方案详情

文

In this study the tensile stress/strain behavior of various consumer plastic thin film materials was measured using a low mass mechanical analyzer. Film thicknesses varied from 19 mm to 66 mm (0.75 mil to 2.6 mil). In this study the force applied to the samples was ramped at 0.05 N/min from 0.05 N to 1 N and sample strain was followed. All measurements were made at ambient conditions.

The tensile behavior of the consumer products were compared qualitatively and quantitatively. Three mechanical phenomena were observed in the materials: linear elastic behavior, a strengthening or increase in modulus, and yielding or rapid elongation with minimal changes in stress. In the linear elastic region modulus was measured as defined by the inverse of the slope of the stress versus strain curve. Modulus values of 87 MPa to 6 GPa were observed.

方案详情

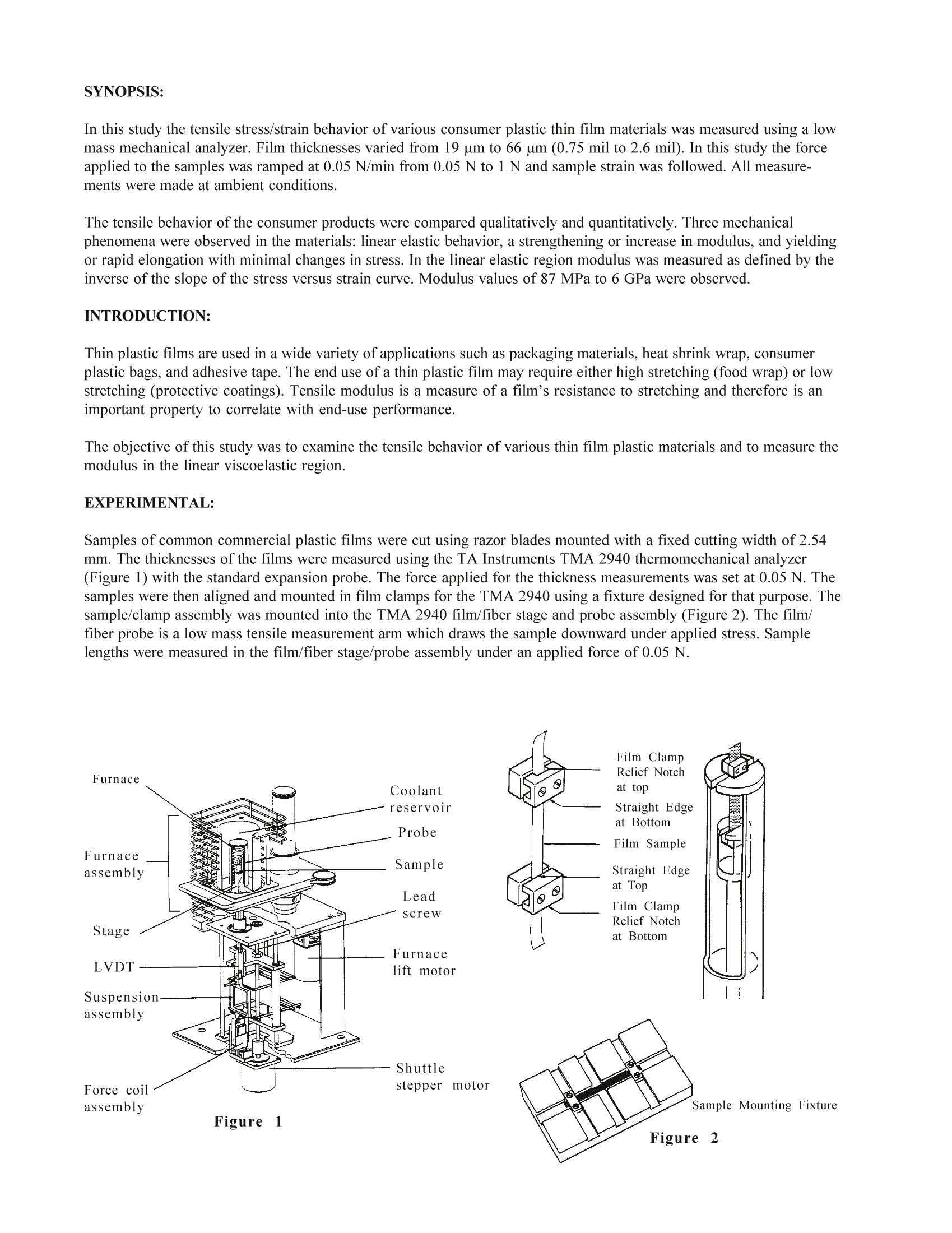

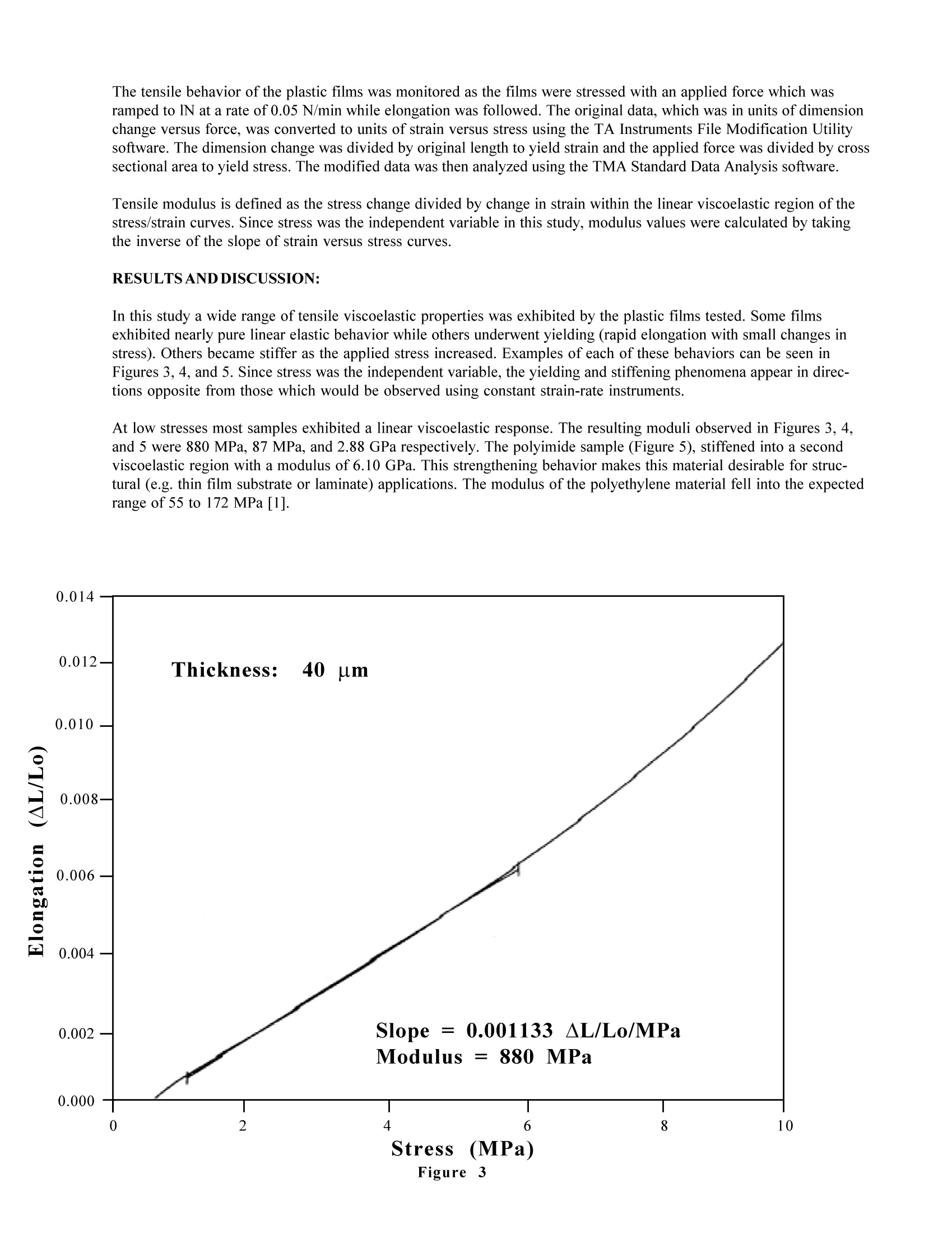

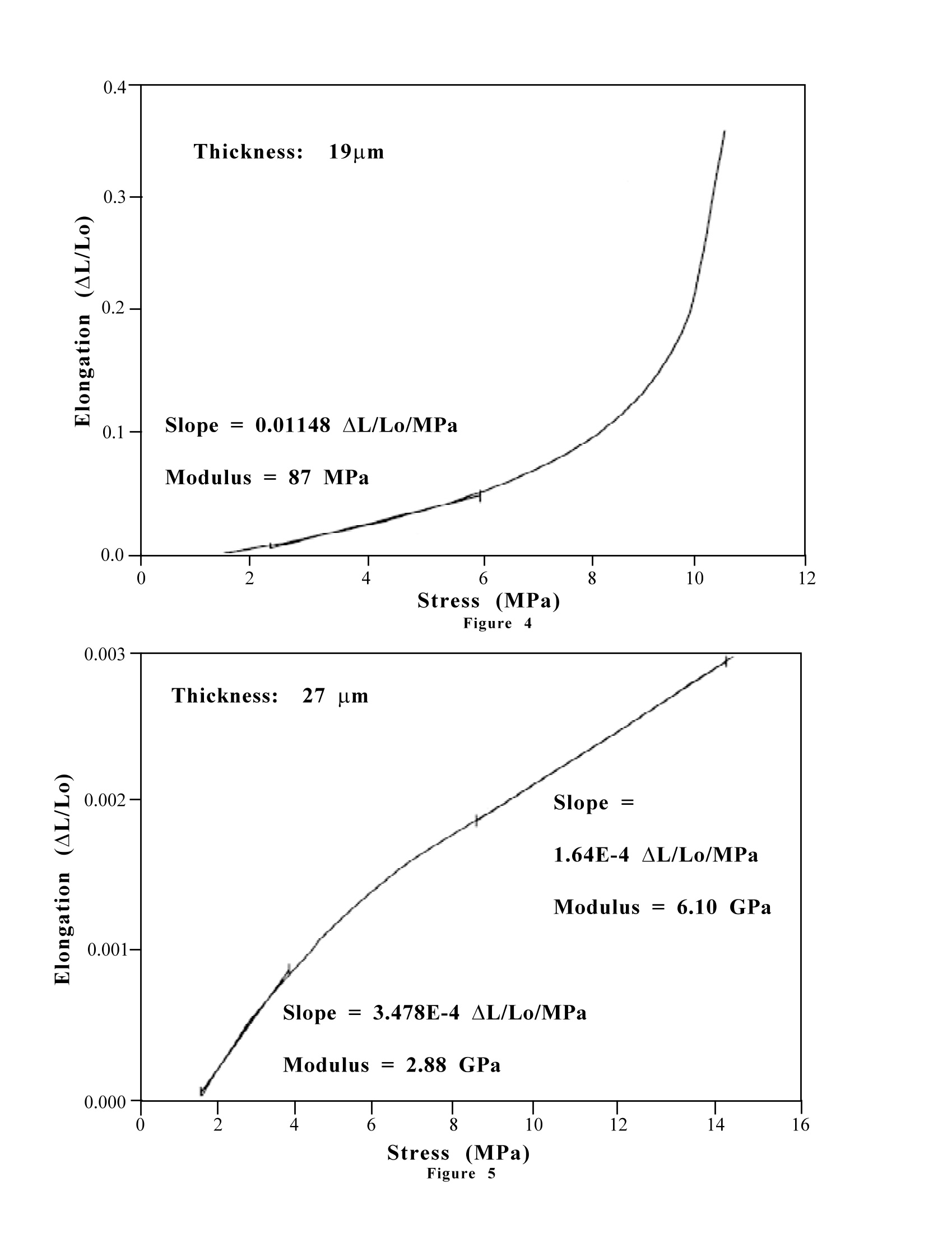

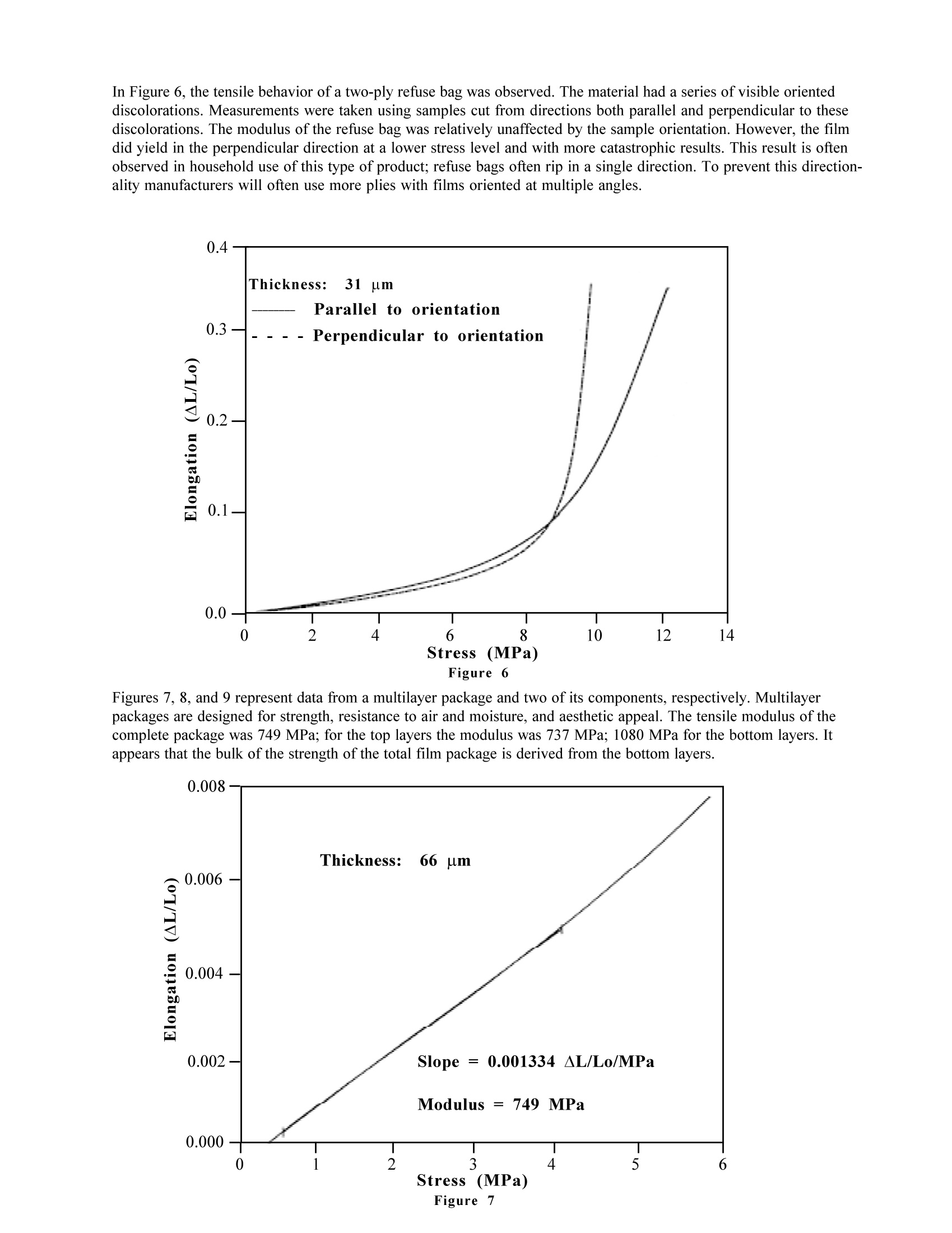

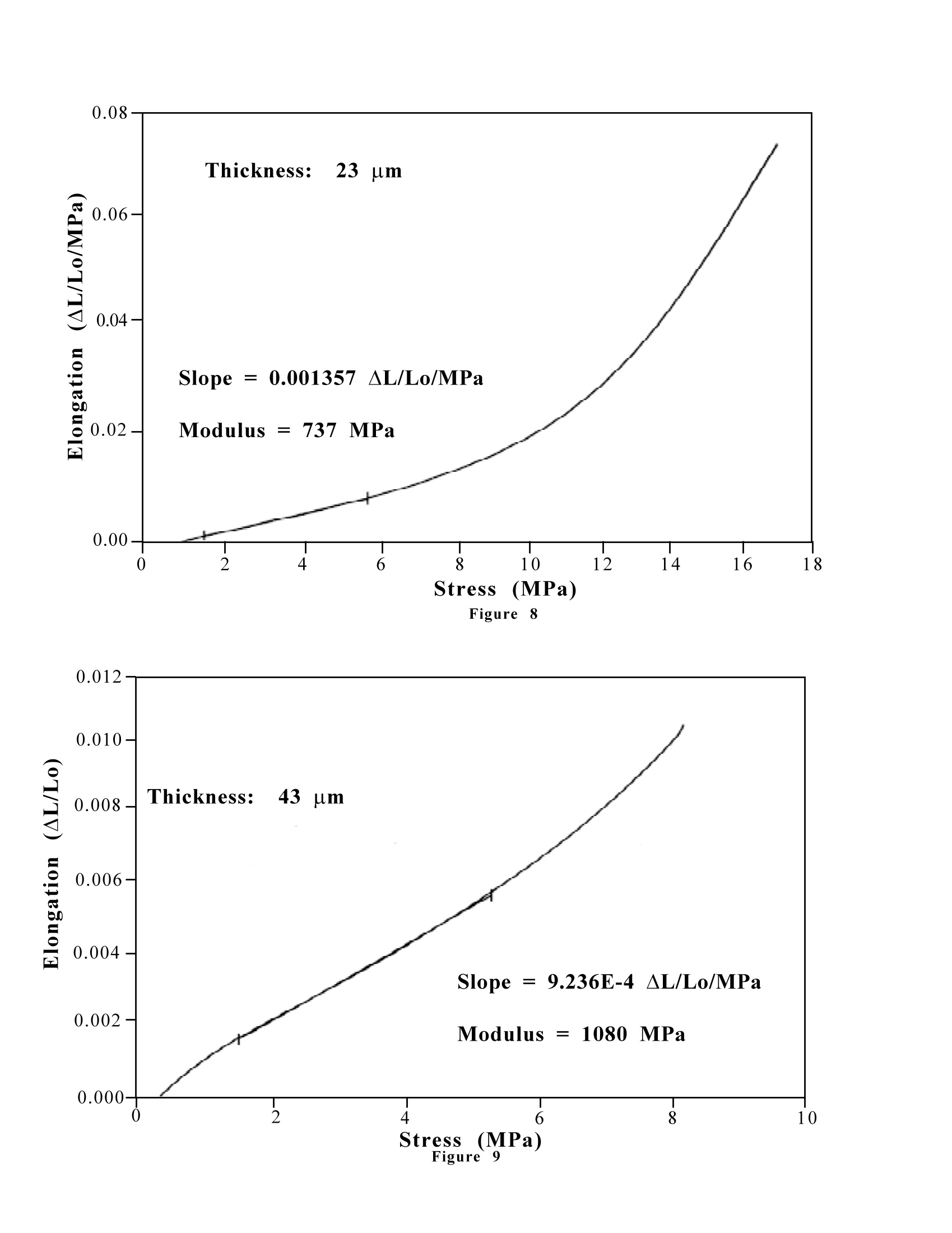

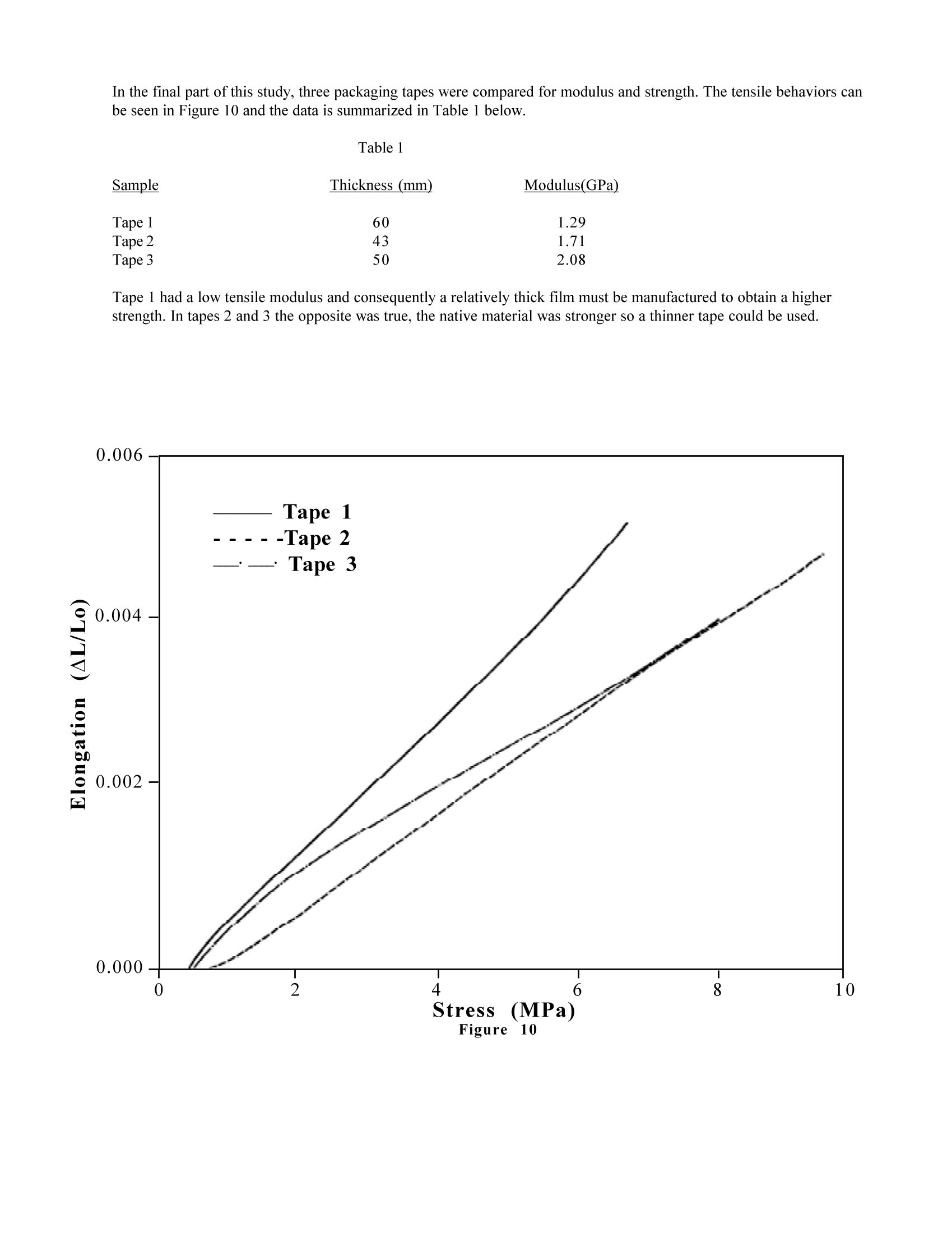

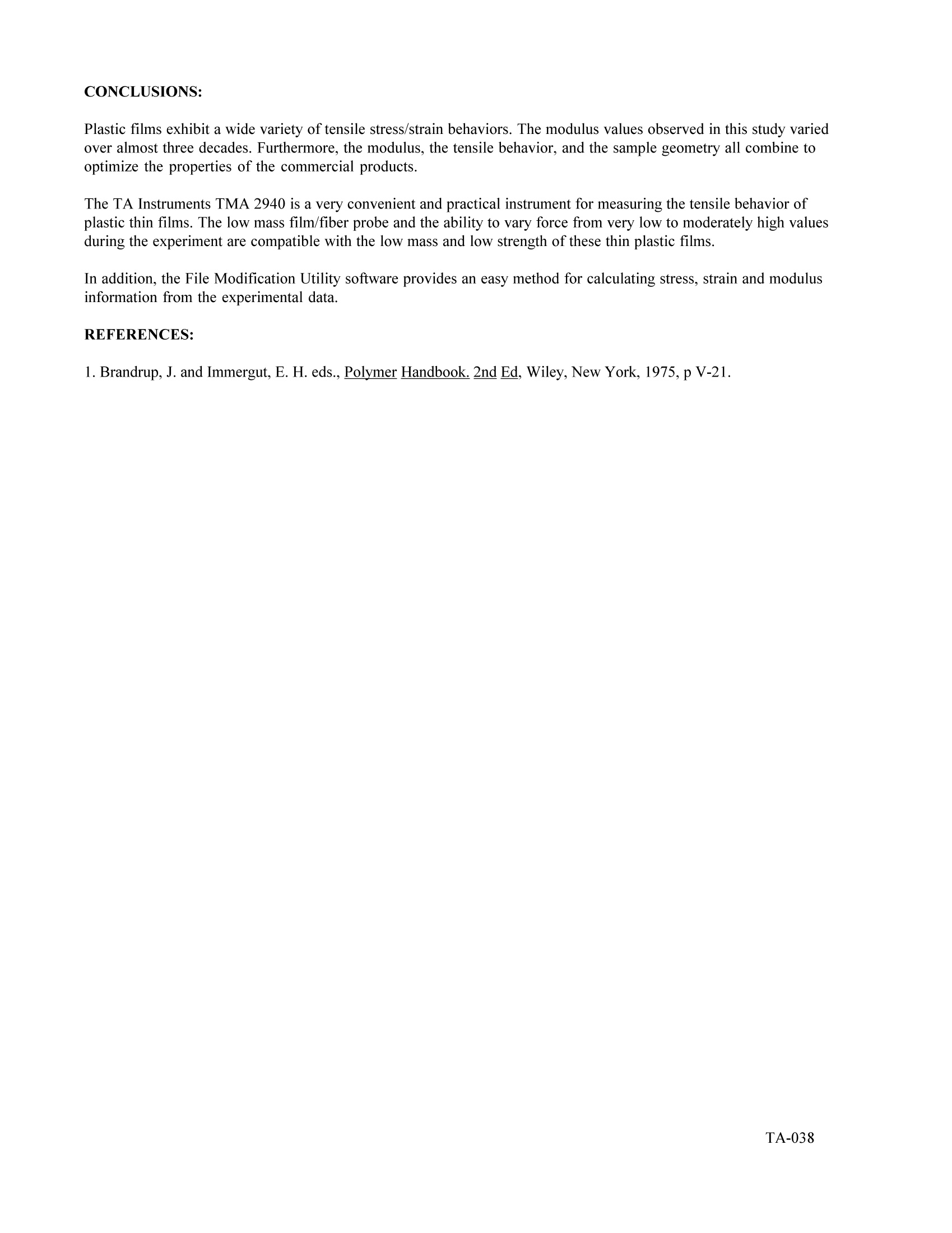

