电网中不断变化的可再生能源中不断增加的电力需要实现像电池和燃料电池这样的转化装置,以实现能源供应与需求之间的平衡。为了优化系统,延长寿命,有必要对这些装置的后操作缺陷和腐蚀情况进行说明。这些设备的许多部件都是复杂的多孔材料,由不同的隔间组成,不仅是关于表面的形貌,而且是关于体积形态的知识。因此,高分辨率的计算机断层扫描(CT)可以用来在微观和纳米尺度上成像三维(三维)结构,提供关于材料的组成和老化效应的定性信息。本文的目的是通过对三种成分的研究和评价,来证明CT在电化学能量存储和转化装置的研究领域中的应用,并给出其内部变化和特性的有价值的信息。附件是奥尔登堡大学的能源技术研究中心的相关研究报告。

方案详情

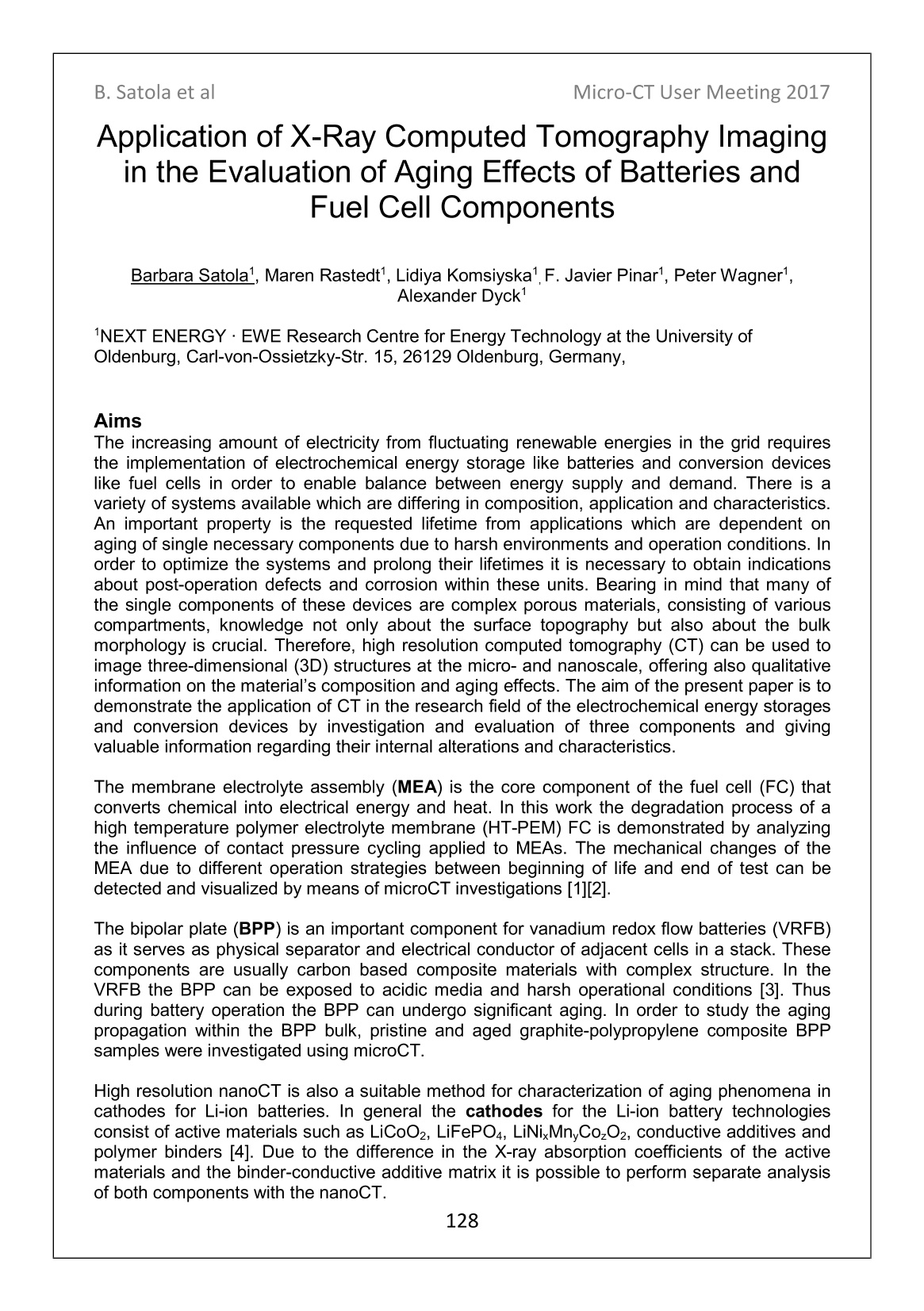

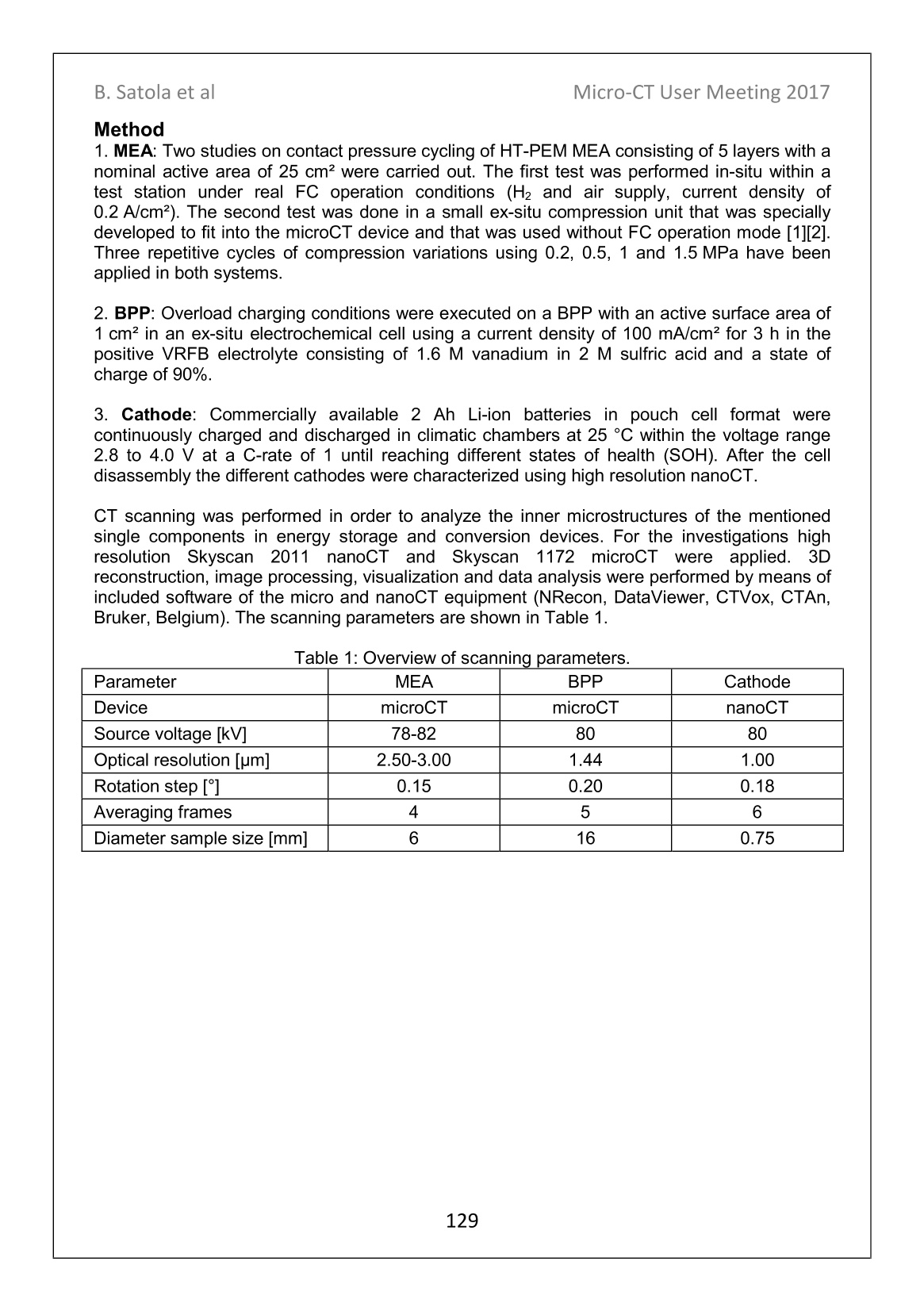

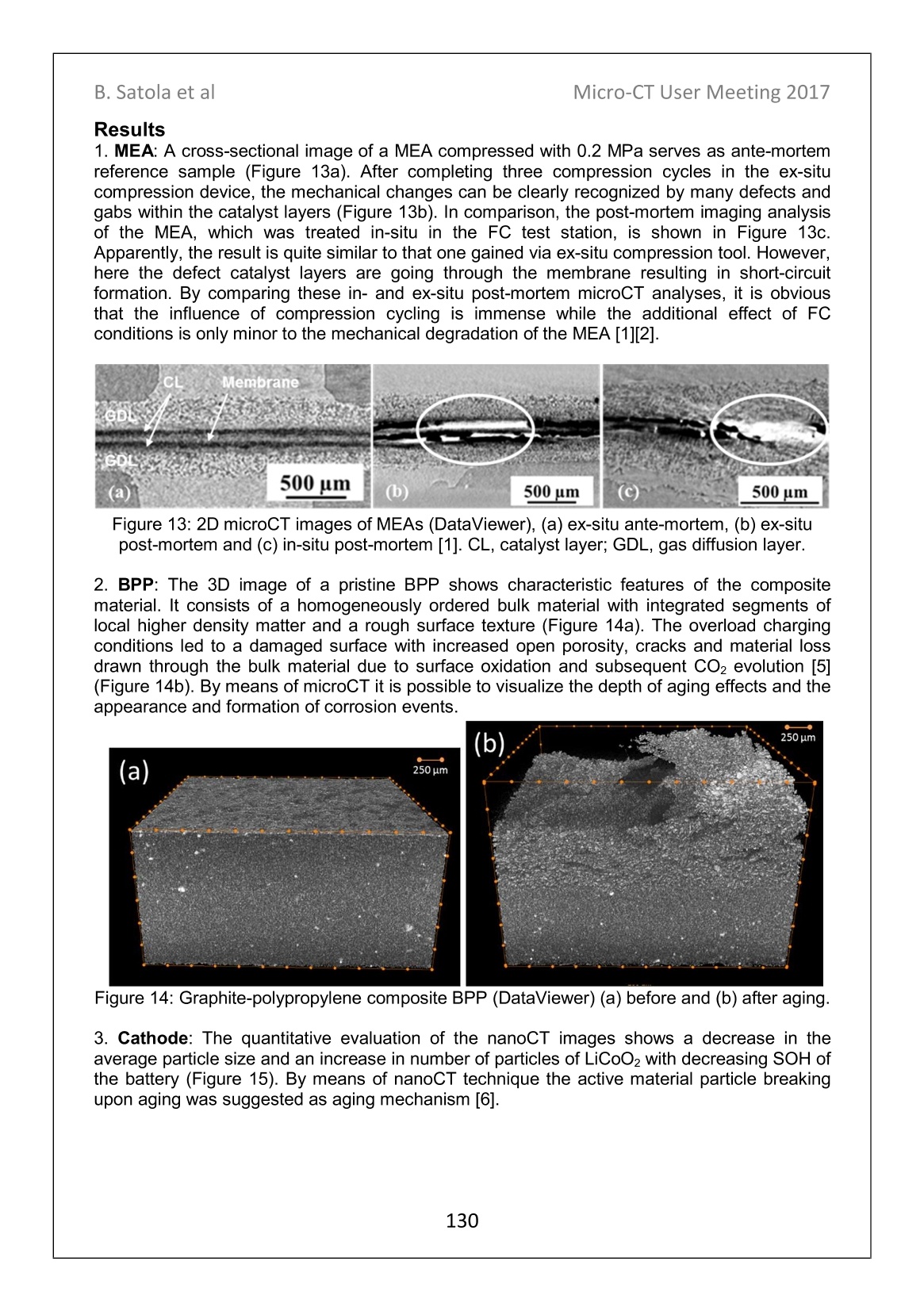

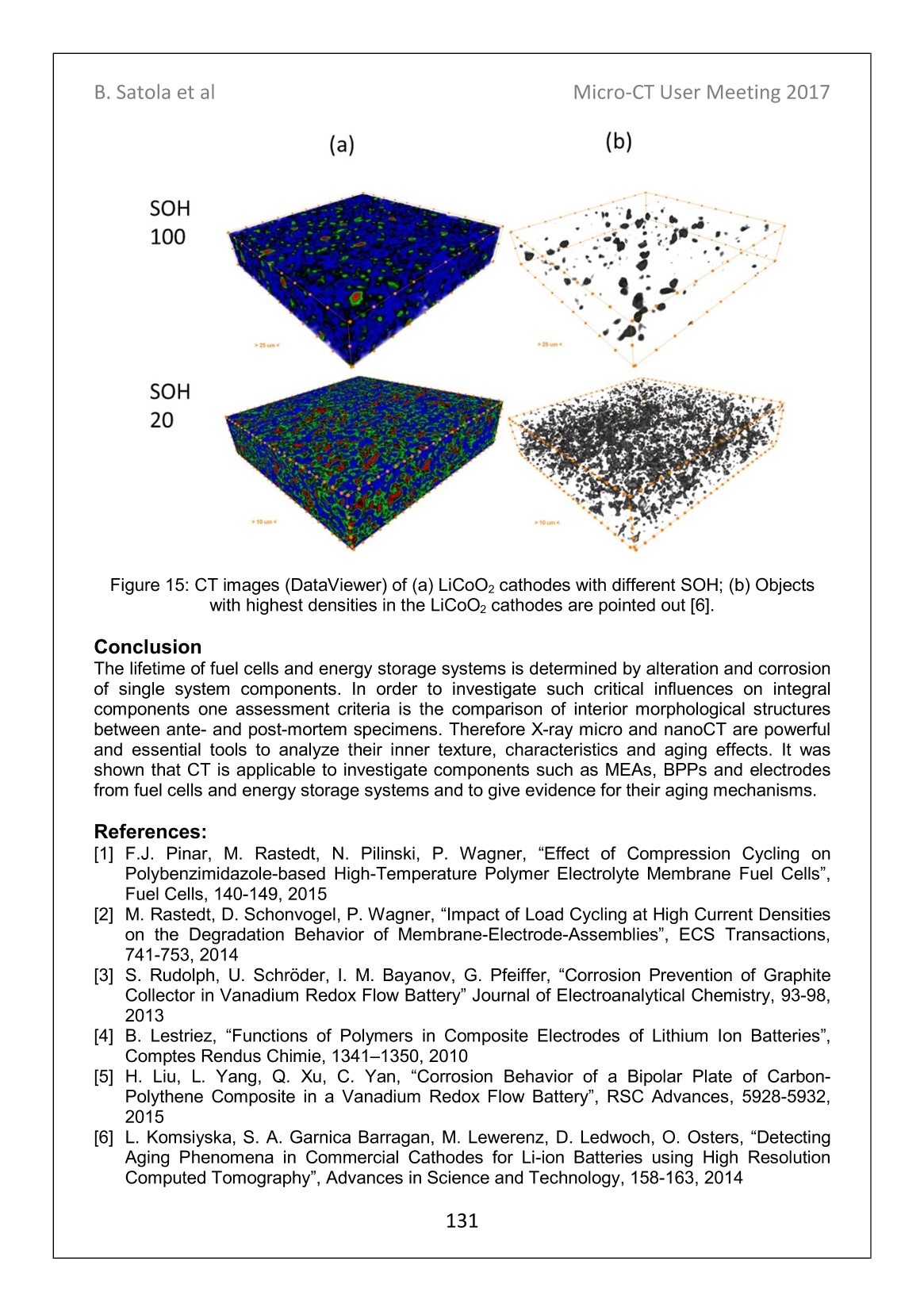

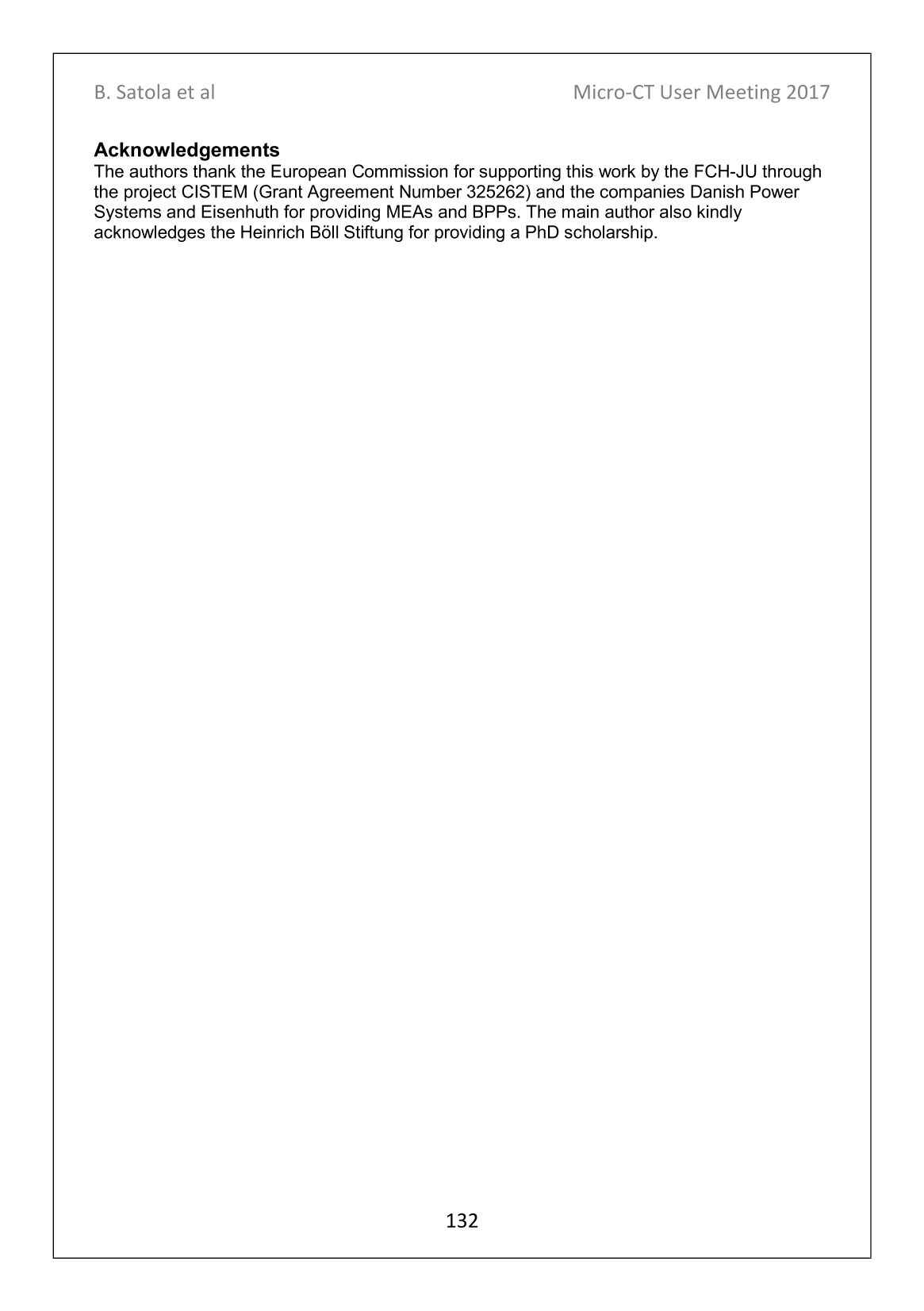

B. Satola et al Micro-CT User Meeting 2017 Application of X-Ray Computed Tomography Imagingin the Evaluation of AgingEffects of Batteries andFuel Cell Components Barbara Satola1, Maren Rastedt1, Lidiya Komsiyska,F. Javier Pinar1, Peter Wagner1,Alexander Dyck 1NEXT ENERGY · EWE Research Centre for Energy Technology at the University ofOldenburg, Carl-von-Ossietzky-Str. 15, 26129 Oldenburg, Germany, Aims The increasing amount of electricity from fluctuating renewable energies in the grid requiresthe implementation of electrochemical energy storage like batteries and conversion deviceslike fuel cells in order to enable balance between energy supply and demand. There is avariety of systems available which are differing in composition, application and characteristics.An important property is the requested lifetime from applications which are dependent onaging of single necessary components due to harsh environments and operation conditions. Inorder to optimize the