方案详情

文

Rheological testing of thermoplastic materials can be performed on both solid samples and on melts. This is important because the choice of material form and physical state is more than a matter of convenience: Product performance issues usually are related to solid samples properties; process ability issues can be correlated with polymer melt properties. In either case, since rheology is an indirect and non-unique measurement of structure, the application of rheology to solving processing and product performance problems often reduces to comparative analysis of good and poor performing samples.

方案详情

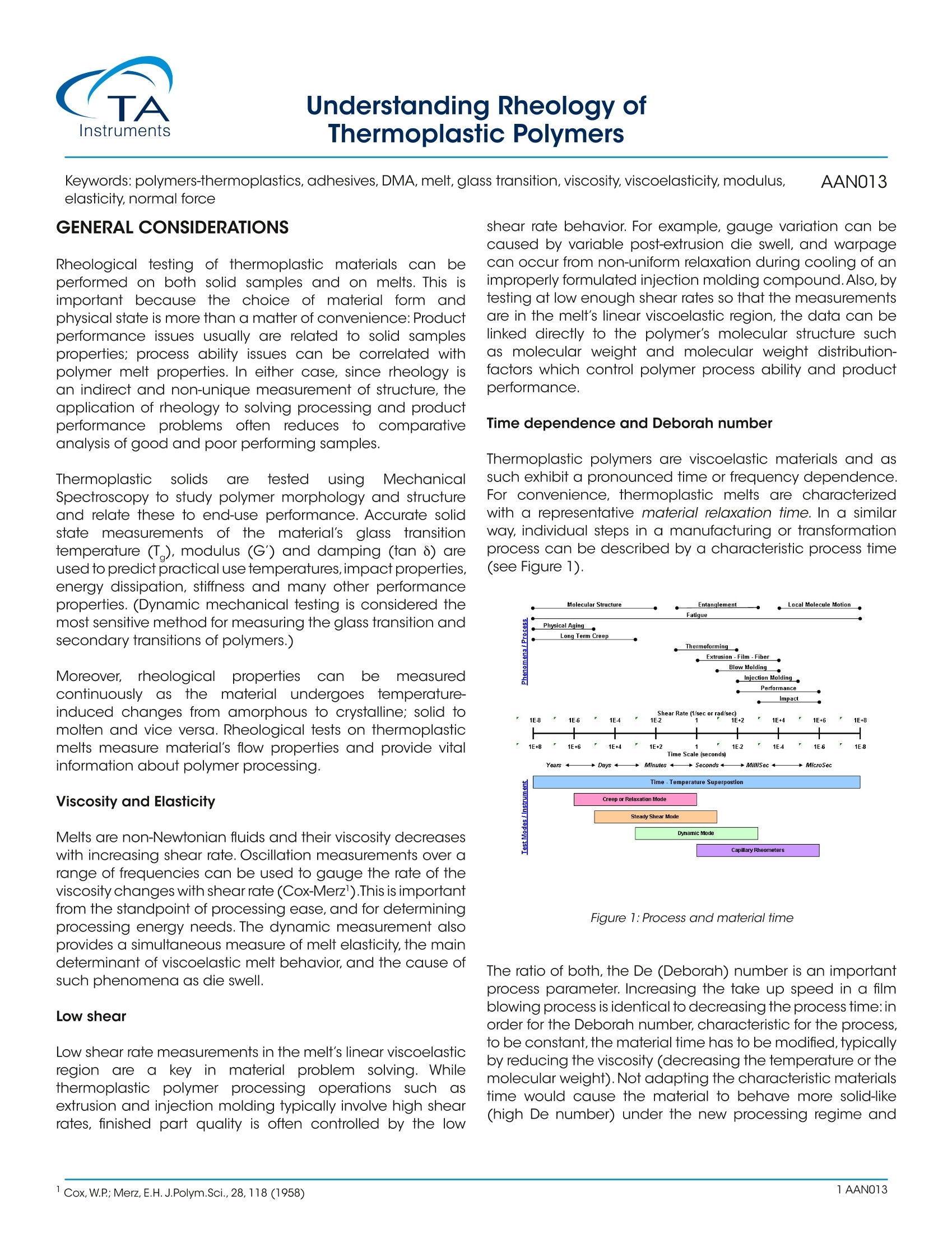

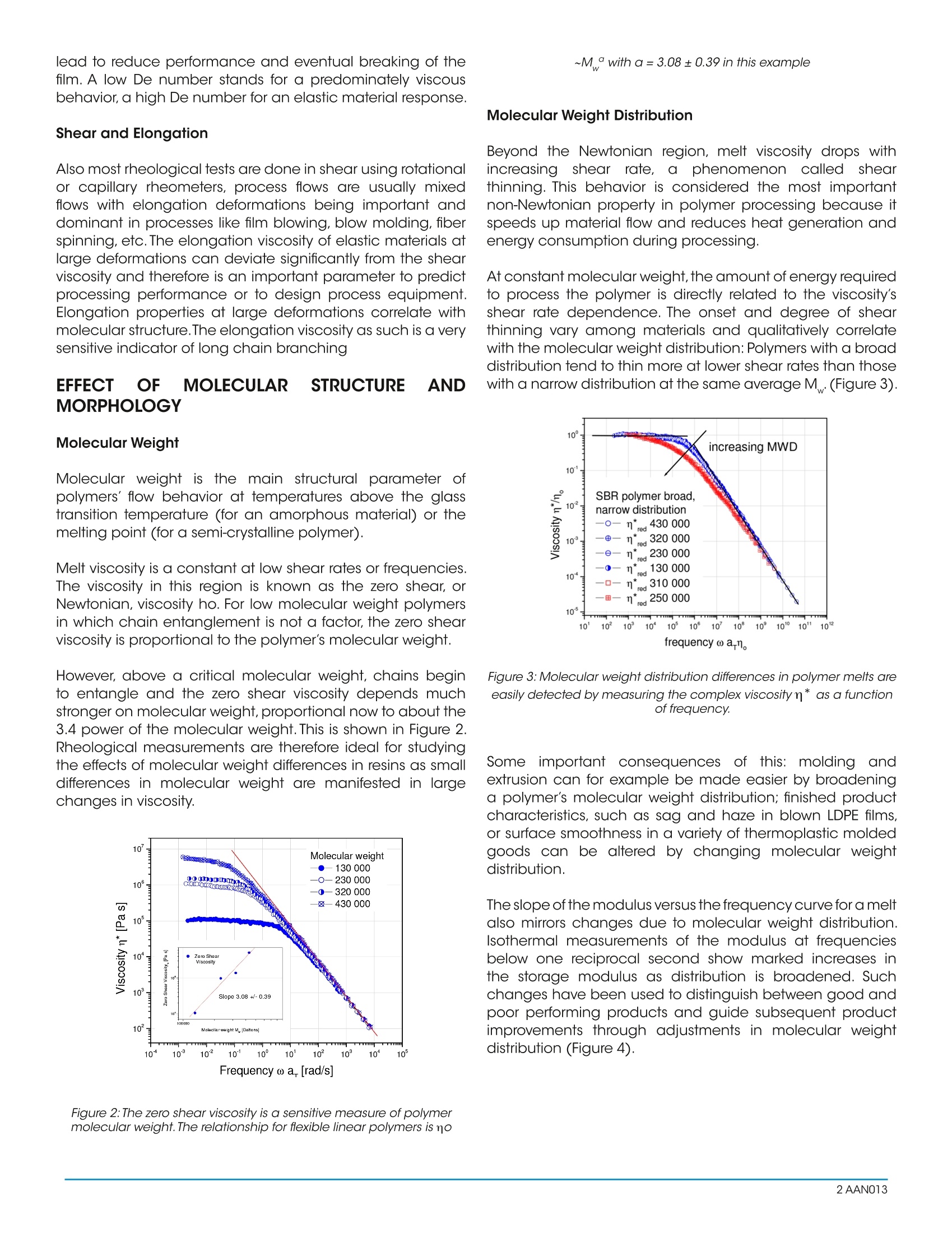

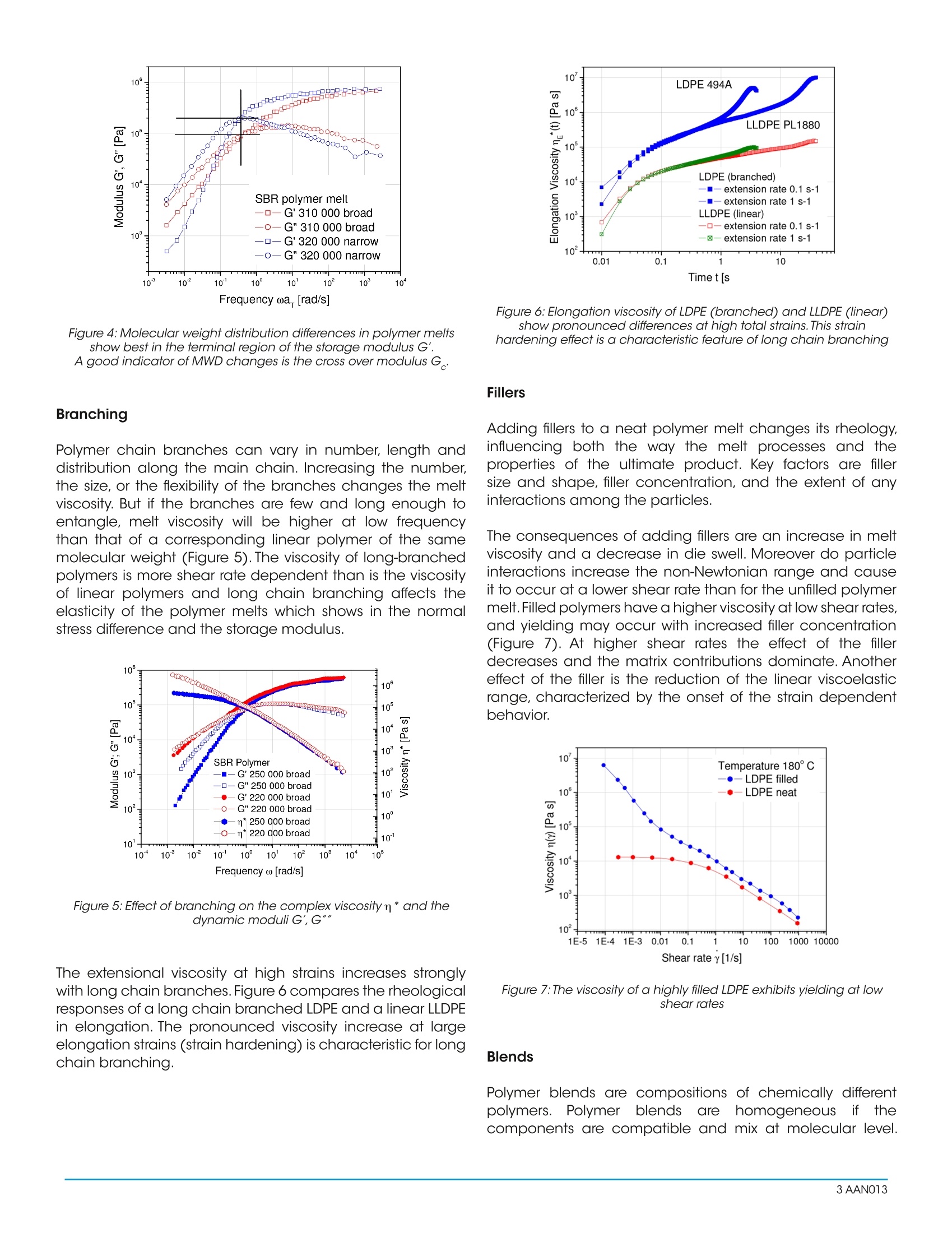

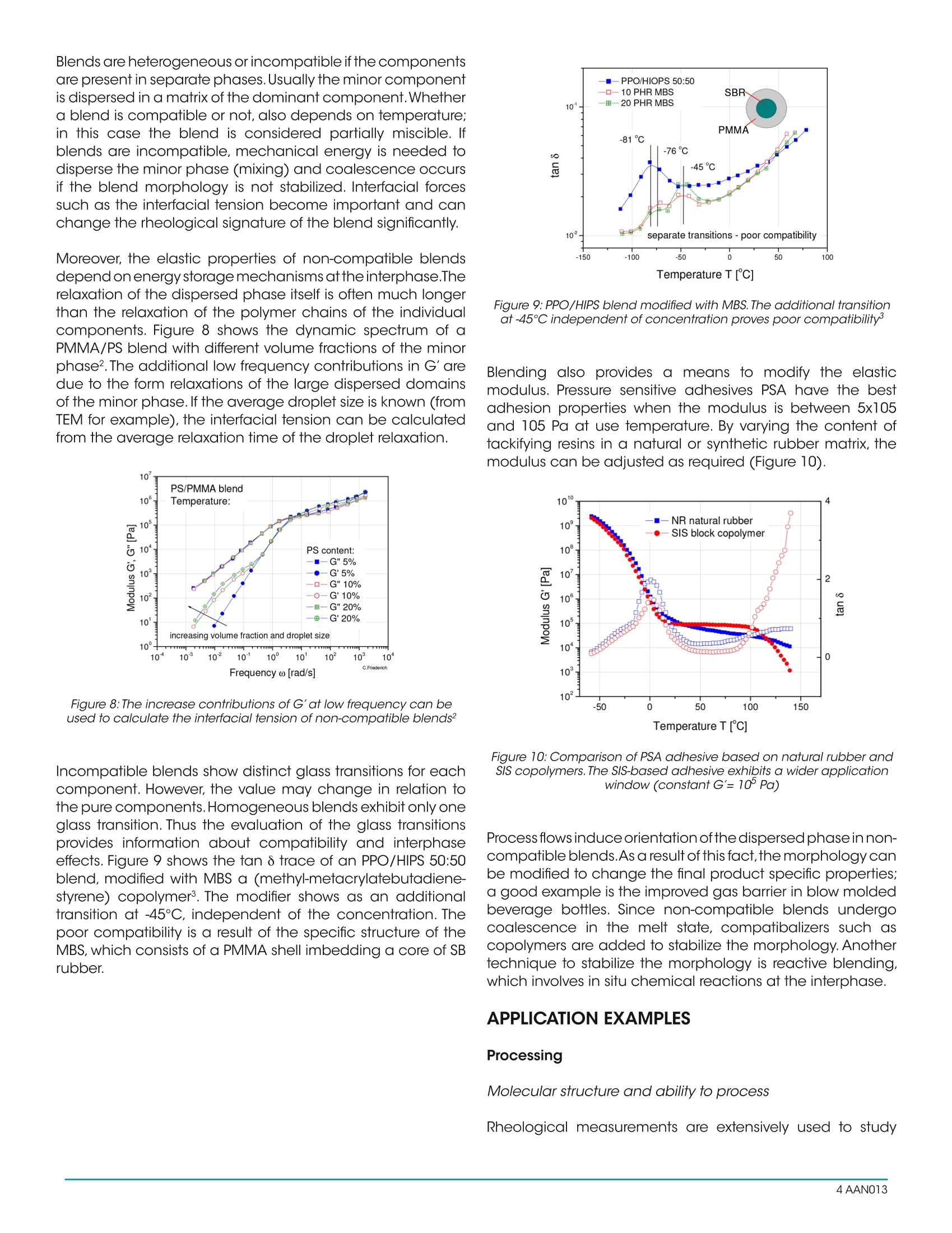

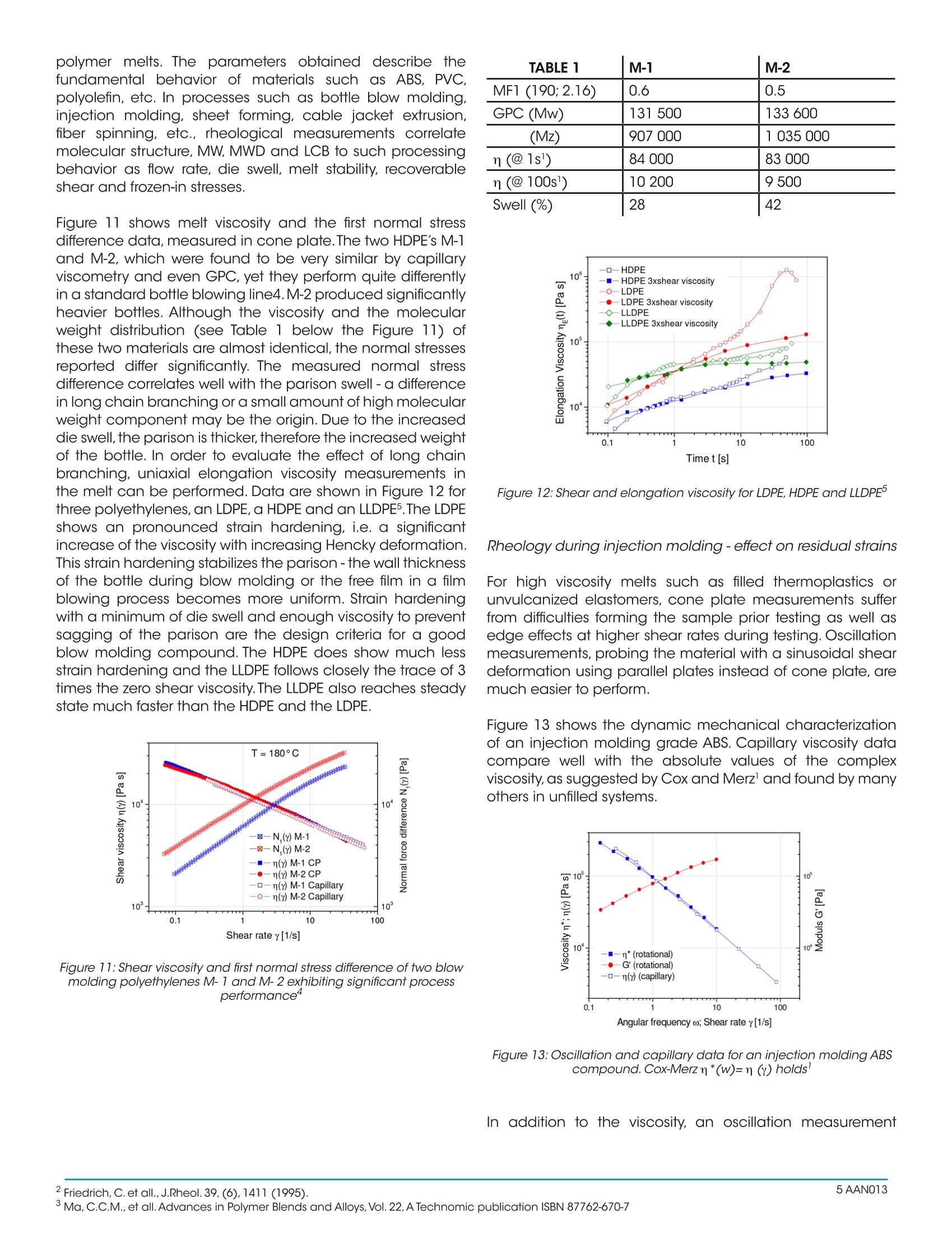

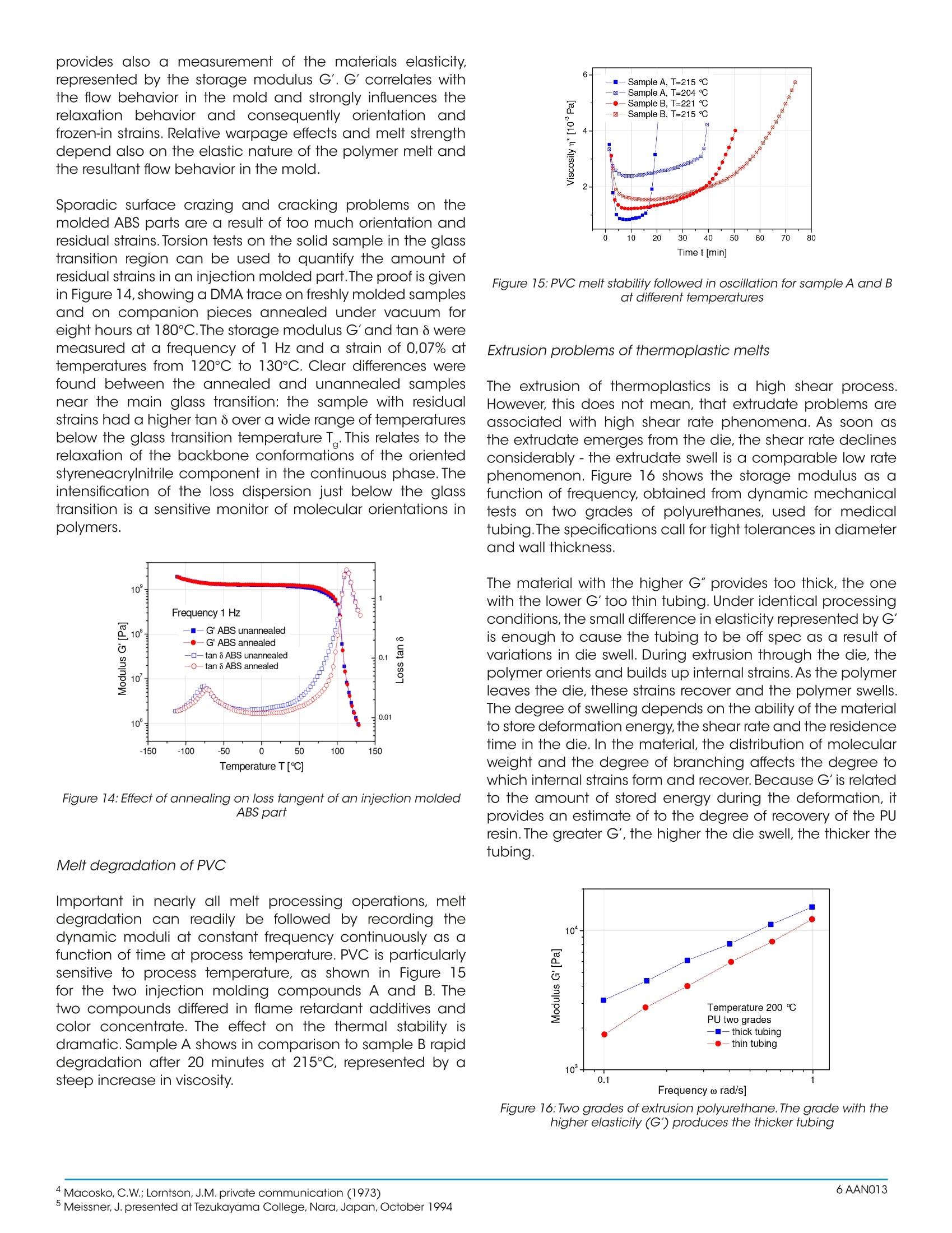

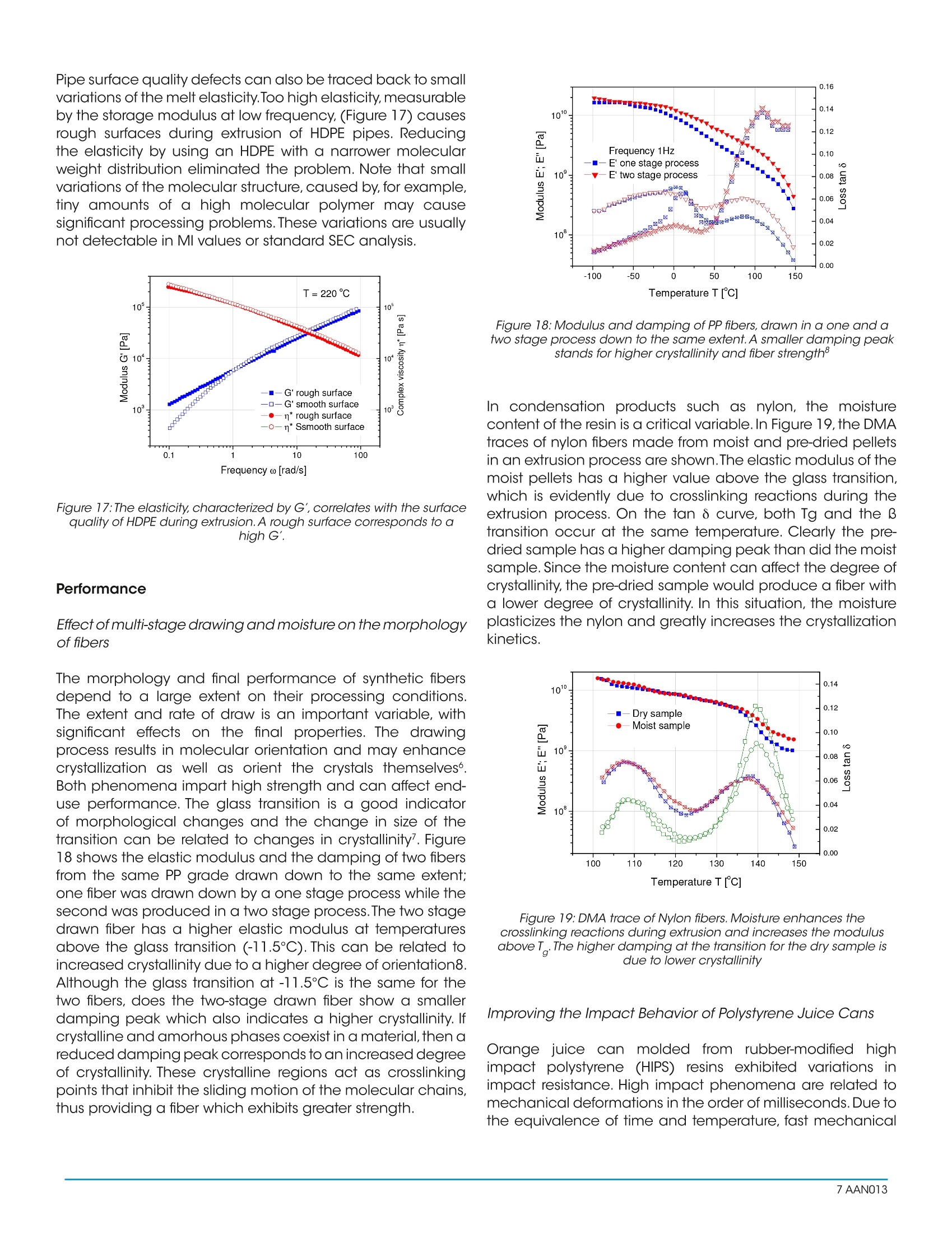

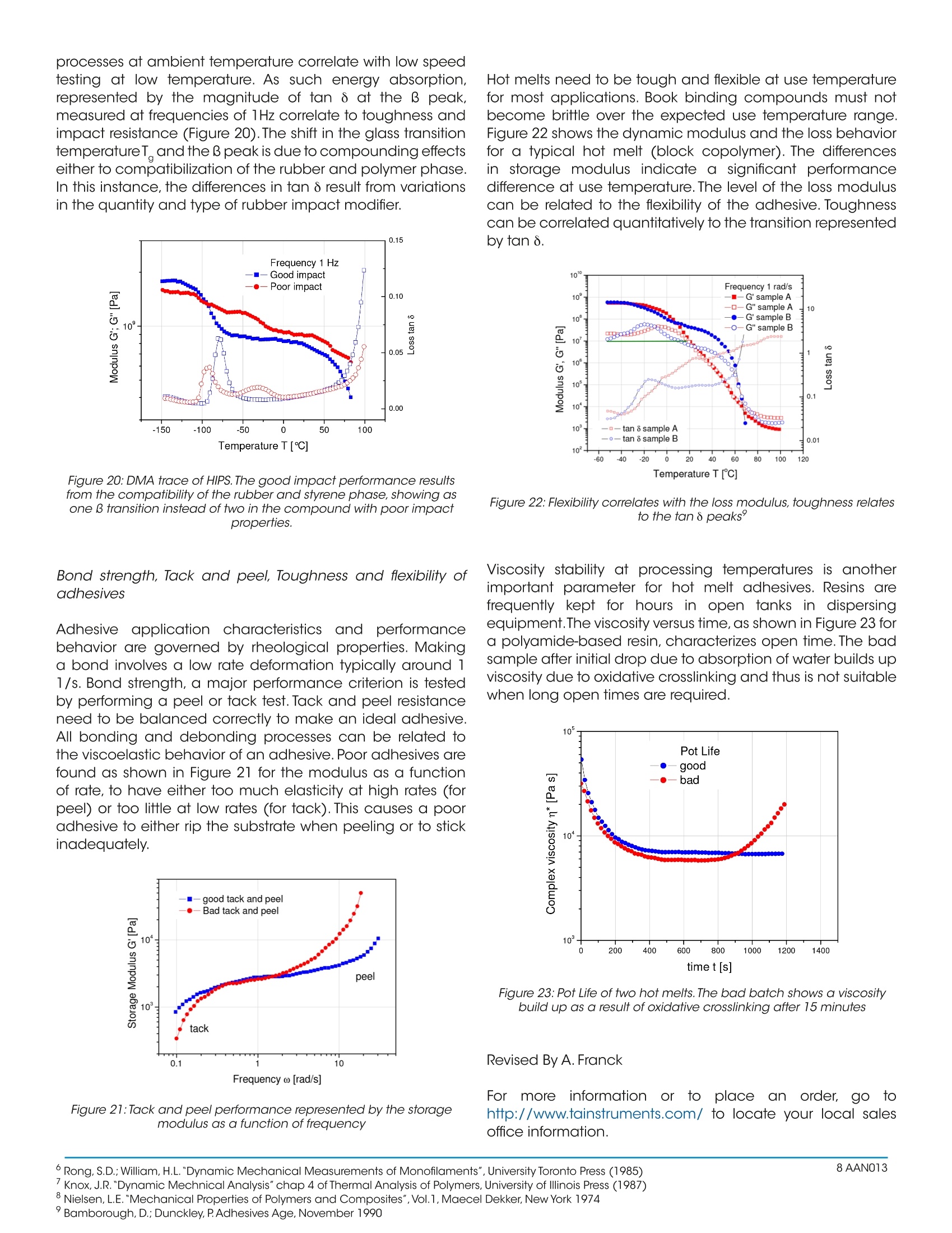

~M’ with a=3.08±0.39 in this example GENERAL CONSIDERATIONS Rheological testing of thermoplastic materials can beperformed on both solid samples and on melts. This isimportant because the choice of material form andphysical state is more than a matter of convenience: Productperformance issues usually are related to solid samplesproperties; process ability issues can be correlated withpolymer melt properties. In either case, since rheology isan indirect and non-unique measurement of structure, theapplication of rheology to solving processing and productperformance problems often reduces to comparativeanalysis of good and poor performing samples. Thermoplasticsolids are tested using MechanicalSpectroscopy to study polymer morphology and structureand relate these to end-use performance. Accurate solidstate measurements of the material’s glass transitiontemperature (T), modulus (G) and damping (tan 8) areused to predict practical use temperatures, impact properties,energy dissipation, stiffness and many other performanceproperties. (Dynamic mechanical testing is considered themost sensitive method for measuring the glass transition andsecondary transitions of polymers.) Moreover,rheological propertiesSCCanbe measuredcontinuously as51the material undergoes1temperature-induced changes from amorphous to crystalline; solid tomolten and vice versa. Rheological tests on thermoplasticmelts measure material's flow properties and provide vitalinformation about polymer processing. Viscosity and Elasticity Melts are non-Newtonian fluids and their viscosity decreaseswith increasing shear rate. Oscillation measurements over arange of frequencies can be used to gauge the rate of theviscosity changes with shear rate (Cox-Merzl).This is importantfrom the standpoint of processing ease, and for determiningprocessing energy needs. The dynamic measurement alsoprovides a simultaneous measure of melt elasticity, the maindeterminant of viscoelastic melt behavior, and the cause ofsuch phenomena as die swell. Low shear Low shear rate measurements in the melt's linear viscoelasticregion are a key in material problem solving. Whilethermoplastic polymer processing operations such asextrusion and injection molding typically involve high shearrates, finished part quality is often controlled by the low shear rate behavior. For example, gauge variation can becaused by variable post-extrusion die swell, and warpagecan occur from non-uniform relaxation during cooling of animproperly formulated injection molding compound.Also,bytesting at low enough shear rates so that the measurementsare in the melt's linear viscoelastic region, the data can belinked directly to the polymer's