Thermal Analysis & Rheology TENSILE MODULUS OF PLASTIC FILMS* Jonathon Foreman,Philip S. Gill,and StevenR. Sauerbrunn TAInstruments,Inc. 109 Lukens Dr.. New Castle, DE 19720 SYNOPSIS: In this study the tensile stress/strain behavior of various consumer plastic thin film materials was measured using a lowmass mechanical analyzer. Film thicknesses varied from 19 um to 66 um (0.75 mil to 2.6 mil). In this study the forceapplied to the samples was ramped at 0.05 N/min from 0.05 N to 1 N and sample strain was followed. All measure-ments were made at ambient conditions. The tensile behavior of the consumer products were compared qualitatively and quantitatively. Three mechanicalphenomena were observed in the materials: linear elastic behavior, a strengthening or increase in modulus, and yieldingor rapid elongation with minimal changes in stress. In the linear elastic region modulus was measured as defined by theinverse of the slope of the stress versus strain curve. Modulus values of 87 MPa to 6 GPa were observed. INTRODUCTION: Thin plastic films are used in a wide variety of applications such as packaging materials, heat shrink wrap, consumerplastic bags, and adhesive tape. The end use of a thin plastic film may require either high stretching (food wrap) or lowstretching (protective coatings). Tensile modulus is a measure of a film’s resistance to stretching and therefore is animportant property to correlate with end-use performance. The objective of this study was to examine the tensile behavior of various thin film plastic materials and to measure themodulus in the linear viscoelastic region. EXPERIMENTAL: Samples of common commercial plastic films were cut using razor blades mounted with a fixed cutting width of 2.54mm. The thicknesses of the films were measured using the TA Instruments TMA 2940 thermomechanical analyzer(Figure 1) with the standard expansion probe. The force applied for the thickness measurements was set at 0.05 N. Thesamples were then aligned and mounted in film clamps for the TMA 2940 using a fixture designed for that purpose. Thesample/clamp assembly was mounted into the TMA 2940 film/fiber stage and probe assembly (Figure 2). The film/fiber probe is a low mass tensile measurement arm which draws the sample downward under applied