方案详情

文

激光粒度仪A22有着宽的测量范围,高分辨率和重复性,使用激光粒度仪A22对三种比较的矿物进行粒径分析,以期对颗粒组成和表面积大小提供参考信息并进行相关性的分析

方案详情

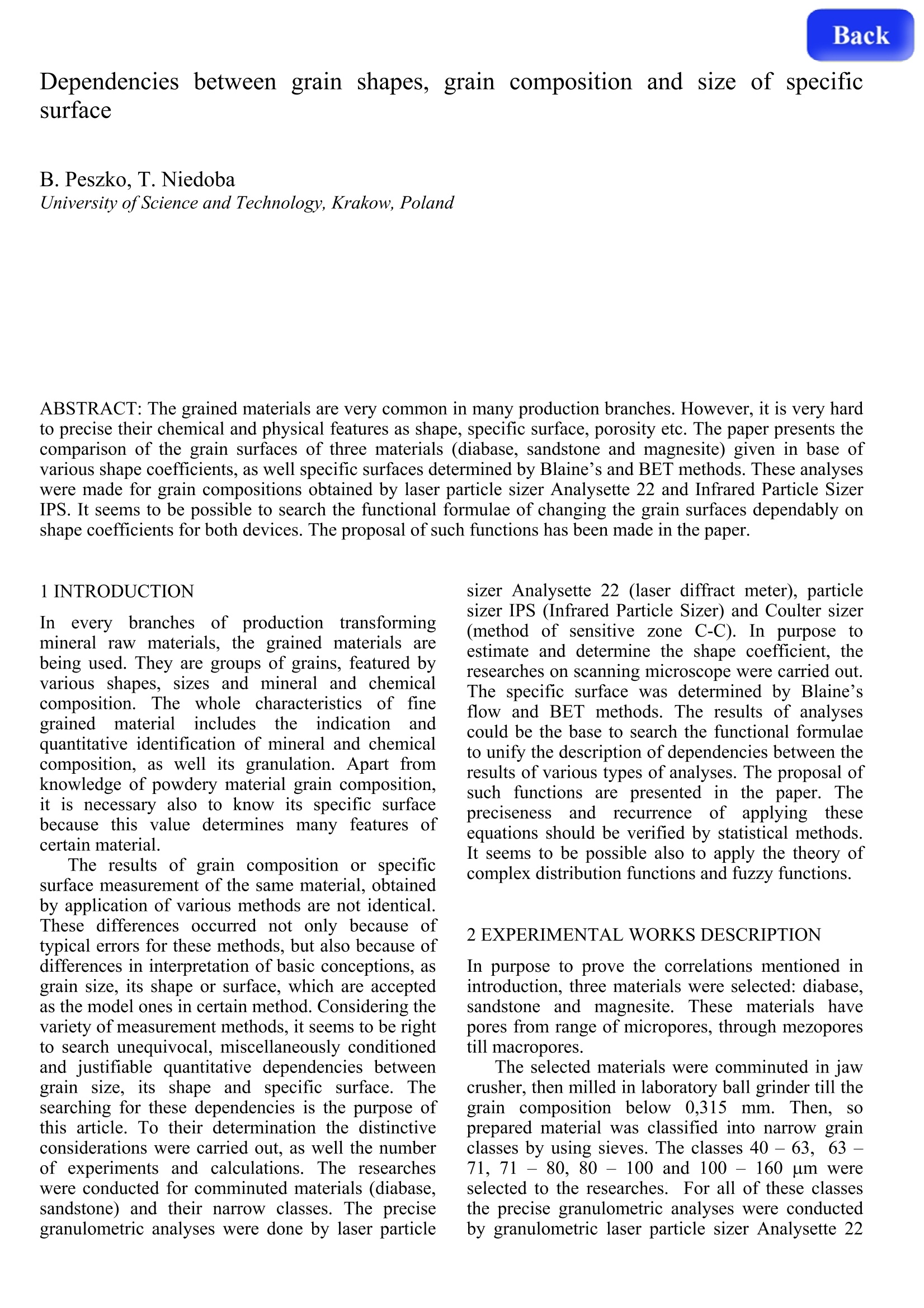

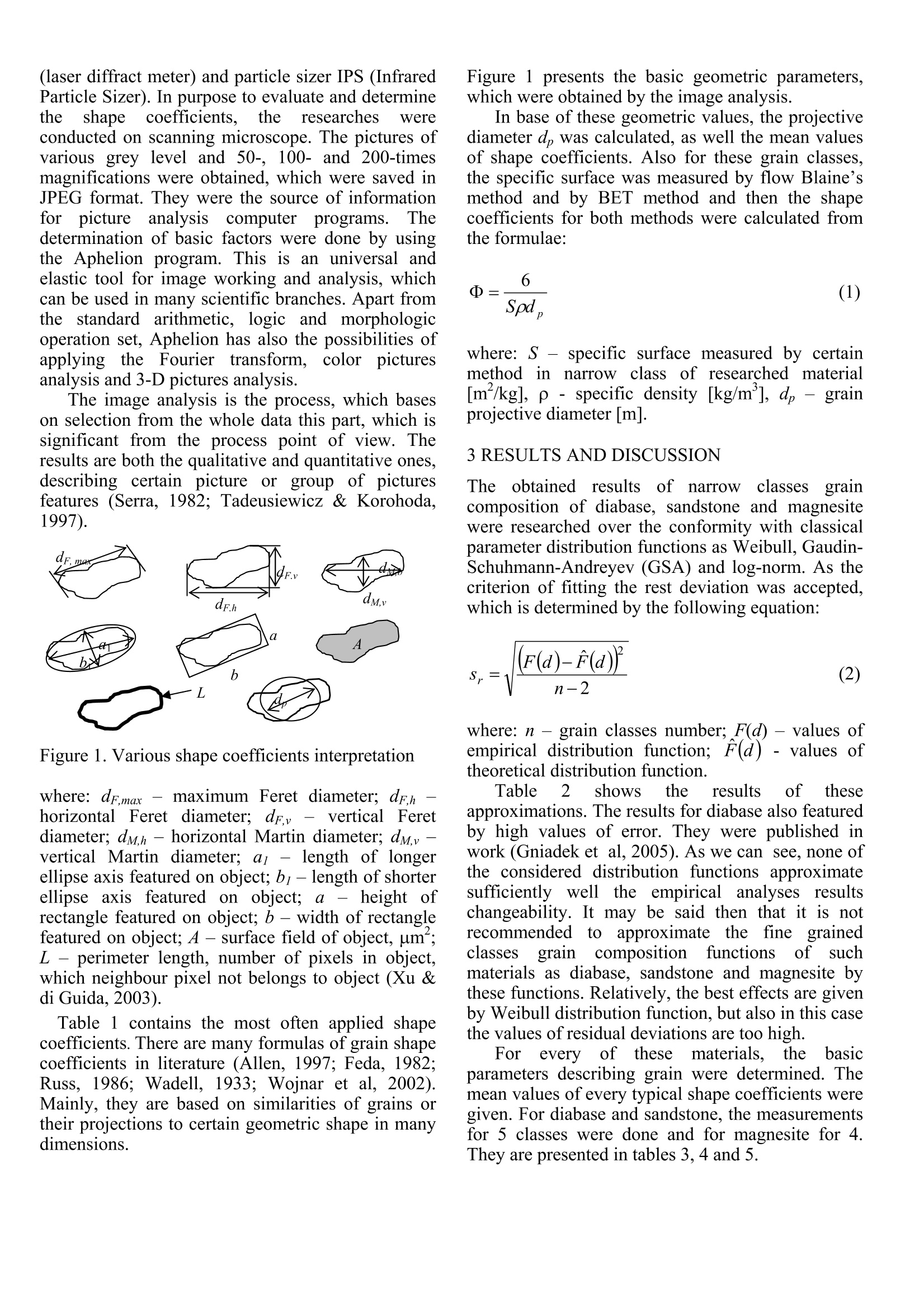

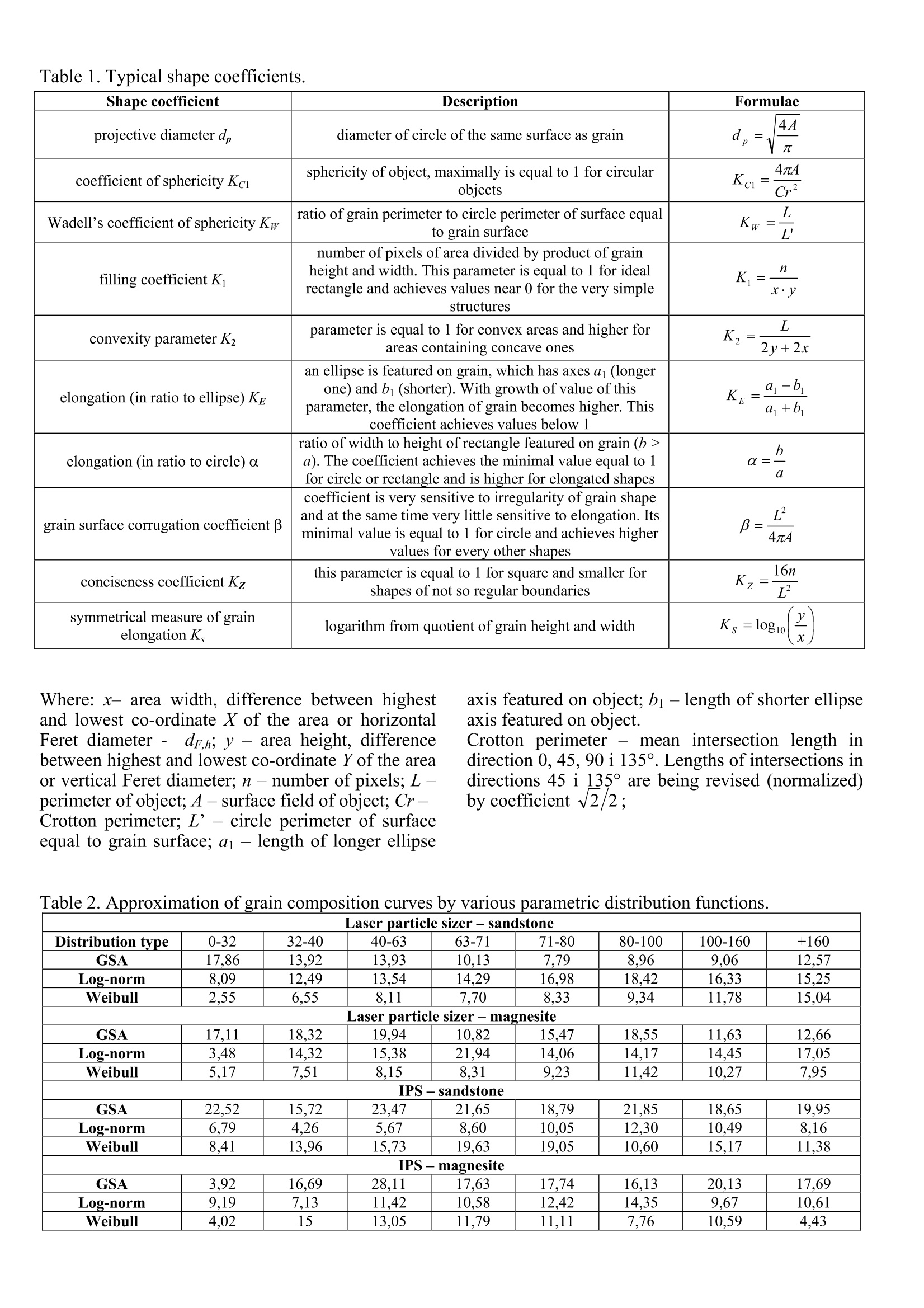

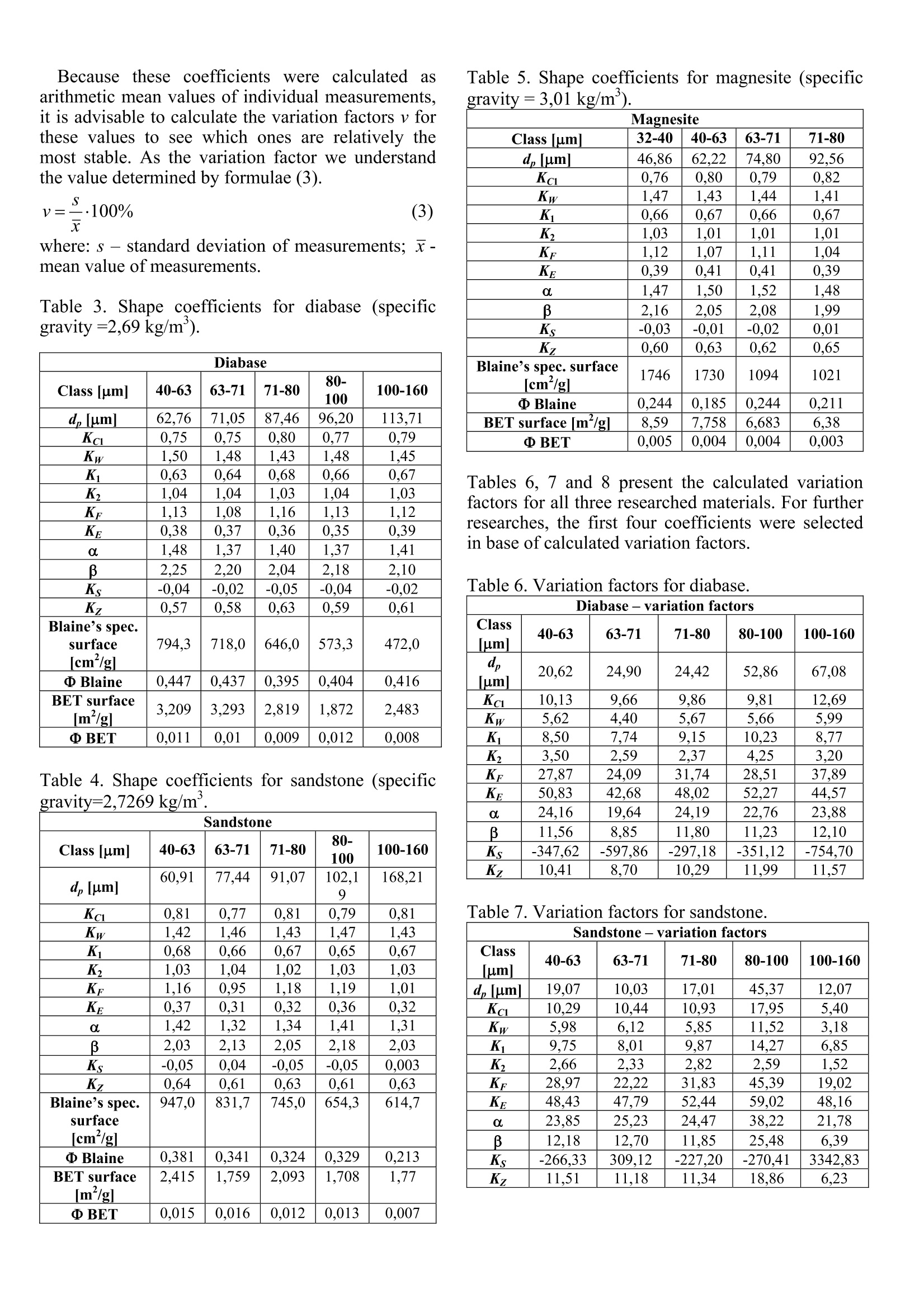

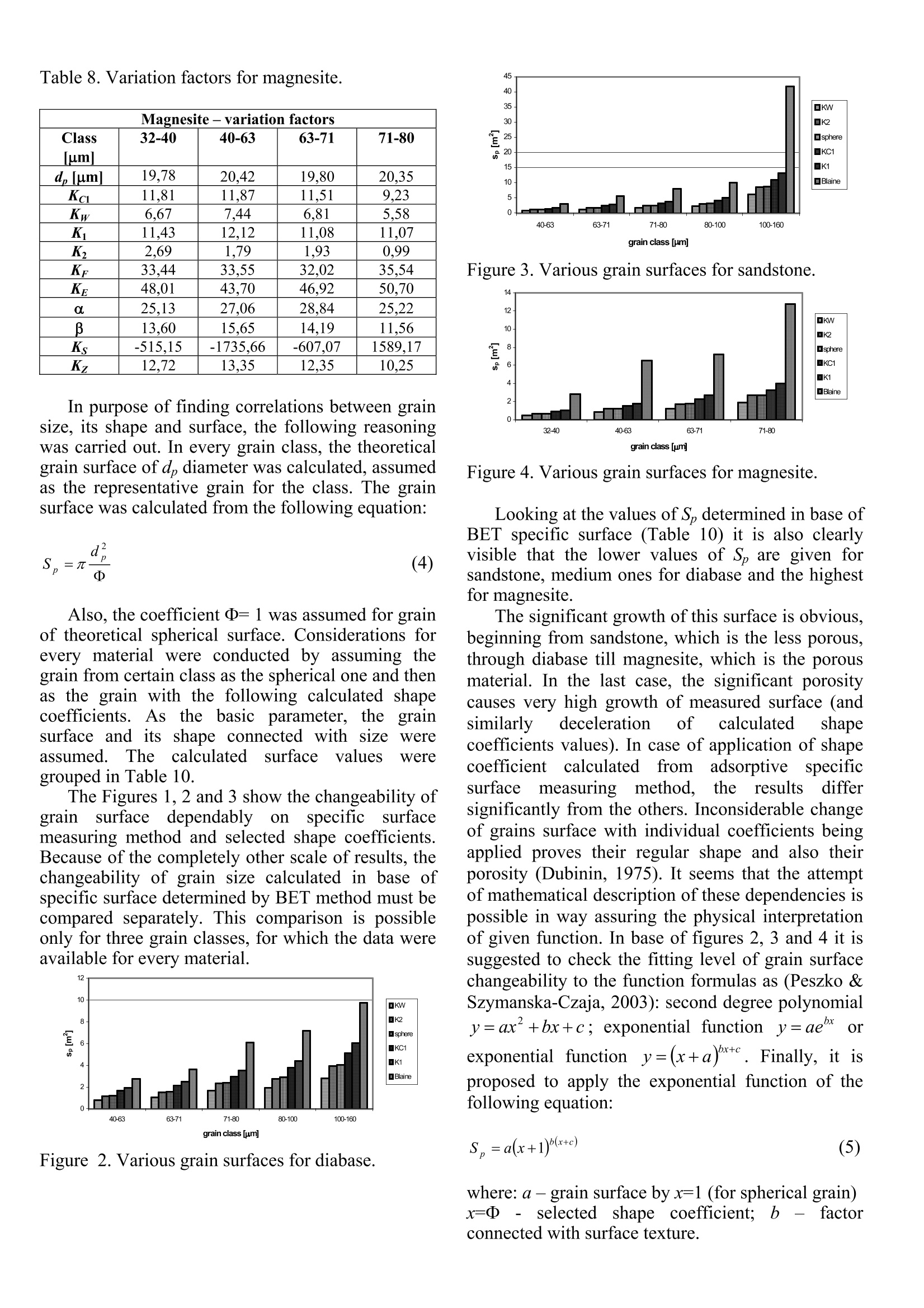

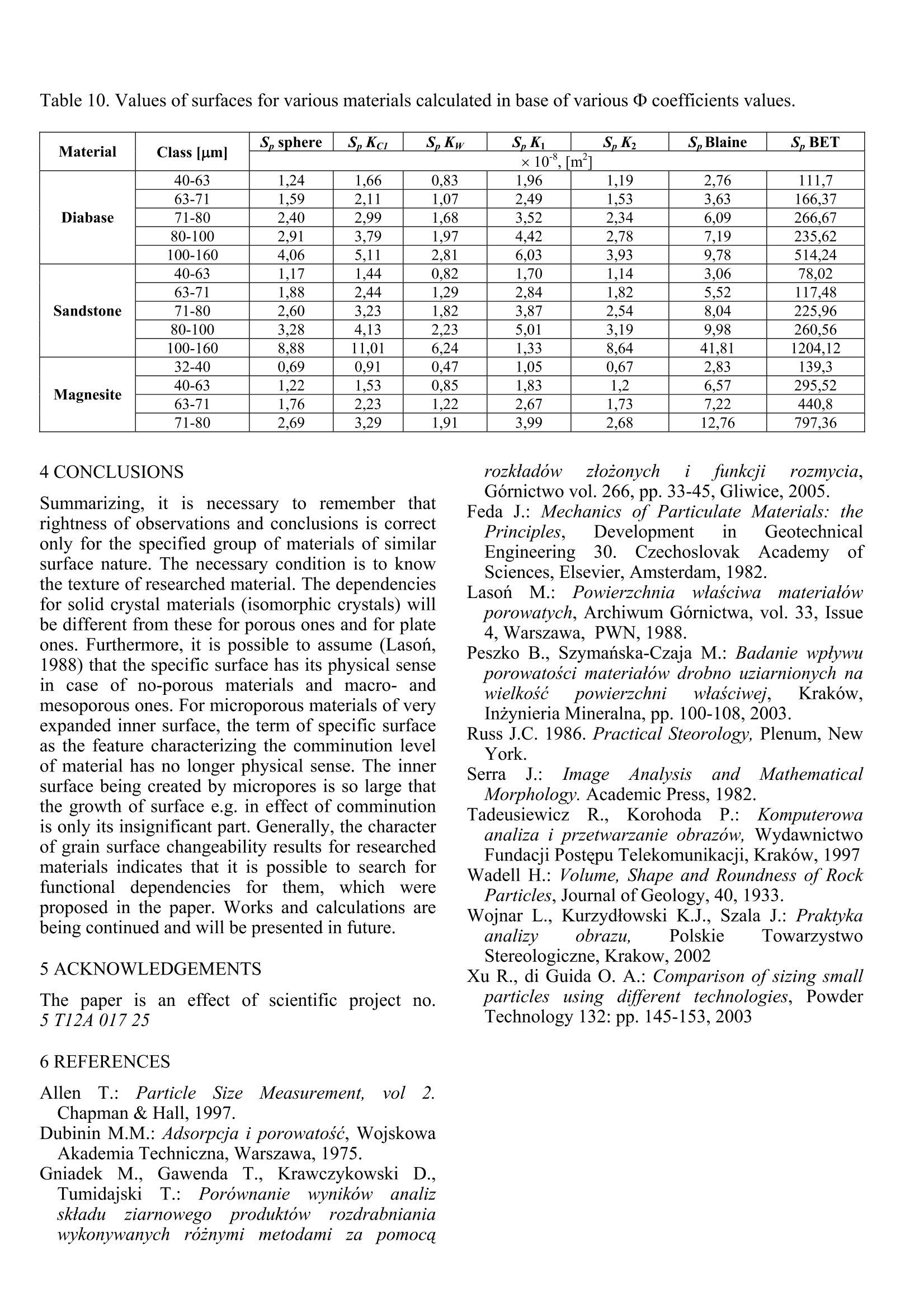

Back Dependencies bettween grain shapes, grain composition and size of specificsurface B. Peszko, T. Niedoba University of Science and Technology, Krakow, Poland ABSTRACT: The grained materials are very common in many production branches. However, it is very hardto precise their chemical and physical features as shape, specific surface, porosity etc. The paper presents thecomparison of the grain surfaces of three materials (diabase, sandstone and magnesite) given in vbase oariousf shape coefficients, as well specific surfaces determined by Blaine’s and BET methods. These analyseswere made for grain compositions obtained by laser particle sizer Analysette 22 and Infrared Particle SizerIPS. It seems to be possible to search the functional formulae of changing the grain surfaces dependably onshape coefficients for both devices. The proposal of such functions has been made in the paper. 1 INTRODUCTION In every branches of productiontransformingmineral raw materials, the grained materials arebeing used. They are groups of grains, featured byvarious shapes, sizes and mineral and chemicalcomposition. The whole characteristics of finegrained material includes the indicationandquantitative identification of mineral and chemicalcomposition, as well its granulation. Apart fromknowledge of powdery material grain composition,it is necessary also to know its specific surfacebecause this value determines many features ofcertain material. The results of grain composition or specificsurface measurement of the same material, obtainedby application of various methods are not identical.These differences occurred not only because oftypical errors for these methods, but also because ofdifferences in interpretation of basic conceptions, asgrain size, its shape or surface, which are acceptedas the model ones in certain method. Considering thevariety of measurement methods, it seems to be rightto search unequivocal, miscellaneously conditionedre s band justitiable quantitative dependencies betweengrain size, its shape and specific surface. Thesearching for these dependencies is the purpose ofthis article. To their determination the distinctiveconsiderations were carried out, as well the numberof experiments and calculations. The researcheswere conducted for comminuted materials (diabase,sandstone) and