方案详情

文

采用德国LaVision公司的数字图像相关测量分析技术DIC,对SiC和Al2O3颗粒强化的铸铝基复合材料的力学性能进行了研究。

方案详情

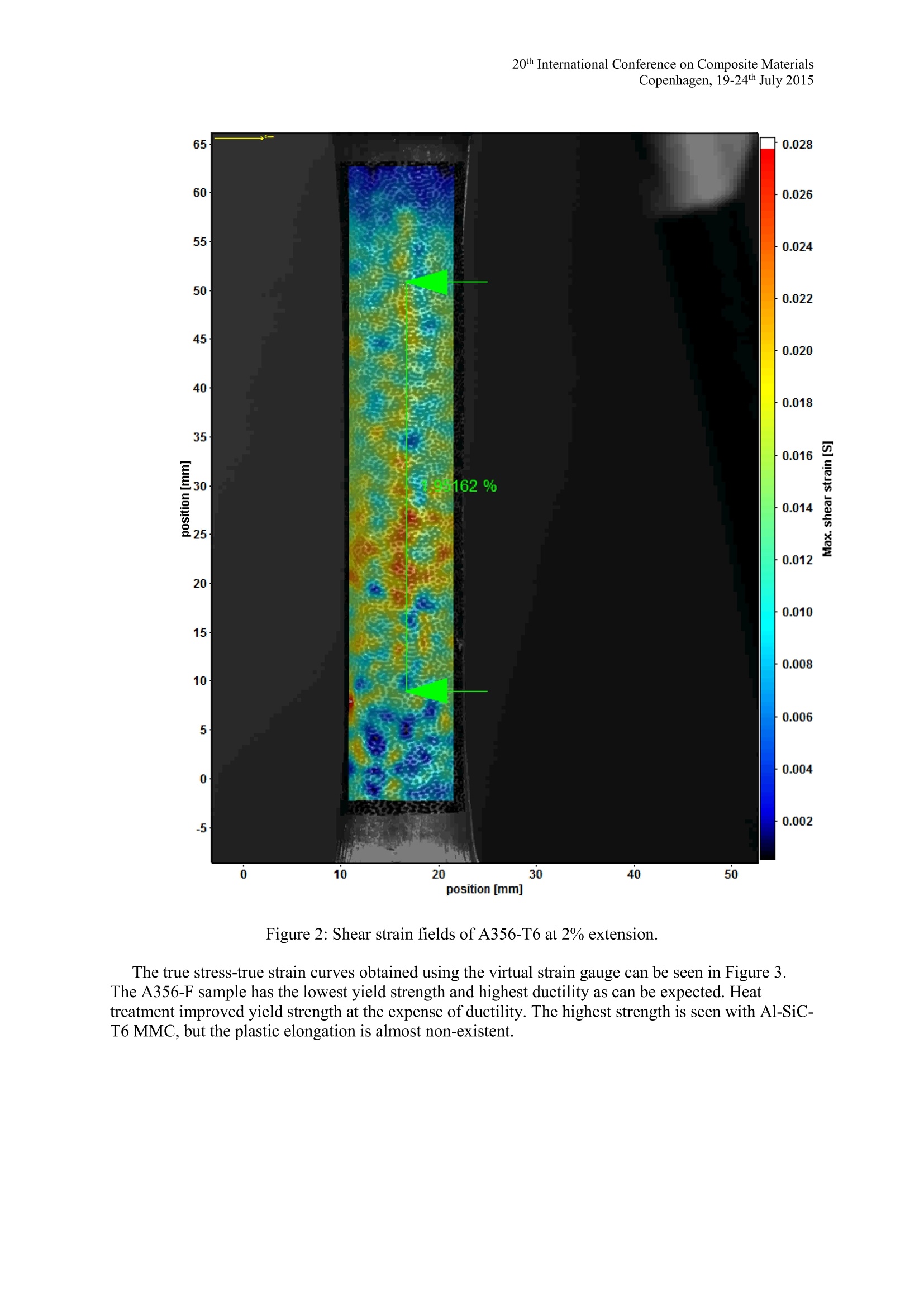

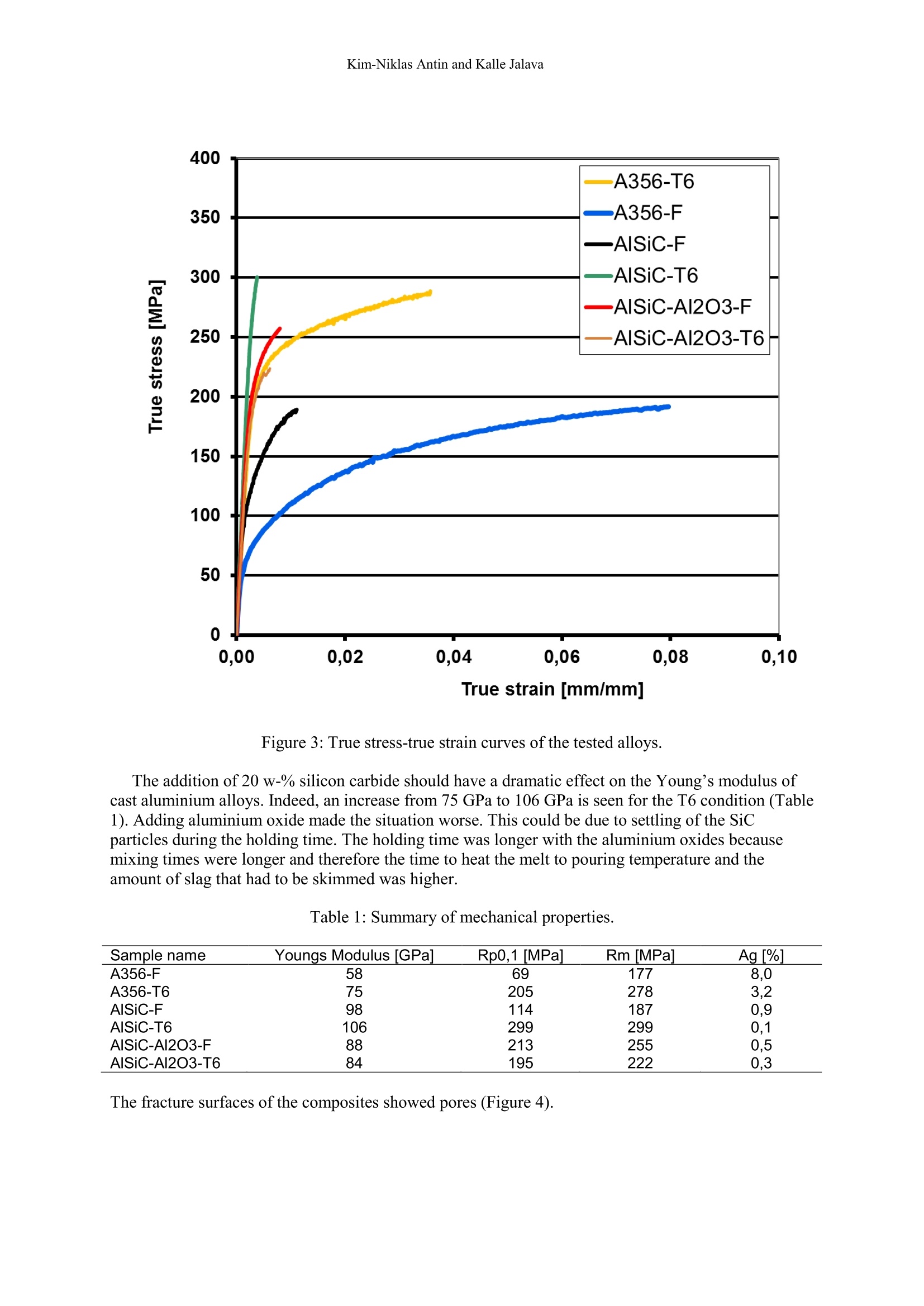

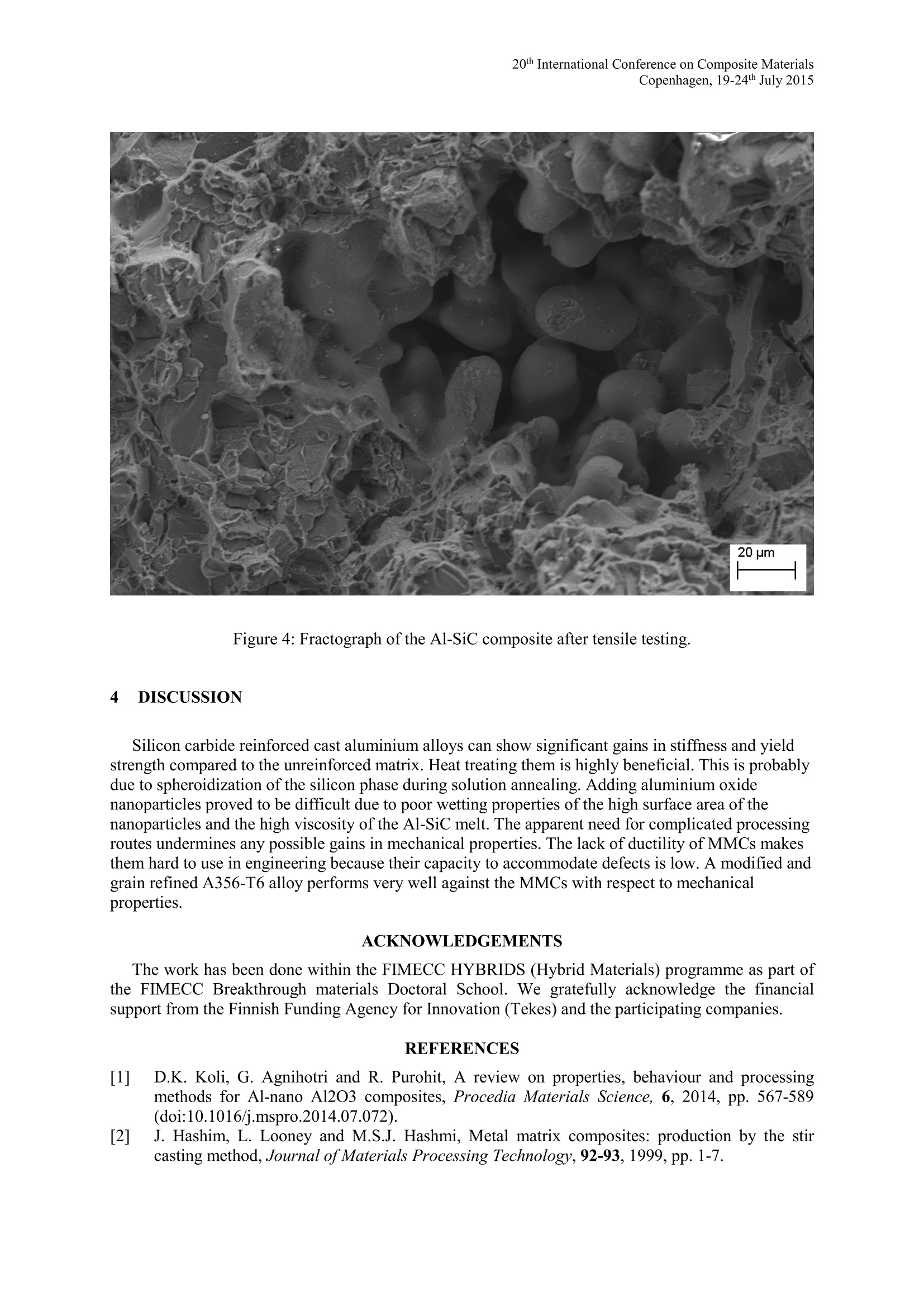

Aalto University 20h International Conference on Composite MaterialsCopenhagen, 19-24th July 2015 This is an electronic reprint of the original article. This reprint may differ from the original in pagination and typographic detail. Antin, Kim-Niklas; Jalava, Kalle Mechanical Properties of Cast Aluminium Matrix Composites Reinforced with SiC and Al2O3Particles Published in: 20th International Conference on Composite Materials Published: 23/07/2015 Document Version Publisher's PDF, also known as Version of record Please cite the original version: Antin, K-N.,& Jalava, K. (2015). Mechanical Properties of Cast Aluminium Matrix Composites Reinforced withSiC and Al2O3 Particles. In 20th International Conference on Composite Materials [4212-2] Denmark:Scandinavian Organizing and Scientific Committee of ICCM. This material is protected by copyright and other intellectual property rights, and duplication or sale of all orpart of any of the repository collections is not permitted, except that material may be duplicated by you foryour research use or educational purposes in electronic or print form. You must obtain permission for anyother use. Electronic or print copies may not be offered, whether for sale or otherwise to anyone who is notan authorised user. MECHANICAL PROPERTIES OF CAST ALUMINIUMMATRIXCOMPOSITES REINFORCED WITH SIC AND AL203 PARTICLES Kim-Niklas Antin and Kalle Jalava Department of Engineering Design and Production, Aalto UniversityPuumiehenkuja 3, 02150 Espoo, Finland Email: kim-niklas.antin@aalto.fi, web page: http://www.aalto.fi Keywords: Metal matrix composite, Digital image correlation, casting, mechanical properties ABSTRACT Aluminium matrix composites have the potential to be high performance materials. The mainbenefits being higher strength, stiffness, wear resistance and thermal conductivity compared to thematrix material alone. However, the down sides are loss in ductility, fracture toughness and difficultprocessing routes. We use state-of-the-art processing parameters to produce an aluminium matrix composite with 30um micro-SiC particles together with 50 nm nano-Al2O3 particles. Both reinforcements have beenused separately before, but we study whether or not additional benefits can be achieved by usingdifferent sized reinforcements in the same composite. 