方案详情

文

由于工程纳米颗粒 (EN) 在各行业中的使用不断增加以及对环境和消费者风险开展的后续研究也在不断增加,对纳米颗粒 (NP) 表征的需求在近年呈现爆炸式增长的趋势。

方案详情

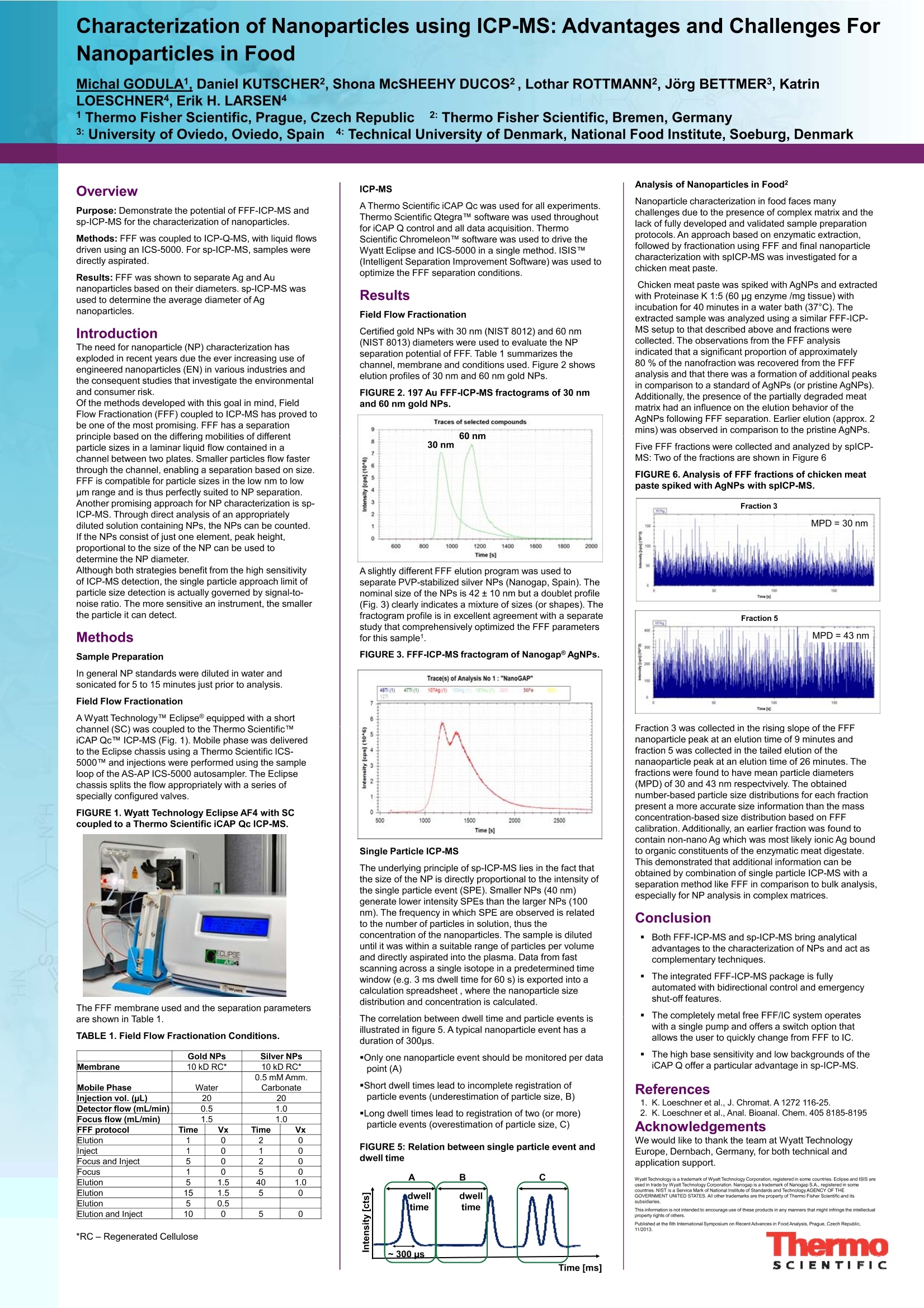

Characterization of Nanoparticles using ICP-MS: Advantages and Challenges ForNanoparticles in Food Michal GODULA1, Daniel KUTSCHER2, Shona McSHEEHYDUCOS2, Lothar ROTTMANN2, Jorg BETTMER3, KatrinLOESCHNER4,Erik H. LARSEN4 1 Thermo Fisher Scientific, Prague, Czech Republic 2: Thermo Fisher Scientific, Bremen, Germany 3.University of Oviedo, Oviedo,Spain4: Technical University of Denmark, National Food Institute, Soeburg, Denmark Purpose: Demonstrate the potential of FFF-ICP-MS andsp-ICP-MS for the characterization of nanoparticles. Methods: FFF was coupled to ICP-Q-MS, with liquid flowsdriven using an ICS-5000. For sp-ICP-MS, samples weredirectly aspirated. Results: FFF was shown to separate Ag and Aunanoparticles based on their diameters. sp-ICP-MS wasused to determine the average diameter of Ag nanoparticles. Introduction The need for nanoparticle (NP) characterization hasexploded in recent years due the ever increasing use ofengineered nanoparticles (EN) in various industries andthe consequent studies that investigate the environmentaland consumer risk. Of the methods developed with this goal in mind, Field Flow Fractionation (FFF) coupled to ICP-MS has proved tobe one of the most promising. FFF has a separationprinciple based on the differing mobilities of differentparticle sizes in a laminar liquid flow contained in a channel between two plates. Smaller particles flow faster through the channel, enabling a separation based on size. FFF is compatible for particle sizes in the low nm to low Another promising approach for NP characterization is sp-ICP-MS. Through direct analysis of an appropriatelydiluted solution containing NPs, the NPs can be counted.If the NPs consist of just one element, peak height,proportional to the size of the NP can be used todetermine the NP diameter. pm range and is thus perfectly suited to NP separation. Although both strategies benefit from the high sensitivityof ICP-MS detection, the single particle approach limit ofparticle size detection is actually governed by signal-to-noise ratio. The more sensitive an instrument, the smallerthe particle it can detect. Methods Sample Preparation In general NP standards were diluted in water andsonicated for 5 to 15 minutes just prior to analysis. Field Flow Fractionation A Wyatt Technology TM Eclipse@equipped with a shortchannel(SC) was coupled to the Thermo Scientific TMiCAP QcTM ICP-MS(Fig. 1). Mobile phase was deliveredto the Eclipse chassis using a Thermo Scientific ICS-5000TM and injections were performed using the sampleloop of the AS-AP ICS-5000 autosampler. The Eclipsechassis splits the flow appropriately with a series of specially configured valves. FIGURE 1. Wyatt Technology Eclipse AF4 with SCcoupled to a Thermo Scientific iCAP Qc ICP-MS. The FFF membrane used and the separation parametersare shown in Table 1. TABLE 1. Field Flow Fractionation Conditions. Gold NPs SilverNPs Membrane 10 kD RC* 10 kD RC* Mobile Phase Water 0.5 mM Amm. Carbonate Injection vol.