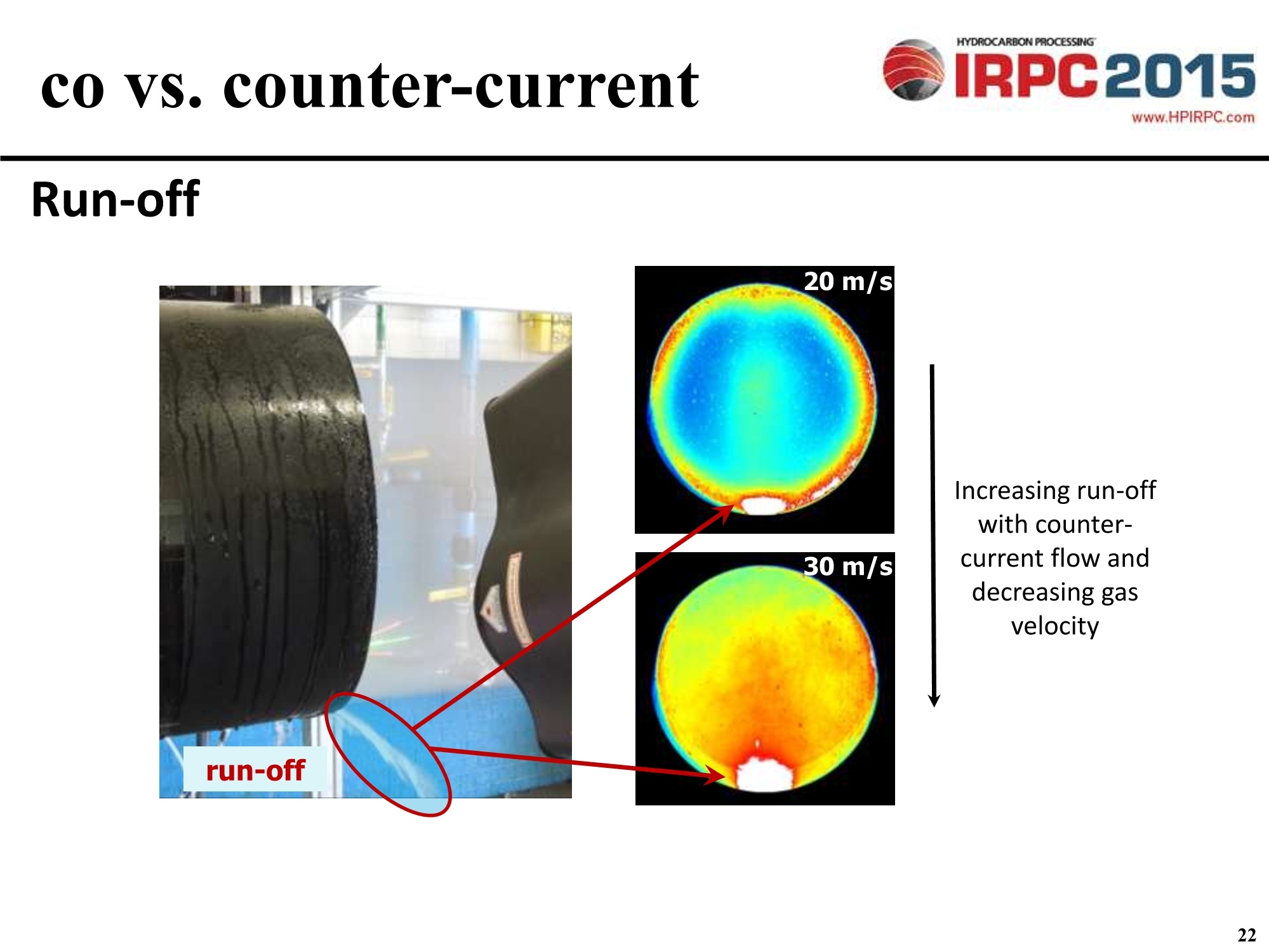

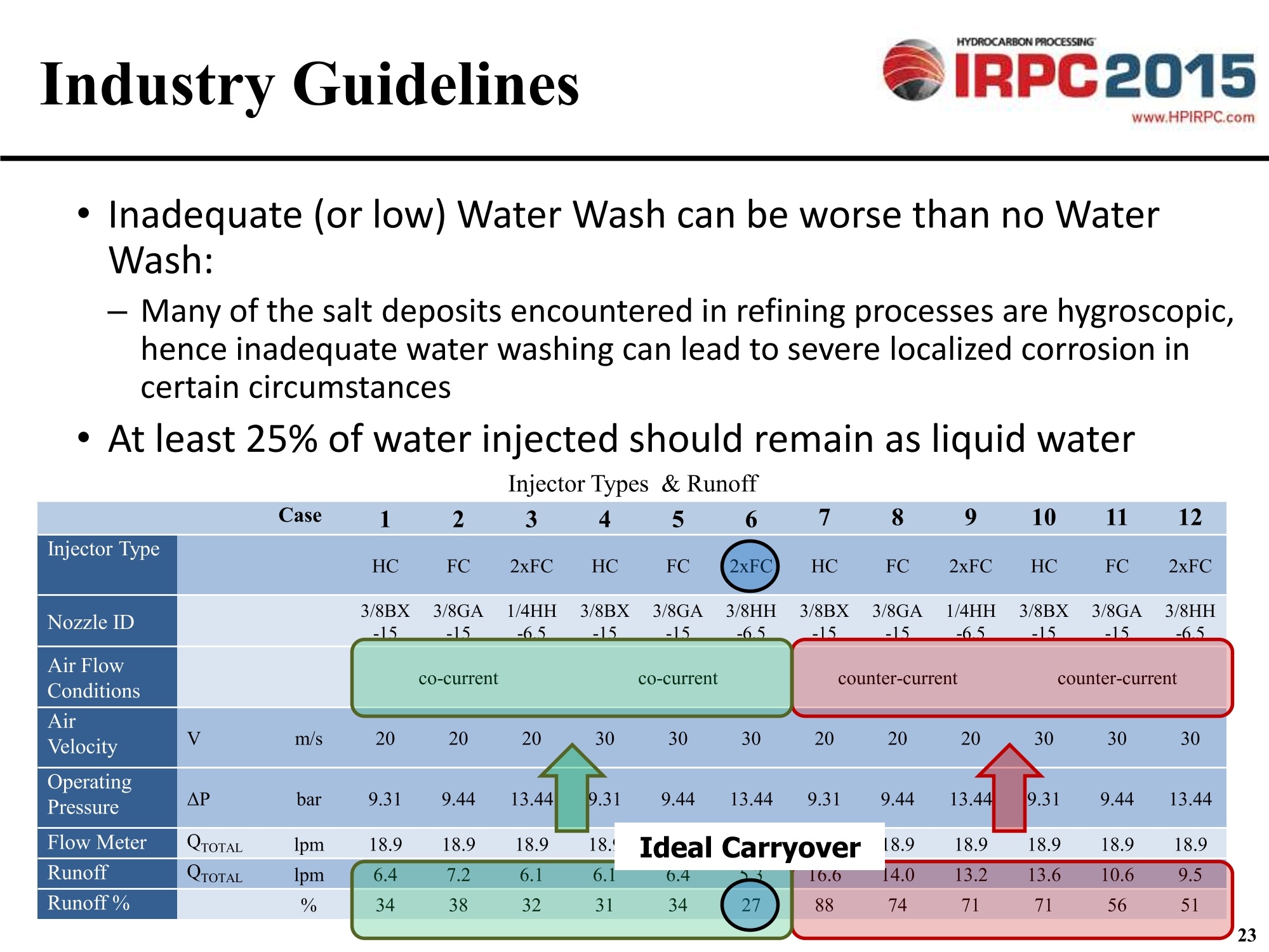

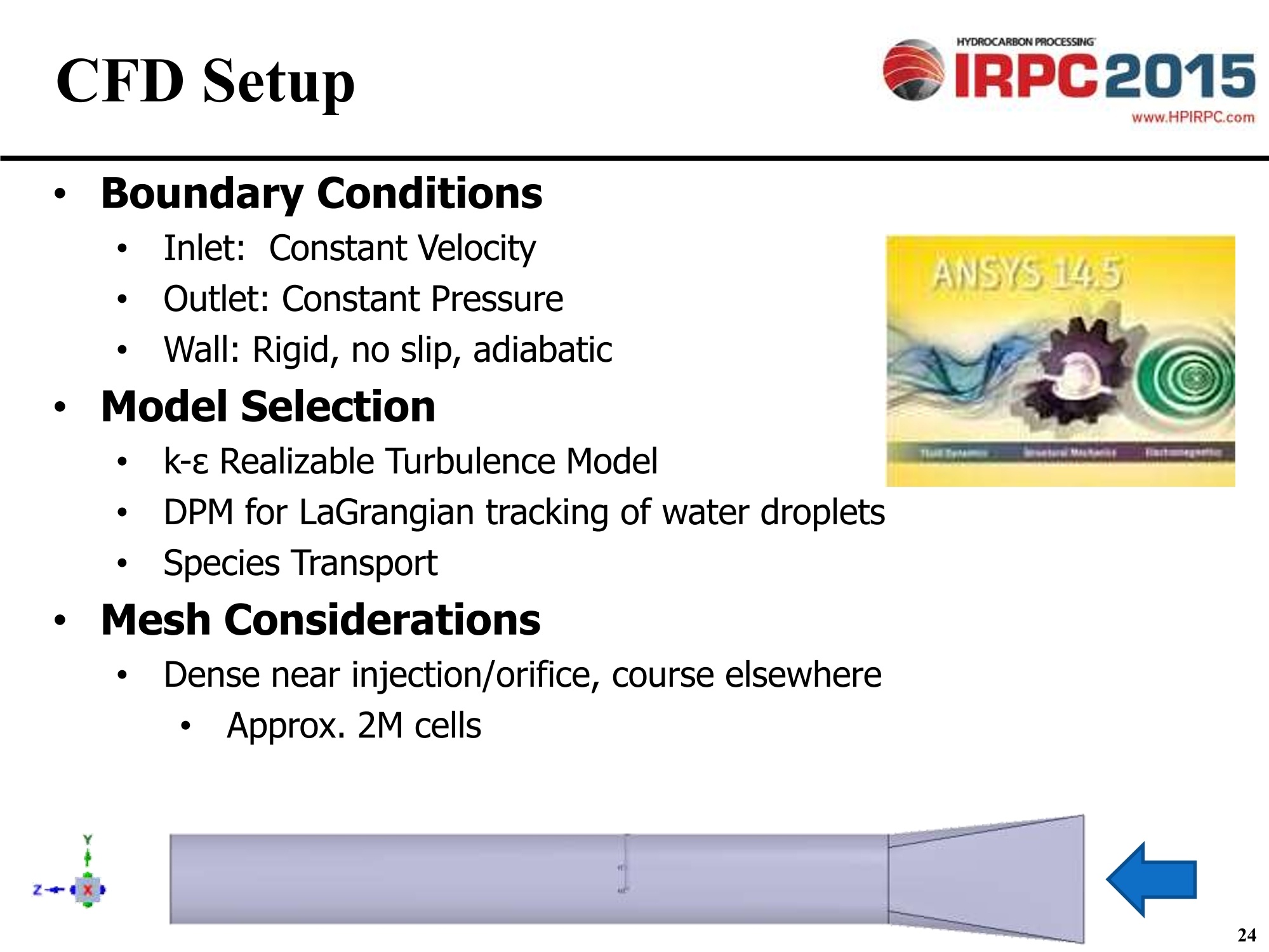

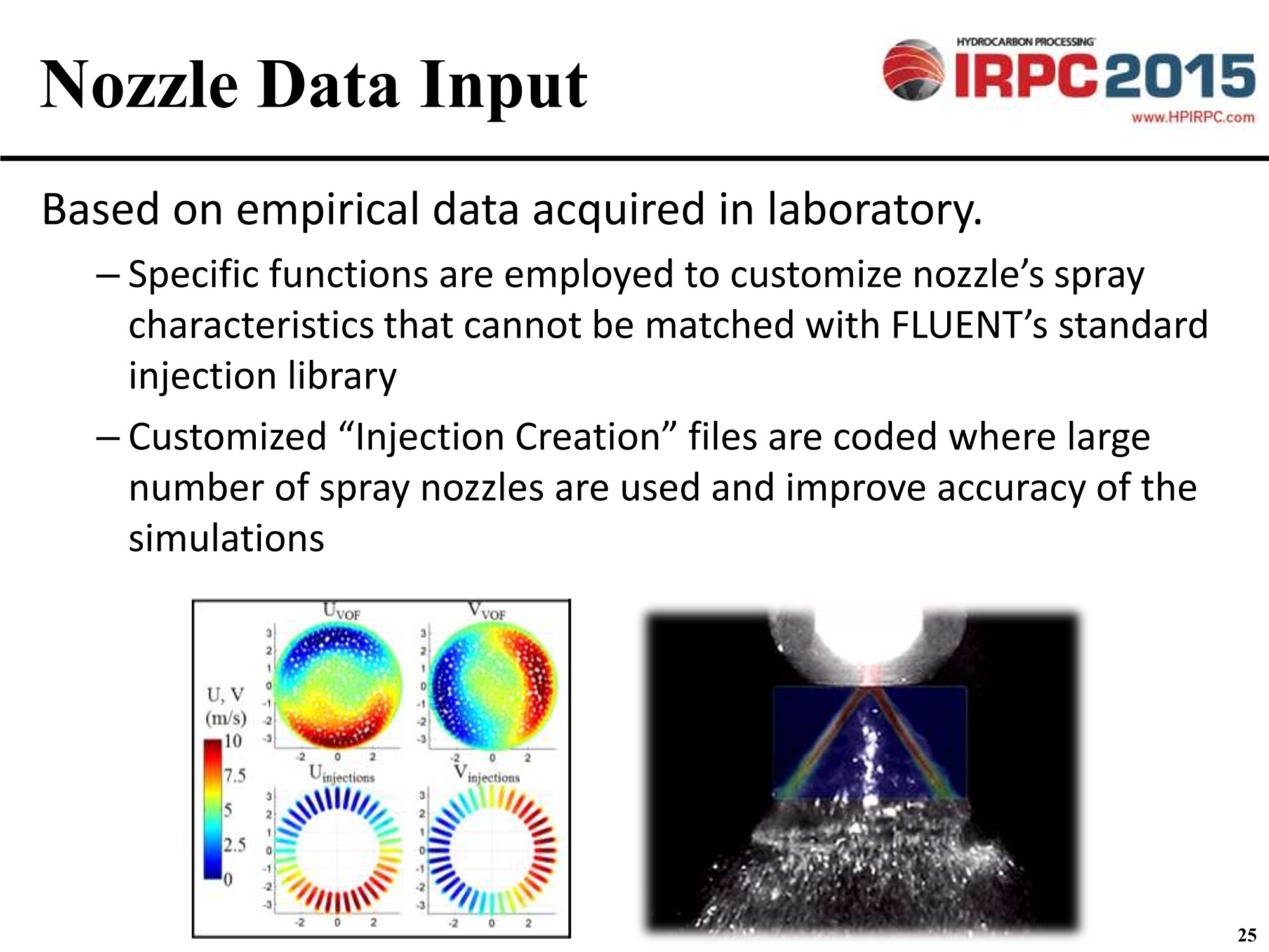

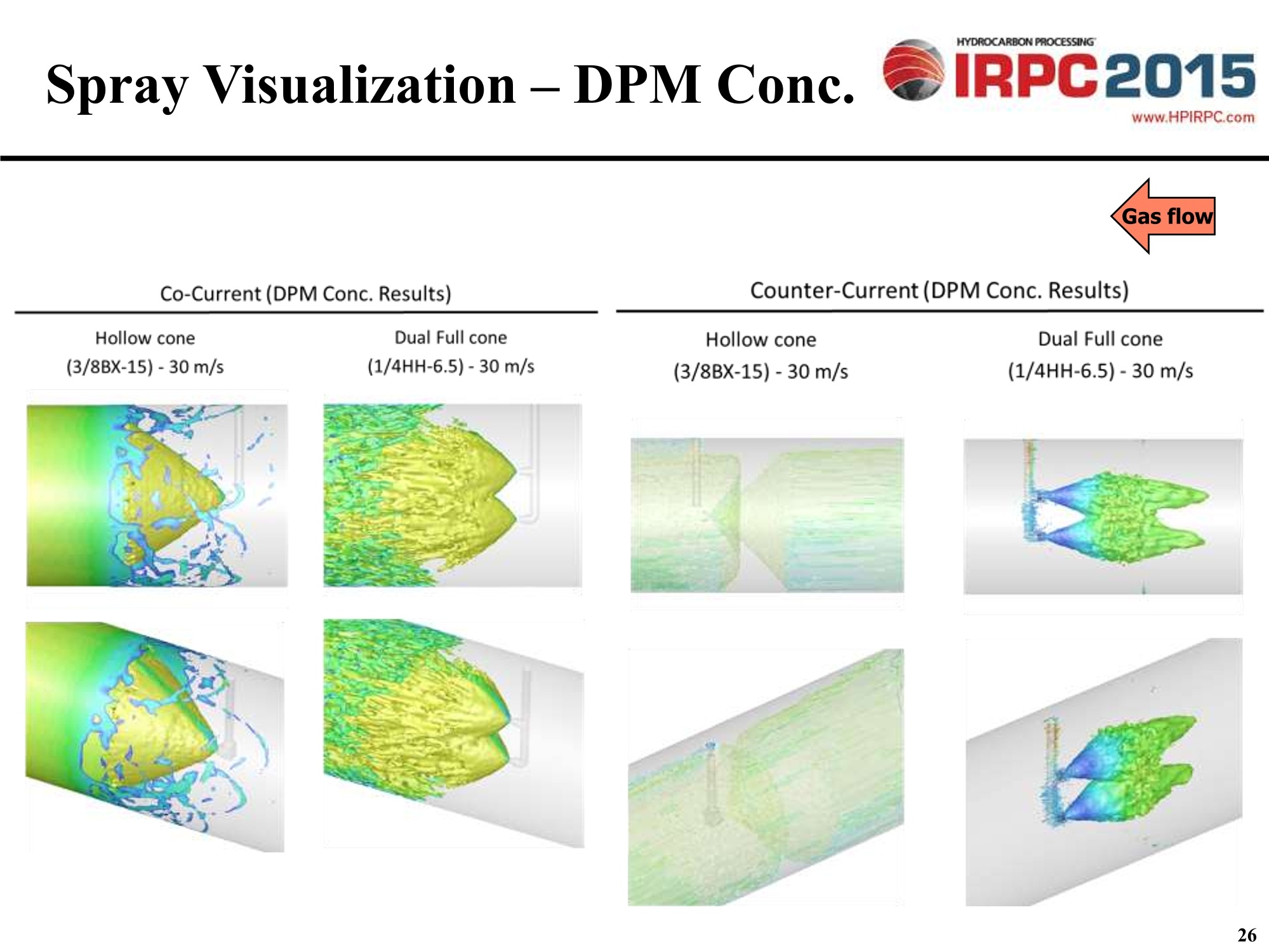

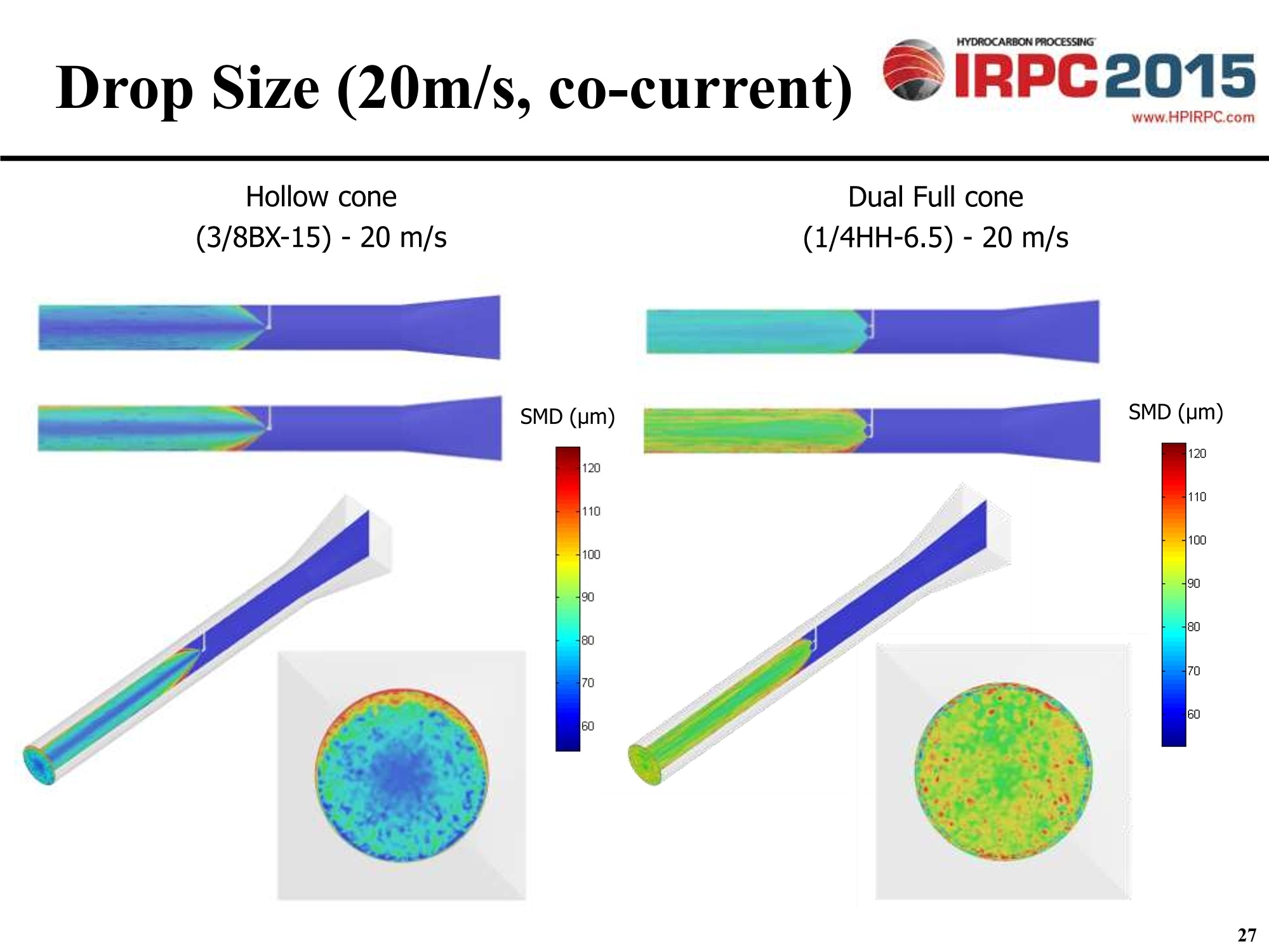

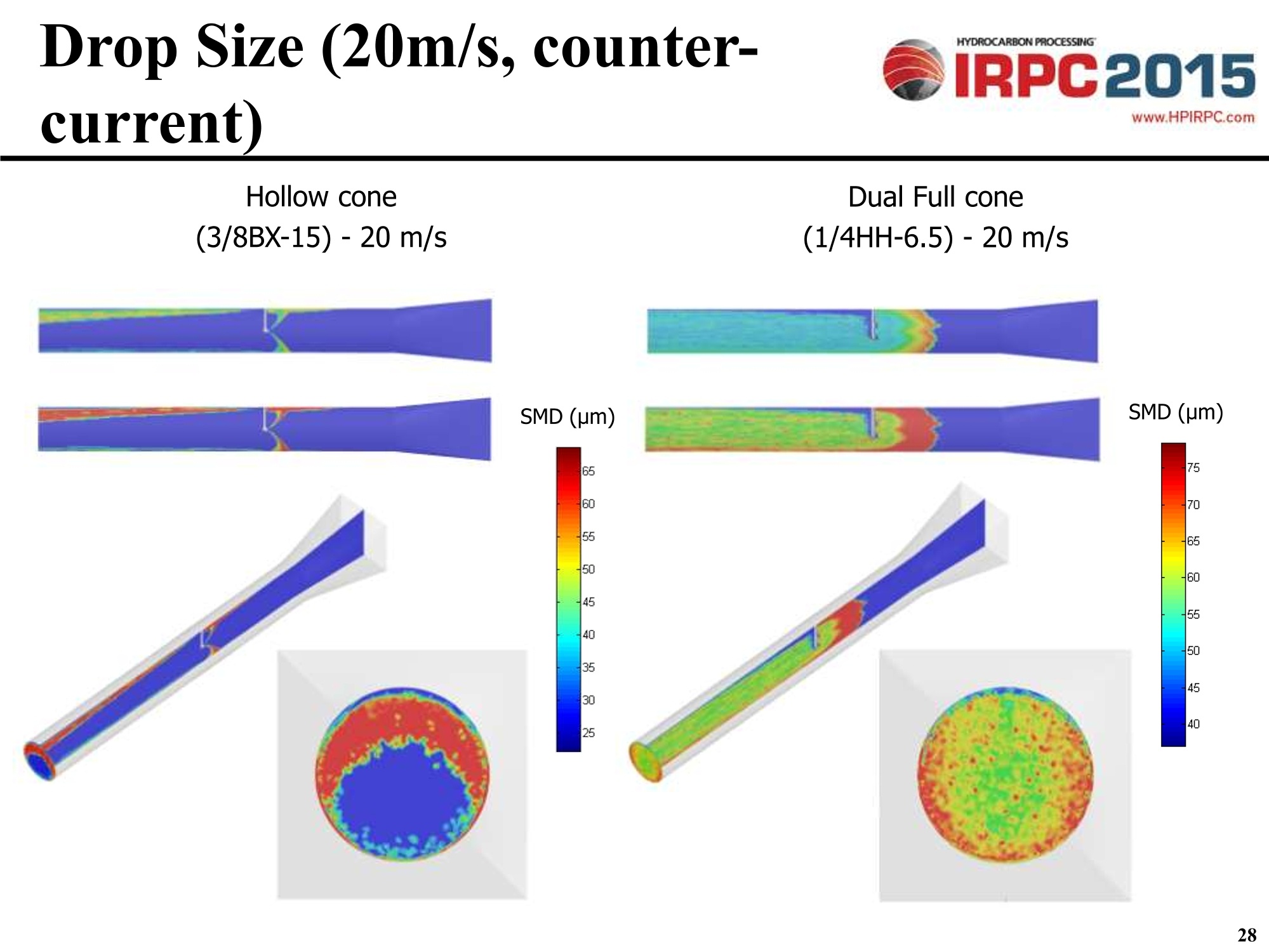

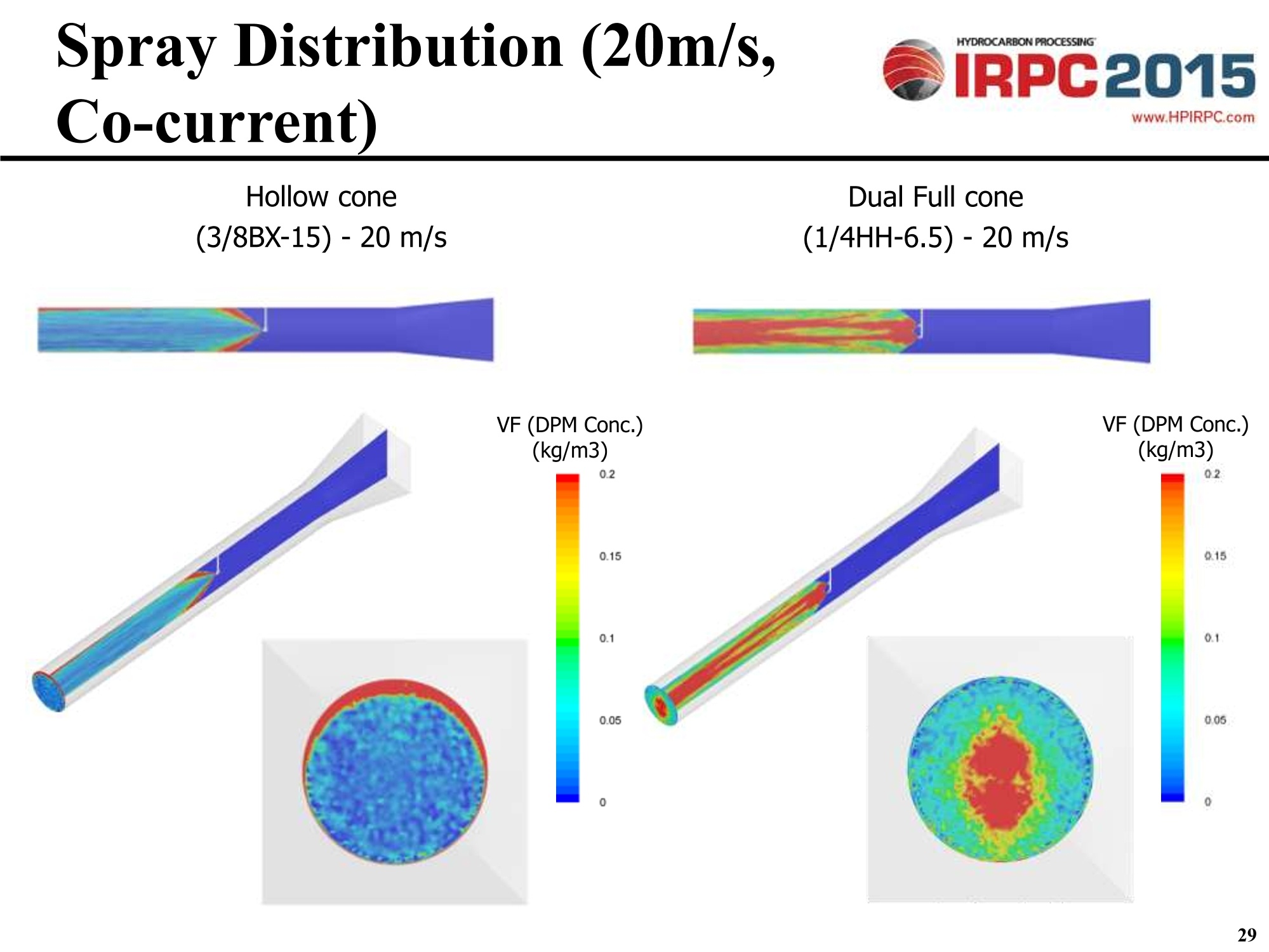

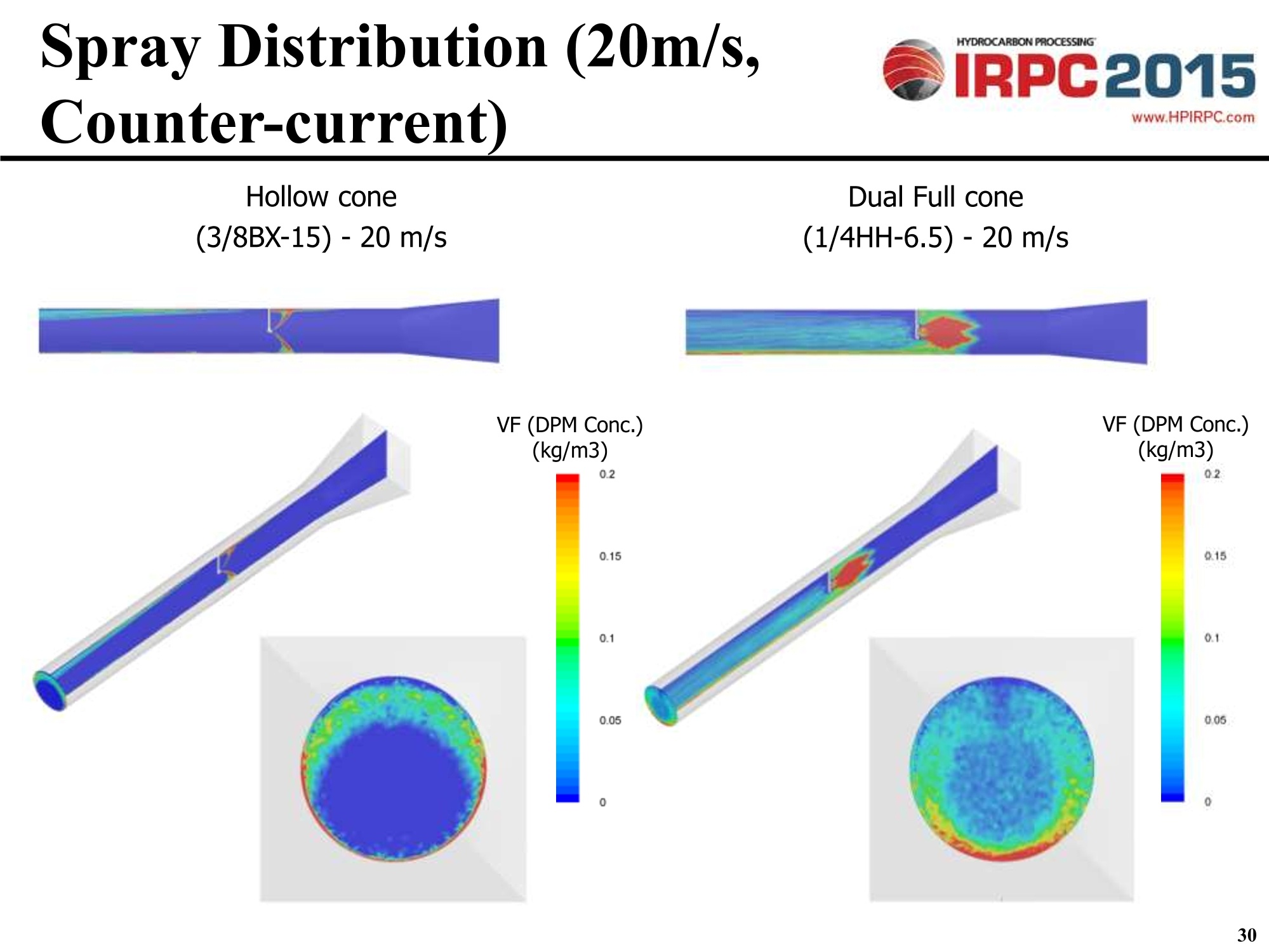

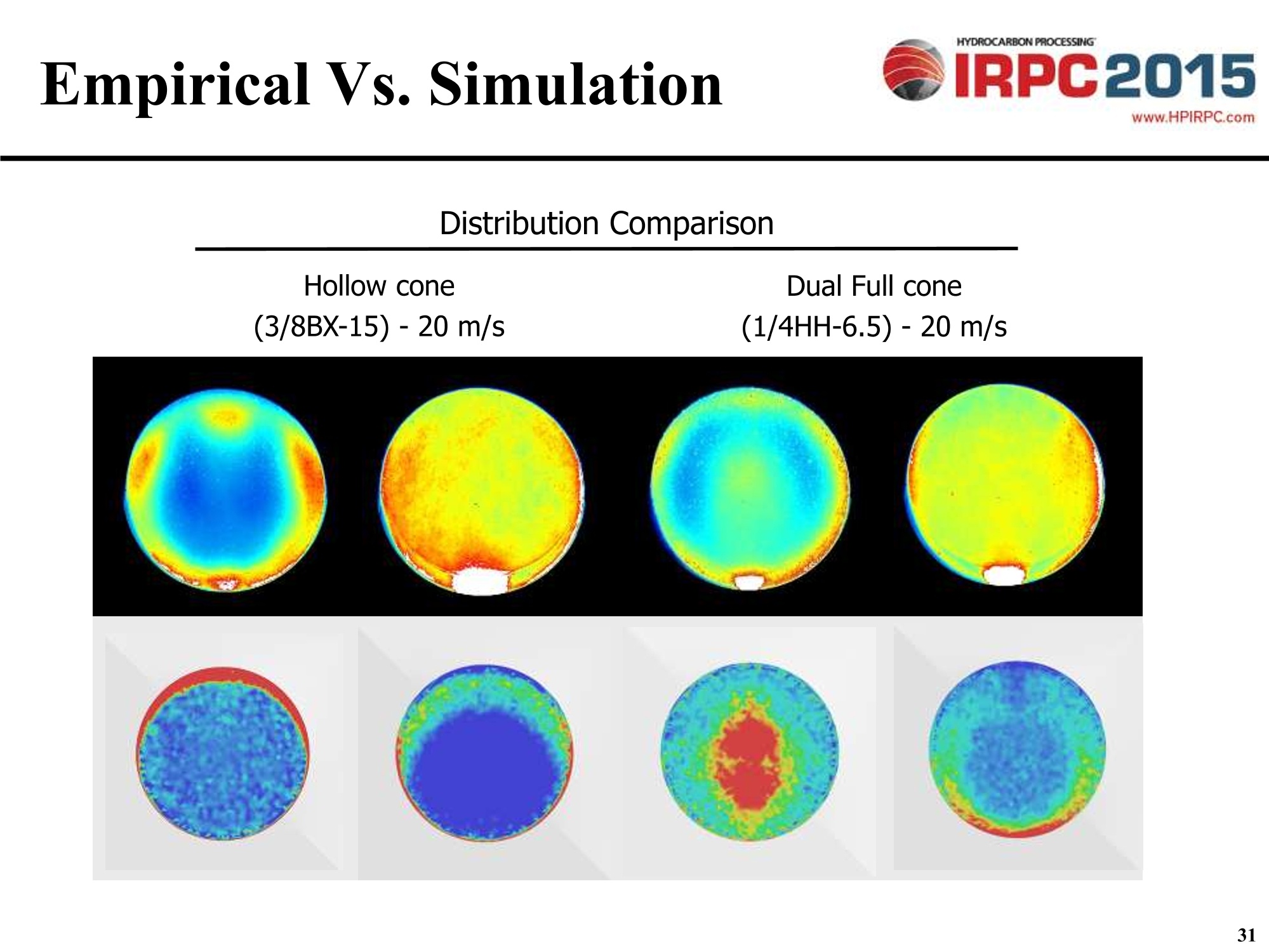

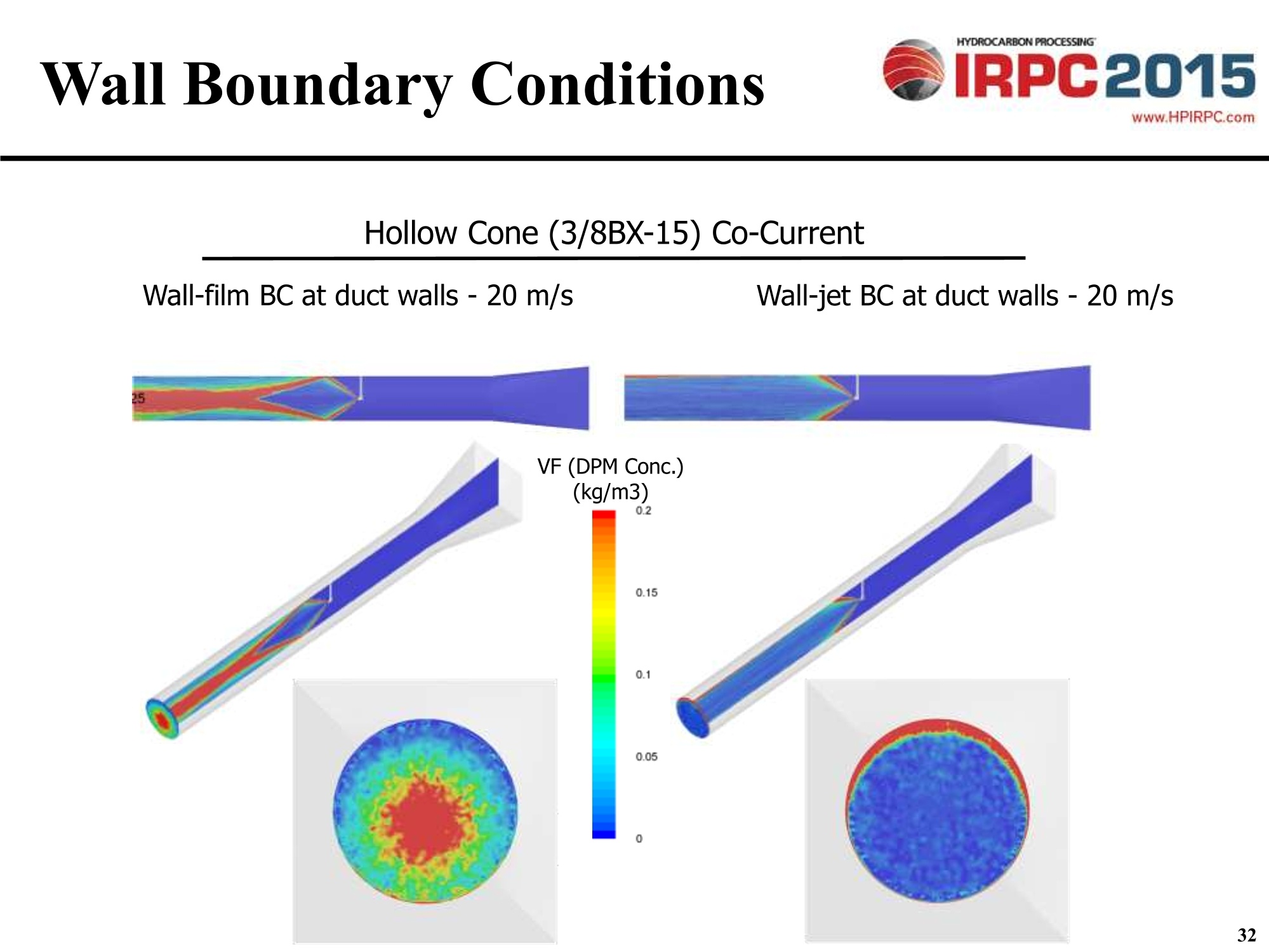

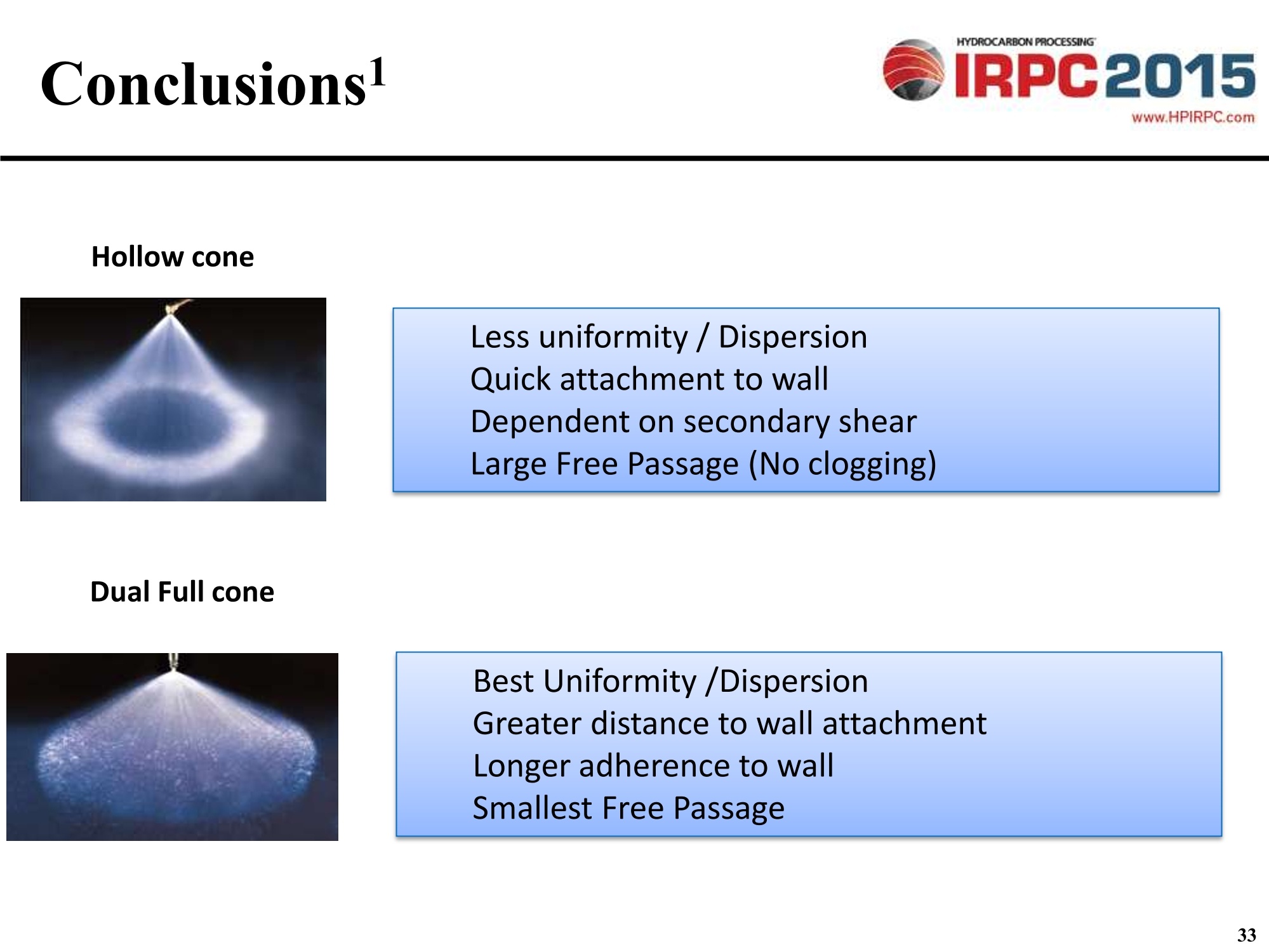

www.HPIRPC.com HYDROCARBON PROCESSINGIRPC2015www.HPIRPC.com Simulation and EmpiricalEyaluation K.J. Brown, W.Kalata,R. J. SchickSpraying Systems Co. HYDROCARBON PROCESSING Spray Analysis and Research Services IRPC2015 From Spraying Systems Co. Presentation Topics ●('Company Overview ·Problem Description Methodology ●Results Conclusion and next steps Who is SprayingSystems Co. World Leader in Spray Technology - Privately owned (Established 1937) - Headquarters in Wheaton, IL Products -Spray nozzles, related systems and accessories Over 120,000 standard and 180,000 non-standard engineered products Access to