1 INTRODUCTION Metal matrix composites (MMC) can show superior properties, such as higher stiffness andstrength, compared to the matrix material alone. There are many routes for processing MMCs [1], butcasting is the most viable. The reinforcement is usually silicon carbide (SiC) or aluminium oxide(Al2O3). Hashim et al. has extensively reported the four challenging aspects in processing Al-SiCcomposites using the casting route [2-5]. Firstly, uniform distribution of reinforcement particles wasfound to be difficult to achieve. Factors affecting the distribution are: type of particle introduction(vortex stirring [6], gas injection etc.), holding time [7], pouring rate, pouring temperature, gatingsystems, particle migration on freezing fronts, solidification rate etc. The second factor to consider iswettability. Wettability can be promoted using coatings, additional alloying elements, heat treatmentof particles, ultrasonication and mechanical stirring in semi-solid state. Thirdly, porosity tends toincrease as particle size decreases or their amount is increased. Sources of porosity are gas entrapmentfpduring mixing, gas layers on reinforcement particles, gas trapped during injection of particles, gasdrawn into the melt during pouring and solidification shrinkage. Lastly, the viscosity of the melt isincreased as particle content rises or particle size decreases. The chemical reaction forming Al4C3willalso increase viscosity and must be avoided. The same conclusions were made by Amirkhanlou in twoduplicate publications [8-9]. The mechanical properties of Al-SiC composites has been studied extensively. Singla et al.reported in a partly plagiarized article an increase in hardness as particle content increases [10].However, hardness or compression tests do not show the effect of porosity. Increased SiC content hasbeen shown to result in higher tensile strength, but the effect on fracture toughness or impacttoughness is negative