systems and prolong their lifetimes it is necessary to obtain indicationsabout post-operation defects and corrosion within these units. Bearing in mind that many ofthe single components of these devices are complex porous materials, consisting of variouscompartments, knowledge not only about the surface topography but also about the bulkmorphology is crucial. Therefore, high resolution computed tomography (CT) can be used toimage three-dimensional (3D) structures at the micro- and nanoscale, offering also qualitativeinformation on the material's composition and aging effects. The aim of the present paper is todemonstrate the application of CT in the research field of the electrochemical energy storagesand conversion devices by investigation and evaluation of three components and givingvaluable information regarding their internal alterations and characteristics. The membrane electrolyte assembly (MEA) is the core component of the fuel cell (FC) thatconverts chemical into electrical energy and heat. In this work the degradation process of ahigh temperature polymer electrolyte membrane (HT-PEM) FC is demonstrated by analyzingthe influence of contact pressure cycling applied to MEAs. The mechanical changes of theMEA due to different operation strategies between beginning of life and end of test can bedetected and visualized by means of microCT investigations [1][2]. The bipolar plate (BPP) is an important component for vanadium redox flow batteries (VRFB)as it serves as physical separator and electrical conductor of adjacent cells in a stack. Thesecomponents are usually carbon based composite materials with complex structure. In theVRFB the BPP can be exposed to acidic media and harsh operational conditions [3]. Thusduring battery operation the BPP can undergo significant aging. In order to study the agingpropagation within the BPP bulk, pristine and aged graphite-polypropylene composite BPPsamples were investigated using microCT. High resolution nanoCT is also a suitable method for characterization of aging phenomena incathodes for Li-ion batteries. In general the cathodes for the Li-ion battery technologiesconsist of active materials such as LiCoO2, LiFePO4,LiNixMnyCozO2, conductive additives andpolymer binders [4]. Due to the difference in the X-ray absorption coefficients of the activematerials and the binder-conductive additive matrix it is possible to perform separate analysisof both components with the nanoCT. B. Satola et al Micro-CT User Meeting 2017 Method 1. MEA: Two studies on contact pressure cycling of HT-PEM MEA consisting of 5 layers with anominal active area of 25 cm² were carried out. The first test was performed in-situ within atest station under real FC operation conditions (H2 and air supply, current density of0.2 A/cm2). The second test was done in a small ex-situ compression unit that was speciallydeveloped to fit into the microCT device and that was used without FC operation mode [1][2].Three repetitive cycles of compression variations using 0.2, 0.5, 1 and 1.5 MPa have beenapplied in both systems. 