采用LaVision的高速图像增强器HS-IRO,Photron SA1.1 高速CMOS相机,以及SIRAH Credo型高速染料激光器,构成了一套时间分辩高速平面激光诱导荧光测量系统。并用这套系统研究了声学驱动非预混火焰接近吹熄状态的动力学过程

方案详情

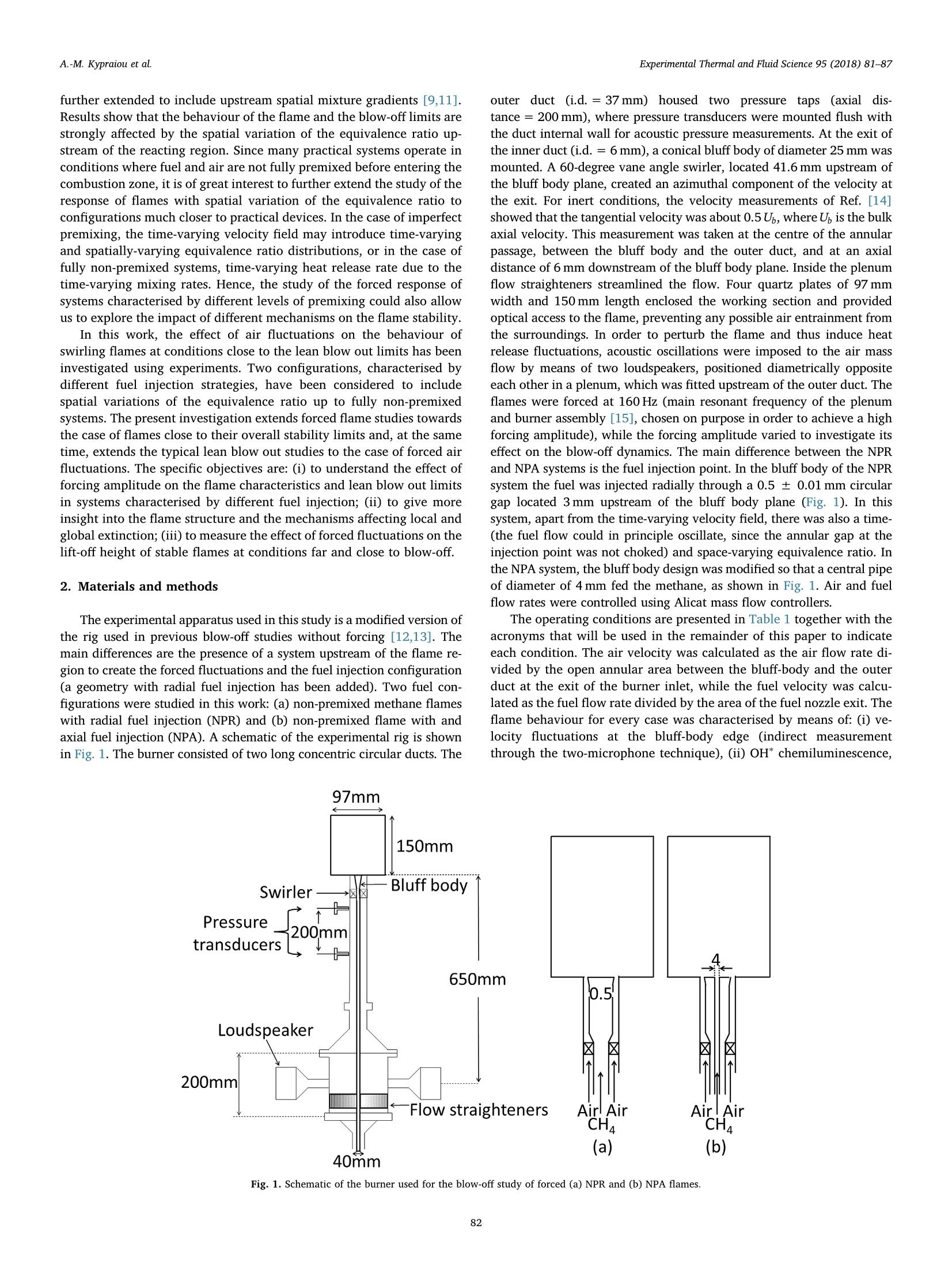

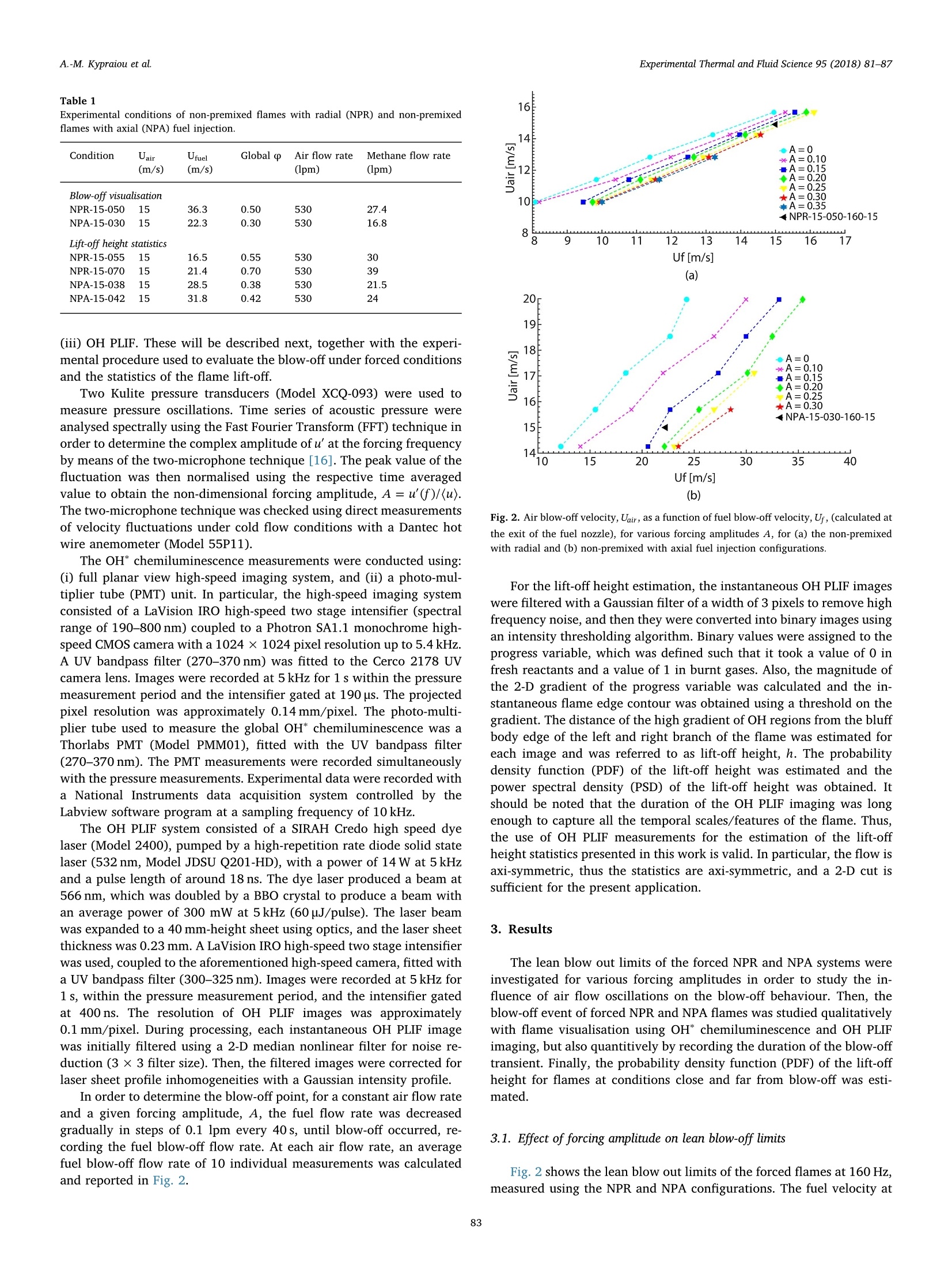

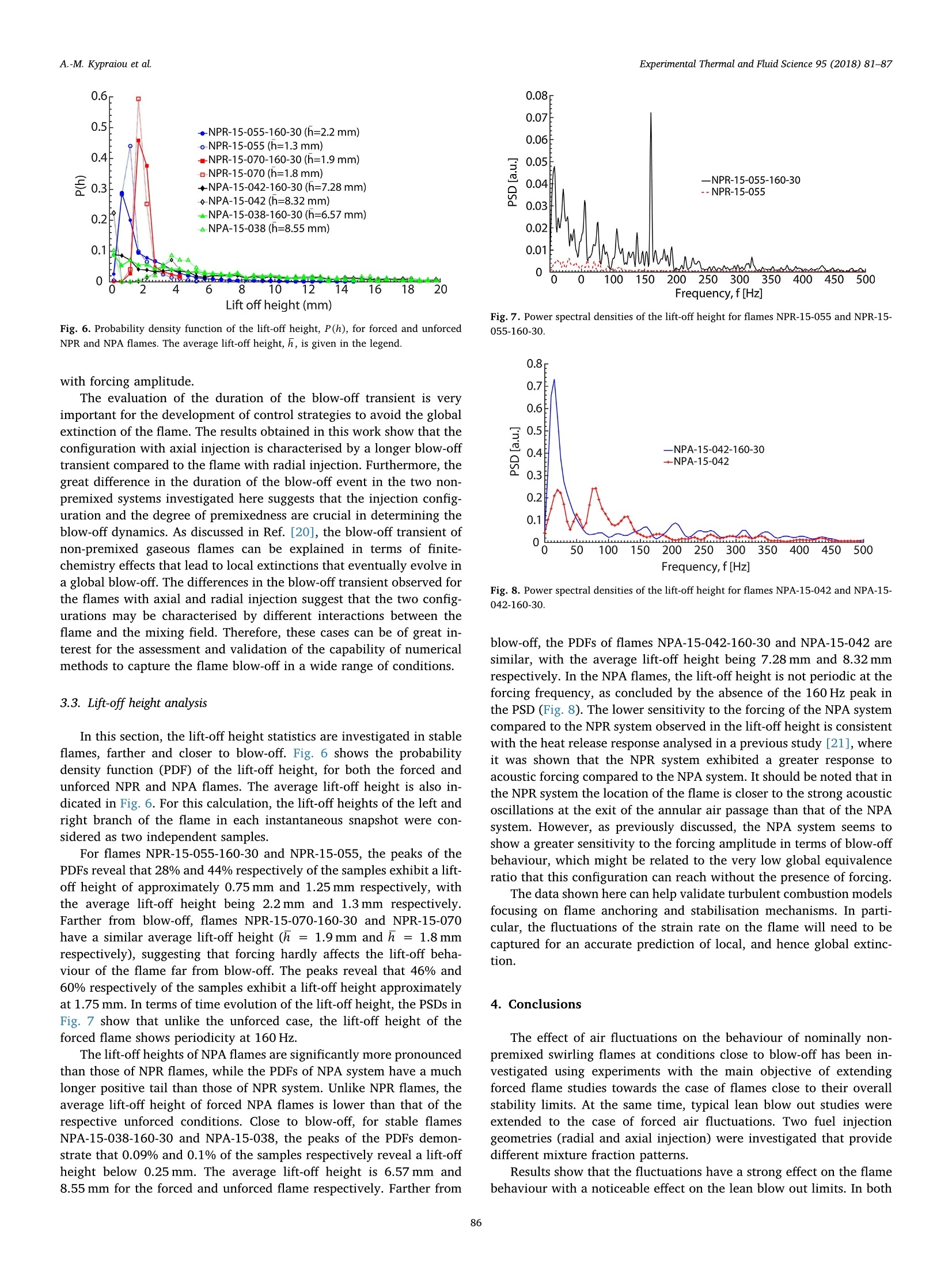

Experimental Thermal and Fluid Science 95 (2018) 81-87 Contents lists available at ScienceDirect Experimental Thermal and Fluid Science journal homepage: www.elsevier.com/locate/etfs Dynamics of acoustically forced non-premixed flames close to blow-off Anna-Maria Kypraiou*, Andrea Giusti, Patton M. Allison, Epaminondas Mastorakos Department of Engineering, University of Cambridge, Cambridge CB2 1PZ, UK ARTICLEINFO ABSTRACT Keywords:Non-premixed flameBlow-offLean blow-off limitsAcoustic oscillationsThermoacousticsLift-off height The effect of forced oscillations on the behaviour of non-premixed swirling methane flames close to the leanblow out limits was investigated using experiments in a lab-scale burner. Two different fuel injection geometries,non-premixed with radial -NPR- and non-premixed with axial -NPA- fuel injection, are considered. The flamebehaviour is studied using 5 kHz OH* chemiluminescence and OH Planar Laser Induced Fluorescence (OH PLIF)imaging. In both systems, acoustic forcing reduces the stability of the flame, and in particular, the stability wasfound to decrease with the increase in forcing amplitude. Flame lift-off was observed in both configurations, withthe magnitude of the effect of forcing depending on the fuel injection configuration. The results provide insighton the effect of superimposed flow field fluctuations in systems operating close to the lean blow out limits andoffer useful data for the development and validation of numerical models for the prediction of the dynamicbehaviour of flames of industrial interest. 1. Introduction In order to reduce the environmental impact of combustion systems,and in particular to reduce NOx emissions, gas turbine manufacturers aredeveloping technologies based on the use of lean flames. However, leancombustion systems are more prone to combustion instabilities [1], whichare becoming one of the main issues for the development of lean burntechnologies. Combustion instabilities can cause vibration and additionalnoise [2], and in the case of large fluctuations, also flame quenching,flashback and damages of the combustor components [3]. The study of the flame behaviour in the presence of flow field fluc-tuations is very important for the understanding of combustion in-stabilities and in general for the development of modern combustorsbased on lean burn technology. Self-excited oscillations can affect thelocal behaviour of the flame [4-6],possibly involving local extinction andre-ignition phenomena. Furthermore, as observed in Refs. [7-9], thepresence of velocity oscillations can have a strong impact on the stabilitylimits (in the sense of flame existence, not in the sense of absence ofpressure oscillations) of the flame. The understanding and prediction offlame blow-off is of crucial importance for the design of modern com-bustors that often operate close to the lean blow out limits. Therefore, it isalso of great interest to study the impact of periodic motions on the localand global extinction of flames of practical interest. Several fundamental studies on the effect of velocity fluctuations onthe local flame behaviour can be found in the literature. Among them,Sung and Law [4] investigated the transient behaviour of counterflowdiffusionl an premixed flames subjected toosinusoidal velociity ( * Corresponding author. ) ( E-mail address : am k 74 @c am. a c. u k ( A.-M. Kypraiou). ) fluctuations. The flame structure of the premixed flame was found to beless sensitive to the fluctuations of the strain rate compared to diffusionflames. Furthermore, the amplitude of the flame response was found todecrease with the increase in the frequency of the oscillations. As far asextinction is concerned, the same study showed that for low forcing fre-quencies the extinction strain rate is independent of mean strain rate [4](the variations of the strain rate are sufficiently slow compared to thechemical time scale and the flame responds to the local value of thestrain). In contrast, for high frequencies, the extinction behaviour dependson the amplitude of the fluctuations and the effective Lewis number of themixture [4]. A similar behaviour was also found in [5,6], where the effectof oscillations of the strain rate on diluted methane counterflow diffusionflames was investigated.Both studies showed that at high