stress. Samplelengths were measured in the film/fiber stage/probe assembly under an applied force of 0.05 N. Film Clamp Relief Notch at top Straight Edge at Bottom Film Sample Straight Edge at Top Film Clamp Relief Notch at Bottom 11 Figure 1 Figuree2 The tensile behavior of the plastic films was monitored as the films were stressed with an applied force which wasramped to IN at a rate of 0.05 N/min while elongation was followed. The original data, which was in units of dimensionchange versus force, was converted to units of strain versus stress using the TA Instruments File Modification Utilitysoftware. The dimension change was divided by original length to yield strain and the applied force was divided by crosssectional area to yield stress. The modified data was then analyzed using the TMA Standard Data Analysis software. Tensile modulus is defined as the stress change divided by change in strain within the linear viscoelastic region of thestress/strain curves. Since stress was the independent variable in this study, modulus values were calculated by takingthe inverse of the slope of strain versus stress curves. RESULTSAND DISCUSSION: In this study a wide range of tensile viscoelastic properties was exhibited by the plastic films tested. Some filmsexhibited nearly pure linear elastic behavior while others underwent yielding (rapid elongation with small changes instress). Others became stiffer as the applied stress increased. Examples of each of these behaviors can be seen inFigures 3, 4, and 5. Since stress was the independent variable, the yielding and stiffening phenomena appear in direc-tions opposite from those which would be observed using constant strain-rate instruments. At low stresses most samples exhibited a linear viscoelastic response. The resulting moduli observed in Figures 3, 4,and 5 were 880 MPa, 87 MPa, and 2.88 GPa respectively. The polyimide sample (Figure 5), stiffened into a secondviscoelastic region with a modulus of 6.10 GPa. This strengthening behavior makes this material desirable for struc-tural (e.g. thin film substrate or laminate) applications. The modulus of the polyethylene material fell into the expectedrange of 55 to 172 MPa [1]. Figure 4 In Figure 6, the tensile behavior of a two-ply refuse bag was observed. The material had