molecular structure suchas molecular weight and molecular weight distribution-factors which control polymer process ability and productperformance. Time dependence and Deborah number Thermoplastic polymers are viscoelastic materials and assuch exhibit a pronounced time or frequency dependence.For convenience, thermoplastic melts are characterizedwith a representative material relaxation time. In a similarway, individual steps in a manufacturing or transformationprocess can be described by a characteristic process time(see Figure 1). Molecular Structure Figure 1: Process and material time The ratio of both, the De (Deborah) number is an importantprocess parameter. Increasing the take up speed in a filmblowing process is identical to decreasing the process time:inorder for the Deborah number, characteristic for the process,to be constant,the material time has to be modified,typicallyby reducing the viscosity (decreasing the temperature or themolecular weight). Not adapting the characteristic materialstime would cause the material to behave more solid-like(high De number) under the new processing regime and lead to reduce performance and eventual breaking of thefilm. A low De number stands for a predominately viscousbehavior, a high De number for an elastic material response. Shear and Elongation Also most rheological tests are done in shear using rotationalor capillary rheometers, process flows are usually mixedflows with elongation deformations being important anddominant in processes like film blowing, blow molding, fiberspinning, etc. The elongation viscosity of elastic materials atlarge deformations can deviate significantly from the shearviscosity and therefore is an important parameter to predictprocessing performance or to design process equipment.Elongation properties at large deformations correlate withmolecular structure.The elongation viscosity as such is a verysensitive indicator of long chain branching EFFECT° OF MOLECULAR STRUCTURE ANDMORPHOLOGY Molecular Weight parameter ofpolymers’ flow behavior at temperatures above the glasstransition temperature (for an amorphous material) or themelting point (for a semi-crystalline polymer). Melt viscosity is a constant at low shear rates or frequencies.The viscosity in this region is known as the zero shear, orNewtonian, viscosity ho. For low molecular weight polymersin which chain entanglement is not a factor, the zero shearviscosity is proportional to the polymer's molecular weight. However, above a critical molecular weight, chains beginto entangle and the zero shear viscosity depends muchstronger on molecular weight, proportional now to about the3.4 power of the molecular weight. This is shown in Figure 2.Rheological measurements are therefore ideal for studyingthe effects of molecular weight differences in resins as smalldifferences in molecular weight are manifested in largechanges in viscosity. Figure 2:The zero shear viscosity is a sensitive measure of polymermolecular weight. The relationship for flexible linear polymers is no Molecular Weight Distribution Beyond the Newtonian region, melt viscosity drops withincreasing shear rate, a phenomenon called shearthinning. This behavior is considered the most importantnon-Newtonian property in polymer processing because itspeeds up material flow and reduces heat generation andenergy consumption during processing. At constant molecular weight, the amount of energy requiredto process the polymer is directly related to the viscosity'sshear rate dependence. The onset and degree of shearthinning vary among materials and qualitatively correlatewith the molecular weight