方案详情

文

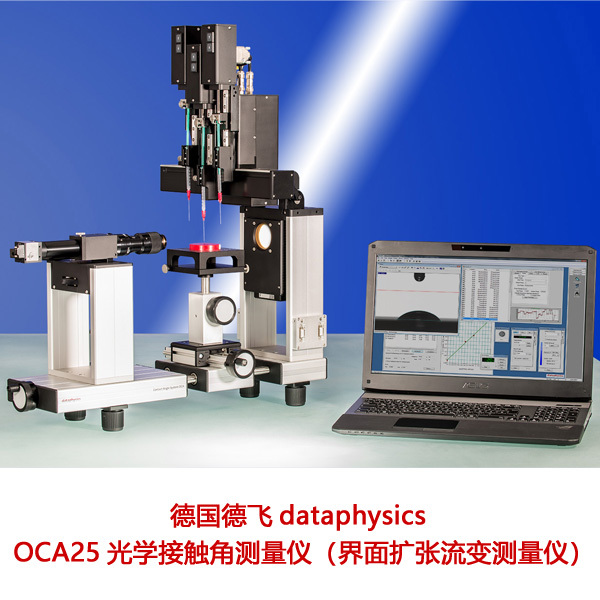

该例介绍了attension theta 光学表/界面张力仪及其微量进样器在喷墨印刷技术研究和开发过程中的应用

方案详情

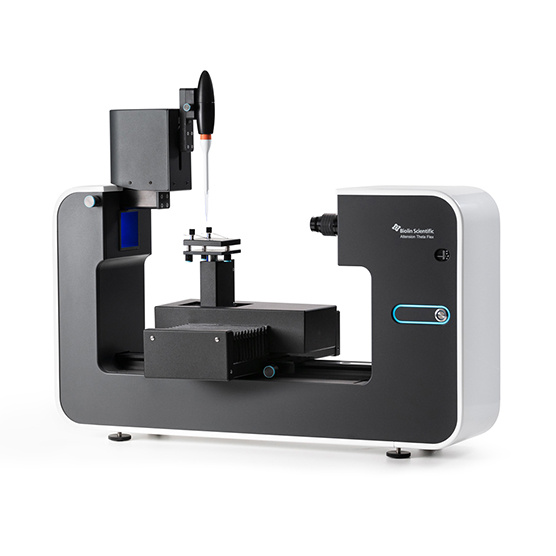

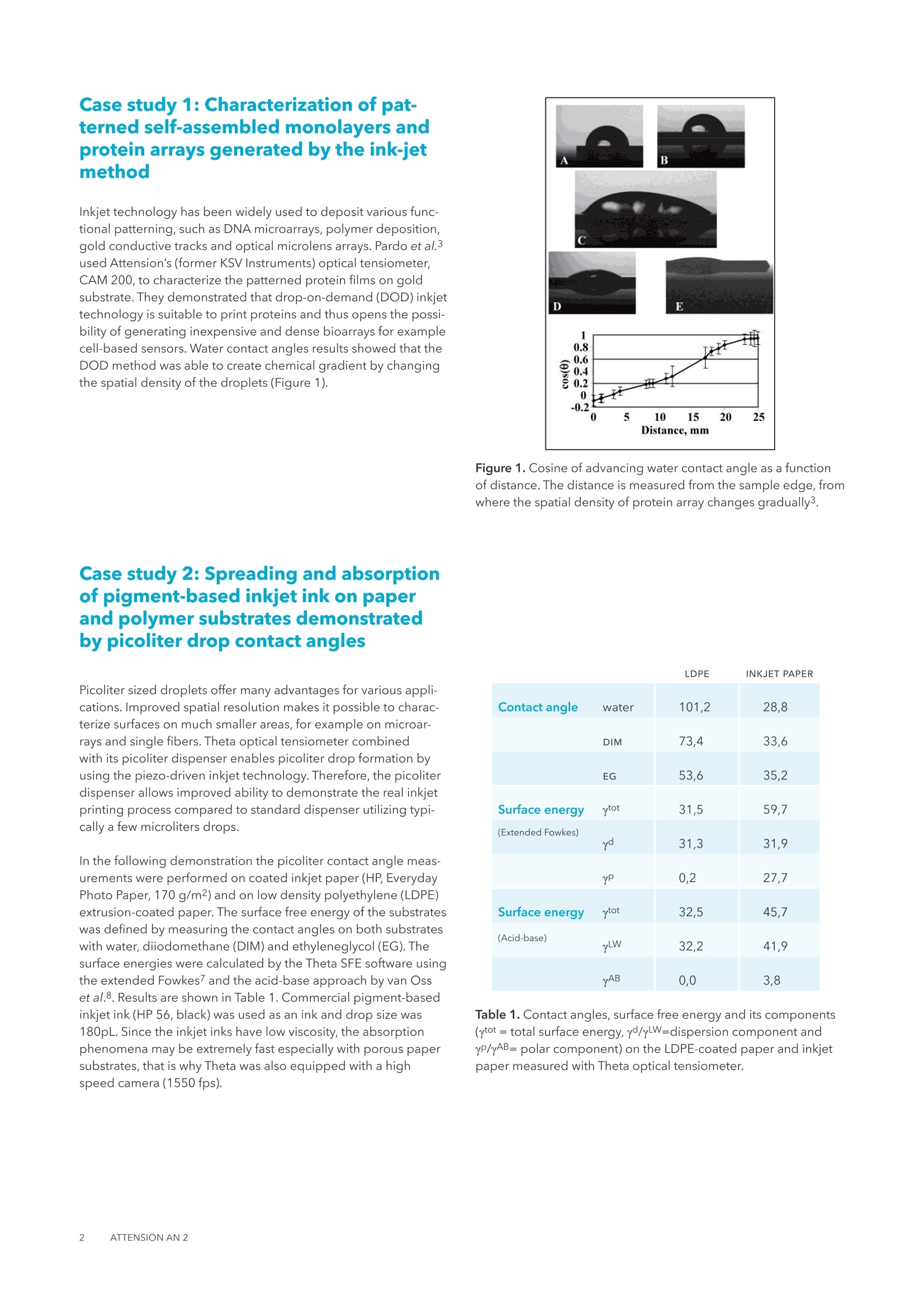

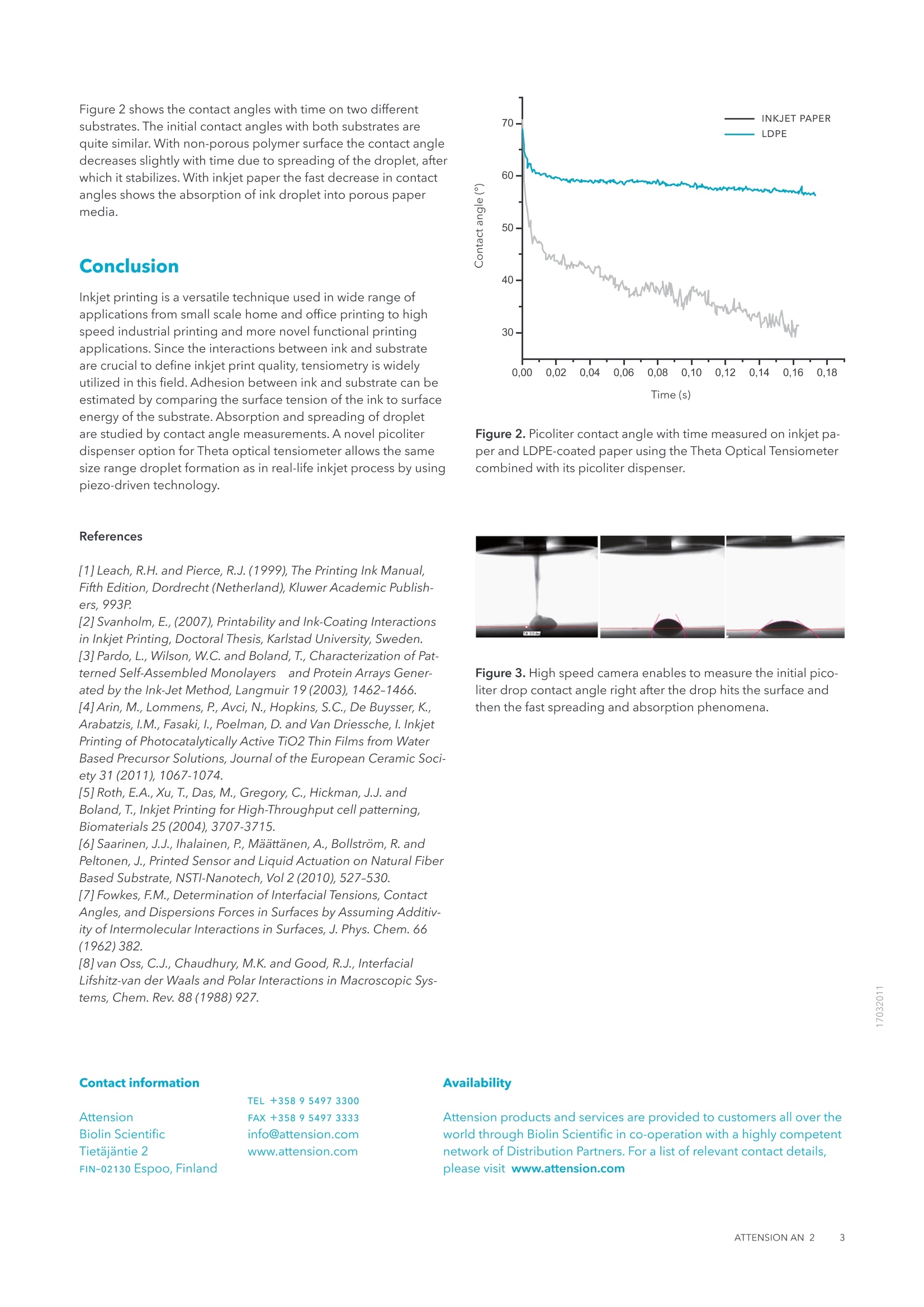

attension APPLICATION NOTE 2 Tensiometry in Inkjet PrintingApplications This application note illustrates how the Attension Theta OpticalTensiometer and its picoliter dispenser can be used to study anddevelop inkjet printing technologies. Inkjet is a relatively young, but expanding printing method. Inkjetis based on digital information transfer, in which an image isformed by ink-droplets that are ejected directly from the printinghead at high speed onto the substrate either by drop-on-de-mand or continuous mode technologies1. This gives freedom topersonalize each printed product and provides print-on-demandprocessing, which is not possible with the currently dominatingnon-digital fixed format printing methods, such as offset. A majoradvantage of inkjet is also its versatility; it can be used with variedcombinations of ink type and substrates. Typically, inkjet is usedin small scale color printing and in low-cost data printing applica-tions, for example in home and office printing.However, due toits advantages compared to conventional printing methods, ithas become common also in the industrial printing and packag-ing industry2. Inkjet printing is also utilized in emerging functionalprinting applications, for example in printed electronics. Inkjet print quality is highly dependent on the properties ofpaper and ink and their interactions. The main components ofinkjet inks are vehicle (water, solvent, oil or UV-based), color-ants, binders and additives. Typically, inkjet inks display very lowviscosity (2-30 mPas) and surface tension is adjusted between25-40 mN/m. The inks can be divided by the type of colorant intodye-based and pigment-based inks. Since the inkjet inks are verypenetrative and low viscous, it sets a high demand on the surfaceproperties of substrates. Surface energy,charge, roughness andporosity are the key elements defining inkjet print quality.1,2 Tensiometry is widely utilized to study the wetting phenomenain inkjet printing applications 