方案详情

文

膳食纤维是复杂有机物质的混合物,包括亲水化合物,如可溶性和不可溶性多糖和不可消化的低聚糖,以及一系列不膨胀或多或少疏水化合物,如角质,亚铁素和木质素。膳食纤维是人类饮食中的一种重要营养素,具有增强饱腹感、调节肠道功能和调节营养吸收的能力。由于其好处,纤维越来越多地用于功能食品,食品制造商在包装上宣布纤维含量作为营养标签的一部分。

方案详情

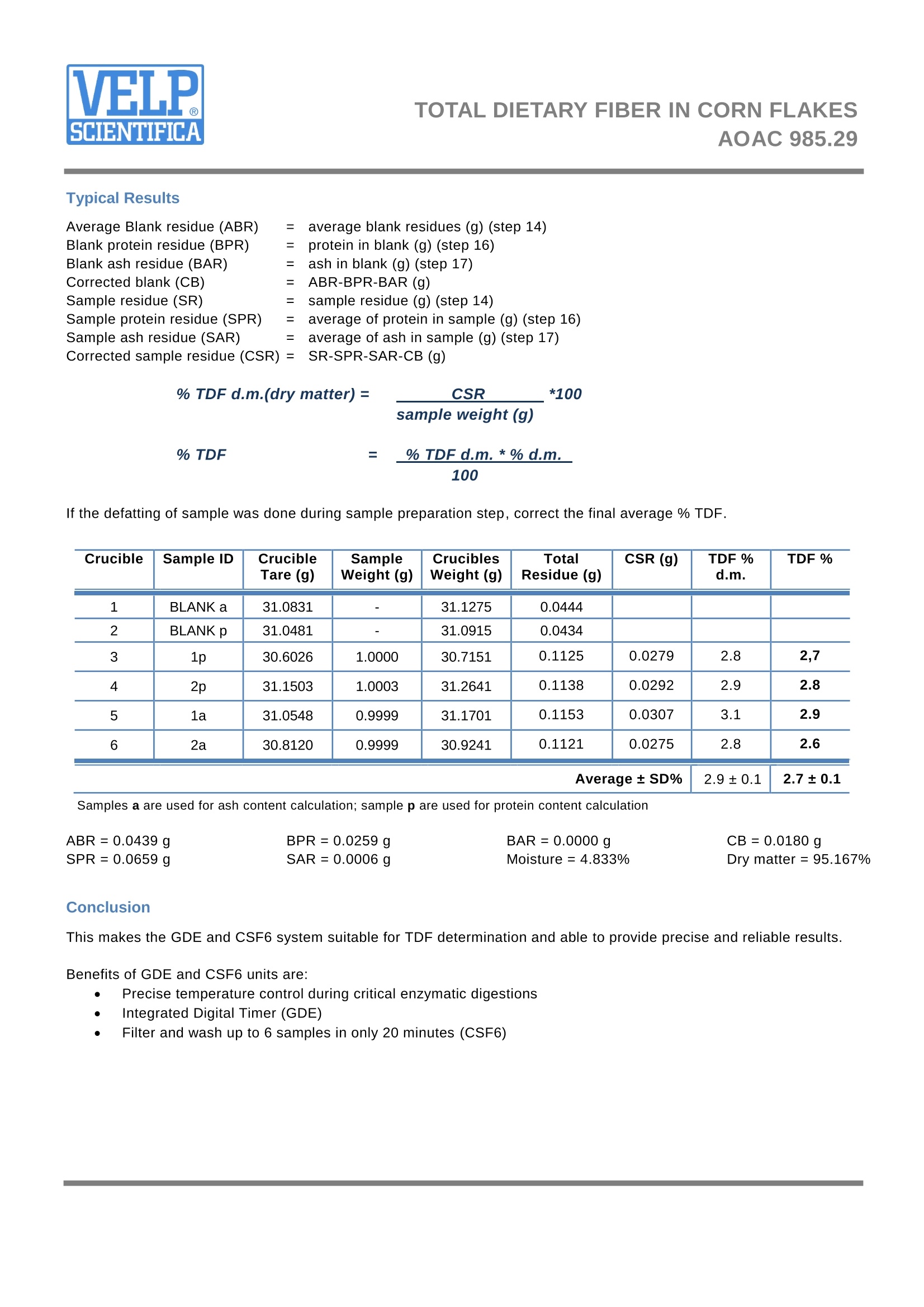

F&F-F-001-2013/A1 TOTAL DIETARY FIBER IN CORN FLAKESAOAC 985.29 APPLICATION NOTE Total Dietary Fiber in Corn Flakesaccording to AOAC 985.29 Reference: AOAC 985.29 Total Dietary Fiber in Foods Tested with VELP Scientifica GDE Enzymatic Digester (Code F30400209)and CSF6 Filtration Unit (CodeF30420210). Protein determination was performed with DK 6 Kjeldahl Digestion Unit (Code F30100182) and UDK 159Automatic Kjeldahl Distillation & Titration System (Code F30200150) Introduction Dietary fiber is a mixture of complex organic substances, including hydrophilic compounds such as soluble and insolublepolysaccharides and non-digestible oligosaccharides as well as a range of nonswellable, more or less hydrophobiccompounds such as cutins, suberins and lignins. Dietary fiber is not digested from human stomach and it represent a crucial nutrient in human diet for its ability toenhance satiety, to regulate intestinal functions and to modulate the nutrients absorption. Thanks to its benefits, the fiber is increasingly used in functional foods, and food manufacturers declare the fiber contenton the package as part of nutritional labeling. Total Dietary Fiber (TDF) in corn flakes sample Total dietary fiber is determined using a combination of enzymatic and gravimetric methods.Duplicate of samples of dried, fat-free foods are gelatinized with heat-stable alpha-amylase and digested usingamyloglucosidase to remove starch, and protease to remove proteins. The soluble dietary fiber is precipitated with ethanol. The residue is then filtered, washed with ethanol and acetone,dried and weighed. One of the duplicate samples is assayed for indigested proteins and the other is ashed. The total dietary fiber is the weight of the enzymatic digestion residue less the weight of the undigested protein and ash. Equimpment .66 glass beakers 400 ml (code A00000999). NMagnetic stirring bars, 6 x 35 mm (code A00001056)P Analytical balance 0.1 mg accuracy pH-meter standardized at pH 4.0 and 7.0 Pool balls (code A00000241) Glass crucibles P2 (code A00000140) .Fan ovenAutomated Pipettor 1 ml, 100 pl, 200 pl.Muffle furnaceAluminum foils . Desiccator Chemicals ●· Petroleum ether 40-60°C, analytical grade . Ethanol 95%v/v. Ethanol 78 % v/v-207 ml of distilled water diluted to 1 L with 95 % ethanol. Mix and if necessary, dilute again tovolume with 95 % ethanol ● Acetone, analytical grade A.PPhosphate buffer, 0.08 M, pH 6.0 -1.400 g of sodium phosphate dibasic anhydrous (Na2HPO4) and 8.400 g ofsodium phosphate monobasic anhydrous (NaH2PO4) dissolved in 1 L distilled water. Check pH with pH-meter. Adjustto pH 6.0 if necessary using either sodium hydroxide solution or phosphoric acid solution Alpha-amylase, heat-stable, solution . Protease solution - 50 mg