方案详情

文

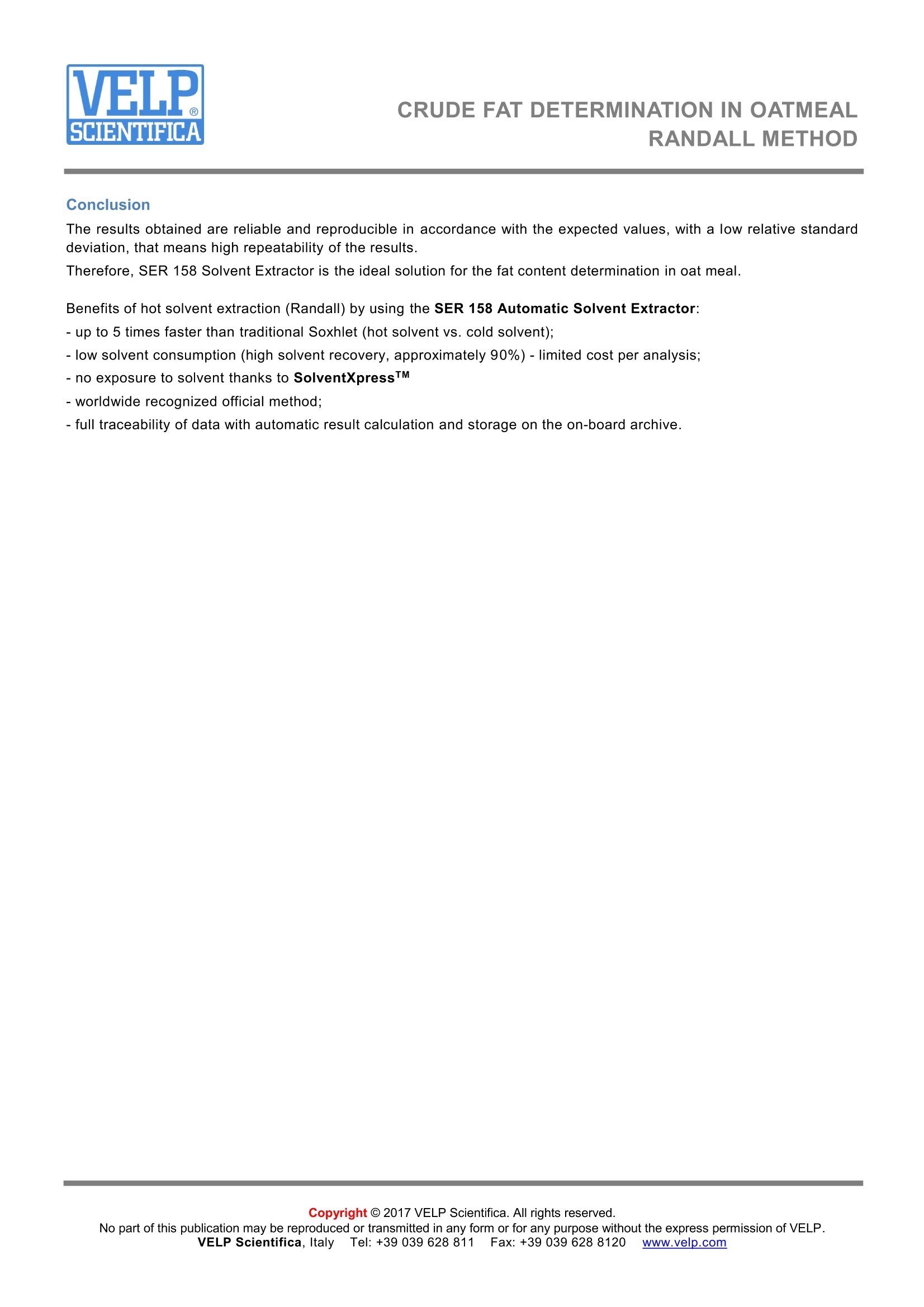

所获得的结果根据预期值是可靠且可重现的,相对标准偏差低,这意味着结果具有较高的可重复性。

因此,SER 158溶剂萃取器是测定燕麦粉中脂肪含量的理想解决方案。

使用SER 158自动溶剂萃取器进行热溶剂萃取的好处:

-比传统的索氏萃取快5倍(热溶剂与冷溶剂);

-低溶剂消耗(高溶剂回收率,约90%)-每次分析的成本有限;

-借助SolventXpressTM,无溶剂暴露

-全球公认的官方方法;