or neutral respectively [11-12]. A decrease in fatigue strength is reported [13],while others have seen an increase [14] as particle content increases. However, the latter article bySkolianos had very low Young’s modulus values (10-20 GPa) which undermines the reliability of theresults. Adding aluminium oxide to aluminium alloys has been reported in a series of redundant/duplicatepublications by Mazahery, Saijjadi and Tahamtan [15-19]. They found that adding AlO3 particles increases strength up to 2% weight fraction after which increased porosity begins to offset the gains.Ball milling the Al2O3particles together with aluminium particles reduces porosity compared to addingthe oxide particles alone. The grain size was reduced significantly by the nano- Al2O3 particles.Wettability of nanoparticles was found to be inferior compared to microparticles, but injection usingan inert gas carrier and heat treatment of particles could be used to improve wettability. Improvedmechanical properties are seen, for example in wear [20]. The aim of this study is to investigate if using two different sized reinforcements, namelymicrosized silicon carbide and nanosized aluminium oxide, brings any additional benefits compared tousing either alone. 2METHODS Three materials were studied in two different conditions each. The investigated alloys are A356,A359-20%SiC and A359-20%SiC-1%Al2O3. The two conditions are as-fabricated (F) and T6 (solutionannealed, quenched and peak aged [21]). The A356 alloy was melted from primary ingots in aradiation furnace, modified and grain refined. The SiC composite was also melted from primary ingot,whereas the SiC+Al2O3 MMC was made by mixing 50 nm nano-Al2O3 with Al-powder and packingthe mixture in aluminium foil. The foil packets were submerged into the melt and a graphite stirrerwas used at 300 rpm at 1/3 depth in the graphite crucible for 15 minutes total. The stirring temperaturewas under 700C, but the alloy was reheated to 760°℃ before pouring into a pre-heated (400°℃) steelmould. The cast tensile test specimens were pulled in a 100 kN MTS tensile machine at a rate of 3·10.The round tensile test specimens had a gauge length of 50 mm and 12,7 mm diameter. Strain wasmeasured using a