您将了解到:

模拟红细胞生成素肽产品的亚可见颗粒含量、配方和剂量与上市后的严重不良事件的相关性

预灌封注射器中的蛋白质聚集和颗粒形成

超越极限:油浸型流式显微镜

利用流动成像显微镜(FLOWCAM)追踪沉积速度,确定PLGA微粒的孔隙率

流动成像显微镜数据的深度卷积神经网络分析对蛋白质配方中的亚细胞进行分类

方案详情

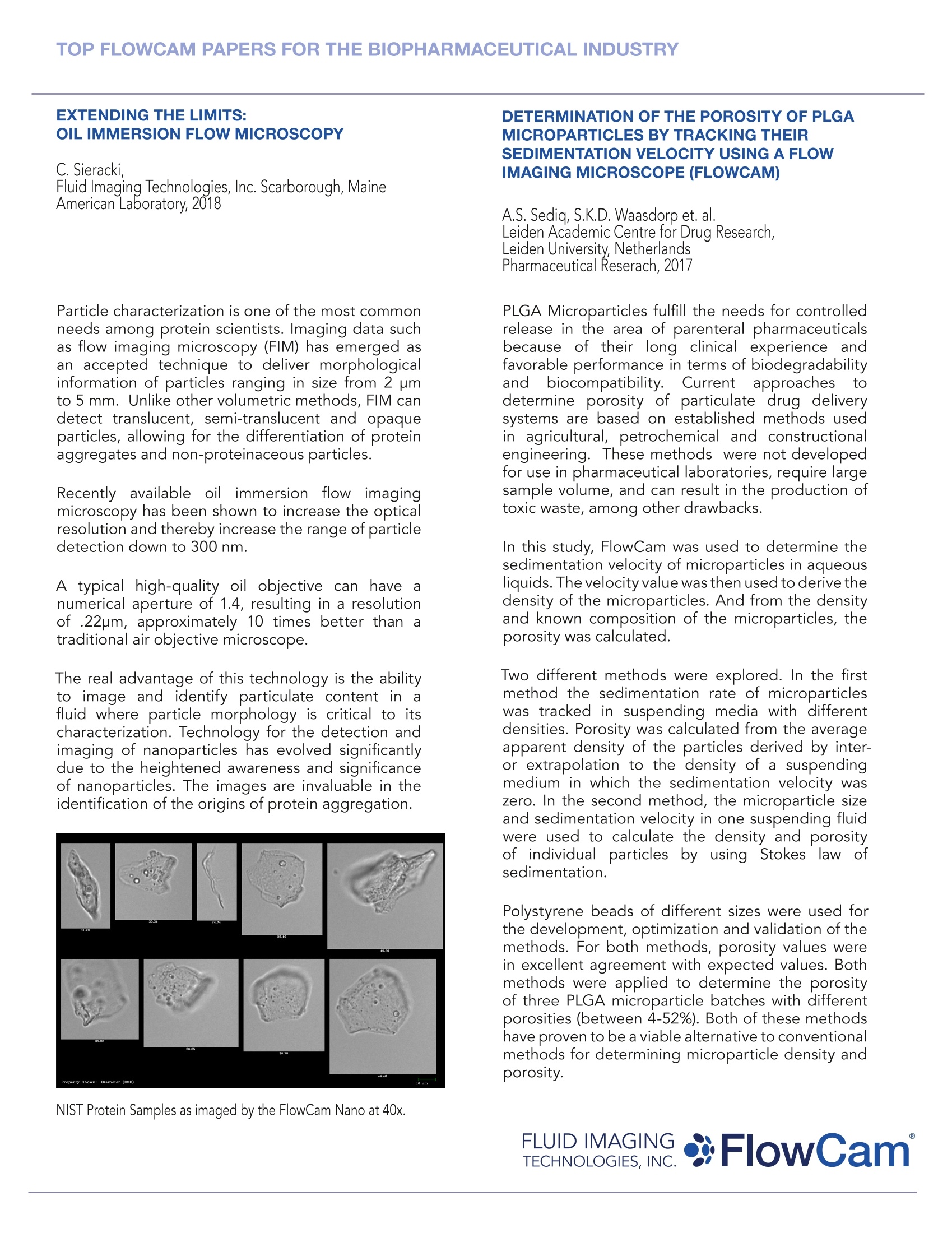

TOP FLOWCAM PAPERS FOR THE BIOPHARMACEUTICAL INDUSTRY Top Influential FlowCam Papers for Biopharmaceutical Industry SUBVISIBLE PARTICLE CONTENT, FORMULATION,AND DOSE OF AN ERYTHROPOIETIN PEPTIDEMIMETIC PRODUCT ARE ASSOCIATED WITHSEVERE ADVERSE POST-MARKETING EVENTS J.Kotarek, C. Stuart et al.Center for Biologics Evaluation & Reserach, US Food and DrugAdministration, Silver Spring, MarylandJournal of Pharmaceutical Sciences, 2016 OmontysQ- a brand name peginesatide injectable -was voluntarily withdrawn from the market less thana year after the product launch. Clinical trials haddemonstrated the drug to be safe and efficacious,but over 40 cases of anaphylaxis, and 7 fatalities werereported soon after the product was introduced to themarket. Omontys was manufactured and approved asboth a single-use vial (SUV) and a multiuse vial (MUV),which differed in their formulation. Clinical trialsprimarily used the SUV formulation, but only the MUVformulation was marketed. In this study the FlowCam was used to evaluate theparticle profile of SUV and MUV samples. The particleimages captured by the FlowCam were then analyzedusing VisualSpreadsheetQ. The:FlowCamnrevealed asignificantly higherconcentration of subvisiblee particles in the MUVPalticiespresentation and correlates to the cases of anaphylaxis.Althoughit isunknownwhetherrthe elevatedparticulate content contributed to these seriousadverse events of the drug, the report illustrates theimportance of capturing and characterizing subvisibleparticulates. The peginesatide samples passed USP <788> limitsfor particulates, but the methods of particle analysisused by the FDA task force suggest that moresensitive analytical monitoring of SVP (via FlowCam)can differentiate protein aggregates, silicon oil, and airbubbles from otherparticles that would otherwise goundetected using light obscuration alone. PROTEIN AGGREGATION AND PARTICLEFORMATION IN PREFILLED GLASS SYRINGES A. Gerhardt, N. McGraw et al.Department of Chemical & Biological Engineering,Universityof Colorado-BoulderJournal of Pharmaceutical Sciences, 2014 The stability of therapeutic proteins formulated inprefilled syringes (PFS) may be negatively impactedby the exposure of protein molecules to siliconeoil-water interfacessandair-water interfaces. Inaddition, agitation, such as that experienced duringtransportation, may increase the detrimental effects(i.e., protein aggregation and particle formation) ofprotein interactions with interfaces. In this study, surfactant-free formulations containingeither a monoclonalI antibody or lysozyme wereincubated in PFS and exposed to silicone oil-waterinterfaces5C(siliconizedssyringe walls),/iair-waterinterfaces (air bubbles), and agitation stress (end-over-end rotation). Using FlowCam particles≥2’ um diameter weredetected under all conditions. In addition to theparticle images that appeared to reflect primarilyspherically shaped silicone oil droplets and non-spherical protein aggregates, there were images ofparticles that