-数据的完全可追溯性,具有自动结果计算并存储在机载档案中

方案详情

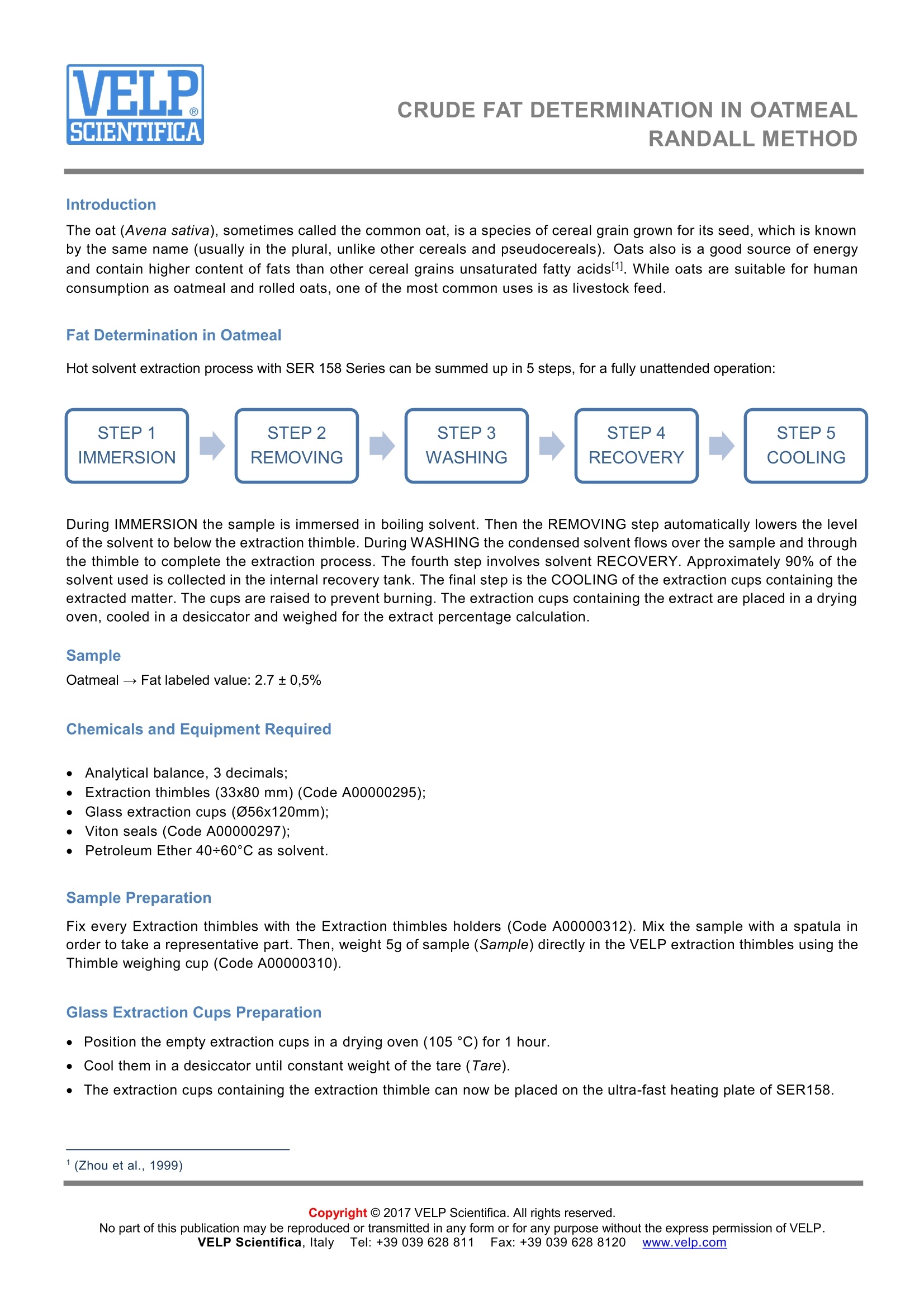

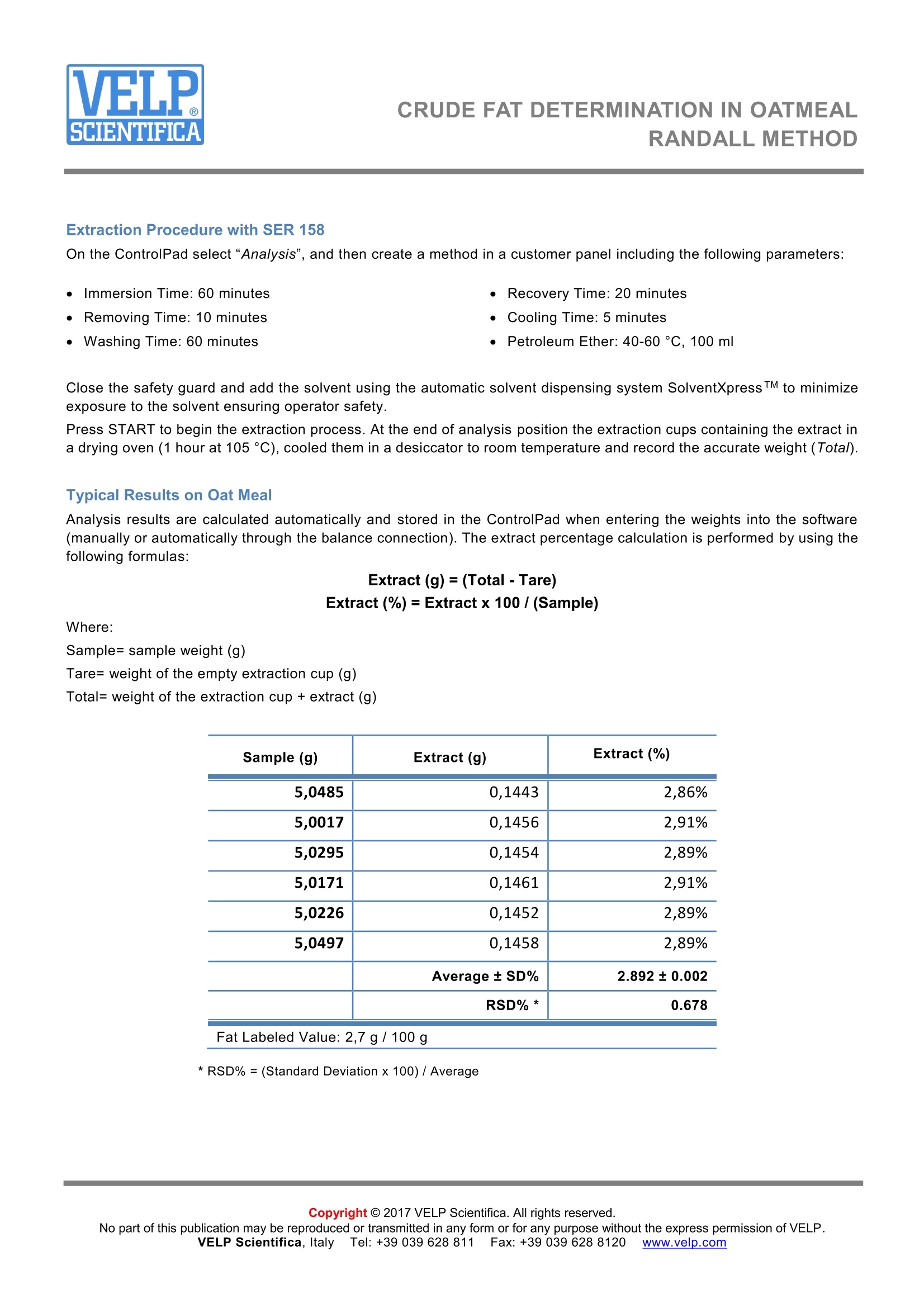

APPLICATION NOTEF&F-S-001-2017/A1 CRUDE FAT DETERMINATION IN OATMEALRANDALL METHOD Crude Fat Determination inOatmeal according to the Randall method Reference: AOAC 2003.05 Crude Fat in Feeds, Cereal Grains,and Forages; Tested with VELP Scientifica SER 158/6 Solvent Auto Extractor (Code S303A0380) Introduction The oat (Avena sativa), sometimes called the common oat, is a species of cereal grain grown for its seed, which is knownby the same name (usually in the plural, unlike other cereals and pseudocereals). Oats also is a good source of energyand contain higher content of fats than other cereal grains unsaturated fatty acids1. While oats are suitable for humanconsumption as oatmeal and rolled oats, one of the most common uses is as livestock feed. Fat Determination in Oatmeal Hot solvent extraction process with SER 158 Series can be summed up in 5 steps, for a fully unattended operation: During IMMERSION the sample is immersed in boiling solvent. Then the REMOVING step automatically lowers the levelof the solvent to below the extraction thimble. During WASHING the condensed solvent flows over the sample and throughthe thimble to complete the extraction process. The fourth step involves solvent RECOVERY. Approximately 90% of thesolvent used is collected in the internal recovery tank. The final step is the COOLING of the extraction cups containing theextracted matter. The cups are raised to prevent burning. The extraction cups containing the extract are placed in a dryingoven,cooled in a desiccator and weighed for the extract percentage calculation. Sample Oatmeal→ Fat labeled value:2.7±0,5% Chemicals and