Market - Global/Regional engineering and manufacturingS:... -85 local sales engineering offices around the world Value added - Recognized global brand for spray technologies Quality,service, support, engineered solutions Serve 50 major industrial markets · Help quench and scrub theoverhead vapors Dilute acids formed Crude Unit Column Overhead-CorrosionWater is usually injected in theCrude oilAir-cooledoverhead piping to:condenserPump+ GasCrudeoil2 atmReflux 43 °C RefluxDrumHot products or pumparoundSourWate一x-r PumpMixing Crude Oil+Naphthavalve water DistillationDesalterTower Crude OilCrude Steam+Brine oil + KeroPrevent any salts or acids from (Jet fuel)PumpCrude Oilforming in the system Pump- —Steam口aroundLightGas Oil立 苫398°c 工 Pump1-Crude OilSteamCrude oil H eav y Gas OilFired Steam-Heater S idecutS t r i p r Pupes m p Crude OilWhen the heat exchanger 十-Residuesymbol is greyed like this, (Fuel oil)it is part of the crude oilPumppreheat exchangers. Even distribution of wash water increases theeffectiveness of a water-wash system. Interaction of a spray plume in the environmentdetermines the level of liquid/gas mixingandabsorption effectiveness. Traditional methods rely of using simple Quills- Single/Dual Hole Design- Slot Design Often ineffective in areas where critica control isneeded Introductionof Spray Nozzle Injectorssignificantly improves the process Even distribution of wash water increases the effectiveness of awater-wash system. Interaction of a spray plume within a confined cross-flowenvironment controls the level of liquid gas mixing and absorptioneffectiveness. The primary focus of this study is to define the distribution ofinjected water wash downstream of the injection point. Modeling is used in environments that are difficult to access,...validation is necessary to be sure injector recommendations areaccurate and optimized. Validation process using experiments and modeling -usedto evaluate spray performance of different nozzles. Experiments Laser Sheet Imaging (LSI) -- spray shape, size and distribution characteristics PhaseDoppler Interferometer (PDI)-- drop size, velocity, angle of trajectory and spray volumeWind tunnel Modeling(CFD) -- spray simulation (custom spray injection