a series of visible orienteddiscolorations. Measurements were taken using samples cut from directions both parallel and perpendicular to thesediscolorations. The modulus of the refuse bag was relatively unaffected by the sample orientation. However, the filmdid yield in the perpendicular direction at a lower stress level and with more catastrophic results. This result is oftenobserved in household use of this type of product; refuse bags often rip in a single direction. To prevent this direction-ality manufacturers will often use more plies with films oriented at multiple angles. Figure 6 Figures 7, 8, and 9 represent data from a multilayer package and two of its components, respectively. Multilayerpackages are designed for strength, resistance to air and moisture, and aesthetic appeal. The tensile modulus of thecomplete package was 749 MPa; for the top layers the modulus was 737 MPa; 1080 MPa for the bottom layers. Itappears that the bulk of the strength of the total film package is derived from the bottom layers. Figure7 Figure 8 o In the final part of this study, three packaging tapes were compared for modulus and strength. The tensile behaviors canbe seen in Figure 10 and the data is summarized in Table 1 below. Table 1 Tape 1 had a low tensile modulus and consequently a relatively thick film must be manufactured to obtain a higherstrength. In tapes 2 and 3 the opposite was true, the native material was stronger so a thinner tape could be used. Figure 110 CONCLUSIONS: Plastic films exhibit a wide variety of tensile stress/strain behaviors. The modulus values observed in this study variedover almost three decades. Furthermore, the modulus, the tensile behavior, and the sample geometry all combine tooptimize the properties of the commercial products. The TA Instruments TMA 2940 is a very convenient and practical instrument for measuring the tensile behavior ofplastic thin films. The low mass film/fiber probe and the ability to vary force from very low to moderately high valuesduring the experiment are compatible with the low mass and low strength of these thin plastic films. In addition, the File Modification Utility software provides an easy method for calculating stress, strain and modulusinformation from the experimental data. REFERENCES: 1. Brandrup, J. and Immergut, E. H. eds., Polymer Handbook. 2nd Ed, Wiley, New York, 1975, p V-21. *Preprint of paper submitted for publication in Journal of Applied Polymer Science. Figure In this study the tensile stress/strain behavior of various consumer plastic thin film materials was measured using a low mass mechanical analyzer. Film thicknesses varied from 19 mm to 66 mm (0.75 mil to 2.6 mil). In this study the force applied to the samples was ramped at 0.05 N/min from 0.05 N to 1 N and sample strain was followed. All measurements were made at ambient conditions.The tensile behavior of the consumer products were compared qualitatively and quantitatively. Three mechanical phenomena were observed in the materials: linear elastic behavior, a strengthening or increase in modulus, and yielding or rapid elongation with minimal changes in stress. In the linear elastic region modulus was measured as defined by the inverse of the slope of the stress versus strain curve. Modulus values of 87 MPa to 6 GPa were observed.

确定

还剩6页未读,是否继续阅读?

TA仪器为您提供《塑料薄膜中拉伸膜量检测方案(动态热机械)》,该方案主要用于其他中拉伸膜量检测,参考标准--,《塑料薄膜中拉伸膜量检测方案(动态热机械)》用到的仪器有

相关方案

更多

该厂商其他方案

更多