2. BPP: Overload charging conditions were executed on a BPP with an active surface area of1 cm² in an ex-situ electrochemical cell using a current density of 100 mA/cm² for 3 h in thepositive VRFB electrolyte consisting of 1.6 M vanadium in 2 M sulfric acid and a state ofcharge of 90%. 3. Cathode: Commercially available 2 Ah Li-ion batteries in pouch cell format werecontinuously charged and discharged in climatic chambers at 25 °C within the voltage range2.8 to 4.0 V at a C-rate of 1 until reaching different states of health (SOH). After the celldisassembly the different cathodes were characterized using high resolution nanoCT. CT scanning was performed in order to analyze the inner microstructures of the mentionedsingle components in energy storage and conversion devices. For the investigations highresolutionSkyscan2011 nanoCTandSkyscan1172microCT were applied. 33Dreconstruction, image processing, visualization and data analysis were performed by means ofincluded software of the micro and nanoCT equipment (NRecon, DataViewer, CTVox, CTAn,Bruker, Belgium). The scanning parameters are shown in Table 1. Table 1: Overview of scanning parameters. Parameter MEA BPP Cathode Device microCT microCT nanoCT Source voltage [kV] 78-82 80 80 Optical resolution [um] 2.50-3.00 1.44 1.00 Rotation step [] 0.15 0.20 0.18 Averaging frames 4 5 6 Diameter sample size [mm] 6 16 0.75 B. Satola et al Micro-CT