methods) -- in situ data for engineering assessment in actual region Empirical Setup Large capacity Wind Tunnel, Ambient air Modified Test Section 040cm x 2.75m, with Optical access Nominally Uniform AirflowOperated at 20m/s and 30m/s Injectors (Flow Rate=19LPM) Hollow cone-3/8BX-15 Full cone-3/8GA-15 Dual Full cone-1/4HH-6.5 Full cone Hollow cone ●Flow Direction (injector relative to gas) Co-current Counter-current Gas Velocitv 个 from previous study Counter-CurrentFlow Conditions Injector Type Flow from previousstudy Co-Current FlowConditions ExperimentalSetup-SprayDistribution Acquisition · Laser Sheet Imaging (LSI)·LaVision GmbH Orientation Mounted at exit of wind tunnelVertical and Horizontal 2D measurement of spray patternTime dependant fluctuations · Light Intensity - Spray uniformityMie Scattering Spray Distribution- counter-current Experimental Setup-DropSize Acguisition Phase DopplerInterferometer (PDI) Artium Technologies Inc. PDI-200MD PDI Orientation Mounted at exit of wind tunnel Vertical and Horizontal Traverse y-2cm measurement resolutionz-6cm measurement resolution Drop Size Distribution AxiaVelocitv Has major impact in increase process effectiveness Effectiveness is increased because Greater Surface Area → increases contact area with gas stream More Uniform Distribution across Duct/Vessel → increasesinteraction and uniformity of reaction ldrag U. Turbulence gas Up No. of Drops Diameter (um) Volume (m3) Surface Area (m2) Percentage increase in Surface Area 1 500 6.54x10-11 1.96x10- 120 100 6.54x10-11 9.42x10-7 484% Heat/Mass Transfer&Chemical Reactions Droplet Surface Area (4ztr2) 100 um 150 pm 200 pm 250 um 300 um400 um500 um Hollow cone (3/8BX-15) Dual Full cone (1/4HH-6.5) SMD (um) SMD (um) SMD for hollow cone nozzle at 20m/s Co-current 120 -5 110 -100 100 -150 90 -22001 480 -250 70 -300 50 -35 Co-Current FlowConditions 50 -400 .4 -3 -2 -1 1 2 3 4 x (cm) x (cm) Counter-current Counter-CurrentFlow Conditions x(cm) Hollow cone(3/8BX-15) Dual Full cone(1/4HH-6.5) SMD (um) SMD (um) SMD for hollow core nozzle at 30m/s Co-current 120 .5 110 -100 -150 100 -201 690 250 80 -300 70 -350 Co-Curr ent Flow 60 Conditions -400 -3 -2 -1 1 2 3 x (cm) Counter-current 34 Counter-CurrentFlow Conditions x (cm) CoCurrent-1-4HH-6.5x2- Counter-1-4HH-6.5x2 CoCurrent-1-4HH-6.5x2 Run-off 20 m/s 22 ·Inadequate (or low) Water Wash can be worse than no WaterWash: —1Many of the salt deposits encountered in refining processes are hygroscopic,hence inadequate water washing can lead to severe localized corrosion incertain circumstances · At least 25% of water injected should remain as liquid water Injector Types & Runoff Case 1 2 3 4 5 6 7 8 9 10 HC FC 2xFC HC FC 2xFC) HC FC 2xFC HC FC Nozzle ID 3/8BX -15 3/8GA -15 1/4HH -6.5 3/8BX -15 3/8GA -15 3/8HH -65 3/8BX -15 3/8GA -15 1/4HH -6.5 3/8BX -15 3/8GA -15 Air FlowConditions co-current co-current counter-current counter-current Air Velocity V m/s 20 20 20 30 30 30 20 20 20 30 30 OperatingPressure AP bar 9.31 9.44 l3.44 9.31 9.44 13.44 9.31 9.44 13.44 9.31 9.44 Flow Meter QTOTAL ipm 18.9 18.9 18.9 18.9 Ideal Carryover 18.9 18.9 18.9 18.9 Runoff QTOTAL 1pm 6.4 7.2 6.1 6.1 6.4 16.6 14.0 13.2 13.6 10.6 Runoff% % 34 38 32 31 34 27 88 74 71 71 56 Boundary Conditions Inlet: Constant Velocity Outlet: Constant Pressure Wall: Rigid, no slip, adiabatic Model Selection k-e Realizable Turbulence Model DPM for LaGrangian tracking of water droplets Species Transport Mesh Considerations Dense near injection/orifice, course elsewhereApprox. 