their narrow classes. The precisegranulometric analyses were done by laser particle sizer Analysette 22 (laser diffract meter), particlesizer IPS (Infrared Particle Sizer) and Coulter sizer(method of sensitive zone C-C). In purpose toestimate and determine the shape coefficient, theresearches on scanning microscope were carried out.The snecific surfac was determined hy Blaine'sflow and BET methods, The results of analysescoulr he the hase to seargh the fiinstinnal farmulaeto unify the description of dependencies between theresults of various types of analyses, The proposal ofsuch functions are presented in the paper. Theprecisenessanddrecrenceof annlying theseequations should be verified by statistical methods.It seems to be possible also to apply the theory ofippcomplex distribution functions and fuzzy functions. 2 EXPERIMENTAL WORKS DESCRIPTION In purpose to prove the correlations mentioned inintroduction, three materials were selected: diabase,sandstone and magnesite. These materialsIShavepores from range of micropores, through mezoporestill macropores. The selected materials were comminuted in jawcrusher, then milled in laboratory ball grinder till thegrain composition below 0,315 mm.Then.ssoprepared material was classified into narrow grainclasses by using sieves. The classes 40 - 63, (63-71,71-80,80-100 and 100 - 160 um wereselected to the researches. For all of these classesthe precise granulometric analyses were conductedby granulometric laser particle sizer Analysette 22 (laser diffract meter) and particle sizer IPS (InfraredParticle Sizer). In purpose to evaluate and determinetheshapee coefficients. the researches wereconducted on scanning microscope. The pictures ofvarious grey level and 50-,100- and 200-timesmagnifications were obtained, which were saved inJPEG format. They were the source of informationforpicture analysiscomputerrpprograms.wThedetermination of basic factors were done by usingthe Aphelion program. This is an universal andelastic tool for image working and analysis, whichcan be used in many scientific branches. Apart fromthe standard arithmetic, logic and morphologicoperation set, Aphelion has also the possibilities ofapplying the Fourier transform, color picturesanalysis and 3-Dpictures analysis. The image analysis is the process, which baseson selection from the whole data this part, which issignificant from the process point of view. Theresults are both the qualitative and quantitative ones,describing certain picture or group of picturesfeatures (Serra, 1982; Tadeusiewicz & Korohoda,1997). Figure 1. Various shape coefficients interpretation where:dFmaxc - maximum Feret diameter; dF.hhorizontal