User Meeting 2017 Results 1. MEA: A cross-sectional image of a MEA compressed with 0.2 MPa serves as ante-mortemreference sample (Figure 13a). After completing three compression cycles in the ex-situcompression device, the mechanical changes can be clearly recognized by many defects andgabs within the catalyst layers (Figure 13b). In comparison, the post-mortem imaging analysisof the MEA, which was treated in-situ in the FC test station, is shown in Figure 13c.Apparently, the result is quite similar to that one gained via ex-situ compression tool. However,here the defect catalyst layers are going through the membrane resulting in short-circuitformation. By comparing these in- and ex-situ post-mortem microCT analyses, it is obviousthat the influence of compression cycling is immense while the additional effect of FCconditions is only minor to the mechanical degradation of the MEA [1][2]. Figure 13: 2D microCT images of MEAs (DataViewer), (a) ex-situ ante-mortem, (b) ex-situpost-mortem and (c) in-situ post-mortem [1]. CL, catalyst layer; GDL, gas diffusion layer. 2. BPP: The 3D image of a pristine BPP shows characteristic features of the compositematerial. It consists of a homogeneously ordered bulk material with integrated segments oflocal higher density matter and a rough surface texture (Figure 14a). The overload chargingconditions led to a damaged surface with increased open porosity, cracks and material lossdrawn through the bulk material due to surface oxidation and