Surfaces with steep flanks and varying reflective properties are usually not measurable with conventional surface measurement techniques, even though there is an ongoing miniaturization of components and rising demand for automation in industry. A solution can be provided by “Focus Variation”, a new optical measurement technique that allows the robust measurement of complex surfaces with vertical resolutions up to 10 nm. In addition to topographic data, true colour information that is perfectly registered to the

height data is obtained. The optical 3D measurement device “InfiniteFocus” is based on this new technology and provides a significant improvement in quality assurance. Allowing surface measurements in the micro and nano range as well as relatively large components, the Instrument can be used in the lab and as a measurement tool during production.

方案详情

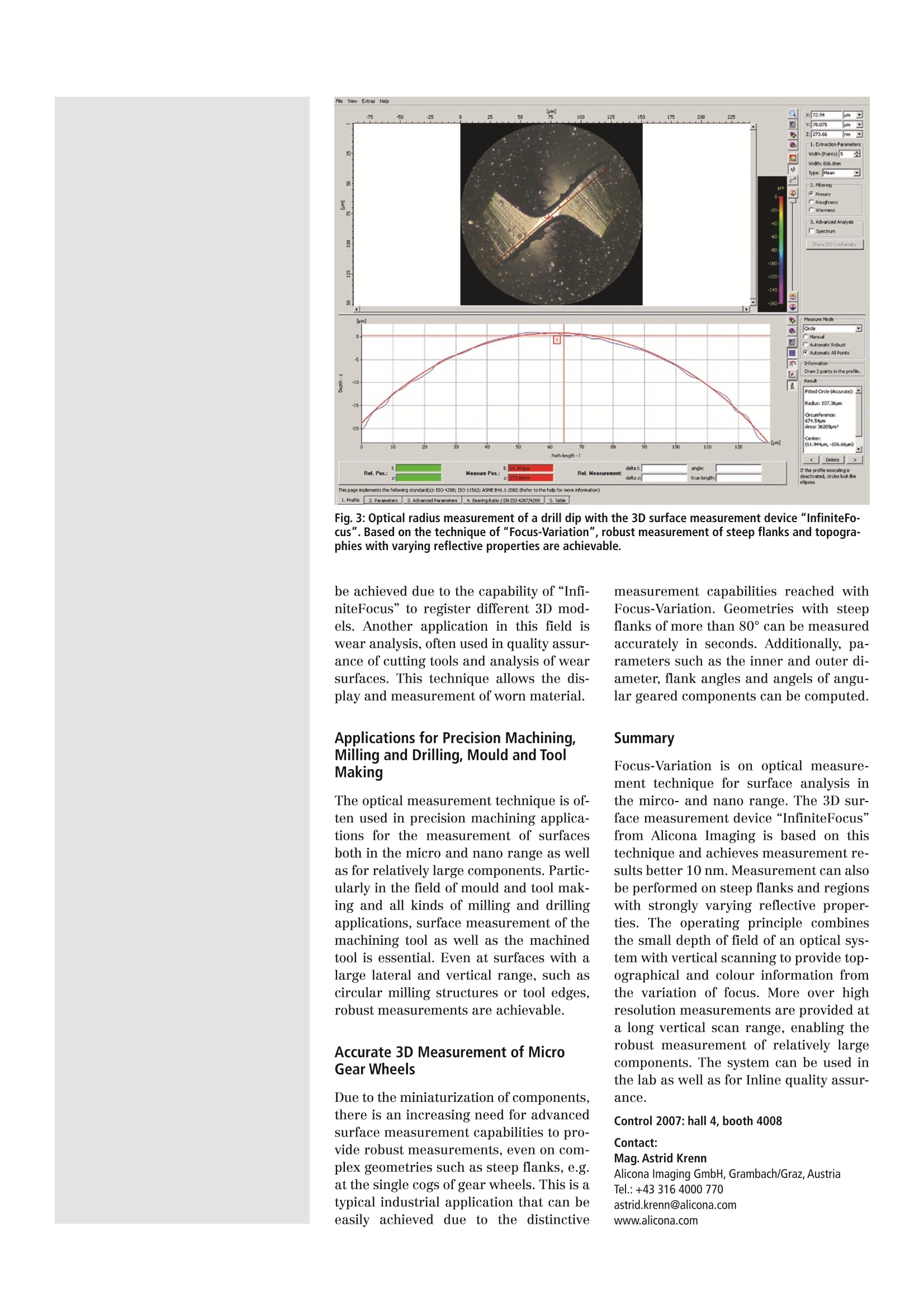

G.I.T. Imaging & Microscopy 01/2007, pp 38-40, GIT VERLAG GmbH & Co. KG, Darmstadtwww.gitverlaq.com www.PRO-4-PRO.com Advanced OpticalSurface Metrology 3D Measurements of Surfaces with Steep Flanks Surfaces with steep flanks and varying reflective properties are usually not measurable with conventionalsurface measurement techniques, even though there is an ongoing miniaturization of components and ris-ing demand for automation in industry. A solution can be provided by "Focus Variation", a new opticalmeasurement technique that allows the robust measurement of complex surfaces with vertical resolutionsup to 10 nm. In addition to topographic data, true colour information that is perfectly registered to theheight data is obtained. The optical 3D measurement device "InfiniteFocus" is based on this new technologyand provides a significant improvement in quality assurance. Allowing surface measurements in the microand nano range as well as relatively large components, the Instrument can be used in the lab and as a meas-urement tool during production. optical surfacemeasurement tech-niques are well established in industry,but they still hardly provide robustmeasurement of surfaces that meets thedemands for speed, accuracy, repeata-bility and Inline-capability. However,“Focus-Variation”allows advanced opti-cal 3D surface metrology enabling therobust and repeatable measurement ofcomponents with steep flanks and vary-ing reflective properties with a verticalresolution up to 10 nm. This new opticaltechnology is the core of the opticalmeasurement system InfiniteFocus anddelivers dense measurements over largeareas with a density of 2 million to 16million measurement points. Regardlesswhether it is used in the lab or duringproduction, this technique works fasterand more accurate than conventionalmethods. Measurementsover ahigh vertical scan range are provided with ahigh vertical resolution, also enablingthe robust measurement of relativelylarge components. Robust Optical Surface Measurement The operating principle of Focus-Varia-tion, developed by Alicona Imaging, com-bines the small depth of field of an opti-cal system with vertical scanning toprovide topographical and colour infor-mation from the variation of focus. De-pending on the topography of a surface,the information from the variation of