方案详情

文

Microcalorimetry has been successfully applied to the study of electrochemical components and structural materials during the design and development of new batteries. The Ampoule form of the Microcalorimeter is ideally suited to the examination of the electrochemical materials in forms such as pastes, liquids, powders or even the entire battery. The method is non-destructive, Analysis of the activity of the components is fast; for example, a reaction normally taking several weeks or months can be observed within a few hours when using this technique. The variable full-scale readout range of the instrument ensures a sensitive measurement of the activity of a wide range of samples.

方案详情

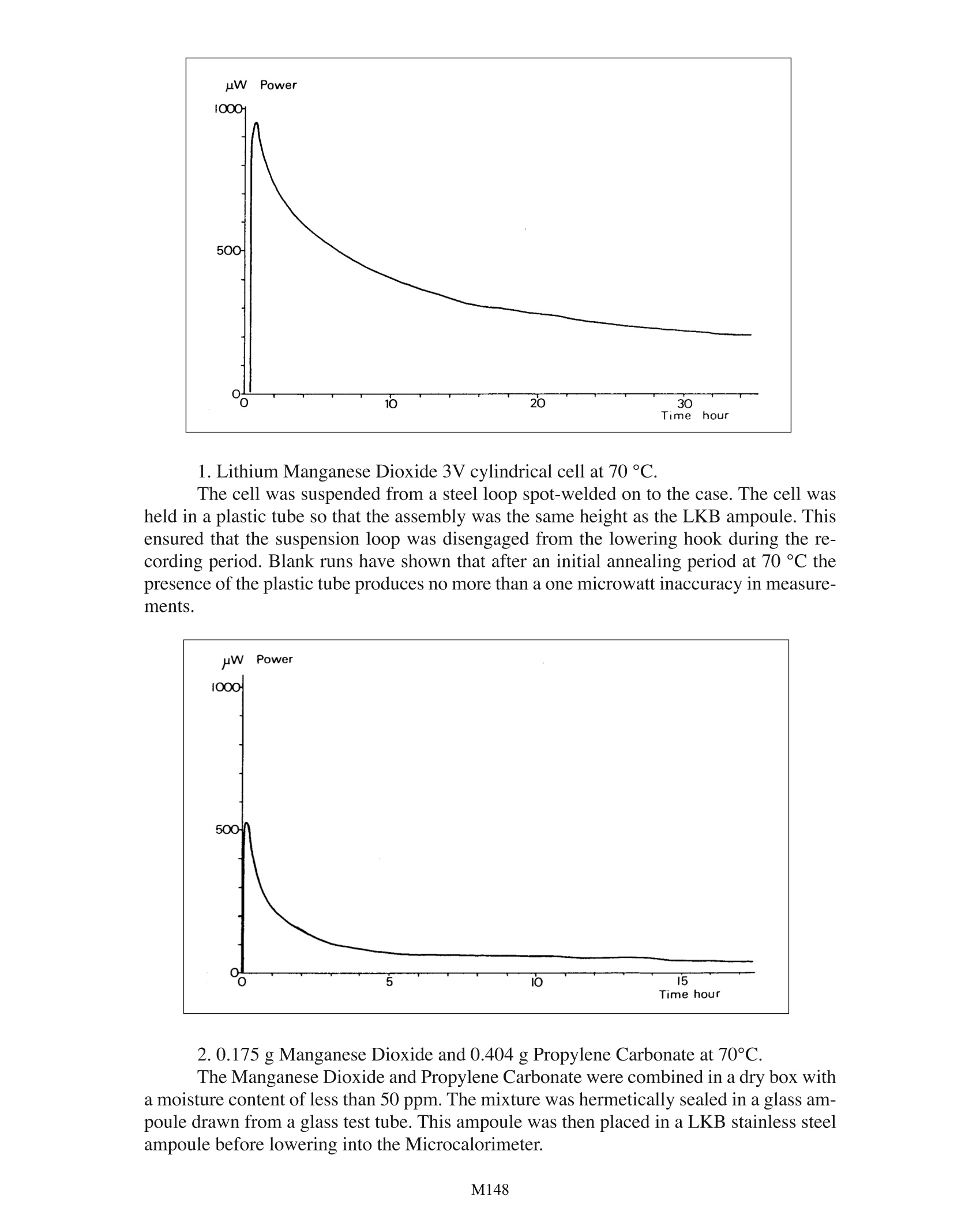

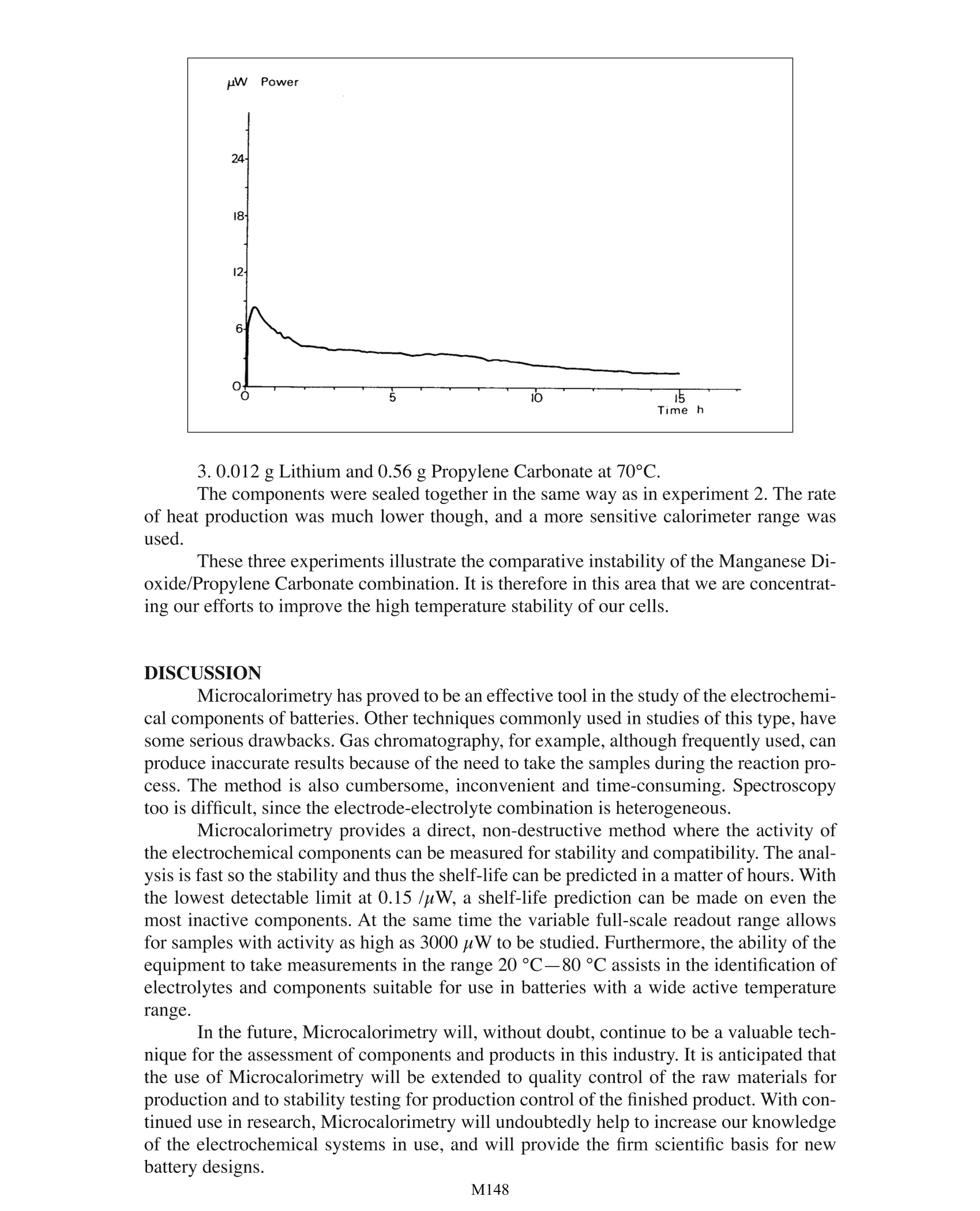

Microcalorimtry for studying the Electrolyte Stability of Lithium/Manganese Dioxide Batteries P. R. Stevenson Venture Technolgy Abingdon,Oxfordshire, England. Instrument: 2277 with Ampoule Measuring Cylinder Field of Application: Material Studies TA Instruments, 109 Lukens Drive, New Castle, DE 19720,USA ABSTRACT Microcalorimetry has been successfully applied to the study of electrochemicalcomponents and structural materials during the design and development of new batter-ies. The Ampoule form of the Microcalorimeter is ideally suited to the examination of theelectrochemical materials in forms such as pastes, liquids, powders or even the entire bat-tery. The method is non-destructive, Analysis of the activity of the components is fast; forexample, a reaction normally taking several weeks or months can be observed within a fewhours when using this technique. The variable full-scale readout range of the instrumentensures a sensitive measurement of the activity of a wide range of samples, INTRODUCTION Venture Technology is involved in the design, development and production of spe-cialist batteries as well as basic and contract research into electrochemical systems. In theirsearch for new materials for the production of a reliable high energy density power source,active in a wide range of temperatures, a fast and accurate method of testing individualcomponents is of paramount importance. Microcalorimetry has fulfilled this need, and hascontributed to the development of batteries with