Equipment Required ●Analytical balance,3 decimals; ●Extraction thimbles (33x80 mm) (Code A00000295); .Glass extraction cups (056x120mm); Viton seals (CodeA00000297); Petroleum Ether 40+60°C as solvent. Sample Preparation Fix every Extraction thimbles with the Extraction thimbles holders (Code A00000312). Mix the sample with a spatula inorder to take a representative part. Then, weight 5g of sample (Sample) directly in the VELP extraction thimbles using theThimble weighing cup (Code A00000310). Glass Extraction Cups Preparation ●Position the empty extraction cups in a drying oven (105°C) for 1 hour. ●·Cool them in a desiccator until constant weight of the tare (Tare). The extraction cups containing the extraction thimble can now be placed on the ultra-fast heating plate of SER158. (Zhou et al., 1999) VELP Scientifica, Italy Tel: +39039628811 Fax: +39 0396288120 www.velp.com Extraction Procedure with SER 158 On the ControlPad select“Analysis”, and then create a method in a customer panel including the following parameters: · Immersion Time: 60 minutes · Recovery Time: 20 minutes ● Removing Time: 10 minutes · Cooling Time: 5 minutes Washing Time: 60 minutes · Petroleum Ether: 40-60°C, 100 ml Close the safety guard and add the solvent using the automatic solvent dispensing system SolventXpress TM to minimizeexposure to the solvent ensuring operator safety. Press START to begin the extraction process. At the end of analysis position the extraction cups containing the extract ina drying oven (1 hour at 105°℃), cooled them in a desiccator to room temperature and record the accurate weight (Total). Typical Results on Oat Meal Analysis results are calculated automatically and stored in the ControlPad when entering the weights