Feret diameter; dFy - vertical Feretdiameter; dM.h - horizontal Martin diameter; dM.v -vertical Martin diameter; a - length of longerellipse axis featured on object; b1-length of shorterellipse axis featured on object; a - height ofrectanele featured an nhiect h- width of rectaneleefeatured an nhinct: 4- surface finld af ahiect um2-nerimeter length: number of nizes in nhiectwhich neighbour pixel not belongs to object (Xu &di Guida 20031 Table 1 contains the most often applied shapecoefficients. There are many formulas of grain shapecoefficients in literature (Allen, 1997; Feda, 1982;Russ, 1986; Wadell, .1933; Woj.nar et al, 2002).Mainly,1...f they are based on similarities of grains ortheir projections to certain geometric shape in manydimensions. Figure 1 presents the basic geometric parameters,which were obtained by the image analysis. In base of these geometric values, the projectivediameter d, was calculated, as well the mean valuesof shape coefficients. Also for these grain classes,the specific surface was measured by flow Blaine’smethod and by BET method and then the shapecoefficients for both methods were calculated fromthe formulae: where: S- specific surface measured by certainmethod in narrow class of researched material[m /kg], p - specific density [kg/m'], dp - grainprojective diameter [m]. 3 RESULTS AND DISCUSSION The obtainedd results of narrow classesgraincomposition of diabase, sandstone and magnesitewere researched over the conformity with classicalparameter distribution functions as Weibull, Gaudin-Schuhmann-Andreyev (GSA) and log-norm. As thecriterion of fitting the rest deviation was accepted,which is determined by the following equation: where: n - grain classes number; F(d) - values ofempirical distribution function; F(d)- values oftheoretical distribution function. Table 2 shows thee results of theseapproximations. The results for diabase also featuredby high values of error. They were published inwork (Gniadek et al, 2005). As we can see, none ofthe considered distribution functions approximatesufficiently well ttlhe empirical analyses resultschangeability. It may be said then that it is notrecommended toapproximate the fineie grainedclassesgrainn composition functionss of suchmaterials as diabase, sandstone and magnesite bythese functions. Relatively, the best effects are givenby Weibull distribution function, but also in this casethe values of residual deviations are too high. Forr every of these: materials.thebasicparameters describing grain were determined. Themean values of every typical shape coefficients weregiven. For diabase and sandstone, the measurementsfor 5 classes were