frequencies thepeak strain rate can be extended further beyond the steady-state extinc-tion limit. Furthermore, the amplitude of the strain that a flame cansustain without extinguishing depends on the value of the mean strainrate and generally decreases with the increase in the mean strain [5]. Considering flame configurations much closer to real engines, lim-ited literature exists on the investigation of the effect of acoustic os-cillations in conditions close to the lean blow out limits. Furthermore,the focus is usually on premixed flames only [7,8,10]. In one of thesestudies [8] the blow-off of bluff-body stabilised premixed flames underharmonic forcing of the upstream mixture velocity was investigated.The results suggest that the presence of velocity fluctuations has astrong impact on the flame behaviour, and both the blow-off me-chanism and stability limits of forced flames can be different from theone observed in unforced flames. These investigations have been ( Received 28 January 2018; Accepted 29 January 2018 ) ( Available online 31 January 2018 ) further extended to include upstream spatial mixture gradients [9,11].Results show that the behaviour of the flame and the blow-off limits arestrongly affected by the spatial variation of the equivalence ratio up-stream of the reacting region. Since many practical systems operate inconditions where fuel and air are not fully premixed before entering thecombustion zone, it is of great interest to further extend the study of theresponse of flames with spatial variation of the equivalence ratio toconfigurations much closer to practical devices. In the case of imperfectpremixing, the time-varying velocity field may introduce time-varyingand spatially-varying equivalence ratio distributions, or in the case offully non-premixed systems, time-varying heat release rate due to thetime-varying mixing rates. Hence, the study of the forced response ofsystems characterised by different levels of premixing could also allowus to explore the impact of different mechanisms on the flame stability. In this work, the effect of air fluctuations on the behaviour ofswirling flames at conditions close to the lean blow out limits has beeninvestigated using experiments. Two configurations, characterised bydifferent fuel injection strategies, have been considered to includespatial variations of the equivalence ratio up to fully non-premixedsystems. The present investigation extends forced flame studies towardsthe case of flames close to their overall stability limits and, at the sametime, extends the typical lean blow out studies to the case of forced airfluctuations. The specific objectives are:(i) to understand the effect offorcing amplitude on the flame characteristics and lean blow out limitsin systems characterised by different fuel injection; (ii) to give moreinsight into the flame structure and the mechanisms affecting local andglobal extinction; (iii) to measure the effect of forced fluctuations on thelift-off height of stable flames at conditions far and close to blow-off. 2. Materials and methods The experimental apparatus used in this study is a modified version ofthe rig used in previous blow-off studies without forcing [12,13]. Themain differences are the presence of a system upstream of the flame re-gion to create the forced fluctuations and the fuel injection configuration(a geometry with radial fuel injection has been added). Two fuel con-figurations were studied in this work: (a) non-premixed methane flameswith radial fuel injection (NPR) and (b) non-premixed flame with andaxial fuel injection (NPA). A schematic of the experimental rig is shownin Fig. 1. The burner consisted of two long concentric circular ducts. The 97mm outer duct (i.d.=37mm) housed two pressure taps (axiall dis-tance =200 mm), where pressure transducers were mounted flush withthe duct internal wall for acoustic pressure measurements. At the exit ofthe inner duct (i.d. =6mm), a conical bluff body of diameter 25 mm wasmounted. A 60-degree vane angle swirler, located 41.6 mm upstream ofthe bluff body plane, created an azimuthal component of the velocity atthe exit. For inert conditions, the velocity measurements of Ref. [14]showed that the tangential velocity was about 0.5 U, where U, is the bulkaxial velocity. This measurement was taken at the centre of the annularpassage, between the bluff body and the outer duct, and at an axialdistance of 6 mm downstream of the bluff body plane. Inside the plenumflow straighteners streamlined the flow. Four quartz plates of 97 mmwidth and 150 mm length enclosed the working