digital image correlation (DIC) software from LaVision GmbH. The pattern on thesample (Figure 1) was optimized for contrast and feature size [22]. A frame rate of 1 Hz was used andthe image sequence was analysed to obtain the strains in tensile direction. A virtual strain gage wasused to obtain average strain over the gauge length. Figure 1: Optimized pattern for DIC [22]. 3 RESULTS The strain field was generally very uniform and the virtual strain gauge can be trusted. In the A356-T6 some local deformation was visible already at low strains (Figure 2). This could be due to a porecausing local stresses. Figure 2: Shear strain fields of A356-T6 at 2%extension. The true stress-true strain curves obtained using the virtual strain gauge can be seen in Figure 3.The A356-F sample has the lowest yield strength and highest ductility as can be expected. Heattreatment improved yield strength at the expense of ductility. The highest strength is seen with Al-SiC-T6 MMC, but the plastic elongation is almost non-existent. Figure 3: True stress-true strain curves of the tested alloys. The addition of 20 w-% silicon carbide should have a dramatic effect on the Young’s modulus ofcast aluminium alloys. Indeed, an increase from 75 GPa to 106 GPa is seen for the T6 condition (Table1). Adding aluminium oxide made the situation worse. This could be due to settling of the SiCparticles during the holding time. The holding time was longer with the aluminium oxides becausemixing times were longer and therefore the time to heat the melt to pouring temperature and theamount of slag that had to be skimmed was higher. Table 1: Summary of mechanical properties. Sample name Youngs Modulus [GPa] Rp0,1 [MPa] Rm [MPal Ag[%] A356-F 58 69 177 8,0 A356-T6 75 205 278 3,2 AISiC-F 98 114 187 0,9 AISiC-T6 106 299 299 0,1 AISiC-AI2O3-F 88 213 255 0,5 AISiC-AI2O3-T6 84 195 222 0,3 The fracture surfaces of the composites showed pores (Figure 4). Figure 4: Fractograph of the Al-SiC composite after tensile testing. 