done and for magnesite for 4.They are presented in tables 3, 4 and 5. Table 1. Typical shape coefficients. Shape coefficient Description Formulae projective diameter d, diameter of circle of the same surface as grain 4A ap=兀 coefficient of sphericity Kci sphericity of object, maximally is equal to 1 for circularobjects 4元A KciCr2 Wadell's coefficient of sphericity Kw ratio of grain perimeter to circle perimeter of surface equalto grain surface L KwL' filling coefficient K number of pixels of area divided by product of grainheight and width. This parameter is equal to 1 for idealrectangle and achieves values near 0 for the very simplestructures nK,= convexity parameter K2 parameter is equal to 1 for convex areas and higher forareas containing concave ones K,=2y+2x elongation (in ratio to ellipse) Kg an ellipse is featured on grain, which has axes a (longerone) and b (shorter). With growth of value of thisparameter, the elongation of grain becomes higher. This coefficient achieves values below 1 KE=a-b a+b elongation (in ratio to circle) a ratio of width to height of rectangle featured on grain (b> a). The coefficient achieves the minimal value equal to 1for circle or rectangle and is higher for elongated shapes ba= a grain surface corrugation coefficient B coefficient is very sensitive to irregularity of grain shapeand at the same time very little sensitive to elongation. Itsminimal value is equal to 1 for circle and achieves highervalues for every other shapes 2 B=- 4元A conciseness coefficient Kz this parameter is equal to 1 for square and smaller forshapes of not so regular boundaries 16n Kz symmetrical measure of grainelongation K, logarithm from quotient of grain height and width Ks =logio X Where: x- area width, difference between highestand lowest co-ordinate X of the area or horizontalFeret diameter -dF,h;y - area height, differencebetween highest and lowest co-ordinate Y of the areaor vertical Feret diameter; n- number of pixels; L一perimeter of object; A - surface field of object; Cr-Crotton perimeter; L’- circle perimeter of surfaceequal to grain surface; a1 -length of longer ellipse axis featured on object; bi-length of shorter ellipseaxis featured on object. Crotton perimeter - mean intersection length indirection 0, 45, 90 i 135°. Lengths of intersections indirections 45 i 135° are being revised (normalized)by coefficient √2/2; Table 2. Approximation of grain composition curves by various parametric distribution functions. Laser particle sizer-sandstone Distribution type 0-32 32-40 40-63 63-71 71-80 80-100 100-160 +160 GSA 17,86 13.92 13.93 10,13 7,79 8.96 9.06 12,57 Log-norm 8.09 12.49 13.54 14.29 16,98 