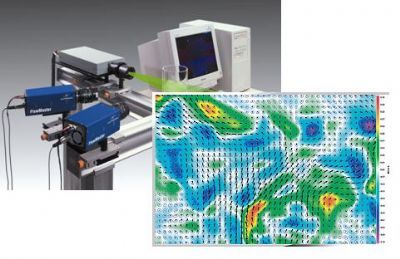

边界层,湍流中速度矢量场检测方案(粒子图像测速)

A flat plate boundary layer flow was generated at the open test section of the circuit type 1m- wind tunnel of

the DLR, Gottingen, at a free stream velocity of U亣 = 7 m/s with zero pressure gradients. A transparent and

smooth surface glass plate is utilized to provide optical access from its bottom and a good flow quality. The

plate has an elliptic leading edge to prevent flow separation. Four tripping wires, one with 1.5 mm diameter

and three with 1 mm diameter were positioned with 1 mm x-distance close to the surface at (Rex). . 290

along the whole span-wise elongation of the plate. This bypass transition of the flow results in the

development of a turbulent boundary layer flow. In a box of about 34 x 18 x 35 mm3 in x-y and z-directions

around (Rex). . 450 tracer particles has been illuminated by laser light pulses at 4 kHz with 21 mJ each in

order to achieve PIV recordings without using the frame straddling method. The light source was a Nd:YAG

laser from Lee Laser inc. Two highly reflective dielectric mirrors aligned in the x-y-direction are installed

nearly parallel and close to the surface of the flat plate on opposite sides of the measurement region. The

collimated laser beam undergoes multiple reflections between the two mirrors passing through the

measurement volume approximately 15 times before exiting (see sketch left). This arrangement resulted in

a light amplification with a factor ~5 with respect to a single pass system. The specific illumination

arrangement has the advantage that all viewing directions collect scattered light both in forward and

backward directions, which provided the level of light needed for imaging particles in the whole volume.

检测样品:

其他

检测项:

速度矢量场

北京欧兰科技发展有限公司

查看联系电话

前往展位

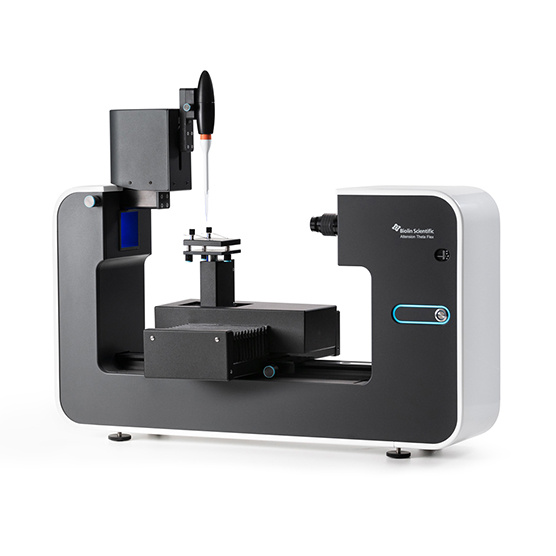

有机包裹体气液比中测量方法研究检测方案(金相显微镜)

摘要 利用激光扫描共聚焦显微镜并结合三维重建软件可以精确获取有机包裹体的气液比。有机包裹体气泡部分采用透射光通道进行系列深度扫描,选取气泡直径最大处的扫描图象进行直径测量,并利用球体体积计算公式得到气泡体积,避免了由于油包裹体液相石油所发出的强烈荧光的遮挡造成的气泡体积偏小;将共聚焦扫描图象进行三维重建获取精确的有机包裹体总体积,与计算所得的气泡体积共同确定出有机包裹体的气液比。利用该方法对渤海湾盆地渤中凹陷BZ25-1-3井的一块流体包裹体样品的气液比进行了研究,测试的气液比为6.85%。精确获取有机包裹体的气液比不仅能为包裹体PVT性质的研究提供精确参数,还对流体包裹体微观性质的对比研究提供了借鉴,具有重要意义。

检测样品:

其他

检测项:

