方案详情

文

脂化反应是有机合成中经典的合成方法。采用连续流动合成(微型反应)方式,除了能加快条件探索外,也可以实现小量的生产。连续合成方式采用类微波条件(快速加热),反应速度快,自动化程度高,操作简单。非常合适在研究中使用

方案详情

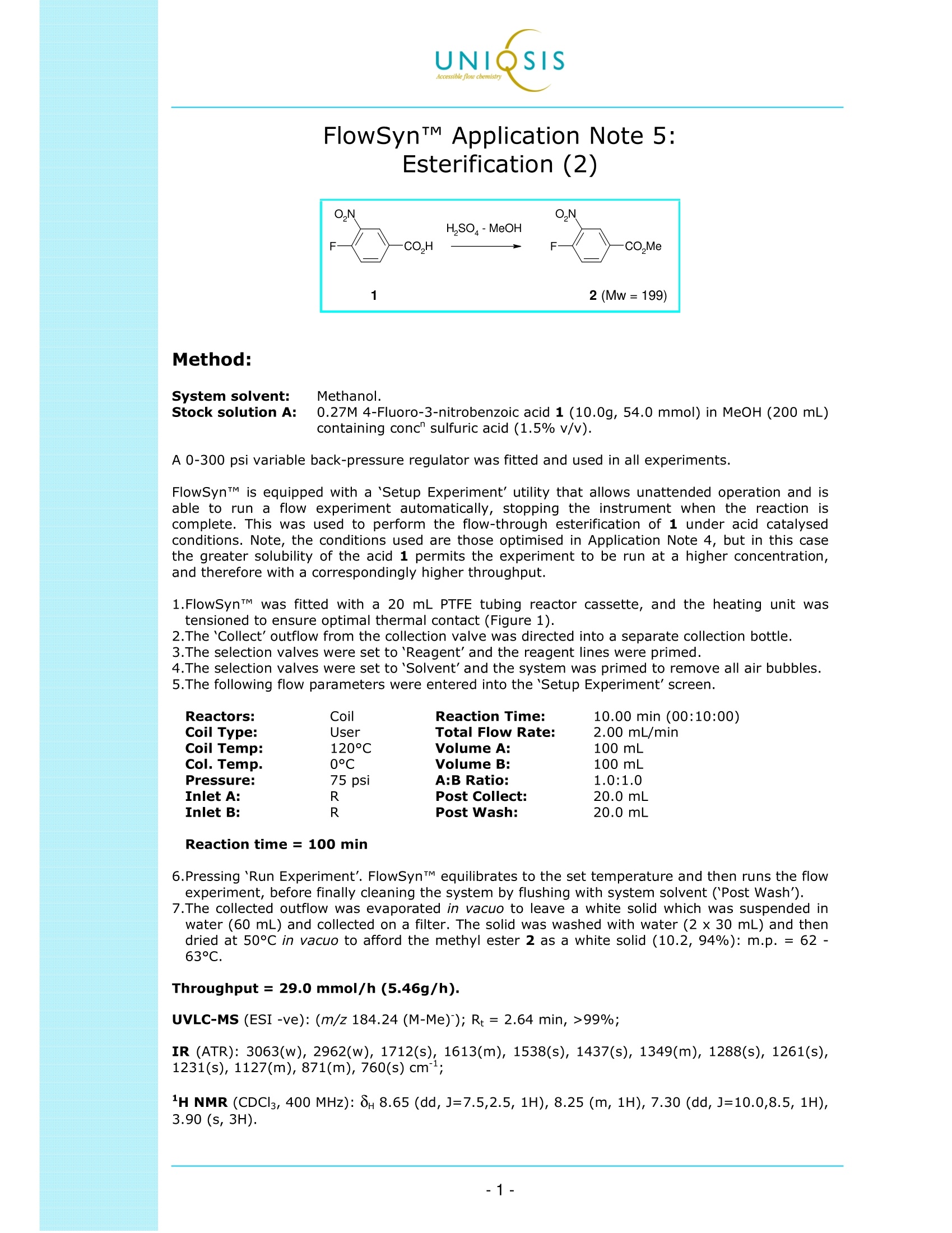

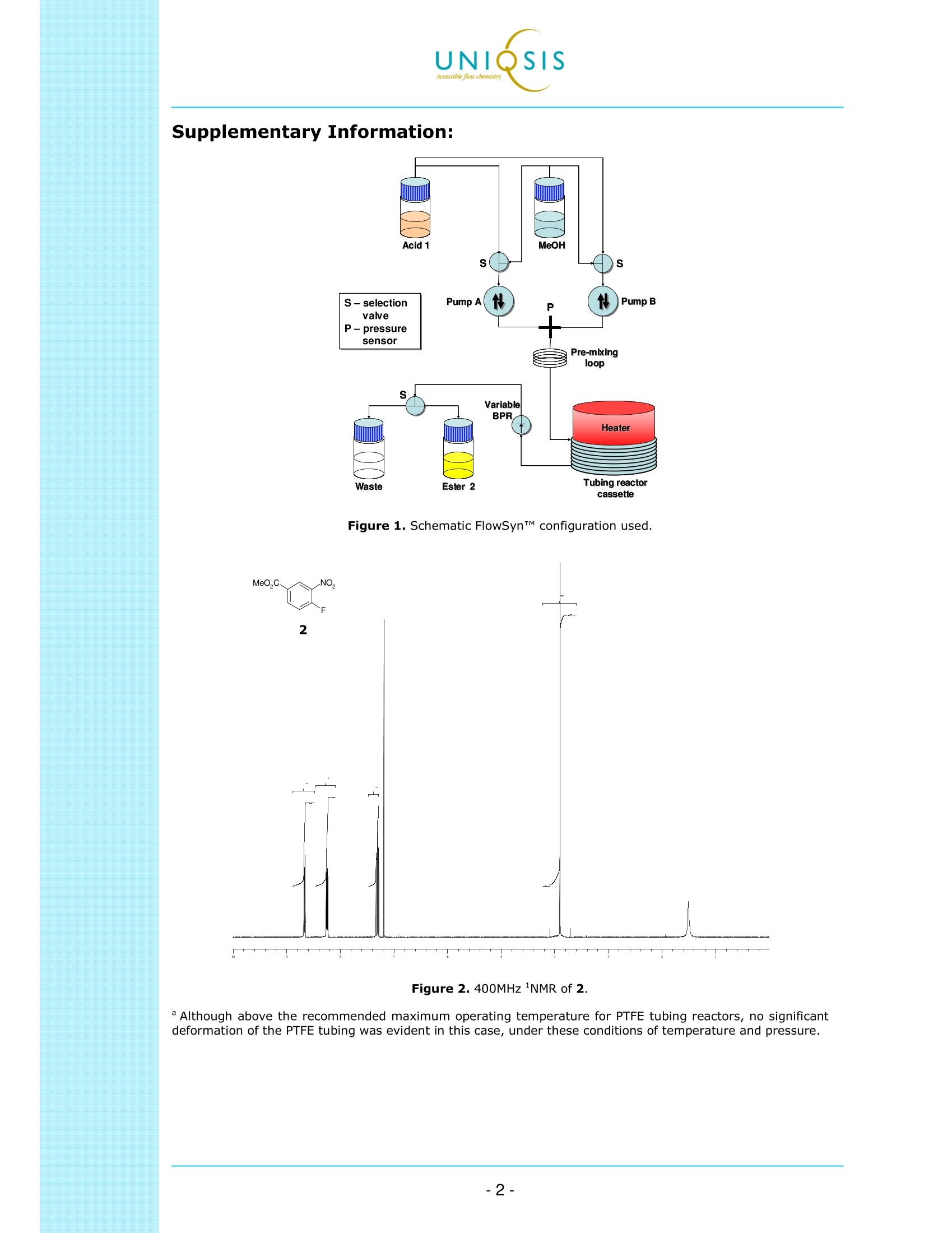

FlowSynTM Application Note 5:Esterification (2) Method: System solvent: Methanol. Stock solution A: 0.27M 4-Fluoro-3-nitrobenzoic acid 1 (10.0g, 54.0 mmol) in MeOH (200 mL)containing conc" sulfuric acid (1.5% v/v). A 0-300 psi variable back-pressure regulator was fitted and used in all experiments. FlowSynTM is equipped with a 'Setup Experiment'utility that allows unattended operation and isable to run a flow experiment automatically, stopping the instrument when the reaction iscomplete. This was used to perform the flow-through esterification of 1 under acid catalysedconditions. Note, the conditions used are those optimised in Application Note 4, but in this casethe greater solubility of the acid 1 permits the experiment to be run at a higher concentration,and therefore with a correspondingly higher throughput 1.FlowSynTM was fitted with a 20 mL PTFE tubing reactor cassette, and the heating unit was.tensioned to ensure optimal thermal contact (Figure 1). 2.The 'Collect’ outflow from the collection valve was directed into a separate collection bottle. 3.The selection valves were set to Reagent' and the reagent lines were primed. 4.The selection valves were set to 'Solvent' and the system was primed to remove all air bubbles. 