18,42 16,33 15.25 Weibull 2,55 6.55 8,11 7,70 8,33 9,34 11,78 15,04 Laser particle sizer - magnesite GSA 17,11 18.32 19,94 10.82 15,47 18.55 11,63 12.66 Log-norm 3.48 14,32 15,38 21,94 14.06 14.17 14.45 17.05 Weibull 5.17 7.51 8,15 8.31 9,23 11,42 10.27 7,95 IPS·-sandstone GSA 22,52 15,72 23,47 21,65 18,79 21,85 18,65 19.95 Log-norm 6,79 4.26 5,67 8,60 10,05 12,30 10.49 8,16 Weibull 8.41 13,96 15,73 19.63 19.05 10.60 15.17 11.38 IPS - magnesite GSA 3,92 16,69 28,11 17,63 17,74 16,13 20,13 17.69 Log-norm 9,19 7,13 11,42 10,58 12,42 14.35 9,67 10.61 Weibull 4,02 15 13,05 11,79 11,11 7.76 10.59 4.43 Because these coefficientswere calculatedasarithmetic mean values of individual measurements.it is advisable to calculate the variation factors v forthese values to see which ones are relatively themost stable. As the variation factor we understandthe value determined by formulae (3). where: s- standard deviation of measurements; x-mean value of measurements. Table 3. Shape coemf3fi)cients for diabase (specificgravity=2,69 kg/m). Diabase Class [um] 40-63 63-71 71-80 80-100 100-160 d,[um] 62,76 71,05 87,46 96,20 113,71 Kci 0,75 0,75 0,80 0,77 0,79 Kw 1.50 1,48 1.43 1.48 1.45 K 0,63 0,64 0,68 0,66 0.67 K2 1,04 1.04 1,03 1.04 1.03 Kr 1.13 1,08 1,16 1.13 1,12 KE 0,38 0.37 0.36 0,35 0.39 以 1.48 1.37 1,40 1.37 1,41 B 2,25 2.20 2,04 2,18 2,10 Ks -0,04 -0,02 -0,05 -0,04 -0,02 Kz 0,57 0,58 0,63 0,59 0,61 Blaine’s spec.surface[cm/g] 794,3 718,0 646,0 573,3 472,0 D Blaine 0,447 0,437 0,395 0,404 0.416 BET surface 3,209 3,293 2,819 1,872 2,483 [m/g] DBET 0,011 0,01 0,009 0,012 0,008 Table 4. Shape coefficients for sandstone (specificgravity=2,7269 kg/m. Sandstone Class [um] 40-63 63-71 71-80 80-100 100-160 d, [um] 60,91 77,44 91,07 102,19 168,21 Kc1 0.81 0,77 0.81 0,79 0.81 Kw 1,42 1,46 1,43 1.47 1.43 Ki 0,68 0,66 0,67 0.65 0,67 K2 1,03 1,04 1,02 1,03 1,03 Kr 1,16 0,95 1,18 1,19 1.01 KE 0.37 0.31 0,32 0.36 0,32 1,42 1,32 1,34 1,41 1,31 B 2,03 2,13 2,05 2,18 2,03 Ks -0,05 0,04 -0,05 -0,05 0,003 Kz 0.64 0.61 0.63 0,61 0,63 Blaine’s spec.surface[cm/g] 947,0 831,7 745,0 654,3 614,7 Blaine 0,381 0,341 0,324 0,329 0,213 BET surface[m/g] 2,415 1,759 2,093 1,708 1,77 BET 0,015 0,016 0,012 0,013 0,007 Table 5. Shape coefficients for magnesite (specificgravity=3,01 kg/m). Magnesite Class [um] 32-40 40-63 63-71 71-80 d,[um 46,86 62,22 74.80 92,56 Kci 0,76 0,80 0,79 0,82 Kw 1.47 1.43 1,44 1,41 K 0,66 0,67 0,66 0,67 K 1,03 1.01 1,01 1,01 Kr 1,12 1,07 1,11 1,04 Ke 0,39 0.41 0.41 0.39 1,47 1.50 1.52 1,48 2,16 2,05 2,08 1.99 Ks -0,03 -0,01 -0,02 0,01 Kz 0.60 0,63 0,62 0.65 Blaine’s spec. surface 1746 1730 1094 1021 [cm/g] Blaine 0,244 0,185 0,244 0.211 