测量方法研究

北京普瑞赛司仪器有限公司

查看联系电话

前往展位

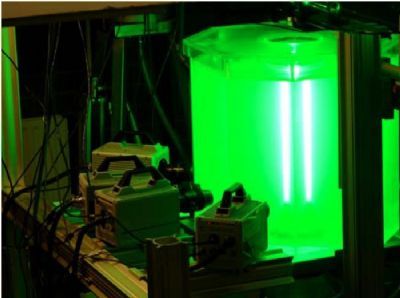

高压燃烧系统,氮氧化物中激光诱导荧光,PLIF,自由基,羟基,浓度场检测方案(流量计)

Practical diagnostic strategies for detection of temperature and nitric oxide (NO) in high pressure (p<60bar) combustion systems using Laser-Induced-Fluorescence (LIF) of nitric oxide are investigated. NO-LIF, when applied to elevated pressures, suffers from a decrease of signal due to pressure broadening and attenuation of the propagating laser beam/fluorescence signals. In addition, overlapping of neighboring excitation lines and interference from LIF of other species (mainly O2 and CO2) can significantly influence the overall signal. The main purpose of this study is to investigate NO-LIF strategies which minimize the impact of these complications or allow for correction of their effects. A comprehensive study of NO-LIF in a laboratory high-pressure flame was carried out for various flame stoichiometries, pressures and excitation wavelengths to develop optimized excitation and detection strategies for high-pressure applications. Four main issues are addressed in this study. First, optimized excitation strategies are investigated for high-pressure applications in the A2Σ+−X2Π (0,0), (0,1) and (0,2) bands of NO. Second, CO2-LIF is identified as a major source of interference in the detection of NO-LIF in high-pressure combustion systems involving hydrocarbon chemistry. Third, an accurate multi-line thermometry technique for steady, high-pressure flames is proposed by fitting wavelength-scanned NO-LIF with computational simulations. Finally, measurements optimizing the detection strategies of 2-D NO-LIF imaging in high-pressure flames are reported. The discussion and demonstrations reported in this study provide a practical guideline for application of instantaneous 1-D or 2-D NO-LIF imaging in high-pressure combustion systems.

检测样品:

其他

检测项:

激光诱导荧光,PLIF,自由基,羟基,浓度场

北京欧兰科技发展有限公司

查看联系电话

前往展位

火焰,燃烧,碳烟中温度场检测方案

Temperature measurements using planar laser-induced fluorescence (PLIF)are most often associated with experimental challenges. In addition, no PLIF technique is generally applicable in all kinds of environment. Especially under sooting conditions problems are prone to arise, which limits the use of these techniques. In this paper the two-line atomic fluorescence (TLAF) technique was investigated in sooting environments. Indium atoms were used as thermometry species and seeded into the combustion region. Data from two-dimensional measurements are often difficult to analyse, because of problems with treating noise. A statistical analysis method for

correction of laser fluctuations was developed to increase the precision of the temperature calculations.

The results show that TLAF holds promise for temperature

measurements in rich combustion, such as diesel engines, where other

techniques have proven to fail. Drawbacks with the TLAF technique are that the probe volume is biased towards the post-flame zone and that seeding is required. The statistical analysis improved the precision considerably and is suitable for evaluation of other two-dimensional thermometry techniques.

This paper also presents a critical review and comparison with alternatives, such as OH and NO thermometry.

检测样品:

其他

检测项:

温度场

北京欧兰科技发展有限公司

查看联系电话

前往展位

流体中时间分辨3D3C速度矢量场检测方案(粒子图像测速)

A survey is conducted to quantitatively visualise the wake flow behind a circular cylinder at Reynolds numbers of 180 to 2500. A time-resolved tomographic PIV method is used to measure the

sequence of three-dimensional vector fields evolving in time. The attention is focused upon the unsteady 3D wake organization with the interaction of primary rollers (Karman-Benard) and the secondary vortices resulting from 3D instability of the vortex wake.