subsequent CO2 evolution [5](Figure 14b). By means of microCT it is possible to visualize the depth of aging effects and theappearance and formation of corrosion events. Figure 14: Graphite-polypropylene composite BPP (DataViewer) (a) before and (b) after aging. 3. Cathode: The quantitative evaluation of the nanoCT images shows a decrease in theaverage particle size and an increase in number of particles of LiCoO2 with decreasing SOH ofthe battery (Figure 15). By means of nanoCT technique the active material particle breakingupon aging was suggested as aging mechanism [6]. Figure 15: CT images (DataViewer) of (a)LiCoO2 cathodes with different SOH; (b) Objectswith highest densities in the LiCoO2 cathodes are pointed out [6]. Conclusion The lifetime of fuel cells and energy storage systems is determined by alteration and corrosionof single system components. In order to investigate such critical influences on integralcomponents one assessment criteria is the comparison of interior morphological structuresbetween ante- and post-mortem specimens. Therefore X-ray micro and nanoCT are powerfuland essential tools to analyze their inner texture, characteristics and aging effects. It wasshown that CT is applicable to investigate components such as MEAs, BPPs and electrodesfrom fuel cells and energy storage systems and to give evidence for their aging mechanisms. References: ( [1] F.J. Pinar, M. Rastedt, N. Pilinski, P. Wagner, “Effect of Compression Cycling o nPolybenzimidazole-based