consisted of silicone oil droplets coatedwith aggregated protein. Furthermore, several imagesshowedlarge agglomerationsi(ofprotein-coatedsilicone oil droplets. The FlowCam was instrumental in identifying underwhat circumstance the highest particle concentrationswere found; in agitated, siliconized syringes containingan air bubble. The particles formed in this conditionconsisted of silicone oil droplets and aggregatedprotein, as well as agglomerates of protein aggregatesand silicone oil. FLUID IMAGINGTECHNOLOGIES, INC. +1-207-289-3200 contact@fluidimaging.com EXTENDING THE LIMITS:OIL IMMERSION FLOW MICROSCOPY aSierack, FluidImaging Technologies, Inc. Scarborough, MaineAmerican Laboratory, 2018 Particle characterization is one of the most commonneeds among protein scientists. Imaging data suchas flow imaging microscopy (FIM) has emerged asan accepted technique to deliver morphologicalinformation of particles ranging in size from 2 pmto 5 mm. Unlike other volumetric methods, FIM candetect translucent, semi-translucent and opaqueparticles, allowing for the differentiation of proteinaggregates and non-proteinaceous particles. Recently available oilimmersion flowimagingmicroscopy has been shown to increase the opticalresolution and thereby increase the range of particledetection down to 300 nm. A typical high-quality oil objective can have anumerical aperture of 1.4, resulting in a resolutionof .22um, approximately 10 times better than atraditional air objective microscope. The real advantage of this technology is the abilityto image and identify particulate content iniafluid where particle morphology is critical to itscharacterization. Technology for the detection andimaging of nanoparticles has evolved significantlydue to the heightened awareness and significanceof nanoparticles. The images are invaluable in theidentification of the origins of protein aggregation. NIST Protein Samples as imaged by the FlowCam Nano at 40x. DETERMINATION OF THE POROSITY OFPLGAMICROPARTICLES BY TRACKING THEIRSEDIMENTATION VELOCITY USING AFLOWIMAGING MICROSCOPE (FLOWCAM) A.S. Sedig, S.K.D. Waasdorp et. al.Leiden Academic Centre for Drug Research,Leiden University, NetherlandsPharmaceutical Reserach, 2017 PLGA Microparticles fulfill the needs for controlledrelease in the area of parenteral pharmaceuticalsbecause of their long clinical experience andfavorable performance in terms of biodegradabilityand comatibilitYSurrentapproachestodetermine porosity of particulate drug deliverysystems are based on established methods usedin agricultural, petrochemicaland constructionalengineering. These methodss were not developedfor use in pharmaceutical laboratories, require largesample volume, and can result in the production oftoxic waste, among other drawbacks. In this study, FlowCam was used to determine thesedimentation velocity of microparticles in aqueousliquids.The velocity value was then used to derive thedensity of the microparticles. And from the densityand known composition of the microparticles, thedgporosity was calculated. Two different methods were explored. In the firstmethod the sedimentation rate of microparticleswas tracked in suspending media with differentdensities. Porosity