2M cells Based on empirical data acquired in laboratory. - Specific functions are employed to customize nozzle's spraycharacteristics that cannot be matched with FLUENT's standardinjection library -Customized“Injection Creation”files are coded where largenumber of spray nozzles are used and improve accuracy of thesimulations Co-Current (DPM Conc.Results) Hollow cone Dual Full cone Drop Size (20m/s, counter-current) Hollow cone(3/8BX-15)- 20 m/s Dual Full cone(1/4HH-6.5)-20 m/s SMD (um) Spray Distribution (20m/s,Co-current) Hollow cone(3/8BX-15)- 20 m/s Dual Full cone(1/4HH-6.5)-20 m/s VF (DPM Conc.) (kg/m3) VF (DPM Conc.)(kg/m3) 0.2 02 0.15 015 0.1 0.1 0.05 0.05 0 0 Spray Distribution (20m/s,Counter-current) Hollow cone(3/8BX-15)- 20 m/s Dual Full cone (1/4HH-6.5)-20 m/sVF (DPM Conc.)(kg/m3)0.2020.150.10.10.050.050 VF (DPM Conc.)(kg/m3) 015 Empirical Vs. Simulation Distribution Comparison Hollow cone (3/8BX-15)- 20 m/s Dual Full cone(1/4HH-6.5)-20 m/s Wall Boundary(Conditions Hollow Cone (3/8BX-15) Co-Current Wall-film BC at duct walls - 20 m/s Wall-jet BC at duct walls - 20 m/s 25 VF (DPM Conc.)(kg/m3) 0.2 0.15 0.1 0.05 Hollow cone Dual Full cone Best Uniformity /DispersionGreater distance to wall attachmentLonger adherence to wallSmallest Free Passage Co-current Less uniformity/DispersionGreater entrainment of full volume of sprayLess evidence of secondary breakup appears Co-Current FlowConditions Counter-current Better uniformity/ DispersionQuick wall attachmentEntrainment/small particles, large amount of run-off Counter-CurrentFlow Conditions ●Secondary breakup estimation with & withouttransient CFD -Additional measurement locations (from injector) Wall interference studies · User feedback - Corrosion and de-salting effectiveness Thank You www.HPIRPC.com

确定

还剩34页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《水洗喷嘴中液滴粒径,液滴速度,速度场,速度矢量场检测方案(干涉仪)》,该方案主要用于其他中液滴粒径,液滴速度,速度场,速度矢量场检测,参考标准--,《水洗喷嘴中液滴粒径,液滴速度,速度场,速度矢量场检测方案(干涉仪)》用到的仪器有激光相位多普勒干涉仪LDV,PDI,PDPA,PDA、Artium PDI-FP 双量程可机载飞行探头、德国LaVision PIV/PLIF粒子成像测速场仪

推荐专场

相关方案

更多

该厂商其他方案

更多