3-6. Surface tension of the ink andsurface free energy of the substrate are important parameters indefining the wettability and adhesion between ink and substrate.Since the image is created by the ink-droplets, the contact anglemeasurement is a useful tool to demonstrate the inkjet print-ability. The contact angle analyses allow to study the dropletspreading and absorption via analyzing the drop dimensions andcontact angle with time. Case study 1: Characterization of pat-terned self-assembled monolayers andprotein arrays generated by the ink-jetmethod Inkjet technology has been widely used to deposit various func-tional patterning, such as DNA microarrays, polymer deposition,gold conductive tracks and optical microlens arrays. Pardo et al.3used Attension’s (former KSV Instruments) optical tensiometer,CAM 200, to characterize the patterned protein films on goldsubstrate. They demonstrated that drop-on-demand (DOD) inkjettechnology is suitable to print proteins and thus opens the possi-bility of generating inexpensive and dense bioarrays for examplecell-based sensors. Water contact angles results showed that theDOD method was able to create chemical gradient by changingthe spatial density of the droplets (Figure 1). Picoliter sized droplets offer many advantages for various appli-cations. Improved spatial resolution makes it possible to charac-terize surfaces on much smaller areas, for example on microar-rays and single fibers. Theta optical tensiometer combinedwith its picoliter dispenser enables picoliter drop formation byusing the piezo-driven inkjet technology.Therefore, the picoliterdispenser allows improved ability to demonstrate the real inkjetprinting process compared to standard dispenser utilizing typi-cally a few microliters drops. In the following demonstration the picoliter contact angle meas-urements were performed on coated inkjet paper (HP, EverydayPhoto Paper, 170 g/m2) and on low density polyethylene (LDPE)extrusion-coated paper. The surface free energy of the substrateswas defined by measuring the contact angles on both substrateswith water, diiodomethane (DIM) and ethyleneglycol(EG). Thesurface energies were calculated by the Theta SFE software usingthe extended