was calculated from the averageapparent density of the particles derived by inter-or extrapolation to the density of a suspendingmedium in which the sedimentation velocity waszero. In the second method, the microparticle sizeand sedimentation velocity in one suspending fluidwere used to calculate the density and porosityof individluuaall particles by using Stokeslawsedimentation. Polystyrene beads of different sizes were used forthe development, optimization and validation of themethods. For both methods, porosity values werein excellent agreement with expected values. Bothmethods were applied to determine the porosityof three PLGA microparticle batches with differentporosities (between 4-52%). Both of these methodshave proven to be a viable alternative to conventionalmethods for determining microparticle density andporosity. Flow-imaging microscopy (FIM) FlowCam, is commonly usedto characterize subvisiblee particles in therapeutic proteinformulations. iAlthough pharmaceutical companies oftencollect large repositories of FIM images of protein therapeuticproducts, current state-of-the-art methods for analyzing theseimages rely on low-dimensional lists of "morphological features"to characterize particles that ignore much of the informationencoded in the existing image databases. Deep convolutional neural networks (sometimes referred to as"CNNs or ConvNets") have demonstrated the ability to extractpredictive information from raw image data without requiringthe selection or specification of "morphological features".However, the inherent heterogeneity of protein therapeuticsand optical phenomena associated with subvisible FIM particlemeasurementsintroducesnewnchallengesregardingttheapplication of ConvNets to FIM image analysis. In this study,aa ssupervised learning technique leveragingConvNets is used to extract information from raw images inorder to predict the process conditions or stress states (freeze-thawing, mechanical shaking, etc.) that produced a variety ofprotein particle morphologies. For example, one ConvNet was trained to differentiate between2 different mixtures of protein aggregates and silicone oilmicrodroplets. Error-free classification of these 2 formulations ofsilicone oil and protein mixtures was obtained. We demonstrate that the new classifier, in combination witha "data pooling" strategy, can nearly perfectly differentiatebetween protein formulations inna variety of scenarios ofrelevance to protein therapeutics quality control and processmonitoring using as few as 20 particles imaged via FIM. Sample FlowCam image collages from 2 of the protein/sili-cone oil mixture data sets +1-207-289-3200,FlowCam FLUID IMAGINGTECHNOLOGIES, INC. contact@fluidimaging.com www.fluidimaging.com ,FlowCam°www.fluidimaging.comCONTINUED ONREVERSE ;FlowCamTECHNOLOGIES, INC. 您将了解到:模拟红细胞生成素肽产品的亚可见颗粒含量、配方和剂量与上市后的严重不良事件的相关性预灌封注射器中的蛋白质聚集和颗粒形成超越极限:油浸型流式显微镜利用流动成像显微镜(FLOWCAM)追踪沉积速度,确定PLGA微粒的孔隙率流动成像显微镜数据的深度卷积神经网络分析对蛋白质配方中的亚细胞进行分类

确定

还剩1页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《PLGA微粒中表征分析检测方案(图像粒度粒形)》,该方案主要用于原料药中理化性质检测,参考标准--,《PLGA微粒中表征分析检测方案(图像粒度粒形)》用到的仪器有流式颗粒成像分析系统FlowCam®8100、颗粒成像法+光阻法分析系统 FlowCam® + LO、纳米流式颗粒成像分析系统 FlowCam® Nano

推荐专场

相关方案

更多

该厂商其他方案

更多