(pL) 20 20 Detector flow (mL/min) 0.5 1.0 Focus flow (mL/min) 1.5 1.0 FFF protocol Time Vx Time Vx Elution 1 2 Inject 1 0 1 0 Focus and Inject 5 0 2 0 FOcUs 1 0 5 0 Elution 5 1.5 40 1.0 Elution 15 1.5 5 0 Elution 5 0.5 Elution and Inject 10 0 5 0 Elution and Inject *RC -Regenerated Cellulose A Thermo Scientific iCAP Qc was used for all experimentsThermo Scientific QtegraTM software was used throughoutfor iCAP Q control and all data acquisition. Thermo Scientific Chromeleon TM software was used to drive theWyatt Eclipse and ICS-5000 in a single method. ISISTM(Intelligent Separation Improvement Software) was used to optimize the FFF separation conditions. Results Field Flow FractionationCertified gold NPs with 30 nm (NIST 8012) and 60 nm(NIST 8013) diameters were used to evaluate the NPseparation potential of FFF. Table 1 summarizes thechannel, membrane and conditions used. Figure 2 showselution profiles of 30 nm and 60 nm gold NPs. FIGURE 2. 197 Au FFF-ICP-MS fractograms of 30 nmand 60 nm gold NPs. A slightly different FFF elution program was used toseparate PVP-stabilized silver NPs (Nanogap, Spain). Thenominal size of the NPs is 42±10 nm but a doublet profile(Fig. 3) clearly indicates a mixture of sizes (or shapes). Thefractogram profile is in excellent agreement with a separatestudy that comprehensively optimized the FFF parametersfor this sample1. FIGURE 3.FFF-ICP-MS fractogram of Nanogap@AgNPs. Single Particle ICP-MS The underlying principle of sp-ICP-MS lies in the fact thatthe size of the NP is directly proportional to the intensity ofthe single particle event (SPE). Smaller NPs (40 nm)generate lower intensity SPEs than the larger NPs (100nm). The frequency in which SPE are observed is relatedto the number of particles in solution, thus theconcentration of the nanoparticles. The sample is diluteduntil it was within a suitable range of particles per volumeand directly aspirated into the plasma. Data from fastscanning across a single isotope in a predetermined timewindow (e.g. 3 ms dwell time for 60 s) is exported into acalculation spreadsheet, where the nanoparticle sizedistribution and concentration is calculated. The correlation between dwell time and particle events isillustrated in figure 5. A typical nanoparticle event has aduration of 300ps. Only one nanoparticle event should be monitored per datapoint(A) ·Short dwell times lead to incomplete registration of particle events (underestimation of particle size, B)▪Long dwell times lead to registration of two (or more) particle events (overestimation of particle size, C) FIGURE 5: Relation between single particle event anddwell time Analysis of Nanoparticles in Food² Nanoparticlecharacterization in food faces manychallenges due to the presence of complex matrix and thelack of fully developed and validated sample preparationprotocols. An approach based on enzymatic extraction,followed by fractionation using FFF and final nanoparticlecharacterization with splCP-MS was investigated for achicken meat paste. Chicken meat paste was spiked with AgNPs and extracted with Proteinase K 1:5 (60 pg enzyme /mg tissue) withincubation for 40 minutes in a water bath (37°C). Theextracted sample was analyzed using a similar FFF-ICP·MS setup to that described above and fractions werecollected. The observations from the FFF analysisindicated that a significant proportion of approximately80 %of the nanofraction was recovered from the FFFanalysis and that there was a formation of additional peaksin comparison to a standard of AgNPs (or pristine AgNPs).Additionally, the presence of the partially degraded meatmatrix had an influence on the elution behavior of the. AgNPs following FFF separation. Earlier elution (approx. 2mins) was observed in comparison to the pristine AgNPs.Five FFF fractions were collected and analyzed by splCP- MS: Two of the fractions are shown in Figure 6 FIGURE 6. Analysis of FFF fractions of chicken meatpaste spiked with AgNPs with splCP-MS. Fraction 3 was collected in the rising slope of the FFFnanoparticle peak at an elution time of 9 minutes andfraction 5 was collected in the tailed elution of thenanaoparticle peak at an elution time of 26 minutes. Thefractions were found to have mean particle diameters(MPD) of 30 and 43 nm respectvively. The obtainednumber-based particle size distributions for each fractionpresent a more accurate size information than the massconcentration-based size distribution based on FFFcalibration. Additionally, an earlier fraction was found tocontain non-nano Ag which was most likely ionic Ag boundto organic constituents of the enzymatic meat digestate.This demonstrated that additional information can beobtained by combination of single particle ICP-MS with aseparation method like FFF in comparison to bulk analysis,especially for NP analysis in complex matrices. Conclusion · Both FFF-ICP-MS and sp-ICP-MS bring analyticaladvantages to the characterization of NPs and act ascomplementarytechniques. · The integrated FFF-ICP-MS package is fullyautomated with bidirectional control and emergencyshut-off features. The completely metal free FFF/IC system operateswith a single pump and offers a switch option thatallows the user to quickly change from FFF to IC. mThe high base sensitivity and low backgrounds of theiCAP Qoffer a particular advantage in sp-ICP-MS. References 1. K. Loeschner et al., J. Chromat. A 1272 116-25. 2. K.Loeschner et al., Anal. Bioanal. Chem. 4058185-8195 Acknowledgements We would like to thank the team at Wyatt TechnologyEurope, Dernbach, Germany, for both technical andapplication support. to itellectuahts of otherPublil:ished at the 6th iational Symposium on F n Food Analysis,Prague.Czech Republic,11/2013 Wyatt Technology is a traderark of Wyatt Technology Corporation, registered in some countries, Eclipse and ISIS areusedin trade by Wyat Technology Corporation. Nanogap is a trademark of Nanogap S.A. reqisterered if nin sontitut YASENGY 9F THEiYFRNNIMFNT L (imi ithi nrninY f Tharme fishir iiniini 由于工程纳米颗粒 (EN) 在各行业中的使用不断增加以及对环境和消费者风险开展的后续研究也在不断增加,对纳米颗粒 (NP)表征的需求在近年呈现爆炸式增长的趋势。

确定

还剩1页未读,是否继续阅读?

赛默飞色谱与质谱为您提供《食品中纳米颗粒检测方案(ICP-AES)》,该方案主要用于其他食品中理化分析检测,参考标准--,《食品中纳米颗粒检测方案(ICP-AES)》用到的仪器有

相关方案

更多

该厂商其他方案

更多