4 DISCUSSION Silicon carbide reinforced cast aluminium alloys can show significant gains in stiffness and yieldstrength compared to the unreinforced matrix. Heat treating them is highly beneficial. This is probablydue to spheroidization of the silicon phase during solution annealing. Adding aluminium oxidenanoparticles proved to be difficult due to poor wetting properties of the high surface area of thenanoparticles and the high viscosity of the Al-SiC melt. The apparent need for complicated processingroutes undermines any possible gains in mechanical properties. The lack of ductility ofMMCs makesthem hard to use in engineering because their capacity to accommodate defects is low. A modified andgrain refined A356-T6 alloy performs very well against the MMCs with respect to mechanicalproperties. ACKNOWLEDGEMENTS The work has been done within the FIMECC HYBRIDS (Hybrid Materials) programme as part ofthe FIMECC Breakthrough materials Doctoral School. We gratefully acknowledge the financialsupport from the Finnish Funding Agency for Innovation (Tekes) and the participating companies. REFERENCES [1] D.K. Koli, G. Agnihotri and R. Purohit, A review on properties, behaviour and processingmethods for Al-nano Al203 composites, Procedia Materials Science, 6, 2014, pp. 567-589(doi:10.1016/j.mspro.2014.07.072). 21 J. Hashim, L. Looney and M.S.J. Hashmi, Metal matrix composites: production by the stircasting method, Journal ofMaterials Processing Technology, 92-93, 1999, pp. 1-7. ( [3] J. Hashim, L. Looney and M.S.J. Hashmi, The enhancement of wettability of SiC particles incast aluminium matrix composites, Journal of Materials Processing Technology, 119, 2001 , pp. 329-335. ) ( [4] J . Hashim, L. Looney and M.S.J. Hashmi, Particle dis t ribution in cast metal matrix composites -Part I, Journal of Materials Processing Technology, 123, 2002, pp.251-257. ) ( [5] J. Hashim, L. Looney and M.S.J. Hashmi, Particle dis t ribution in cast metal matrix composites -Part I, Journal of Materials Processing Technology,123, 2002, pp. 258-263. ) ( [6] S.B. P rabu, L. K arunamoorthy, S. K a thiresan and B. Mo h an. Influence of stirring sp e ed an d stirring time on d istribution o f p articles in cast metal m atrix composite, Journal ofM a terialsProcessing Technology, 171, 2006, pp. 268-273. ) ( [7] A. O urdjini, K .C. Chew and B.T. Kho o . Sett l ing of silicon carbide particles in cast metal ma t rixcomposites, Journal ofMaterials Processing Technology, 