检测样品:

其他

检测项:

时间分辨3D3C速度矢量场

北京欧兰科技发展有限公司

查看联系电话

前往展位

变温光致发光在InGaAs/GaAs量子点研究中的应用

在利用带内载流子跃迁的太赫兹应用领域内,InGaAs/GaAs和InAs/GaAs量子点被认为是非常合适的材料。这类应用包括化学生物媒介的远程探测、红外计数测量、激光雷达、污染监测、分子和固态光谱、非损伤医学诊断。通过调整量子点的大小、形状和结构,量子点的类原子光电特性可被优化用于特定的应用。

变温光致发光光谱是一种分析含有量子点和量子阱材料的有效手段,辅助优化上述InGaAs/GaAs分子的性质。制冷一般采用两种冷冻机,一种是液氮或液氦制冷;另一种是封闭循环冷冻机,冷冻液在系统中循环。冷冻样品被激光激发,光致发光信号通过光学接口被耦合进光谱仪。

检测样品:

其他

检测项:

HORIBA(中国)

查看联系电话

前往展位

流场中3D3C速度矢量场检测方案

Tomographic PIV as a full volume 3D-3C flow field measurement technique can also be applied

to thin sheets used in standard PIV. Tomographic PIV and Stereo PIV are compared with experimental data

from an impinging jet in water. The field of view is 60 mm x 40 mm, the light sheet thickness is varied from

8 to 55 pixel. Images have been recorded with 4 cameras to gain results from two independent Stereo PIV

systems and from Tomographic PIV using 2-4 cameras. Different error sources for both techniques are

quantified. It is shown that instantaneous flow fields from Tomographic PIV deviate less from each of the

two stereo systems, than the two stereo systems deviate from each other. A systematic error pattern is

identified for the two stereo systems, which is not present for Tomographic PIV. Thin volume Tomographic

PIV allows the calculation of multiple vector planes. Two planes can be calculated even for the thinnest light

sheet (8 pixel) providing the full 3x3 strain-tensor. Thicker sheets with up to twelve vector planes allow the

visualization of the small vortex structures in this experiment.

检测样品:

其他

检测项:

3D3C速度矢量场

北京欧兰科技发展有限公司

查看联系电话

前往展位

扫描电子显微镜图像系统改造方法

扫描电子显微镜是观察物质微观表面形貌的主要工具,它主要由真空系统、电子光学系统、图像系统和控制系统组成。现代扫描电子显微镜图像显示系统和控制系统都已经实现PC控制下的数字化,同时增加了图像处理功能,能够容易的与通用软件相结合,方便编辑报告、论文和信息传送。对于早期模拟图像系统和专用计算机控制的数字图像系统的扫描电子显微镜可以通过外接计算机图像采集系统实现模拟图像数字化,或图像系统数字化。

什么是模拟图像数字化?就是将获取的图像模拟信号经过模数转换器(ADC)变成数据输入到计算机中存储、显示和处理。根据这种原理制成的图像系统,就是我们常说的被动式图像系统。其优点:采集卡电路简单,价格便宜。缺点:安装、调试困难,因为它需要和扫描电子显微镜的扫描系统同步,所以要改变原扫描电子显微镜内部电路,稍不小心就会造成事故,给扫描电子显微镜带来硬伤。另外,由于不能和扫描电子显微镜扫描真正同步,采集到的图像变形,最为明显的是圆变为椭圆,同时不能实时处理,只有将采集到的图像存储以后进行处理,才可以输出。

什么是图像系统数字化?用数字扫描系统替代模拟扫描系统,由此获取的图像信号数据,完全对应电子束扫描点上的样品信息,图像显示分辨率对应电子束在样品上扫描过的行和列的点数,图像扫描和图像显示全数字化。需要说明的是现代数字扫描电子显微镜自定义分辨率值为:1024×1024,这是一个最佳值(从采集速度和分辨率两方面考虑),这和被动式图像系统所谓的图像分辨率不是一个概念。我们称这样的系统为主动式图像系统,国外升级扫描电子显微镜也是采用此种方法。其优点:图像质量高,速度快,不会产生图像变形等问题,安装简单,因为所有扫描电子显微镜都预留有外部图像控制接口,当外部控制信号到来时,内部扫描部分自动被旁路,显示部分被消隐,不需要改变任何内部电路结构。缺点:采集卡电路复杂,成本高。

综述,以上介绍了两种扫描电子显微镜改造图像系统的方法,最主要的区别在于是“被动式图像系统”还是“主动式图像系统”上,其中主动式图像系统是近年来国际上普遍使用的,因为被动式图像系统是一种早期图像数字化过渡产品,所谓的图像分辨率实质上是模拟信号取样点数,并非数字图像分辨率,像质较差,而主动式图像系统标称的分辨率才真正是数字图像分辨率,可以有效提高图像质量。