Fowkes and the acid-base approach by van Osset a1.8. Results are shown in Table 1. Commercial pigment-basedinkjet ink (HP 56, black) was used as an ink and drop size was180pL. Since the inkjet inks have low viscosity, the absorptionphenomena may be extremely fast especially with porous papersubstrates, that is why Theta was also equipped with a highspeed camera (1550 fps). Figure 1. Cosine of advancing water contact angle as a functionof distance. The distance is measured from the sample edge, fromwhere the spatial density of protein array changes gradually3. Contact angle water 101,2 28,8 DIM 73,4 33,6 EG 53,6 35,2 Surface energy ytot 31,5 59,7 (Extended Fowkes) yd 31,3 31,9 yP 0,2 27,7 Surface energy ytot 32,5 45,7 (Acid-base) yLW 32,2 41,9 yAB 0,0 3,8 Table 1. Contact angles, surface free energy and its components(ytot=total surface energy,yd/yLW=dispersion component andyP/yAB= polar component) on the LDPE-coated paper and inkjetpaper measured with Theta optical tensiometer. Figure 2 shows the contact angles with time on two differentsubstrates.The initial contact angles with both substrates arequite similar. With non-porous polymer surface the contact angledecreases slightly with time due to spreading of the droplet, afterwhich it stabilizes. With inkjet paper the fast decrease in contactangles shows the absorption of ink droplet into porous papermedia. Conclusion Inkjet printing is a versatile technique used in wide range ofapplications from small scale home and office printing to highspeed industrial printing and more novel functional printingapplications. Since the interactions between ink and substrateare crucial to define inkjet print quality, tensiometry is widelyutilized in this field. Adhesion between ink and substrate can beestimated by comparing the surface tension of the ink to surfaceenergy of the substrate. Absorption and spreading of dropletare studied by contact angle measurements. A novel picoliterdispenser option for Theta optical tensiometer allows the samesize range droplet formation as in real-life inkjet process by usingpiezo-driven technology. ( References ) ( [1] Leach, R.H. and P ierce, R.J. (1999), The Printing Ink Manual,Fifth Edition,Dordrecht (Netherland), Kluwer Academic Publish-ers, 993P. ) ( [2] Svanholm, E., (2007), P r intability and Ink-Coating Interactionsin Inkjet Printing, Doctoral Thesis, K arlstad University, Sweden. ) ( [3] Pardo, L . , Wilson, W.C. and Boland, T., Characterization of Pat- terned Self-Assembled Monolayers a n d Protein Arrays Gener-ated by the Ink - Jet Method, Langmuir 1 9 (2003), 1 462-1466. ) ( [4] Arin , M., Lommens, P, Avci, N., Hopkins, S.C., D e Buysser, K . , Arabatzis, I .M., Fasaki, l., Poelman,D. and Van D riessche, l. Inkjet Printing of Photocatalytically Active TiO2 Thin F ilms from Water Based Precu r sor S o lutions, Journal of the E uropean Ceramic Soci-ety 31(2011),1067-1074. ) ( [5] Roth,E.A., Xu, T., Das, M., Gregory, C. , Hickman, J.J. and Boland, T., Inkjet Printing fo r High-Throughput cell patterning, Biomaterials 25 (2004),3707-3715. ) ( [6]Saarinen, J.J., Ihalainen, P . , Maattanen, A., Bollstrom,R . andPeltonen,J., Printed Sensor and Liquid Actuation on Natural Fiber Based Substrate,N S TI-Nanotech, Vo l 2 (2010), 5 2 7-530. [7] Fowkes, F.M., D etermination of Interfacial Tensions, Contact Angles, a nd Dispersions Forces in Surfaces by Assuming Additiv-ity of Intermolecular Interactions in Surfaces, J . Phys. Chem. 66 (1962) 382. ) ( [8] van O ss, C.J. , Chaudhury, M. K . an d Good, R.J., Int e r facial L i fshitz-van der Waals and Polar I nteractions in Macroscopic Systems, Chem. Rev.88 (1988) 927. ) Figure 2. Picoliter contact angle with time measured on inkjet pa-per and LDPE-coated paper using the Theta Optical Tensiometercombined with its picoliter dispenser. Figure 3. High speed camera enables to measure the initial pico-liter drop contact angle right after the drop hits the surface andthen the fast spreading and absorption phenomena. ( At te ns i on Bioli n S c i en tif ic Tie t a jan ti e 2 F I N - 0 21 3 0 Es po o, F i n lan d ) ( T E L +3 5 8 9 5 497 33 0 0FA X +35 8 9 5497 3 333 i nf o @a tte ns i o n. c omwww.a t t ensio n.com ) TTENSION AN Contact informationATTENSIONAN

确定

还剩1页未读,是否继续阅读?

瑞典百欧林科技有限公司为您提供《表面接触角测量仪在喷墨印刷技术中的应用》,该方案主要用于其他中--检测,参考标准--,《表面接触角测量仪在喷墨印刷技术中的应用》用到的仪器有Attension Theta Flex 光学接触角仪、Theta Lite 光学接触角仪、Theta QC 光学接触角仪

推荐专场

相关方案

更多

该厂商其他方案

更多