section and providedoptical access to the flame, preventing any possible air entrainment fromthe surroundings. In order to perturb the flame and thus induce heatrelease fluctuations, acoustic oscillations were imposed to the air massflow by means of two loudspeakers, positioned diametrically oppositeeach other in a plenum, which was fitted upstream of the outer duct. Theflames were forced at 160 Hz (main resonant frequency of the plenumand burner assembly [15], chosen on purpose in order to achieve a highforcing amplitude), while the forcing amplitude varied to investigate itseffect on the blow-off dynamics. The main difference between the NPRand NPA systems is the fuel injection point. In the bluff body of the NPRsystem the fuel was injected radially through a 0.5 ± 0.01mm circulargap located 3mm upstream of the bluff body plane (Fig. 1). In thissystem, apart from the time-varying velocity field, there was also a time-(the fuel flow could in principle oscillate, since the annular gap at theinjection point was not choked) and space-varying equivalence ratio. Inthe NPA system, the bluff body design was modified so that a central pipeof diameter of 4 mm fed the methane, as shown in Fig. 1. Air and fuelflow rates were controlled using Alicat mass flow controllers. The operating conditions are presented in Table 1 together with theacronyms that will be used in the remainder of this paper to indicateeach condition. The air velocity was calculated as the air flow rate di-vided by the open annular area between the bluff-body and the outerduct at the exit of the burner inlet, while the fuel velocity was calcu-lated as the fuel flow rate divided by the area of the fuel nozzle exit. Theflame behaviour for every case was characterised by means of: (i) ve-locity fluctuations at the bluff-body edge (indirect measurementthrough the two-microphone technique), (ii) OH* chemiluminescence, Fig. 1. Schematic of the burner used for the blow-off study of forced (a) NPR and (b) NPA flames. Experimental conditions of non-premixed flames with radial (NPR) and non-premixedflames with axial (NPA) fuel injection. Condition Uair Ufuel Global o Air flow rate Methane flow rate (m/s) (m/s) (lpm) (pm) Blow-off visualisation NPR-15-050 15 36.3 0.50 530 27.4 NPA-15-030 15 22.3 0.30 530 16.8 Lift-off height statistics NPR-15-055 15 16.5 0.55 530 30 NPR-15-070 15 21.4 0.70 530 39 NPA-15-038 15 28.5 0.38 530 21.5 NPA-15-042 15 31.8 0.42 530 24 (iii) OH PLIF. These will be described next, together with the experi-mental procedure used to evaluate the blow-off under forced conditionsand the statistics of the flame lift-off. Two Kulite pressure transducers (Model XCQ-093) were used tomeasure pressure oscillations. Time series of acoustic pressure wereanalysed spectrally using the Fast Fourier Transform (FFT) technique inorder to determine the complex amplitude of u’ at the forcing frequencyby means of the two-microphone technique [16]. The peak value of thefluctuation was then normalised using the respective time averagedvalue to obtain the non-dimensional forcing amplitude, A=u'(f)/(u).The two-microphone technique was checked using direct measurementsof velocity fluctuations under cold flow conditions with a Dantec hotwire anemometer (Model 55P11). The OH* chemiluminescence measurements were conducted using:(i) full planar view high-speed imaging system, and (ii) a photo-mul-tiplier tube (PMT) unit. In particular, the high-speed imaging systemconsisted of a LaVision IRO high-speed two stage intensifier (spectralrange of 190-800 nm) coupled to a Photron SA1.1 monochrome high-speed CMOS camera with a 1024 ×1024 pixelresolution up to 5.4 kHz.A UV bandpass filter (270-370nm) was fitted to the Cerco 2178 UVcamera lens. Images were recorded at 5 kHz for 1s within the pressuremeasurement period and the intensifier gated at 190 us. The projectedpixel resolution was approximately 0.14 mm/pixel. The photo-multi-plier tube used to measure the global OH* chemiluminescence was aThorlabs PMT (Model PMM01), fitted with the UV bandpass filter(270-370 nm). The PMT measurements were recorded simultaneouslywith the pressure measurements. Experimental data were recorded witha National Instruments data acquisition system controlled by theLabview software program at a sampling frequency of 10 kHz. The OH PLIF system consisted of a SIRAH Credo high speed dyelaser (Model 2400), pumped by a high-repetition rate diode solid statelaser (532 nm, Model JDSU Q201-HD), with a power of 14 W at 5 kHzand a pulse length of around 18 ns. The dye laser produced a beam at566 nm, which