in 1 ml phosphate buffer .Amyloglucosidase solution Sodium hydroxide solution, 1.0 N, analytical grade. SSodium hydroxide solution 0.275 N -275 ml of 1.0 N sodium hydroxide diluted to 1 L with distilled water.Hydrochloric acid solution, 1.0 N, analytical gradeHydrochloric acid solution 0.325 N - 325 ml of 1.0 N hydrochloric acid diluted to 1 L with distilled water ●Celite, acid washed Sample Corn flakes Fiber labeled value:3 % Sample Preparation Homogenize test sample and dry over night in oven at 105 C. Cool in desiccator and grind test sample to 0.3-0.5 mm mesh. Enzymatic Digestion and Filtration Procedure Run 2 blanks through entire procedure to control possible contributions from reagents to final result. 1. Mix 1 g of sample, weigh 0.1 mg, with 50 ml of phosphate buffer pH 6.0 in a 400 ml beaker. Add a magnetic stirringbar. 2. Add 100 pl of heat stable alpha-amylase solution. Mix thoroughly. Cover the beakers with aluminum foil and place inGDE at 95-100 °℃ for 30 min. Incubation with sample temperature reaching95-100 °C for 15 minutes is neededunder continuous stirring. 3. Remove beaker from boiling water bath and let cool to room temperature. 4. Remove aluminum foils and rinse flask inner walls with 10 ml of distilled water.Adjust pH to 7.5 ± 0.2 with~10 ml of sodium hydroxide solution 0.275 N. 5. Set the temperature of GDE to 60 °C adding cool distilled water to lower temperature from 95-100 °C. 6. Add 100 ul of protease solution. Incubate the beakers covered with aluminium foils for 30 minutes at 60 °C under continuous stirring. 7. Cool to room temperature. Adjust pH to 4.5± 0.2 with~10 ml of hydrochloric acid solution 0.325 N. Control pH by a pH meter. 8. Add 200 pl of amyloglucosidase solution. Incubate the beakers covered with aluminium foils for 30 minutes at 60 °℃under continuous stirring. Start timing when the temperature reaches 60 °C. 9. Remove magnetic stirring bar. Add 280 ml of 95 % ethanol preheated to 60 °c (measure volume before heating).Let precipitate form during 60 minutes at room temperature. 10.Glass crucibles are to be thoroughly cleaned and about 1 g of celite is added, placed in muffle at 550 C during 5hours, cooled at room temperature in a dessiccator up to constant weight, and weighed to nearest 0.1 mg (Crucibletare). 11. Wet the crucibles containing celite with some ml of 78 % EtOH, getting a uniform celite bed, without holes 12.Set the crucibles in CSF 6 filtration equipment. Apply vacuum. Transfer quantitatively enzymatic digested to crucible through funnel. Start the filtration. 13. After the filtration rinse the residue in crucible with three 20 ml volumes of 78 % ethanol, two 10 ml volumes of 95 %ethanol and two 10 ml volumes of acetone. If a gummy film on residue impairs filtration, retaining liquid, break thesurface with a slight air flow operating the air valve on filtration unit. 14. Dry crucible with residue and celite overnight in an air oven at 105 °℃ (70°C in a vacuum oven).Let cool in a desiccator and weigh to nearest 0.1 mg. The weight of residue is obtained by subtracting the weight of crucible tare from the final weight. 