方案详情

文

固态材料样品制备与分析指南,包括:针对不同材料的用于显微分析的样品制备方法、显微分析和硬度测试方法,以及腐蚀剂的选择和实验室安全等。

方案详情

Table of ContentsIntroduction...........................................................................6Sampling ...............................................................................7Goals of Specimen Preparation.......................................9Method Development........................................................9Sectioning.............................................................................10Abrasive Wheel Cutting..........................................10Precision Saws............................................................12Mounting of Specimens...................................................14Clamp Mounting.......................................................14Compression Mounting.........................................14Castable Resins for Mounting..............................15Edge Preservation....................................................17Grinding 20Grinding Media..........................................................20Grinding Equipment................................................22Polishing................................................................................23Mechanical Polishing..............................................24Electrolytic Polishing...............................................24Manual “Hand” Polishing........................................24Automatic Polishing................................................25Polishing Clothes......................................................25Polishing Abrasives..................................................27Examples of Preparation Procedure............................29The Traditional Method..........................................29Contemporary Methods.........................................29Procedures for Specific Materials.................................32Periodic Table of Elements....................................33Light Metals: Al, Mg and Be...................................34Aluminum..........................................................34Magnesium.......................................................36Beryllium............................................................37Low Melting Point Metals:Sb, Bi, Cd, Pb, Sn and Zn.................................38Refractory Metals: Ti, Zr, Hf, Cr, Mo,Nb, Re, Ta, V and W...........................................40Titanium.............................................................40Zirconium and Hafnium...............................41Other Refractory Metals: Cr, Mo, Nb,Re, Ta, V and W..................................................43Ferrous Metals............................................................45Copper, Nickel & Cobalt..........................................48Copper................................................................45Nickel...................................................................49Cobalt..................................................................50Precious Metals..........................................................51Thermally-Spray Coated Specimens..................53Sintered Carbides.....................................................55Ceramics.......................................................................57Composites.................................................................59Printed Circuit Boards.............................................61Eletronic Materials....................................................62Polymers......................................................................65Etching...................................................................................67Etching Procedures..................................................67Selective Etching.......................................................68Electrolytic Etching and Anodizing....................71Heat Tinting................................................................71Interference Layer Method...................................72Commonly Used Etchants forMetals and Alloys......................................................73Light Optical Microscopy................................................78The Light Microscope..............................................79Microscope Components......................................79Resolution...................................................................82D epth of Field............................................................83Imaging Modes.........................................................83Microindentation Hardness Testing............................87The Vickers Test.........................................................87The Knoop Test..........................................................88Factors Affecting Accuracy, Precisionand Bias........................................................................89Automation.................................................................91Image Capture & Analysis...............................................93Acquisition..................................................................93Clarification.................................................................96Operator Interactive Measurements.................96Automated Measurements...................................96Thresholding..............................................................96Binary Operations.....................................................98Common Applications............................................99Laboratory Safety............................................................ 101Laboratory Equipment........................................ 102Personal Protective Equipment (PPE)............. 102Chemicals, Storage and Handling.................... 103Etchants..................................................................... 103Solvents..................................................................... 104Acids........................................................................... 106Bases........................................................................... 110Other Chemicals..................................................... 110Summary............................................................................ 112References.......................................................................... 113Appendices........................................................................ 115ASTM Metallography Standards................................ 123ISO Standards................................................................... 124Other National Standards............................................. 125Buehler Trademarks........................................................ 128Index.................................................................................... 129Worldwide Sales Offices................................................ 132

确定

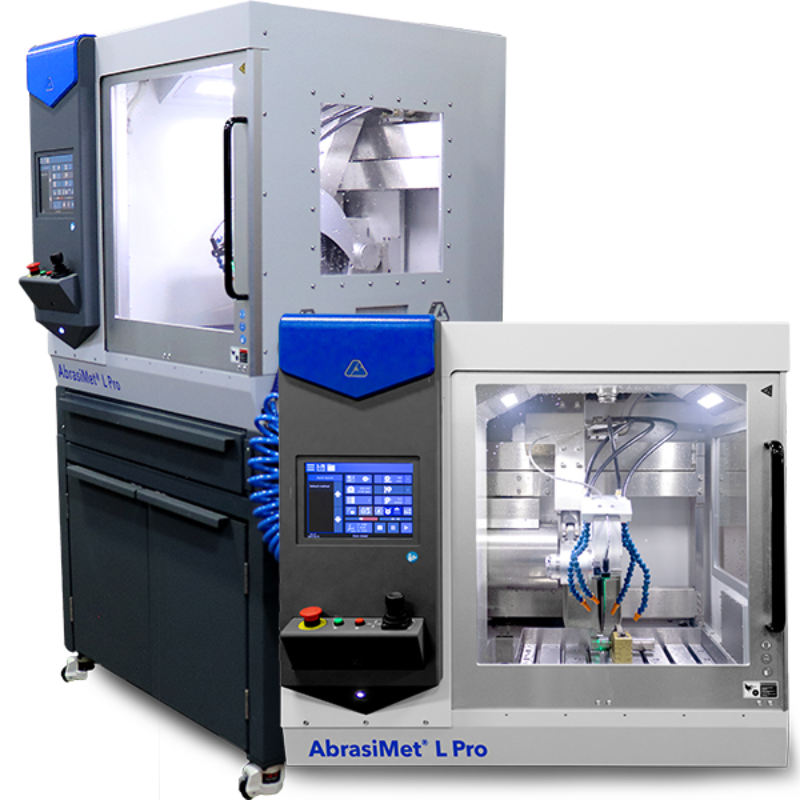

美国标乐为您提供《固态材料中样品制备检测方案(磨抛机)》,该方案主要用于其他中样品制备检测,参考标准--,《固态材料中样品制备检测方案(磨抛机)》用到的仪器有美国标乐 Buehler | EcoMet 30 磨抛机、IsoMet 1000精密切割机、美国标乐 Buehler | SimpliMet 4000自动镶嵌机、洛氏硬度计Rockwell® 2000

相关方案

更多