was doubled by a BBO crystal to produce a beam withan average power of 300 mW at 5 kHz (60 pJ/pulse). The laser beamwas expanded to a 40 mm-height sheet using optics, and the laser sheetthickness was 0.23 mm. A LaVision IRO high-speed two stage intensifierwas used, coupled to the aforementioned high-speed camera, fitted witha UV bandpass filter (300-325 nm). Images were recorded at 5 kHz for1 s, within the pressure measurement period, and the intensifier gatedat 400 ns. The resolution of OH PLIF images was approximately0.1 mm/pixel. During processing, each instantaneous OH PLIF imagewas initially filtered using a 2-D median nonlinear filter for noise re-duction (3 ×3 filter size). Then, the filtered images were corrected forlaser sheet profile inhomogeneities with a Gaussian intensity profile. In order to determine the blow-off point, for a constant air flow rateand a given forcing amplitude, A, the fuel flow rate was decreasedgradually in steps of 0.1 lpm every 40 s, until blow-off occurred, re-cording the fuel blow-off flow rate. At each air flow rate, an averagefuel blow-off flow rate of 10 individual measurements was calculatedand reported in Fig.2. Fig.2. Air blow-off velocity, Uair, as a function of fuel blow-off velocity,Ur, (calculated atthe exit of the fuel nozzle), for various forcing amplitudes A, for (a) the non-premixedwith radial and (b) non-premixed with axial fuel injection configurations. For the lift-off height estimation, the instantaneous OH PLIF imageswere filtered with a Gaussian filter of a width of 3 pixels to remove highfrequency noise, and then they were converted into binary images usingan intensity thresholding algorithm. Binary values were assigned to theprogress variable, which was defined such that it took a value of 0 infresh reactants and a value of 1 in burnt gases. Also, the magnitude ofthe 2-D gradient of the progress variable was calculated and the in-stantaneous flame edge contour was obtained using a threshold on thegradient. The distance of the high gradient of OH regions from the bluffbody edge of the left and right branch of the flame was estimated foreach image and was referred to as lift-off height, h. The probabilitydensity function (PDF) of the lift-off height was estimated and thepower spectral density (PSD) of the lift-off height was obtained. Itshould be noted that the duration of the OH PLIF imaging was longenough to capture all the temporal scales/features of the flame. Thus,the use of OH PLIF measurements for the estimation of the lift-offheight statistics presented in this work is valid. In particular, the flow isaxi-symmetric, thus the statistics are axi-symmetric, and a 2-D cut issufficient for the present application. 3. Results The lean blow out limits of the forced NPR and NPA systems wereinvestigated for various forcing amplitudes in order to study the in-fluence of air flow oscillations on the blow-off behaviour. Then, theblow-off event of forced NPR and NPA flames was studied qualitativelywith flame visualisation using OH* chemiluminescence and OH PLIFimaging, but also quantitively by recording the duration of the blow-offtransient. Finally, the probability density function (PDF) of the lift-offheight for flames at conditions close and far from blow-off was esti-mated. 3.1. Effect of forcing amplitude on lean blow-off limits Fig. 2 shows the lean blow out limits of the forced flames at 160 Hz,measured using the NPR and NPA configurations. The fuel velocity at blow-off constitutes the average value of ten blow-off events, while thestandard deviation of these measurements normalised by the meanvalue was approximately 0.03. It should be noted that this low valuewas made possible because the step of fuel flow rate reduction was verysmall (0.1 lpm) and a large number of blow-off measurements wereconducted. For both NPR and NPA flames, it can be deduced that forcing re-duces the stability of the flame,which decreases with increasing forcingamplitude. In particular, for a constant Uair at blow-off, the greater theforcing amplitude A, the greater the U at blow-off, whereas for aconstant U, the greater the forcing amplitude, the lower the Uair atblow-off. Also, for a given forcing amplitude A, as the U increases, theUair increases. This is consistent with the findings of previous studies onthe blow-off behaviour of forced premixed flames [7,17] as well as withfundamental studies on laminar counterflow diffusion flames [4-6]. Itwas deduced that the acoustic forcing had a great influence on blow-offequivalence ratios, which was found to depend on the modulationfrequency