BET surface [ [m/g] 8,59 7,758 6.683 6,38 O BET 0,005 0,004 0,004 0,003 Tables 6, 7 and 8 present the calculated variationfactors for all three researched materials. For furtherresearches, the first four coefficients were selectedin base of calculated variation factors. Table 6. Variation factors for diabase. Diabase-variation factors Classum 40-63 63-71 71-80 80-100 100-160 um 20,62 24,90 24,42 52,86 67,08 Kci 10.13 9,66 9,86 9,81 12,69 Kw 5.62 4,40 5,67 5,66 5.99 K 8,50 7,74 9.15 10,23 8,77 Kz 3.50 2,59 2,37 4.25 3,20 KF 27,87 24,09 31,74 28.51 37,89 Ke 50.83 42,68 48,02 52,27 44,57 以 24,16 19,64 24,19 22,76 23,88 B 11.56 8,85 11.80 11.23 12,10 Ks -347,62 -597,86 -297,18 -351,12 -754.70 Kz 10.41 8,70 10,29 11.99 11,57 Table 7. Variation factors for sandstone. Sandstone-variation factors Classum 40-63 63-71 71-80 80-100 100-160 d,[um] 19,07 10,03 17,01 45,37 12,07 Kci 10.29 10.44 10,93 17.95 5.40 Kw 5,98 6,12 5,85 11.52 3.18 K 9,75 8,01 9,87 14.27 6,85 K2 2,66 2,33 2,82 2,59 1,52 KF 28.97 22,22 31,83 45.39 19,02 KE 48,43 47,79 52,44 59.02 48,16 23,85 25,23 24,47 38,22 21,78 12,18 12,70 11,85 25,48 6,39 Ks -266.33 309,12 -227,20 -270,41 3342.83 Kz 11.51 11,18 11,34 18.86 6,23 Table 8. Variation factors for magnesite. Magnesite-variation factors Class [umj 32-40 40-63 63-71 71-80 d,[um] 19,78 20.42 19.80 20.35 Kci 11,81 11,87 11,51 9.23 Kw 6,67 7.44 6,81 5.58 K 11,43 12.12 11,08 11,07 K2 2,69 1,79 1,93 0,99 Kr 33,44 33.55 32.02 35,54 KE 48,01 43,70 46,92 50.70 以 25,13 27.06 28,84 25.22 13,60 15,65 14,19 11.56 Ks -515.15 -1735,66 -607,07 1589.17 Kz 12,72 13.35 12,35 10.25 In purpose of finding correlations between grainsize, its shape and surface, the following reasoningwas carried out. In every grain class, the theoreticalgrain surface of d diameter was calculated, assumedas the representative grain for the class. The grainsurface was calculated from the following equation: Also, the coefficient D=1 was assumed for grainof theoretical spherical surface. Considerations forevery material were conducted by assuming thegrain from certain class as the spherical one and thenas the grain with the following calculated shapecoefficients. As the basic parameter, the grainsurface and its shape connected with size wereassumed. The calculated surface valuesweregrouped in Table 10. The Figures 1, 2 and 3 show the changeability ofgrain surface dependablyon sspecific surfacemeasuring method and selected shape coefficients.Because of the completely other scale of results, thechangeability of grain size calculated in base ofspecific surface determined by BET method must becompared separately. This comparison is possibleonly for three grain classes, for which the data wereavailable for every material. Figure 2. Various grain surfaces for diabase. 