distribution: Polymers with a broaddistribution tend to thin more at lower shear rates than thosewith a narrow distribution at the same average M. (Figure3). Figure 3: Molecular weight distribution differences in polymer melts areeasily detected by measuring the complex viscosityn* as a functionof frequency. Some important consequences of this: molding andextrusion can for example be made easier by broadeninga polymer's molecular weight distribution; finished productcharacteristics, such as sag and haze in blown LDPE films,or surface smoothness in a variety of thermoplastic moldedgoods can be altered by changing molecular weightdistribution. The slope of the modulus versus the frequency curve for a meltalso mirrors changes due to molecular weight distribution.Isothermal measurements of the modulus at frequenciesbelow one reciprocal second show marked increases inthe storage modulus as distribution is broadened. Suchchanges have been used to distinguish between good andpoor performing products and guide subsequent productmprovements through adjustments in molecular weightdistribution (Figure 4). Figure 4: Molecular weight distribution differences in polymer meltsshow best in the terminal region of the storage modulus G.A good indicator of MWD changes is the cross over modulus G. Branching Polymer chain branches can vary in number, length anddistribution along the main chain. Increasing the number,the size, or the flexibility of the branches changes the meltviscosity. But if the branches are few and long enough toentangle, melt viscosity will be higher at low frequencythan that of a corresponding linear polymer of the samemolecular weight (Figure 5). The viscosity of long-branchedpolymers is more shear rate dependent than is the viscosityof linear polymers and long chain branching affects theelasticity of the polymer melts which shows in the normalstress difference and the storage modulus. Figure 5:Effect of branching on the complex viscosity n* and thedynamic moduli G, G"" The extensional viscosity at high strains increases stronglywith long chain branches. Figure 6 compares the rheologicalresponses of a long chain branched LDPE and a linear LLDPEin elongation. The pronounced viscosity increase at largeelongation strains (strain hardening) is characteristic for longchain branching. Figure 6:Elongation viscosity of LDPE (branched) and LLDPE (linear)show pronounced differences at high total strains. This strainhardening effect is a characteristic feature of long chain branching Fillers Adding fillers to a neat polymer melt changes its rheology,influencing both the way the melt processes and theproperties of the ultimate product. Key factors are fillersize and shape, filler concentration, and the extent of anyinteractions among the particles. The consequences of adding fillers are an increase in meltviscosity and a decrease in die swell. Moreover do particleinteractions increase the non-Newtonian range and causeit to occur at a lower shear rate than for the unfilled polymermelt.Filled polymers have a higher viscosity at low shear rates,and yielding may occur with increased filler concentration(Figure 7). At higher shear rates the effect of the fillerdecreases and the matrix contributions dominate. Anothereffect of the filler is the reduction of the linear viscoelasticrange, characterized by the onset of the strain dependentbehavior. Figure 7:The viscosity of a highly filled LDPE exhibits yielding at lowshear rates Blends Polymer blends are compositions of chemically differentpolymers. PPoollyymmeerr blendsarehomogeneousififthecomponents are compatible and mix at molecular level. Blends