unique cell construction, tolerant to abuse,and completely safe under all conditions of use. To extend the shelf-life, the chemical stability of components were tested system-atically using Microcalorimetry. Tests, such as the interaction of the lithium anode andthe manganese dioxide cathode with the electrolyte were performed. The reaction of eachcomponent with the metal container and sealant material was also examined. To ensure awide active temperature range,tests were carried out at various temperatures. EXPERIMENTAL All measurements were madewith the Microcalorimeter in a controlled temperatureroom. 1. Lithium Manganese Dioxide 3V cylindrical cell at 70°C. The cell was suspended from a steel loop spot-welded on to the case. The cell washeld in a plastic tube so that the assembly was the same height as the LKB ampoule. Thisensured that the suspension loop was disengaged from the lowering hook during the re-cording period. Blank runs have shown that after an initial annealing period at 70C thepresence of the plastic tube produces no more than a one microwatt inaccuracy in measure-ments. 2. 0.175 g Manganese Dioxide and 0.404 g Propylene Carbonate at 70°C. The Manganese Dioxide and Propylene Carbonate were combined in a dry box witha moisture content of less than 50 ppm. The mixture was hermetically sealed in a glass am-poule drawn from a glass test tube. This ampoule was then placed in a LKB stainless steelampoule before lowering into the Microcalorimeter. 3. 0.012 g Lithium and 0.56 g Propylene Carbonate at 70°℃. The components were sealed together in the same way as in experiment 2. The rateof heat production was much lower though, and a more sensitive calorimeter range wasused. These three experiments illustrate the comparative instability of the Manganese Di-oxide/Propylene Carbonate combination. It is therefore in this area that we are concentrat-ing our efforts to improve the high temperature stability of our cells. DISCUSSION Microcalorimetry has proved to be an effective tool in the study of the electrochemi-cal components of batteries. Other techniques commonly used in studies of this type, havesome serious drawbacks. Gas chromatography, for example, although frequently used, canproduce inaccurate results because of the need to take the