into the software(manually or automatically through the balance connection). The extract percentage calculation is performed by using thefollowing formulas: Where: Sample=sample weight (g) Tare= weight of the empty extraction cup (g) Total= weight of the extraction cup + extract (g) Sample (g) Extract (g) Extract (%) 5,0485 0,1443 2,86% 5,0017 0,1456 2,91% 5,0295 0,1454 2,89% 5,0171 0,1461 2,91% 5,0226 0,1452 2,89% 5,0497 0,1458 2,89% Average±SD% 2.892±0.002 RSD%* 0.678 Fat Labeled Value: 2,7 g/ 100 g *RSD%= (Standard Deviation x 100) / Average Conclusion The results obtained are reliable and reproducible in accordance with the expected values, with a low relative standarddeviation, that means high repeatability of the results. Therefore, SER 158 Solvent Extractor is the ideal solution for the fat content determination in oat meal. Benefits of hot solvent extraction (Randall) by using the SER 158 Automatic Solvent Extractor: - up to 5 times faster than traditional Soxhlet (hot solvent vs. cold solvent); - low solvent consumption (high solvent recovery, approximately 90%)- limited cost per analysis; -no exposure to solvent thanks to SolventXpressTM -worldwide recognized official method; - full traceability of data with automatic result calculation and storage on the on-board archive. Copyright C VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel: + Fax: + www.velp.com VELP SER158 全自动脂肪测定仪分析燕麦片中的粗脂肪含量:燕麦(Avena sativa),有时也称为普通燕麦,是一种因其种子而生长的谷类谷物,其名称相同(通常为复数形式,与其他谷物和假谷物不同)。 燕麦也是一种良好的能源,其脂肪含量高于其他谷物不饱和脂肪酸[1]。 虽然燕麦适合作为燕麦片和燕麦片供人类食用,但最常见的用途之一是作为牲畜饲料。 详细分析方法请下载全文参考。

确定

还剩2页未读,是否继续阅读?

意大利VELP公司为您提供《燕麦片中粗脂肪检测方案(抽提萃取)》,该方案主要用于其他粮食加工品中营养成分检测,参考标准--,《燕麦片中粗脂肪检测方案(抽提萃取)》用到的仪器有VELP SER 158 全自动脂肪测定仪(索式抽提仪)

推荐专场

相关方案

更多

该厂商其他方案

更多