明胶具有保水、结合、稳定、乳化等特点,并具有保持甜点果冻典型形状的特点。近年来,对于分布在冷冻状态下的家用菜肴来说,它是一种常用于与微波炉兼容的食物,支持当代食品文化,如防止食物在分布过程中变形,以及汤的质量保存、糊化等。使用EMS粘度计测量明胶溶液的凝胶化过程中的动态粘度的范例,该粘度计可以通过密封、灭菌和非接触来测量。

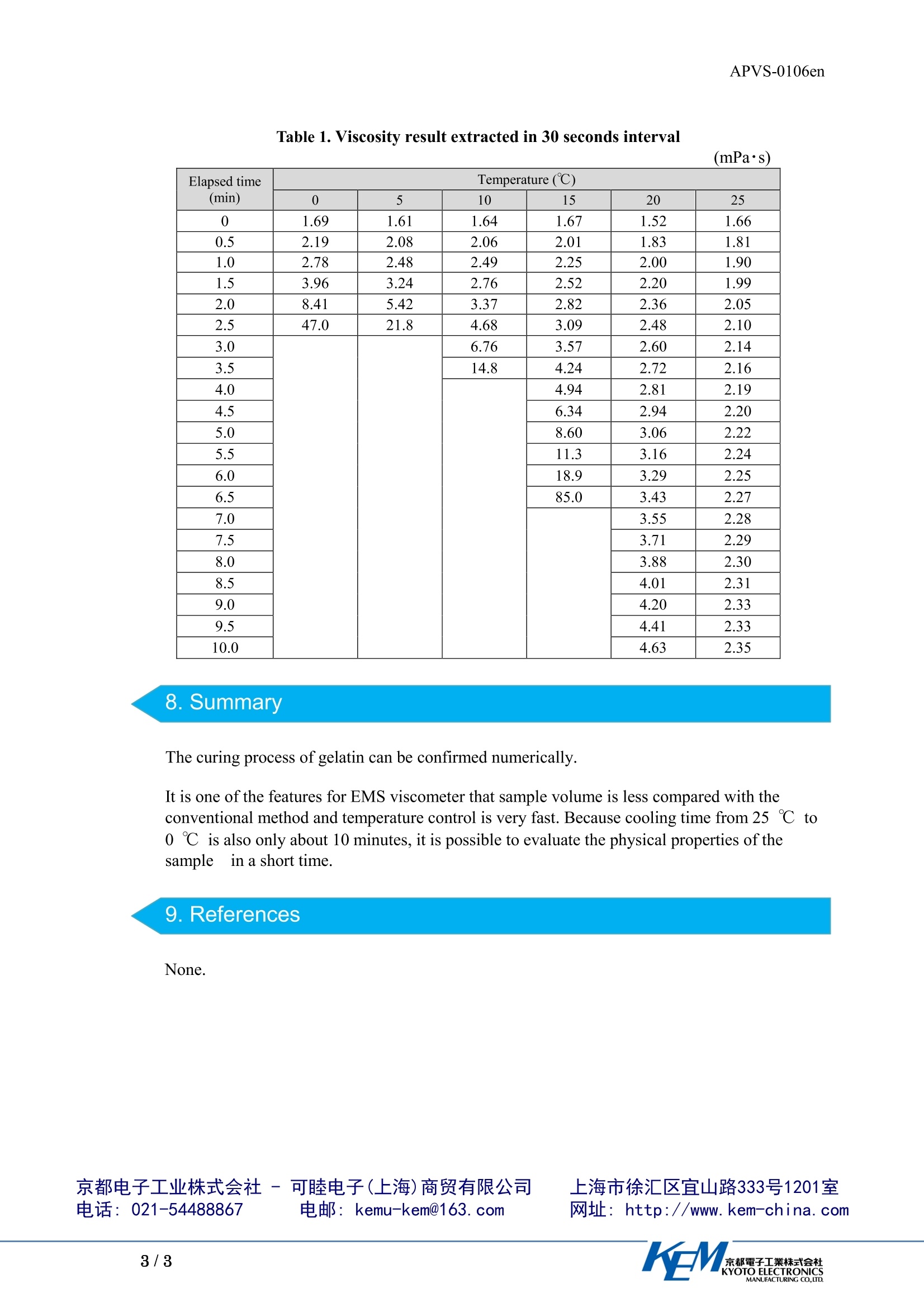

对明胶的固化过程进行了数值模拟。EMS粘度计的特点之一是样品量比传统方法少,温度控制速度快。由于从25°C到0°C的冷却时间也只有10分钟左右,所以可以在短时间内评估样品的物理性能。