116, 2001, pp. 72-76. ) ( 81 S. Amirkhanlou and B. N oroumand, Synthesis a n d c h aracterization of 356-SiCp composites b ystir castin g and compocasting methods. T ransaction o f Nonferrous Metals Society of China 20,2010, pp. 7 88-793. ) ( [9] S. Amirkhanlou a n d B. Niroumand. Development of Al356/SiCp cast compo s ites by injectionof SiCp c ontaining composite powders. Materials and De s ign 32, 2011, pp. 189 5 -1902. (doi:10. 1 016/j.matdes.2010.12.013). ) ( [10]M. Singla, D.D. Dwivedi, L . Singh and V. Chawla. Development of aluminium based siliconcarbide particulate metal matrix composite, Journal of Minerals & Materials Characterization& Engineering, 8, 2 009, pp. 455-467 ) ( [11] K.K. Alaneme an d A.O. Aluko, Fra c ture toughness (K1C) and tensile properties of a s- c ast andage-hardened aluminium (60 6 3)-silicon car b ide particulate composite, Scientia Iranica A, 19,2012, pp. 992-996 (doi: 1 0 .1016/j.scient.2012.06.001). ) ( [12] A.R.I. Kheder, G.S. Marahleh and D .M.K. Al-Jamea, S trenghening of aluminium by S iC,Al203 a n d MgO, Jordan Journal of Mechanical and Industrial Engineering, 5, 2011, pp . 533- 541. ) ( 13]P.K.R o hatgi, S. A l araj, R.B. Thakkar and D. D aoud, Variation in fati g ue prop e rties of castA359-SiC composites under total strain c o ntrolled conditions: Effect of p orosity and inclusions,Composites: Part A, 38, 2007, pp. 1829-1841 (doi:10.1016/j.compositesa.2007.04.005). ) ( [14] S. Skolianos. Mechanical b ehavior of cast SiCp-reinforced A Al-4.5%Cu-1.5%Mg alloy,Materials Science and Engineering A, 210, 1996, pp . 76-82. ) ( [15]A. M azahery, H . Abdizadeh a nd H . R. B a harvandi, D evelopmentt of h igh-performanceA356/nano-Al2O3 composites, Material Science and Engineering A 518, 2009, pp. 61-64 (doi:10.1016/j.msea.2009.04.014). ) ( [16]S.A. S ajjadi, H.R. Ezatpour a n d H. Be y gi, Microstructure and mechanical properties of Al-Al2O3 micro and nano composites fabricated by stir casting, Material Science and EngineeringA528,2011,pp.8765-8771 (doi: 10.1016/j.msea.2011.08.052). ) ( [17]S.A. Sajjadi , H.R. Ezatpour and M. Torabi Parizi, Comparison o f m icrostructure andmechanical p roperties o f A356 aluminium all o y/Al2O3 composites fabr i cated by s t ir and compo-casting processes, Materials and Design 34. 