are heterogeneous or incompatible if the componentsare present in separate phases. Usually the minor componentis dispersed in a matrix of the dominant component. Whethera blend is compatible or not, also depends on temperature;in this case the blend is considered partially miscible. Ifblends are incompatible, mechanical energy is needed todisperse the minor phase (mixing) and coalescence occursif the blend morphology is not stabilized. Interfacial forcessuch as the interfacial tension become important and canchange the rheological signature of the blend significantly. Moreover, the elastic properties of non-compatible blendsdepend on energy storage mechanisms at the interphase.Therelaxation of the dispersed phase itself is often much longerthan the relaxation of the polymer chains of the individualcomponents. Figure 8 shows the dynamic spectrum of aPMMA/PS blend with different volume fractions of the minorphase2.The additional low frequency contributions in G'aredue to the form relaxations of the large dispersed domainsof the minor phase. If the average droplet size is known (fromTEM for example), the interfacial tension can be calculatedfrom the average relaxation time of the droplet relaxation. Figure 8: The increase contributions of G'at low frequency can beused to calculate the interfacial tension of non-compatible blends? Incompatible blends show distinct glass transitions for eachcomponent. However, the value may change in relation tothe pure components.Homogeneous blends exhibit only oneglass transition. Thus the evaluation of the glass transitionsprovides information about compatibility and interphaseeffects. Figure 9 shows the tan 8 trace of an PPO/HIPS 50:50blend, modified with MBS a (methyl-metacrylatebutadiene-styrene) copolymer3. The modifier shows as an additionaltransition at -45℃,independent of the concentration. Thepoor compatibility is a result of the specific structure of theMBS, which consists of a PMMA shell imbedding a core of SBrubber. Figure 9: PPO/HIPS blend modified with MBS. The additional transitionat -45℃ independent of concentration proves poor compatibility Blending also provides a means to modify the elasticmodulus. Pressure sensitive adhesives PSA have the bestadhesion properties when the modulus is between 5x105and 105 Pa at use temperature. By varying the content oftackifying resins in a natural or synthetic rubber matrix, themodulus can be adjusted as required (Figure 10). Figure 10: Comparison of PSA adhesive based on natural rubber andSIS copolymers. The SIS-based adhesive exhibits a wider applicationwindow (constant G’= 10 Pa) Processflows induce orientation of the dispersed phaseinnon-compatible blends.As a result of this fact,the morphology canbe modified to change the final product specific properties;a good example is the improved gas barrier in blow moldedbeverage bottles. Since non-compatible blends undergocoalescence in the melt state, compatibalizers such ascopolymers are added to stabilize the morphology. Anothertechnique to stabilize the morphology is reactive blending,which involves in situ chemical reactions at the interphase. APPLICATION EXAMPLES Processing polymer melts. The parameters obtained describe thefundamental behavior of materials such as ABS, PVCpolyolefin, etc. In processes such as bottle blow molding,injection molding, sheet forming, cable jacket extrusion,fiber spinning, etc., rheological measurements correlatemolecular structure, MW, MWD and LCB to such processingbehavior as flow rate, die swell, melt stability, recoverableshear and frozen-in stresses. Figure 11 shows melt viscosity and the first normal