方案详情

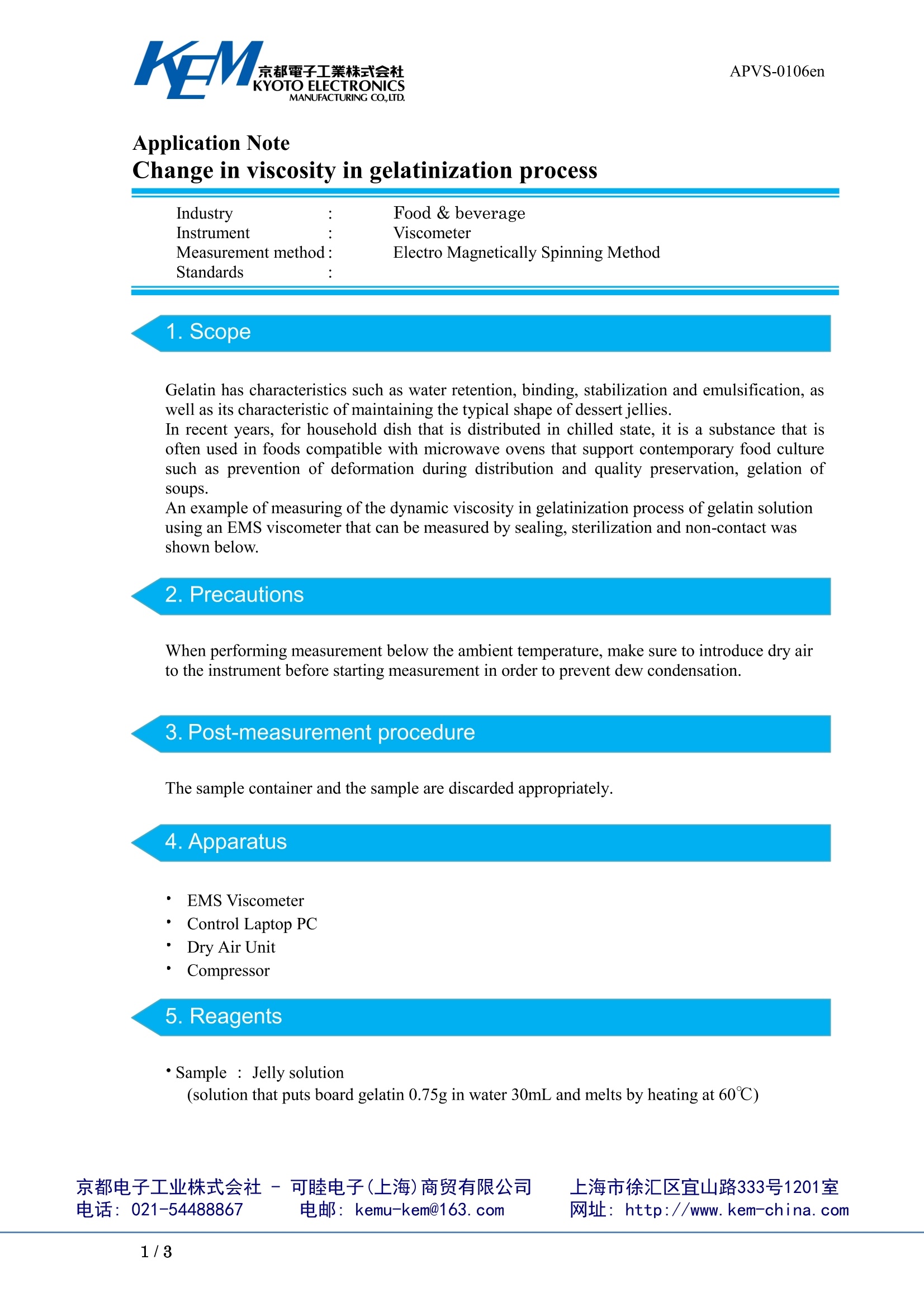

京都電子工業株式会社KYOTO ELECTRONICSAPVS-0106enMANUFACTURING CO.,LTD. APVS-0106en6.Procedure Application Note Change in viscosity in gelatinization process IndustryFood & beverageInstrumentViscometerMeasurement method:Electro Magnetically Spinning MethodStandards 1. Scope Gelatin has characteristics such as water retention, binding, stabilization and emulsification, aswell as its characteristic of maintaining the typical shape of dessert jellies. In recent years, for household dish that is distributed in chilled state, it is a substance that isoften used in foods compatible with microwave ovens that support contemporary food culturesuch as prevention of deformation during distribution and quality preservation, gelation ofsoups. An example of measuring of the dynamic viscosity in gelatinization process of gelatin solutionusing an EMS viscometer that can be measured by sealing, sterilization and non-contact wasshown below. 2.Precautions When performing measurement below the ambient temperature, make sure to introduce dry airto the instrument before starting measurement in order to prevent dew condensation. 3. Post-measurement procedure The sample container and the sample are discarded appropriately. 4. Apparatus EMS Viscometer Control Laptop PC Dry Air Unit Compressor 5.Reagents Sample : Jelly solution (solution that puts board gelatin 0.75g in water 30mL and melts by heating at 60℃) 京都电子工业株式会社-可睦电子(上海)商贸有限公司上海市徐汇区宜山路333号1201室电话:021-54488867 电邮: kemu-kem@163.com网址: http://www.kem-china.com 1) Enter the following conditions in measurement condition of the sequence mode of controlsoftware. Measurement mode :Sequence mode Measurement temperature :0-25℃ (5℃ interval) Motor rotation speed :1,000 rpm Measurement time :I(1 second) Repeat count :100 times (measurement is interrupted when cured) ◇Measurement interval :5 seconds 2) Place an aluminum spherical probe of p 2 mm and the sample in the solid state to a container.cover with a cap and packing, set the sample container in the EMS Viscometer, and click themeasurement button. 3) Set another sample container with the sample into the instrument and change the temperatureafter the measurement of the first sample is completed. After about 10 minutes, measure it insequence. 