检测样品:

其他

检测项:

北京博远微纳科技有限公司

查看联系电话

前往展位

微尺度流体中流场检测方案(粒子图像测速)

Microscopic particle image velocimetry (microPIV) experiments were performed on a polydimethylsiloxane (PDMS) microchannel

with a cross-section measuring 320 lm · 330 lm for Reynolds numbers between 272 and 2853. Care was taken to ensure that the

seed particle density was great enough that accurate instantaneous velocity vector fields could be obtained for all the Reynolds numbers

investigated. Velocity fluctuations were calculated from ensembles of microPIV velocity fields. The hu0i/umax fluctuation showed

an increase at Re = 1535 and a further increase as Reynolds numbers were increased, suggesting that transition to turbulence began

near Re = 1535, a Reynolds number lower than predicted by classical theory. The hu0i/umax data also suggest the flow was fullydeveloped

at a Reynolds number between 2630 and 2853, also lower than classical results. This finding was confirmed in plots of

the mean velocity profile. For the fully developed flow, the measured hu0 i/umax fluctuation agreed well with classical results for turbulent

duct flow, but the hv0 i/umax fluctuation was 25–40% lower than turbulent duct flow results. Finally, spatial correlations of

velocity fluctuations were calculated to lend some insights into the characteristics of the large-scale turbulent structures observed

in the turbulent microchannel flow.

检测样品:

其他

检测项:

