方案详情

文

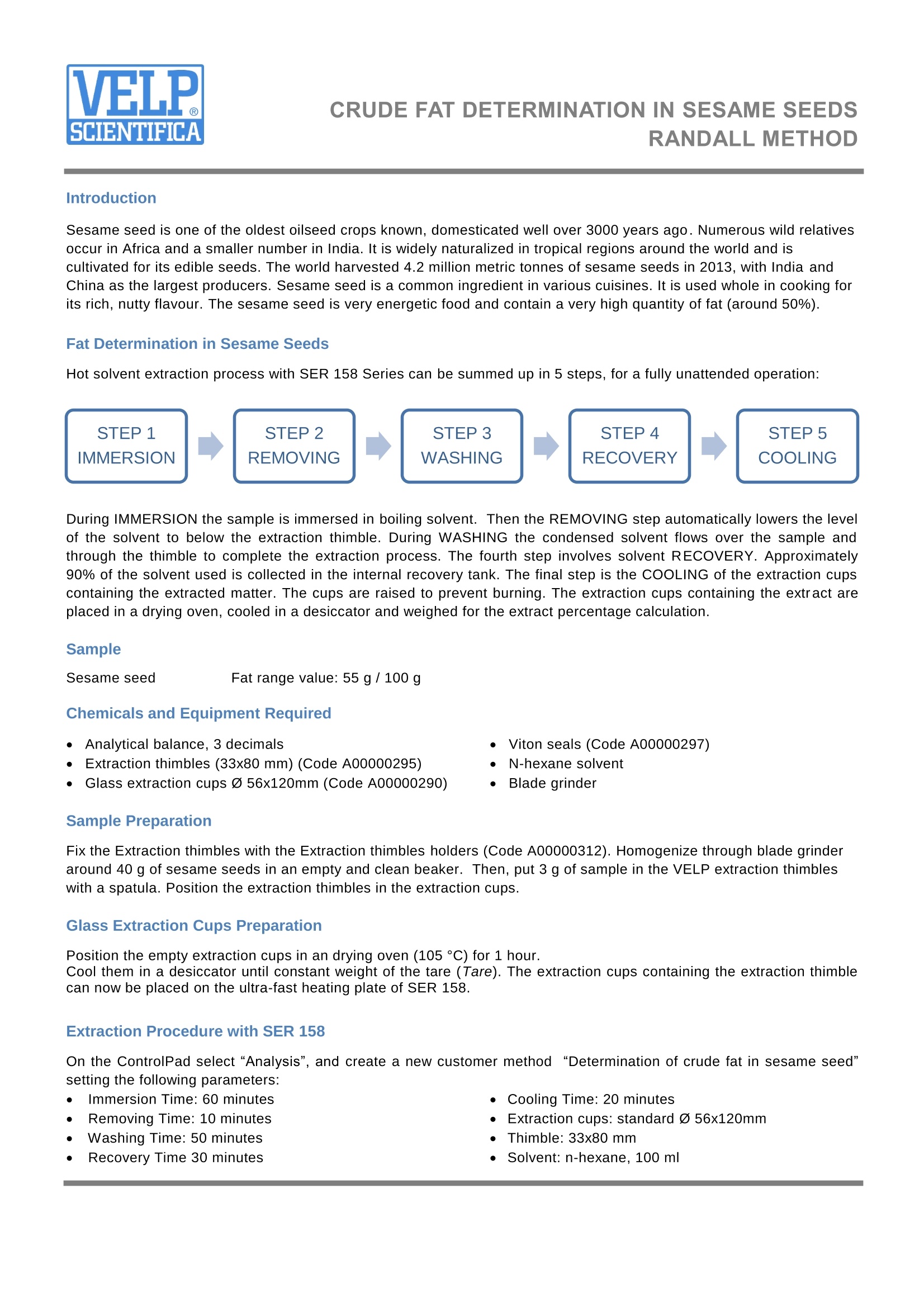

芝麻是已知的最古老的油料作物之一,2013年,全球收获了420万吨芝麻种子,其中印度和中国是最大的生产国。芝麻是各种菜肴中常见的食材。因为它有浓郁的坚果味,所以在烹饪时要食用。芝麻是非常高热量的食物,含有非常高的脂肪(约50%)。