2012. pp. 106-111 (doi:10.1016/j.matdes.2011. 0 7.037). ) ( [18]S.A. S ajjadi, M. Torabi P arizi, H.R. Ezatpour and A . S e dghi, Fabrication of A356 compositereinforced with micro and nano Al203 p articles by a developed compocasting method andstudy o f i ts properties. Journa l of Alloys and Compounds 5 11, 2 012, p p . 2 2 6-231 (doi:10.1016/j.jallcom.2011.08.105). ) ( [19]S. Tahamtan, A. Halvaee, M. Emamy and M . S. Zabihi. Fabrication of Al/A206-A12O3nano/micro c omposite by c o mbining ball m i lling and s t ir c asting technology, Materials andDesign, 49, 2013, pp.347-359 (doi: 10.1016/j.matdes.2013.01.032). ) ( [20] V. B harat, M. Nagaral, V. Auradi and S.A. Kori, Preparation of 6061 Al - A12O3 MMC’s byt stircasting and evaluation of mechanical and wear properties,Procedia Materials Science, 6, 2014,pp. 1658-1667 (doi: 1 0.1016/j.Mspro.2014.07.151). ) ( [21] J-H. P eng, X -L. Tang, J - T. He and D- Y . Xu, Eff e ct of heat treatment on microstructure and tensile propertie s of A356 alloys , Transactio n ofNonferrous Metals Society of China 21, 2011,pp. 1950-1956. ) ( [221 S. Bossuyt, O p timized patterns fo r di g ital i ma ge correlation, Pr o ceedings of t he A nnu a lConference on Experimental and Applied Mechanics, Costa Mesa, US A , 2012, pp. 239-248. ) Aluminium matrix composites have the potential to be high performance materials. The main benefits being higher strength, stiffness, wear resistance and thermal conductivity compared to the matrix material alone. However, the down sides are loss in ductility, fracture toughness and difficult processing routes.We use state-of-the-art processing parameters to produce an aluminium matrix composite with 30 μm micro-SiC particles together with 50 nm nano-Al2O3 particles. Both reinforcements have been used separately before, but we study whether or not additional benefits can be achieved by using different sized reinforcements in the same composite.

确定

还剩6页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《铸铝基复合材料中形变应变场检测方案(其它无损检测仪器/设备)》,该方案主要用于其他中理化分析检测,参考标准--,《铸铝基复合材料中形变应变场检测方案(其它无损检测仪器/设备)》用到的仪器有LaVision StrainMaster 形变应变成像测量系统、LaVision DaVis 智能成像软件平台

推荐专场

相关方案

更多

该厂商其他方案

更多