7.Example The viscosity change in curing process is shown in Figure 1. And the viscosity result extractedin 30 seconds interval at each temperature is shown in Table 1. The cure rate is changed largelydepending on the measurement temperature. Jerry solution is cured more rapidly as the temperature is lower, and its viscosity hardly changed,even if 10 minutes has passed from the start of the measurement at 20℃ or more. Figure 1. Viscosity change in curing process of gelatin 京都电子工业株式会社-可睦电子(上海)商贸有限公司 上海市徐汇区宜山路333号1201室电话:021-54488867 电邮: kemu-kem@163. com 网址: http://www.kem-china.com Table 1. Viscosity result extracted in 30 seconds interval (mPa's) Elapsed time(min) Temperature (℃) 0 5 10 15 20 25 0 1.69 1.61 1.64 1.67 1.52 1.66 0.5 2.19 2.08 2.06 2.01 1.83 1.81 1.0 2.78 2.48 2.49 2.25 2.00 1.90 1.5 3.96 3.24 2.76 2.52 2.20 1.99 2.0 8.41 5.42 3.37 2.82 2.36 2.05 2.5 47.0 21.8 4.68 3.09 2.48 2.10 3.0 6.76 3.57 2.60 2.14 3.5 14.8 4.24 2.72 2.16 4.0 4.94 2.81 2.19 4.5 6.34 2.94 2.20 5.0 8.60 3.06 2.22 5.5 11.3 3.16 2.24 6.0 18.9 3.29 2.25 6.5 85.0 3.43 2.27 7.0 3.55 2.28 7.5 3.71 2.29 8.0 3.88 2.30 8.5 4.01 2.31 9.0 4.20 2.33 9.5 4.41 2.33 10.0 4.63 2.35 8.Summary The curing process of gelatin can be confirmed numerically. It is one of the features for EMS viscometer that sample volume is less compared with theconventional method and temperature control is very fast. Because cooling time from 25℃ to0℃ is also only about 10 minutes, it is possible to evaluate the physical properties of thesamplein a short time. 9. References None. 京都电子工业株式会社-可睦电子(上海)商贸有限公司 上海市徐汇区宜山路333号1201室电话:021-54488867 电邮: kemu-kem@163.com 网址: http://www.kem-china.com 都電子工業株式会社KYOTO ELECTRONICSMANUFACTURING CO.,LTD 明胶糊化过程中黏度的变化的研究 明胶具有保水、结合、稳定、乳化等特点,并具有保持甜点果冻典型形状的特点。近年来,对于分布在冷冻状态下的家用菜肴来说,它是一种常用于与微波炉兼容的食物,支持当代食品文化,如防止食物在分布过程中变形,以及汤的质量保存、糊化等。使用EMS粘度计测量明胶溶液的凝胶化过程中的动态粘度的范例,该粘度计可以通过密封、灭菌和非接触来测量。 对明胶的固化过程进行了数值模拟。EMS粘度计的特点之一是样品量比传统方法少,温度控制速度快。由于从25°C到0°C的冷却时间也只有10分钟左右,所以可以在短时间内评估样品的物理性能。

确定

还剩1页未读,是否继续阅读?

可睦电子(上海)商贸有限公司-日本京都电子(KEM)为您提供《明胶中糊化过程中黏度变化检测方案(粘度计)》,该方案主要用于其他食品中理化分析检测,参考标准--,《明胶中糊化过程中黏度变化检测方案(粘度计)》用到的仪器有EMS-1000S 电磁旋转粘度计

推荐专场

相关方案

更多

该厂商其他方案

更多