流场

北京欧兰科技发展有限公司

查看联系电话

前往展位

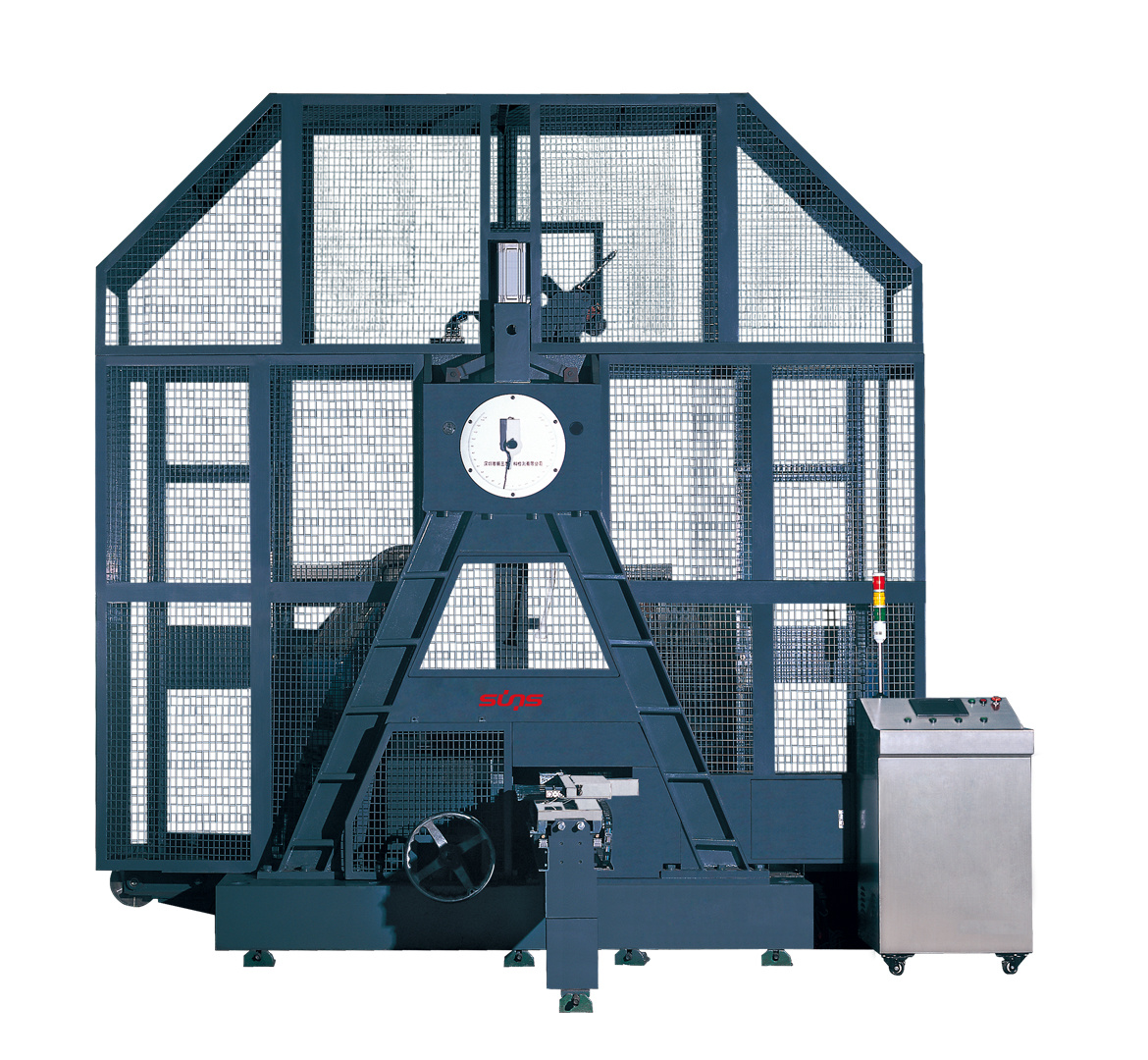

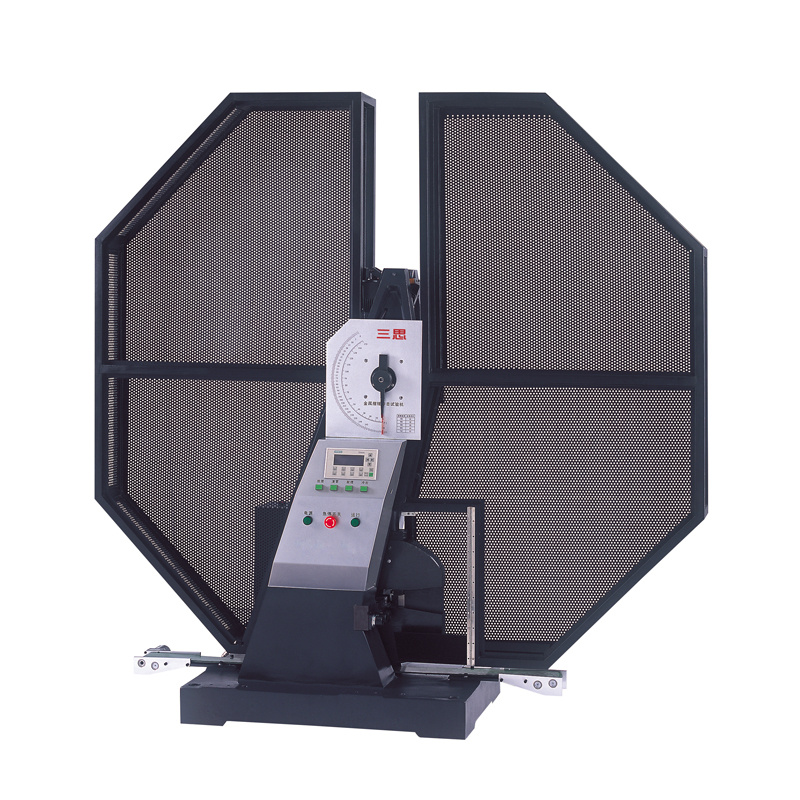

样品制备中方法与过程检测方案(切割机)

标乐有限公司出版 第1卷,第8期

技 术 评 论

运 用 显 微 组 织 分 析 解 决 实 际 问 题

试样制备的新观念

作者:George Blann

实验室服务及材料分析主管

George Vander Voort

标乐有限公司研究与技术部主任

美国伊利诺州Lake Bluff

传统方法

由于我们两个人的年龄加在一起超过了110岁,我们自认为是“旧时代”的人,正因为如此,我们不得不追忆在那“美好的旧日子里”事情是怎么做的。当30多年前我们还是年轻的金相技术人员时,一种当今称之为“传统方法”的试样制备方案日臻成熟。总的来说,试样经过切割和镶嵌(如果需要的话)后,就要用一系列粒度由粗到细的碳化硅(SiC)防水砂纸进行磨光。多数情况下,所用砂纸粒度的顺序为120、240、320、400、600号(美国ANSI/CAM粒度标准,见表1),并使用水作为冷却剂和润滑剂,同时也作为清洗剂,以便将磨屑冲刷出砂纸表面。如果采用手工磨光(在那个时代还是很普遍的),人们在更换砂纸时还需将试样转动45º 至90º 角。当人们手握试样沿转盘边缘移向中心时,还应注意使试样与砂纸保持垂直。转盘的转速一般为150转/分或300转/分,每道砂纸大约需要磨1到2分钟。