45 Figure 3. Various grain surfaces for sandstone. grain class [um] Figure 4. Various grain surfaces for magnesite. Looking at the values ofS, determined in base ofBET specific surface (Table 10) it is also clearlyvisible that the lower values of Sp are given forsandstone, medium ones for diabase and the highestfor magnesite. The significant growth of this surface is obvious,beginning from sandstone, which is the less porous,through diabase till magnesite, which is the porousmaterial. In the last case, the significant porositycauses very high growth of measured surface (andsimilarlydeceleration ofcalculated shapecoefficients values). In case of application of shapecoefficient (calculatedfromadsorptive specificsurface measuring method,tthee results idiffersignificantly from the others. Inconsiderable changeof grains surface with individual coefficients beingapplied proves their regular shape and also theirporosity (Dubinin, 1975). It seems that the attemptof mathematical description of these dependencies ispossible in way assuring the physical interpretationof given function. In base of figures 2, 3 and 4 it issuggested to check the fitting level of grain surfacechangeability to the functiaonn ffaormilisisirmulas as (Peszko &Szymanska-Czaja, 2003): second degree polynomialy=ax²+bx+c; exponential function y=aer corexponential function y=(x+a)ox+e. Finally, iitt isproposed to apply the exponential function of thefollowing equation: where: a-grain surface by x=1 (for spherical grain)x=)- selected shape coefficient;1b factorconnected with surface texture. Material Class [um] S,sphere S,Kci S,Kw S,K1 S,K2 S,Blaine S, BET ×10.nm²1 Diabase 40-63 1.24 1.66 0,83 1.96 1,19 2.76 111,7 63-71 1.59 2,11 1,07 2.49 1.53 3.63 166.37 71-80 2,40 2,99 1,68 3,52 2.34 6,09 266,67 80-100 2,91 3,79 1.97 4,42 2.78 7.19 235.62 100-160 4,06 5.11 2.81 6,03 3.93 9,78 514.24 Sandstone 40-63 1,17 1.44 0,82 1,70 1,14 3,06 78,02 63-71 1,88 2,44 1,29 2,84 1,82 5,52 117,48 71-80 2,60 3,23 1,82 3,87 2,54 8,04 225,96 80-100 3,28 4,13 2.23 5,01 3,19 9,98 260,56 100-160 8.88 11,01 6,24 1.33 8,64 41,81 1204.12 Magnesite 32-40 0,69 0.91 0,47 1.05 0,67 2.83 139.3 40-63 1,22 1.53 0,85 1,83 1.2 6,57 295.52 63-71 1,76 2.23 1,22 2,67 1.73 7.22 440,8 71-80 2.69 3,29 1,91 3,99 2,68 12.76 797.36 4 CONCLUSIONS Summarizing, it isnecessary to remember thatrightness of observations and conclusions is correctonly for the specified group of materials of similarsurface nature. The necessary condition is to knowthe texture of researched material. The dependenciesfor