samples during the reaction pro-cess. The method is also cumbersome, inconvenient and time-consuming. Spectroscopytoo is difficult, since the electrode-electrolyte combination is heterogeneous. Microcalorimetry provides a direct, non-destructive method where the activity ofthe electrochemical components can be measured for stability and compatibility. The anal-ysis is fast so the stability and thus the shelf-life can be predicted in a matter of hours. Withthe lowest detectable limit at 0.15 /uW, a shelf-life prediction can be made on even themost inactive components. At the same time the variable full-scale readout range allowsfor samples with activity as high as 3000 uW to be studied. Furthermore, the ability of theequipment to take measurements in the range 20℃-80 °C assists in the identification ofelectrolytes and components suitable for use in batteries with a wide active temperaturerange. In the future, Microcalorimetry will, without doubt, continue to be a valuable tech-nique for the assessment of components and products in this industry. It is anticipated thatthe use of Microcalorimetry will be extended to quality control of the raw materials forproduction and to stability testing for production control of the finished product. With con-tinued use in research, Microcalorimetry will undoubtedly help to increase our knowledgeof the electrochemical systems in use, and will provide the firm scientific basis for newbattery designs. M Microcalorimetry has been successfully applied to the study of electrochemical components and structural materials during the design and development of new batteries. The Ampoule form of the Microcalorimeter is ideally suited to the examination of the electrochemical materials in forms such as pastes, liquids, powders or even the entire battery. The method is non-destructive, Analysis of the activity of the components is fast; for example, a reaction normally taking several weeks or months can be observed within a few hours when using this technique. The variable full-scale readout range of the instrument ensures a sensitive measurement of the activity of a wide range of samples.

确定

还剩1页未读,是否继续阅读?

TA仪器为您提供《电池中电解质稳定性检测方案(差示扫描量热)》,该方案主要用于锂电池中电解质稳定性检测,参考标准--,《电池中电解质稳定性检测方案(差示扫描量热)》用到的仪器有TA仪器+等温量热仪+TAM Air

推荐专场

相关方案

更多