and mixture velocity. In addition, another study on blow-offof forced premixed flames with spatial mixture gradients [9] reportedthat the blow-off equivalence ratio increased with forcing amplitude forf = 100 Hz and f= 200 Hz. This was associated with the greater un-steadiness at the flame base, in agreement with the results of Ba-lachandran et al. [15]. The NPA system shows a greater sensitivity to changes in forcingamplitude compared to the NPR configuration, since for a given air flowrate and forcing amplitude it exhibits larger variations of the fuel flowrate (overall equivalence ratio) compared to the case without forcing.For example, considering a constant Uair = 15.7 m/s, between A=0and A= 0.25, for the NPA system, U changes in the range of 15.5-26.9 m/s (the maximum variation from the U value at A =0 isapproximately 70%). In the NPR system, for Uair =15.7 m/s, betweenA =0 and A =0.25, U changes in the range of 15.0-16.1 m/s (themaximum variation from the U value at A = 0 is approximately 7%).This implies that the operating range of the NPA system is significantlyreduced in the presence of forcing. However, considering the globalequivalence ratio at blow-off, it should be noted that the NPA systemcan be operated much leaner compared to the NPR system for all theforcing amplitudes investigated in this work. Therefore, the highersensitivity of the NPA system to changes in the amplitude of the fluc-tuations could be attributed to the higher sensitivity typically asso-ciated to very lean conditions (small global equivalence ratio). Thefluctuations of the air flow might have an important impact on therecirculation zone, changing significantly the mixing pattern andtherefore affecting the lean blow out. In contrast, in the NPR system thehigher equivalence ratio at blow-off (for a given air velocity at theinlet), also in the absence of forcing, indicates that this injection con-figuration is intrinsically less stable and this can be related to the in-jection location that causes the flame to be in a high strain region. Thepresence of air flow oscillations only slightly changes the operatingrange (already smaller compared to the NPA system). This also suggeststhat in the NPR case, the fluctuations of the air flow have a lower effecton the mixing pattern than that in the NPA case. 3.2. Blow-off event visualisation As far as the unforced case NPR-15-050 is concerned (Fig. 3), theOH PLIF images demonstrate that the OH fluorescence signal is rela-tively continuous and concentrates mainly in a thin zone, located in the Fig. 3. Instantaneous OH chemiluminescence images of (a) unforced stable flame NPR-15-050 and (b) forced blow-off flame NPR-15-050-160-15, and (c, d) the respective OH PLIFimages. For the forced case,images correspond to 40, 20, 10 and 1 ms from blow-off. 100 Fig. 4. Instantaneous OH" chemiluminescence images of (a) unforced stable flame NPA-15-030 and (b) forced blow-off flame NPA-15-030-160-15 and (c, d) the respective OH PLIFimages. For the forced case,images correspond to 40, 20, 10 and 1 ms from blow-off. inner shear layer (ISL) region,suggesting that the flame branches areanchored at the bluff body edge. For forced flame with radial injection,NPR-15-050-160-15, a decrease in the size of the heat release zone isobserved, while the OH zone is fragmented in different regions. Com-plete or partial absence of the flame branch in the ISL and/or wall re-gion, and attachment and lift-off at the bluff body edge can be seen.Concerning the unforced stable flame NPA-15-030 (Fig. 4), the OH PLIFimages reveal that the OH fluorescence signal is relatively continuous,with occasional flame lift-off.The visualisation of the blow-off event forflame NPA-15-030-160-15 shows a gradual decrease in the size of theheat release zone, with the last flame fragments seen inside the innerrecirculation zone and in the vicinity of the fuel nozzle exit. On thecontrary, in the case of NPR-15-050-160-15, the last flame fragmentsduring blow-off are observed in the ISL region. This is associated withthe fact that in the NPA system the fuel is injected axially in the innerrecirculation zone, whereas in the NPR system the fuel is injected ra-dially upstream of the bluff body plane. As also observed in previousstudies with swirling flames without forcing [12,13], as the flame ap-proaches the blow-off, it becomes more and more fragmented withholes along the flame sheet, interpreted as local extinctions of theflame. The presence of local extinction and their evolution into a globalblow-off has also been confirmed by advanced