15. One of the duplicate residues is to be analyzed by Kjeldahl method for undigested protein content determination (N x6.25). Second duplicate residue is to be incinerated for the ash content determination. 16.Kjeldahl Protein Determination: transfer all the content of 3 crucibles in 3 Kjeldahl test tubes and proceed as inApplication Note “N/Protein Determination in Feed products" 17.Ash Determination: second duplicate residue is to be incinerated in a muffle at 550 °C during 5 hours. In order toavoid thermal shocks it is suggested to perform a gradual heating. Let crucible cool in a dessicator and weigh tonearest 0.1 mg. 18. Correct the result for undigested proteins and ash content determined separately. To reach temperatures of 95-100 °C with GDE, floating balls use is recommended (code A00000241). Typical Results Average Blank residue (ABR) = average blank residues (g) (step 14) Blank protein residue (BPR) protein in blank (g) (step 16) Blank ash residue (BAR) ash in blank (g) (step 17) Corrected blank (CB) ABR-BPR-BAR(9) Sample residue (SR) = sample residue (g) (step 14) Sample protein residue (SPR) average of protein in sample (g) (step 16) Sample ash residue (SAR) average of ash in sample (g) (step 17) Corrected sample residue (CSR)=SR-SPR-SAR-CB (g) If the defatting of sample was done during sample preparation step, correct the final average % TDF. Crucible Sample ID CrucibleTare (g) SampleWeight (g) CruciblesWeight (g) TotalResidue (g) CSR (g) TDF%d.m. TDF% 1 BLANK a 31.0831 31.1275 0.0444 2 BLANKp 31.0481 - 31.0915 0.0434 3 1p 30.6026 1.0000 30.7151 0.1125 0.0279 2.8 2,7 4 2p 31.1503 1.0003 31.2641 0.1138 0.0292 2.9 2.8 5 1a 31.0548 0.9999 31.1701 0.1153 0.0307 3.1 2.9 6 2a 30.8120 0.9999 30.9241 0.1121 0.0275 2.8 2.6 Average± SD% 2.9±0.1 2.7±0.1 Samples a are used for ash content calculation; sample p are used for protein content calculation ABR=0.0439g BPR=0.0259 g BAR=0.0000 g CB=0.0180 g SPR=0.0659 gSAR=0.0006 gMoisture=4.833%Dry matter= 95.167% Conclusion This makes the GDE and CSF6 system suitable for TDF determination and able to provide precise and reliable results. Benefits of GDE and CSF6 units are: Precise temperature control during critical enzymatic digestions ● Integrated Digital Timer (GDE) 膳食纤维是复杂有机物质的混合物,包括亲水化合物,如可溶性和不可溶性多糖和不可消化的低聚糖,以及一系列不膨胀或多或少疏水化合物,如角质,亚铁素和木质素。膳食纤维是人类饮食中的一种重要营养素,具有增强饱腹感、调节肠道功能和调节营养吸收的能力。由于其好处,纤维越来越多地用于功能食品,食品制造商在包装上宣布纤维含量作为营养标签的一部分。检测样品:Corn flakes Fiber labeled value: 3 %(玉米片 纤维素含量3%)检测仪器:膳食纤维测定仪(意大利VELP)参考标准:AOAC 985.29 Total Dietary Fiber in Foods检测结果:结论:这使得GDE和CSF6系统适用于TDF的测定,能够提供准确可靠的结果。 GDE和CSF优势如下:在关键的酶解过程中精确的温度控制集成数字定时器(GDE)在20分钟内过滤和洗涤6个样品(CSF6)

确定

还剩2页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《玉米片中总膳食纤维检测方案(纤维测定仪)》,该方案主要用于其他粮食加工品中营养成分检测,参考标准--,《玉米片中总膳食纤维检测方案(纤维测定仪)》用到的仪器有VELP-膳食纤维测定仪GDE-CFS6

推荐专场

相关方案

更多

该厂商其他方案

更多