stressdifference data,measured in cone plate.The two HDPE's M-1and M-2, which were found to be very similar by capillaryviscometry and even GPC, yet they perform quite differentlyin a standard bottle blowing line4. M-2 produced significantlyheavier bottles. Although the viscosity and the molecularweight distribution (see Table 1 below the Figure 11) ofthese two materials are almost identical, the normal stressesreported differ significantly. The measured normal stressdifference correlates well with the parison swell- a differencein long chain branching or a small amount of high molecularweight component may be the origin. Due to the increaseddie swell, the parison is thicker, therefore the increased weightof the bottle. In order to evaluate the effect of long chainbranching, uniaxial elongation viscosity measurements inthe melt can be performed. Data are shown in Figure 12 forthree polyethylenes, an LDPE, a HDPE and an LLDPE5.The LDPEshows an pronounced strain hardening, i.e. a significantincrease of the viscosity with increasing Hencky deformation.This strain hardening stabilizes the parison - the wall thicknessof the bottle during blow molding or the free film in a filmblowing process becomes more uniform. Strain hardeningwith a minimum of die swell and enough viscosity to preventsagging of the parison are the design criteria for a goodblow molding compound.The HDPE does show much lessstrain hardening and the LLDPE follows closely the trace of 3times the zero shear viscosity. The LLDPE also reaches steadystate much faster than the HDPE and the LDPE. Figure 11:Shear viscosity and first normal stress difference of two blowmolding polyethylenes M- 1 and M-2 exhibiting significant processperformance" TABLE 1 M-1 M-2 MF1 (190;2.16) 0.6 0.5 GPC (Mw) 131 500 133600 (Mz) 907 000 1 035 000 n (@1sl) 84 000 83000 n (@100s) 10 200 9 500 Swell (%) 28 42 Figure 12: Shear and elongation viscosity for LDPE, HDPE and LLDPE’ Rheology during injection molding-effect on residual strains For high viscosity melts such as filled thermoplastics orunvulcanized elastomers, cone plate measurements sufferfrom difficulties forming the sample prior testing as well asedge effects at higher shear rates during testing. Oscillationmeasurements, probing the material with a sinusoidal sheardeformation using parallel plates instead of cone plate, aremuch easier to perform. Figure 13 shows the dynamic mechanical characterizationof an injection molding grade ABS. Capillary viscosity datacompare well with the absolute values of the complexviscosity, as suggested by Cox and Merz' and found by manyothers in unfilled systems. Figure 13: Oscillation and capillary data for an injection molding ABScompound.Cox-Merzn*(w)=n (Y) holds’ In addition to the viscosity, an oscillation measurement provides also a measurement of the materials elasticity,represented by the storage modulus G'. G'correlates withthe flow behavior in the mold and strongly influences therelaxation behavior and consequently orientation andfrozen-in strains. Relative warpage effects and melt strengthdepend also on the elastic nature of the polymer melt andthe resultant flow behavior in the mold. Sporadic surface crazing and cracking problems on themolded ABS parts are a result of too much orientation andresidual strains. Torsion tests on the solid sample in the glasstransition region can be used to quantify the amount ofresidual strains in an injection molded part.The proof is givenin Figure 14, showing a DMA trace on freshly molded samplesand on companion pieces annealed under vacuum foreight hours at 180℃.The storage modulus G'and tan 8 weremeasured