H i gh-Temperature Polymer Electrolyte Membrane Fuel Cells", Fuel Cells, 140-149, 2015 ) ( [2] M. Rastedt, D. Schonvogel, P. Wagner,“I m pact of Load Cy c ling at High Current Densitieson t he D egradation Behavior o f M e mbrane-Electrode-Assemblies", EC S Transactions, 741-753,2014 ) ( [3] S. Rudolph, U . S c hroder, I. M. Bayanov, G. Pfe i ffer, “C o rrosion Pre v ention of GraphiteCollector in Vanadium R edox Flow Battery”Journal of Electroanalytical Chemistry, 93-98, 2013 ) ( [4] B. Lestriez, “Functions of Polymers in Composite E l ectrodes o f Lithium lon B a tteries”,Comptes Rendus Chimie, 1341-1350,2010 ) [5] H. Liu, L. Yang, Q. Xu, C. Yan, “Corrosion Behavior of a Bipolar Plate of Carbon-Polythene Composite in a Vanadium Redox Flow Battery”, RSC Advances, 5928-5932,2015 [6] L. Komsiyska, S. A. Garnica Barragan, M. Lewerenz, D. Ledwoch, O. Osters,“DetectingAging Phenomena in Commercial Cathodes for Li-ion Batteries using High ResolutionComputed Tomography”, Advances in Science and Technology, 158-163, 2014 电网中不断变化的可再生能源中不断增加的电力需要实现像电池和燃料电池这样的转化装置,以实现能源供应与需求之间的平衡。为了优化系统,延长寿命,有必要对这些装置的后操作缺陷和腐蚀情况进行说明。这些设备的许多部件都是复杂的多孔材料,由不同的隔间组成,不仅是关于表面的形貌,而且是关于体积形态的知识。因此,高分辨率的计算机断层扫描(CT)可以用来在微观和纳米尺度上成像三维(三维)结构,提供关于材料的组成和老化效应的定性信息。本文的目的是通过对三种成分的研究和评价,来证明CT在电化学能量存储和转化装置的研究领域中的应用,并给出其内部变化和特性的有价值的信息。附件是奥尔登堡大学的能源技术研究中心的相关研究报告。

确定

还剩3页未读,是否继续阅读?

束蕴仪器(上海)有限公司为您提供《电池组件中CT老化效应检测方案(工业CT)》,该方案主要用于锂电池中CT老化效应检测,参考标准--,《电池组件中CT老化效应检测方案(工业CT)》用到的仪器有skyscanX射线纳米CT

推荐专场

相关方案

更多

该厂商其他方案

更多