方案详情

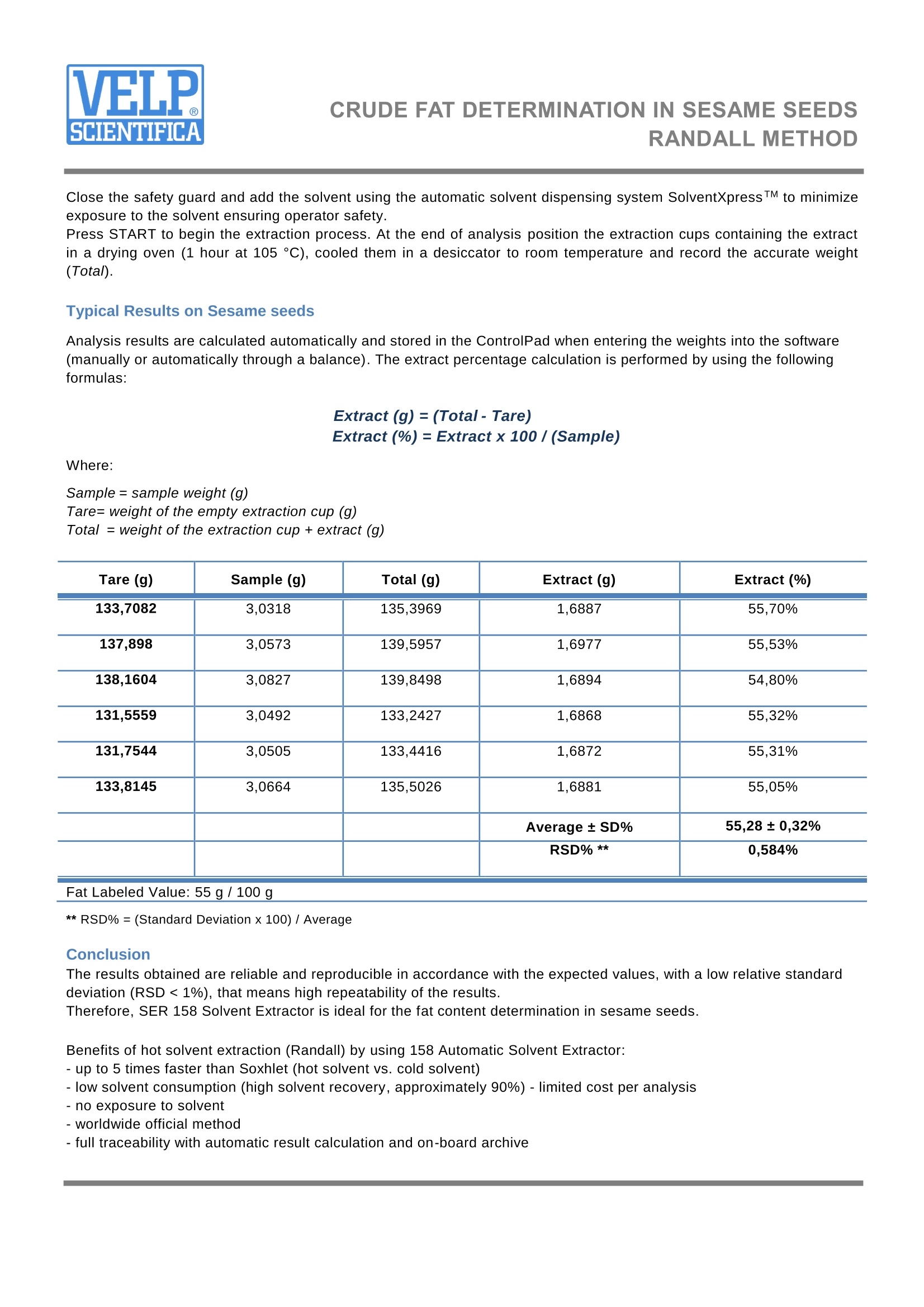

APPLICATION NOTEF&F-S-007-2016/A1 CRUDE FAT DETERMINATION IN SESAME SEEDSRANDALL METHOD Crude Fat Determination in SesameSeeds according to the Randall method Reference: AOAC Official Method 2003.06 Tested with VELP Scientifica SER 158/6 Solvent AutoExtractor (Code S303A0380) Introduction Sesame seed is one of the oldest oilseed crops known, domesticated well over 3000 years ago. Numerous wild relativesoccur in Africa and a smaller number in India. It is widely naturalized in tropical regions around the world and iscultivated for its edible seeds. The world harvested 4.2 million metric tonnes of sesame seeds in 2013, with India andChina as the largest producers. Sesame seed is a common ingredient in various cuisines. It is used whole in cooking forits rich, nutty flavour. The sesame seed is very energetic food and contain a very high quantity of fat (around 50%). Fat Determination in Sesame Seeds Hot solvent extraction process with SER 158 Series can be summed up in 5 steps, for a fully unattended operation: During IMMERSION the sample is immersed in boiling solvent. Then the REMOVING step automatically lowers the levelof the solvent to below the extraction thimble. During WASHING the condensed solvent flows over the sample andthrough the thimble to complete the extraction process. The fourth step involves solvent RECOVERY. Approximately90% of the solvent used is collected in the internal recovery tank. The final step is the COOLING of the extraction cupscontaining the extracted matter. The cups are raised to prevent burning. The extraction cups containing the extract areplaced in a drying oven, cooled in a desiccator and weighed for the extract percentage calculation. Sample Sesame seed Fat range value: 55 g/ 100 g Chemicals and Equipment Required Analytical balance, 3 decimals Viton seals (Code A00000297) Extraction thimbles (33x80 mm) (Code A00000295) ·NN-hexane solvent Glass extraction cups 0 56x120mm (Code A00000290) Blade grinder Sample Preparation Fix the Extraction thimbles with the Extraction thimbles holders (Code A00000312). Homogenize through blade grinderaround 40 g of sesame seeds in an empty and clean beaker. Then, put 3 g of sample in the VELP extraction thimbleswith a spatula. Position the extraction thimbles in the extraction cups. Glass Extraction Cups Preparation Position the empty extraction cups in an drying oven (105°C) for 1 hour. Cool them in a desiccator until constant weight of the tare (Tare). The extraction cups containing the extraction thimblecan now be placed on the ultra-fast heating plate of SER 158. Extraction Procedure with SER 158 On the ControlPad select “Analysis", and create a new customer method “Determination of crude fat in sesame seecsetting the following parameters: · Immersion Time: 60 minutes ·Cooling Time: 20 minutes Removing Time: 10 minutesEExtraction