at a frequency of 1 Hz and a strain of 0,07% attemperatures from 120℃ to 130C. Clear differences werefound between the annealed and unannealed samplesnear the main glass transition: the sample with residualstrains had a higher tan 8 over a wide range of temperaturesbelow the glass transition temperature T. This relates to therelaxation of the backbone conformations of the orientedstyreneacryInitrile component in the continuous phase.Theintensification of the loss dispersion just below the glasstransition is a sensitive monitor of molecular orientations inpolymers. Figure 14:Effect of annealing on loss tangent of an injection moldedABS part Melt degradation of PVC Important in nearly all melt processing operations, meltdegradation can readily be followed by recording thedynamic moduli at constant frequency continuously as afunction of time at process temperature. PVC is particularlysensitive to process temperature, as shown in Figure 15for the two injection molding compounds A and B. Thetwo compounds differed in flame retardant additives andcolor concentrate. The effect on the thermal stability isdramatic. Sample A shows in comparison to sample B rapiddegradation after 20 minutes at 215℃, represented by asteep increase in viscosity. Figure 15: PVC melt stability followed in oscillation for sample A and Bat different temperatures Extrusion problems of thermoplastic melts The extrusion of thermoplastics is a high shear process.However, this does not mean, that extrudate problems areassociated with high shear rate phenomena. As soon asthe extrudate emerges from the die, the shear rate declinesconsiderably-the extrudate swell is a comparable low ratephenomenon. Figure 16 shows the storage modulus as afunction of frequency, obtained from dynamic mechanicaltests on two grades of polyurethanes, used for medicaltubing.The specifications call for tight tolerances in diameterand wall thickness. The material with the higher G" provides too thick, the onewith the lower G' too thin tubing. Under identical processingconditions, the small difference in elasticity represented by G’is enough to cause the tubing to be off spec as a result ofvariations in die swell. During extrusion through the die, thepolymer orients and builds up internal strains. As the polymereaves the die, these strains recover and the polymer swells.The degree of swelling depends on the ability of the materialto store deformation energy, the shear rate and the residencetime in the die. In the material, the distribution of molecularweight and the degree of branching affects the degree towhich internal strains form and recover. Because G'is relatedto the amount of stored energy during the deformation, itprovides an estimate of to the degree of recovery of the PUresin. The greater G', the higher the die swell, the thicker thetubing. Frequency o rad/s] Figure 16: Two grades of extrusion polyurethane. The grade with thehigher elasticity (G') produces the thicker tubing Pipe surface quality defects can also be traced back to smallvariations of the melt elasticity.Too high elasticity, measurableby the storage modulus at low frequency, (Figure 17) causesrough surfaces during extrusion of HDPE pipes. Reducingthe elasticity by using an HDPE with a narrower molecularweight distribution eliminated the problem. Note that smallvariations of the molecular structure,caused by, for example,tiny amounts of a high molecular polymer may causesignificant processing problems. These variations are usuallynot detectable in Ml values or standard SEC analysis. Figure 17:The elasticity, characterized by G', correlates with the surfacequality of