检测样品:

其他

检测项:

方法与过程

美国标乐

查看联系电话

前往展位

内燃机中速度场,浓度场,发光现象检测方案(粒子图像测速)

Measurements of the local flow and mixture condition near the spark plug of internal combustion engines are important to characterize their influence on ignition and combustion performance. This is especially true for direct-injection engines where limited time is

available for mixture formation and optimum stratification of the fuel/air mixture to achieve best performance. Transient processes need to be visualized in an optically challenging environment.

The application of digital Particle Image Velocimetry (PIV) for flow field measurements along with crank angle-resolved planar laser induced fluorescence (PLIF) and chemiluminescence imaging is discussed in the context of investigations of a highly stratified sprayguided direct-injection engine. Flow fields were captured in a firing optical single-cylinder engine to study the interaction of the fast spray and the underlying in-cylinder tumble flow. The

impingement of the fuel spray on the spark plug electrodes and subsequent dispersion of the fuel cloud was filmed at a rate of 12kHz with a new PLIF technique using a diode-pumped Nd:YAG laser. Subsequent flame development and combustion progress could be followed via high-speed imaging of OH* chemiluminescence. This approach was also combined with double-pulse PLIF imaging of fuel distributions.

检测样品:

其他

检测项:

速度场,浓度场,发光现象

北京欧兰科技发展有限公司

查看联系电话

前往展位

纳米碳管-钙钛石复合催化剂氧电极交换电流密度的测试与分析

以纳米碳管与钙钛石制备了复合催化剂氧电极,分析了电极中氧还原的催化机理,利用稳态阴极极化测试法,测试并分析了所制氧电极的交换电流密度. 结果表明:复合催化剂催化能力优于单一催化剂;不同种类钙钛石催化能力大小顺序为:La0. 8Sr0. 2CoO3 > La0. 6Ca0. 4CoO3 > La0. 6Ni0. 4CoO3 >La0.8Sr0. 2MnO3 ,正交试验确定的最佳氧电极催化剂配比为:纳米碳管0.1g ,La0.6Sr0.4CoO30.02g ,Na2SO4 0.1g ,PTFE 0.5mL ,此时,交换电流密度最大,达0.1441 mA/ cm2 ;单因素试验结果显示,复合催化剂中w (La0. 8Sr0. 2CoO3) =9.09 % ,w (Na2SO4) = 45. 45 %时电极的阴极极化程度最小.

检测样品:

其他

检测项:

武汉科思特仪器股份有限公司

查看联系电话

前往展位

燃气轮机,模型燃烧器,燃烧,合成气中速度场,浓度场检测方案(粒子图像测速)

A parameter study was conducted to characterize the combustion of a hydrogen-rich syngas fuel in swirl-stabilized flames in a gas turbine model combustor with optical access. Three thermal power-loadings were tested and equivalence ratio was varied in a range of Φ ≈ 0.4 - 0.6 by changing the fuel flow rates at constant air flow.

Velocity, heat-release and flame zone shape were studied using optical diagnostics including PIV, OH-LIF and OH* chemiluminescence imaging. A main goal of this work was the establishment of an experimental data base for the validation of numerical simulations.

The syngas burned stably and without significant thermo-acoustic oscillations at all operating conditions. The inner recirculation zone is identified as a key stabilization mechanism for this burner. This is consistent with previous studies for syngas mixtures with a high CO content in the same burner. Changes in equivalence ratio and the thermal power of the flame had only a small impact on the overall flame shape and the burning behavior.

检测样品:

其他

检测项:

速度场,浓度场

北京欧兰科技发展有限公司

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供2243篇其他检测方案,可分别用于,参考标准主要有等