numerical simulations[18-20]. After the qualitative description of the blow-off event for both NPRand NPA flames, the duration of the blow-off transient, tB, is quantified,as shown in Fig. 5. The beginning of the transient is defined as the lastpoint in time at which the OH* chemiluminescence signal is at thesteady-state mean value. Sufficiently far from blow-off, a nearly peri-odic response, with small variations in amplitude is observed, followedby a transition to zero OH* chemiluminescence signal as the completeextinction is approached. It is evident that the duration of the blow-off Fig. 5. Time series of OH chemiluminescence signal, normalised by its maximum value,for flames NPR-15-050-160-15 and NPA-15-030-160-15, used to quantify the duration ofthe blow-off transient, tB. event is significantly greater for flame NPA-15-030-160-15 compared tothe flame NPR-15-050-160-15 (147.2 ms vs 31.9 ms). Given that thetwo configurations have the same air bulk velocity, it could be sug-gested that this is attributed to the difference in the fuel injectionconfiguration. The blow-off event duration of flame NPA-15-030-160-15, whichlasts for 23.5 cycles for the 160 Hz oscillation, is much greater than theaverage blow-off duration of unforced non-premixed flames (46.6 ms),measured in the same burner [12]. This is consistent with the results ofa previous study on the response and extinction behaviour of laminarcounterflow diffusion and premixed flames [4], which reported that thepresence of oscillation retards extinction. In addition, it was found thatthe blow-off duration increases with forcing frequency and decreases Fig. 6. Probability density function of the lift-off height, P(h), for forced and unforcedNPR and NPA flames. The average lift-off height, h, is given in the legend. with forcing amplitude. The evaluation of the duration of the blow-off transient is veryimportant for the development of control strategies to avoid the globalextinction of the flame. The results obtained in this work show that theconfiguration with axial injection is characterised by a longer blow-offtransient compared to the flame with radial injection. Furthermore,thegreat difference in the duration of the blow-off event in the two non-premixed systems investigated here suggests that the injection config-uration and the degree of premixedness are crucial in determining theblow-off dynamics. As discussed in Ref. [20], the blow-off transient ofnon-premixed gaseous flames can be explained in terms of finite-chemistry effects that lead to local extinctions that eventually evolve ina global blow-off. The differences in the blow-off transient observed forthe flames with axial and radial injection suggest that the two config-urations may be characterised by different interactions between theflame and the mixing field. Therefore, these cases can be of great in-terest for the assessment and validation of the capability of numericalmethods to capture the flame blow-off in a wide range of conditions. 3.3. Lift-off height analysis In this section, the lift-off height statistics are investigated in stableflames, farther and closer to blow-off. Fig. 6 shows the probabilitydensity function (PDF) of the lift-off height, for both the forced andunforced NPR and NPA flames. The average lift-off height is also in-dicated in Fig.6. For this calculation, the lift-off heights of the left andright branch of the flame in each instantaneous snapshot were con-sidered as two independent samples. For flames NPR-15-055-160-30 and NPR-15-055, the peaks of thePDFs reveal that 28% and 44% respectively of the samples exhibit a lift-off height of approximately 0.75 mm and 1.25 mm respectively, withthe average lift-off height being 2.2mm and 1.3 mm respectively.Farther from blow-off, flames NPR-15-070-160-30 and NPR-15-070have a similar average lift-off height (h =1.9 mm and h = 1.8 mmrespectively), suggesting that forcing hardly affects the lift-off beha-viour of the flame far from blow-off. The peaks reveal that 46% and60% respectively of the samples exhibit a lift-off height approximatelyat 1.75 mm. In terms of time evolution of the lift-off height, the PSDs inFig. 