solid crystal materials (isomorphic crystals) willbe different from these for porous ones and for plateones. Furthermore, it is possible to assume (Lason,1988) that the specific surface has its physical sensein case of no-porous materials and macro- andmesoporous ones. For microporous materials of veryexpanded inner surface, the term of specific surfaceas the feature characterizing the comminution levelof material has no longer physical sense. The innersurface being created by micropores is so large thatthe growth of surface e.g. in effect of comminutionis only its insignificant part. Generally, the characterof grain surface changeability results for researchedmaterials indicates that it is possible to search forfunctional dependencies for them, whichwereproposed in the paper. Works and calculations arebeing continued and will be presented in future. 5 ACKNOWLEDGEMENTS The paper isan effect of scientific project no.5 T124 017 25 6 REFERENCES ( Allen T.: .. Particle Size Measurement, vol 2. Chapman & Hall, 1997. ) Dubinin M.M.: Adsorpcja i porowatosc, WojskowaAkademia Techniczna, Warszawa, 1975. ( Gniadek M., Gawendaa T., Krawczykowski D .,Tumidajski T.: Porownanie 1 wynikow analizsktadu ziarnowego produktow 1 rozdrabniania wykonywanych r oznymi metodami z a a p omoca ) ( rozktadow v ztozonyc h h ijunkcj i rozmycia, Gornictwo vol. 266, pp. 33-45, Gliwice,2005. ) ( Feda J .: Mechanics of Particulate Materials: the DevelPrinciples,opment in Geotechnical30. C ze Engineering30. C ze choslovak Academy yof Sciences, Else .CC S , vier, Amsterdam, 1982. ) ( Lason M.: Powierzchnia w tasciwa i materiatow porowatych, Archiwum Gornictwa, vol. 33 , Issue4, Warszawa, PWN, 1988. ) ( Peszko B., Szymanska-Czaja M .: B adanie w plywu porowatosci materialow drobno u ziarnionych na wielkosc powierzchn i wlasciwej, Krakow Inzynieria Mineralna, pp. 100-108,2003. ) ( Russ J.C. 1986. Practical Steorology, Plenum , New York. ) ( Serra J.: : Image A nalysis and Mathematical Morphology. Academic Press,1982. ) ( Tadeusiewicz KorohodaP: 4:1 Komputerowaanaliza i przetwarzani e obrazow, WydawnictwoFundacji Postepu T elekomunikacji, Krakow, 1997 ) ( Wadell H.: Volume, Shape a nd Roundness of RockParticles, Journal of Geology,40, 1933. ) ( Wojnar L.. K urzydlowski K . J.. Szala J .: Praktvkaanalizy zU. Polskie Towarzystwo Stereologiczne, Krakow, 2002 ) ( Xu R., di Guida O. A .: Comparison o f sizing smallparticles using different technologies, Powder T echnology 132: pp. 145-153,2003 )

确定

还剩4页未读,是否继续阅读?

北京飞驰科学仪器有限公司为您提供《矿物中粒径分布检测方案(激光粒度仪)》,该方案主要用于其他中粒径分布检测,参考标准--,《矿物中粒径分布检测方案(激光粒度仪)》用到的仪器有德国FRITSCH(飞驰)A22大量程纳米激光粒度仪

推荐专场

相关方案

更多

该厂商其他方案

更多