HDPE during extrusion.A rough surface corresponds to ahighG. Performance Effect of multi-stage drawing and moisture on the morphologyof fibers The morphology and final performance of synthQCeetic fibersdepend to a large extent on their processing conditions.The extent and rate of draw is an important variable, withsignificant effects on the final properties. The drawingprocess results in molecular orientation and may enhancecrystallization as well as orient the crystals themselves.Both phenomena impart high strength and can affect end-use performance. The glass transition is a good indicatorof morphological changes and the change in size of thetransition can be related to changes in crystallinity7. Figure18 shows the elastic modulus and the damping of two fibersfrom the same PP grade drawn down to the same extent;one fiber was drawn down by a one stage process while thesecond was produced in a two stage process.The two stagedrawn fiber has a higher elastic modulus at temperaturesabove the glass transition (-11.5℃). This can be related toincreased crystallinity due to a higher degree of orientation8.Although the glass transition at -11.5℃ is the same for thetwo fibers, does the two-stage drawn fiber show a smallerdamping peak which also indicates a higher crystallinity. Ifcrystalline and amorhous phases coexist in a material, then areduced damping peak corresponds to an increased degreeof crystallinity. These crystalline regions act as crosslinkingpoints that inhibit the sliding motion of the molecular chains,thus providing a fiber which exhibits greater strength. Figure 18: Modulus and damping of PP fibers, drawn in a one and atwo stage process down to the same extent. A smaller damping peakstands for higher crystallinity and fiber strength: In condensation products such as nylon, the moisturecontent of the resin is a critical variable. In Figure 19, the DMAtraces of nylon fibers made from moist and pre-dried pelletsin an extrusion process are shown.The elastic modulus of themoist pellets has a higher value above the glass transition,which is evidently due to crosslinking reactions during theextrusion process. On the tan 8 curve, both Tg and the 3transition occur at the same temperature. Clearly the pre-dried sample has a higher damping peak than did the moistsample. Since the moisture content can affect the degree ofcrystallinity, the pre-dried sample would produce a fiber witha lower degree of crystallinity. In this situation, the moistureplasticizes the nylon and greatly increases the crystallizationkinetics. Figure 19: DMA trace of Nylon fibers. Moisture enhances thecrosslinking reactions during extrusion and increases the modulusabove T. The higher damping at the transition for the dry sample isdue to lower crystallinity Improving the Impact Behavior of Polystyrene Juice Cans Orange juice can rmolded from rubber-modified highimpact polystyrene (HIPS) resins exhibited variations inimpact resistance. High impact phenomena are related tomechanical deformations in the order of milliseconds. Due tothe equivalence of time and temperature, fast mechanical processes at ambient temperature correlate with low speedtesting at low temperature. As such energy absorption,represented by the magnitude of tan 8 at the 3 peak,measured at frequencies of 1Hz correlate to toughness andimpact resistance (Figure 20). The shift in the glass transitiontemperatureT, and the 3 peak is due to compounding effectseither to compatibilization of the rubber and polymer phase.In this instance, the differences in tan 8 result from variationsin the quantity and type of rubber impact modifier. Figure 20: DMA trace of HIPS. The good impact performance resultsfrom the compatibility of the rubber and styrene phase, showing asone 3 transition instead of two in the compound with poor impactproperties. Bond strength, Tack and peel, Toughness and flexibility ofadhesives Adhesive application characteristics and performancebehavior are governed by rheological properties. Makinga bond involves a low rate deformation typically around 11/s. Bond strength, a major performance criterion is testedby performing a peel or tack test. Tack and peel resistanceneed to be balanced correctly to make an ideal adhesive.All bonding and debonding processes can be related tothe viscoelastic behavior of an adhesive.Poor adhesives arefound as shown in Figure 21 for the modulus as a functionof rate, to have either too much elasticity at high rates (forpeel) or too little at low rates (for tack). This causes a pooradhesive to either rip the substrate when peeling or to stickinadequately. Figure 21: Tack and peel performance represented by the storagemodulus as a function of frequency Hot melts need to be tough and flexible at use temperaturefor most applications. Book binding compounds must notbecome brittle over the expected use temperature range.Figure 22 shows the dynamic modulus and the loss behaviorfor a typical hot melt (block copolymer). The differencesin storage modulus indicate a significant performancedifference at use temperature. The level of the loss moduluscan be related to the flexibility of the adhesive. Toughnesscan be correlated quantitatively to the transition representedby tan 8. Figure 22: Flexibility correlates with the loss modulus, toughness relatesto the tan 8 peaks’ Viscosity stability at processing temperatures is anotherimportant parameter for hot melt adhesives. Resins arefrequently kept for hours in open tanks in dispersingequipment.The viscosity versus time, as shown in Figure 23 fora polyamide-based resin, characterizes open time. The badsample after initial drop due to absorption of water builds upviscosity due to oxidative crosslinking and thus is not suitablewhen long open times are required. Figure 23:Pot Life of two hot melts. The bad batch shows a viscositybuild up as a result of oxidative crosslinking after 15 minutes Revised By A. Franck For more iinformation or to place an order, go tohttp://www.tainstruments.com/ to locate your local salesoffice information. ( ° Rong, S.D.;William , H.L."Dynamic Mechanical Measurements of Monofilaments",University Toro n to Press (1985) ) ( 'Knox,J.R."Dynamic Mechnical Analysis"chap 4 of Ther m al Analysis of Polymers, University of Ilinois Press (1987 ) ) ( °Nielsen, L.E. "Mechanical Properties of Polymers and Composites",Vol. 1 , Maecel Dekker, New Y ork 1974 ) ( Bamborough,D.; Dunckley, P.Adhesives Age, November 1990 ) ANox, W.P; Merz,E.H. J.Polym.Sci.,( AN Rheological testing of thermoplastic materials can be performed on both solid samples and on melts. This is important because the choice of material form and physical state is more than a matter of convenience: Product performance issues usually are related to solid samples properties; process ability issues can be correlated with polymer melt properties. In either case, since rheology is an indirect and non-unique measurement of structure, the application of rheology to solving processing and product performance problems often reduces to comparative analysis of good and poor performing samples.

确定

还剩6页未读,是否继续阅读?

TA仪器为您提供《材料、塑料、胶黏剂中熔融、玻璃化转变、粘度、粘弹性模量、弹性检测方案(流变仪)》,该方案主要用于其他中熔融、玻璃化转变、粘度、粘弹性模量、弹性检测,参考标准--,《材料、塑料、胶黏剂中熔融、玻璃化转变、粘度、粘弹性模量、弹性检测方案(流变仪)》用到的仪器有

相关方案

更多

该厂商其他方案

更多