7 show that unlike the unforced case, the lift-off height of theforced flame shows periodicity at 160 Hz. The lift-off heights of NPA flames are significantly more pronouncedthan those of NPR flames, while the PDFs of NPA system have a muchlonger positive tail than those of NPR system. Unlike NPR flames, theaverage lift-off height of forced NPA flames is lower than that of therespective unforced conditions. Close to blow-off, for stable flamesNPA-15-038-160-30 and NPA-15-038, the peaks of the PDFs demon-strate that 0.09% and 0.1% of the samples respectively reveal a lift-offheight below 0.25 mm. The average lift-off height is 6.57 mm and8.55 mm for the forced and unforced flame respectively. Farther from Fig. 7. Power spectral densities of the lift-off height for flames NPR-15-055 and NPR-15-055-160-30. Fig. 8. Power spectral densities of the lift-off height for flames NPA-15-042 and NPA-15-042-160-30. blow-off, the PDFs of flames NPA-15-042-160-30 and NPA-15-042 aresimilar, with the average lift-off height being 7.28 mm and 8.32 mmrespectively. In the NPA flames, the lift-off height is not periodic at theforcing frequency, as concluded by the absence of the 160 Hz peak inthe PSD (Fig. 8). The lower sensitivity to the forcing of the NPA systemcompared to the NPR system observed in the lift-off height is consistentwith the heat release response analysed in a previous study [21], whereit was shown that the NPR system exhibited a greater response toacoustic forcing compared to the NPA system. It should be noted that inthe NPR system the location of the flame is closer to the strong acousticoscillations at the exit of the annular air passage than that of the NPAsystem. However, as previously discussed, the NPA system seems toshow a greater sensitivity to the forcing amplitude in terms of blow-offbehaviour, which might be related to the very low global equivalenceratio that this configuration can reach without the presence of forcing. The data shown here can help validate turbulent combustion modelsfocusing on flame anchoring and stabilisation mechanisms. In parti-cular, the fluctuations of the strain rate on the flame will need to becaptured for an accurate prediction of local, and hence global extinc-tion. 4. Conclusions The effect of air fluctuations on the behaviour of nominally non-premixed swirling flames at conditions close to blow-off has been in-vestigated using experiments with the main objective of extendingforced flame studies towards the case of flames close to their overallstability limits. At the same time, typical lean blow out studies wereextended to the case of forced air fluctuations. Two fuel injectiongeometries (radial and axial injection) were investigated that providedifferent mixture fraction patterns. Results show that the fluctuations have a strong effect on the flamebehaviour with a noticeable effect on the lean blow out limits. In both configurations studied in this work, it was found that the acousticforcing reduces the stability of the flame and the stability decreaseswith the increase in forcing amplitude. The system with axial injectionshowed a greater sensitivity to the forcing amplitude compared to thesystem with radial injection in terms of changes in the operabilitylimits. Both systems, at the blow-off condition showed a gradual de-crease in the flame size, with the flame sheet being fragmented in dif-ferent regions, together with intermittent attachment and lift-off fromthe bluff-body. In both configurations investigated here, the last frag-ments of the flame were detected in the region close to the injectionlocation suggesting that during the blow-off event the flame movescloser and closer to the fuel injection system. The duration of the blow-off event was found to be significantly greater in the case with axialinjection, suggesting that the injection configuration and hence themixture fraction pattern have an important effect on the blow-off dy-namics. The presence of forcing also affects the lift-off height. In particular,in the configuration with radial injection the spectrum of the lift-offheight showed a clear peak at the forcing frequency. This peak is lessevident in the spectrum of flames with axial injection suggesting againthat the injection geometry and mixing behaviour may have an im-portant impact on the dynamic response of the flame. Acknowledgements The financial assistance of the EPSRC, Rolls-Royce Group, andOnassis Foundation is acknowledged. ( References ) extinction of counterflow diffusion flames, Symp. (Int.) Combust. 27 (1998)703-710. [6] J.S. Kistler, C.J. Sung, T.G. Kreut, C.K. Law, M. Nishioka, Extinction of counterflowdiffusion flames under velocity oscillations, Symp. (Int.) Combust. 