cups: standard O 56x120mmWashing Time: 50 minutesThimble: 33x80 mmRecovery Time 30 minutes· Solvent: n-hexane, 100 ml Close the safety guard and add the solvent using the automatic solvent dispensing system SolventXpress TM to minimizeexposure to the solvent ensuring operator safety. Press START to begin the extraction process. At the end of analysis position the extraction cups containing the extractin a drying oven (1 hour at 105℃), cooled them in a desiccator to room temperature and record the accurate weight(Total). Typical Results on Sesame seeds Analysis results are calculated automatically and stored in the ControlPad when entering the weights into the software(manually or automatically through a balance). The extract percentage calculation is performed by using the followingformulas: Extract (g)=(Total-Tare) Extract (%)=Extract x 100/ (Sample) Where: Sample= sample weight (g) Tare= weight of the empty extraction cup (g) Total =weight of the extraction cup + extract (g) Tare (g) Sample (g) Total (g) Extract (g) Extract (%) 133,7082 3,0318 135,3969 1,6887 55,70% 137,898 3,0573 139,5957 1,6977 55,53% 138,1604 3,0827 139,8498 1,6894 54,80% 131,5559 3,0492 133,2427 1,6868 55,32% 131,7544 3,0505 133,4416 1,6872 55,31% 133,8145 3,0664 135,5026 1,6881 55,05% Average ±SD% 55,28±0,32% RSD% ** 0,584% Fat Labeled Value: 55 g / 100 g ** RSD%=(Standard Deviation x 100)/Average Conclusion The results obtained are reliable and reproducible in accordance with the expected values, with a low relative standarddeviation (RSD <1%), that means high repeatability of the results. Therefore, SER 158 Solvent Extractor is ideal for the fat content determination in sesame seeds. Benefits of hot solvent extraction (Randall) by using 158 Automatic Solvent Extractor: - up to 5 times faster than Soxhlet (hot solvent vs. cold solvent) -low solvent consumption (high solvent recovery, approximately 90%)-limited cost per analysis -no exposure to solvent -worldwide official method - full traceability with automatic result calculation and on-board archive 芝麻是已知的最古老的油料作物之一,2013年,全球收获了420万吨芝麻种子,其中印度和中国是最大的生产国。芝麻是各种菜肴中常见的食材。因为它有浓郁的坚果味,所以在烹饪时要食用。芝麻是非常高热量的食物,含有非常高的脂肪(约50%)。检测样品:Sesame seed Fat range value: 55 g / 100 g(芝麻籽,脂肪含量55 g / 100 g)检测仪器:SER158脂肪测定仪(意大利VELP)参照标准:AOAC Official Method 2003.06检测结果:在软件中输入重量时,分析结果会自动计算并存储在ControlPad中(手动或自动通过平衡)。提取百分比计算采用如下公式:Extract (g) = (Total - Tare) Extract (%) = Extract x 100 / (Sample) Sample = sample weight (g) Tare= weight of the empty extraction cup (g) Total = weight of the extraction cup + extract (g)结论:结果可靠,重复性好,相对标准偏差较小(RSD < 1%),重复性好。因此,SER 158脂肪测定仪是测定芝麻中脂肪含量的理想方法。SER158脂肪测定仪-比索氏快5倍(热溶剂对冷溶剂)-低溶剂消耗(高溶剂回收率,约90%)-每次分析的成本低-不接触溶剂-符合标注方法-完整的可追溯性,自动计算结果和存档

确定

还剩1页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《芝麻中粗脂肪检测方案(抽提萃取)》,该方案主要用于种子中营养成分检测,参考标准--,《芝麻中粗脂肪检测方案(抽提萃取)》用到的仪器有全自动脂肪测定仪-SER158、VELP-脂肪测定仪SER148/6

推荐专场

该厂商其他方案

更多