fo-cus is analyzed in relation to the dis-tance to the optics. Usingconventionalopticall measurement techniquesahigh vertical resolution can only bereached with a small vertical scan-ning range,whereas the use of Infi-niteFocus yields a high verticalresolution over the entire scan-ning range, allowing a dynamicof 1:200000. Unlike other techniques, Fo-cus-Variation simultaneously cap-tures the entire surface topographic in-formation, in combination with its truecolour information. Both, the topographicand colour information are perfectly reg-istered to each other. Additionally, aquality measure is determined for eachmeasurement point. The advanced technology is the core ofthe optical 3D measurement device“Infi-niteFocus”. The main component of thisoptical metrology instrument is a preci-sion optic consisting of various lens sys-tems. It can be equipped with differentobjectives allowing measurement withdifferent resolutions. With a beam split-ting mirror, light emerging from a whitelight source is inserted into the opticalpath of the system and focused onto thespecimen via the objective. Depending onthe topography of the specimen, the lightis reflected into several directions as soonas it hits the specimen. If the topographyincludes diffuse reflective properties, thelight is reflected equally strong into eachdirection. In case of specular reflections,the light is reflected mainly into one di-rection. All rays emerging from the speci-men and hitting the objective are bundledin the optics and gathered by a light sen-sitive sensor behind the beam splittingmirror. Due to the small depth of field ofthe optics, only small regions of the objectare sharply imaged. To allow a completedetection of the surface with full depth offield, the precision optic is moved verti-cally along the optical axis. This meansthat each region of the object is sharplyfocused. A sensor captures a series of 2D datasets during this scanning processThereby, all sensor parameters are opti-mized at each vertical position accordingto the reflective properties of the surface.After the scanning process, the 2D data-sets are evaluated to generate 3D infor-mation as well as an image with full depthof field. This is achieved by analyzing thevariation of focus along the vertical axis. Fig. 2: Optical 3D measurement device "Infinite-Focus" for surface measurement in the microand nano range.Topographical and colour infor-mation is provided from the variation of focus. Due to the large amount of data, mechani-cal restrictions can be eliminated allow-ing measurement results with a high res-olution. Once all height measurementsare determined, an image with full depthof field is computed. The technique of Focus-Variation hasbeen accepted as a unique technique inISO 25178, a recently developed stand-ard for the classification of topographicalmeasurement techniques to be publishedthis Year. Focus-Variation Based on Focus-Variation, optical 3Dmeasurement can be performed in thelab as well as during production. Depend-ing on the desired measurement task andapplication, several sensors are offeredin order to provide Inline quality assur-ance. Both alternatives provide robustand dense measurements even at com-plex geometrics such as steep