26 (1996)113-120. [7] A.A. Chaparro, B.M. Cetegen, Blowoff characteristics of bluff-body stabilized con-ical premixed flames under upstream velocity modulation, Combust. Flame 144(2006) 318-335. i[8S]. Chaudhuri, S. Kostka,M.W. Renfro, B.M. Cetegen, Blowoff mechanism of har-monically forced bluff body stabilized turbulent premixed flames, Combust. Flame159(2012)638-640. [9] S. Chaudhuri, B.M. Cetegen, Blowoff characteristics of bluff-body stabilized conicalpremixed flames with upstream spatial mixture gradients and velocity oscillations,Combust. Flame 153 (2008) 616-633. [10] S. Biswas, K. Kopp-Vaughn, M.W. Renfro, B.M. Cetegen, Phase resolved char-acterization of conical premixed flames near and far frf.Somhuom blowoff, Combust. Flame160 (2013) 2843-2855. [11] S. Chaudhuri, B.M. Cetegen, Response dynamics of bluff-body stabilized conicalpremixed turbulent flames with spatial mixture gradients, Combust. Flame 156(2009)706-720. ( [12]D . E . C av a li e r e,J. K a ri uk i , E . M as tor ak o s, A c om p a r is o n o f t he bl o w- o ff b eha vi ou r o f s w i rl - s tabil iz ed p r e m i x e d , n o n - premixed a n d s p ra y f l a mes , Fl o w Tu rbulenc e C omb u st 91 ( 201 3 )34 7- 3 72. ) ( [13] 1 R . Yu an , M e a s urement s in S w irl-st a b il i s ed Spr ay F la mes a t Blow-off, D epartme nt o f ) ( E n gin e er i n g, U ni v e r s i t y o f C am br i dge, Ca mb r i dge, 201 5, p . 7 8 . ) ( [14] 1 D.E. Cavaliere, B low-off in gas turbine combustors, in: Department of En g ineering,University of Cambridge, Cambridge, UK, 2013. ) ( [15 ] R . B ala c han d ran, B . O. A y oola , C . F . K a mi ns k i, A . P . D owl ing , E . M a s tor a k o s, E x p e r im ental i n ve s ti ga t io n o f the nonli n e a r re s ponse of turbulent p re mi x ed flame s t o i mp o s ed i n l e t ve l oc i t y os c i l l at i o n s , Co m b u s t . F la m e 1 43 ( 200 5 ) 3 7-55 . ) ( [16 ] A .F. S ey bert, D . F . R oss , E x p er im en tal d e t ermin at io n of a c o us t ic prop e rti es u s i n g a two- m icrophone r a ndom-excita t ion t e chn i q u e, J. A c oust. S oc. A m. 6 1 ( 1 9 77) 1 3 62- 13 7 0 . ) [17] A. Chaparro, E. Landry, B.M. Cetegen, Transfer function characteristics of bluff-body stabilized, conical V-shaped premixed turbulent propane-air flames, Combust.Flame 145 (2006) 290-299. ( [18] A . G iusti, E . M a st ora k o s , D et a i le d c h e m istr y LES / C M C s i m u la t ion o f a s w i r l i ng e thanol s pray f lame ap proac h in g b lo w-of f , P r o c. C o m b ust. In s t . 3 6 (20 1 7) 2 6 2 5 -2 632. ) [19]H1. Zhang, A. Garmory, D.E. Cavaliere, E. Mastorakos, Large Eddy simulation/con-ditional moment closure modeling of swirl-stabilized non-premixed flames withlocal extinction, Proc. Combust. Inst. 35 (2015)1167-1174. ( [20] H . Zh an g , E . M ast o r akos, P r e d i ction of g l o b a l ext i nc t ion c o n diti o n s and d y na m ic s i n s wi rl ing non-premi x ed f l am e s u sing LES / C M C m od e ll i ng , F low T u r bu le nce Comb u st 96 ( 2 016) 86 3- 889. ) ( [ 21] A .M. K y praiou, N.A. Worth, E. Ma s torakos, Experimental investigation of t he re- s ponse of p remixed and n o n-premixed turbulent flames to ac o ustic fo r cing, i n : 5 4thAIAA Aerospace Sc i ences Meeting, American Institute of Aeronautics and Astronautics, 2016. ) C The Authors. Published by Elsevier Inc. This is an open access article under the CC BY license (http://creativecommons.org/licenses/BY/./). The effect of forced oscillations on the behaviour of non-premixed swirling methane flames close to the lean blow out limits was investigated using experiments in a lab-scale burner. Two different fuel injection geometries, non-premixed with radial -NPR- and non-premixed with axial -NPA- fuel injection, are considered. The flame behaviour is studied using 5 kHz OH∗ chemiluminescence and OH Planar Laser Induced Fluorescence (OH PLIF) imaging. In both systems, acoustic forcing reduces the stability of the flame, and in particular, the stability was found to decrease with the increase in forcing amplitude. Flame lift-off was observed in both configurations, with the magnitude of the effect of forcing depending on the fuel injection configuration. The results provide insight on the effect of superimposed flow field fluctuations in systems operating close to the lean blow out limits and offer useful data for the development and validation of numerical models for the prediction of the dynamic behaviour of flames of industrial interest.

确定

还剩5页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《非预混火焰中5 kHz OH∗ 自发荧光和 OH 平面激光诱导荧光(OH PLIF)检测方案(CCD相机)》,该方案主要用于煤炭中5 kHz OH∗ 自发荧光和 OH 平面激光诱导荧光(OH PLIF)检测,参考标准--,《非预混火焰中5 kHz OH∗ 自发荧光和 OH 平面激光诱导荧光(OH PLIF)检测方案(CCD相机)》用到的仪器有LaVision IRO 图像增强器、PLIF平面激光诱导荧光火焰燃烧检测系统、德国LaVision PIV/PLIF粒子成像测速场仪、LaVision DaVis 智能成像软件平台

推荐专场

CCD相机/影像CCD

更多

相关方案

更多

该厂商其他方案

更多