5.The following flow parameters were entered into the Setup Experiment'screen. Reactors:CoilReaction Time:10.00 min(00:10:00)Coil Type:UserTotal Flow Rate:2.00 mL/minCoil Temp:120°CVolume A:100 mLCol. Temp.0°CVolume B:100 mLPressure:75 psiA:B Ratio:1.0:1.0Inlet A:RPost Collect:20.0mLInlet B:RPost Wash:20.0 mL Reaction time = 100 min 6.Pressing `Run Experiment'. FlowSynTM equilibrates to the set temperature and then runs the flowexperiment, before finally cleaning the system by flushing with system solvent (`Post Wash'). 7.The collected outflow was evaporated in vacuo to leave a white solid which was suspended in water (60 mL) and collected on a filter. The solid was washed with water (2 x 30 mL) and thendried at 50°C in vacuo to afford the methyl ester 2 as a white solid (10.2, 94%): m.p. = 62 -63°C. Throughput = 29.0 mmol/h (5.46g/h). UVLC-MS (ESI -ve): (m/z 184.24(M-Me)); Rt = 2.64 min, >99%; IR (ATR): 3063(w), 2962(w), 1712(s), 1613(m), 1538(s), 1437(s), 1349(m), 1288(s),1261(s),1231(s), 1127(m), 871(m), 760(s) cm; 'H NMR (CDCl3, 400 MHz): 8- 8.65 (dd,J=7.5,2.5, 1H), 8.25(m, 1H), 7.30 (dd,J=10.0,8.5, 1H),3.90 (s, 3H). Supplementary Information: Figure 1. Schematic FlowSynTM configuration used. Figure 2. 400MHz 'NMR of 2. a Although above the recommended maximum operating temperature for PTFE tubing reactors, no significantdeformation of the PTFE tubing was evident in this case, under these conditions of temperature and pressure. -- --

确定

还剩1页未读,是否继续阅读?

博盛技术(中国)有限公司为您提供《脂化反应中连续流动合成检测方案(化学合成仪)》,该方案主要用于其他中理化分析检测,参考标准--,《脂化反应中连续流动合成检测方案(化学合成仪)》用到的仪器有流动合成系统

推荐专场

相关方案

更多