flanks andstrong reflections. The robust and com-pact design of the sensors also allows theoperation in rough environments. Evaluation of Tolerances and WearAnalysis Mechanical components are manufac-tured based on CAD models. In order toevaluate their manufacturing quality ithas to be determined whether the meas-ured values are within pre-defined toler-ances. The measurement of variation can Fig.3: Optical radius measurement of a drill dip with the 3D surface measurement device "InfiniteFo-cus". Based on the technique of "Focus-Variation", robust measurement of steep flanks and topogra-phies with varying reflective properties are achievable. be achieved due to the capability of “Infi-niteFocus”to register different 3D mod-els. Another application in this field iswear analysis, often used in quality assur-ance of cutting tools and analysis of wearsurfaces. This technique allows the dis-play and measurement of worn material. Applications for Precision Machining,Milling and Drilling, Mould and ToolMaking The optical measurement technique is of-ten used in precision machining applica-tions for the measurement of surfacesboth in the micro and nano range as wellas for relatively large components. Partic-ularly in the field of mould and tool mak-ing and all kinds of milling and drillingapplications, surface measurement of themachining tool as well as the machinedtool is essential. Even at surfaces with alarge lateral and vertical range, such ascircular milling structures or tool edges,robust measurements are achievable. Accurate 3D Measurement of MicroGear Wheels Due to the miniaturization of components,there is an increasing need for advancedsurface measurement capabilities to pro-vide robust measurements,even on com-plex geometries such as steep flanks, e.g.at the single cogs of gear wheels. This is atypical industrial application that can beeasily achieved due to the distinctive measurement capabilities reached withFocus-Variation. Geometries with steepflanks of more than 80°can be me3aas81uredaccurately in seconds. Additionally, pa-rameters such as the inner and outer di-ameter, flank angles and angels of angu-lar geared components can be computed. Summary Focus-Variation is on optical measure-ment technique for surface analysis inthe mirco- and nano range. The 3D sur-face measurement device“InfiniteFocus”from Alicona Imaging is based on thistechnique and achieves measurement re-sults better 10 nm.Measurement can alsobe performed on steep flanks and regionswith strongly varying reflective proper-ties. The operating principle combinesthe small depth of field of an optical sys-tem with vertical scanning to provide top-ographical and colour information fromthe variation of focus. More over highresolution measurements are provided ata long vertical scan range, enabling therobust measurement of relatively largecomponents. The system can be used inthe lab as well as for Inline quality assur-ance. Control 2007: hall 4, booth 4008 Contact: Mag.Astrid KrennAlicona Imaging GmbH, Grambach/Graz, AustriaTel.: +43 316 4000 770 astrid.krenn@alicona.com www.alicona.com

确定

还剩1页未读,是否继续阅读?

北京东方德菲仪器有限公司为您提供《陡峭斜面中3D表面检测方案(轮廓仪)》,该方案主要用于其他中3D表面检测,参考标准--,《陡峭斜面中3D表面检测方案(轮廓仪)》用到的仪器有

相关方案

更多

该厂商其他方案

更多