方案详情

文

■自动化水解对牛奶进行水解,无需样本转移

■全自动溶剂萃取,提高效率

■溶剂回收率高达90%,节省成本

方案详情

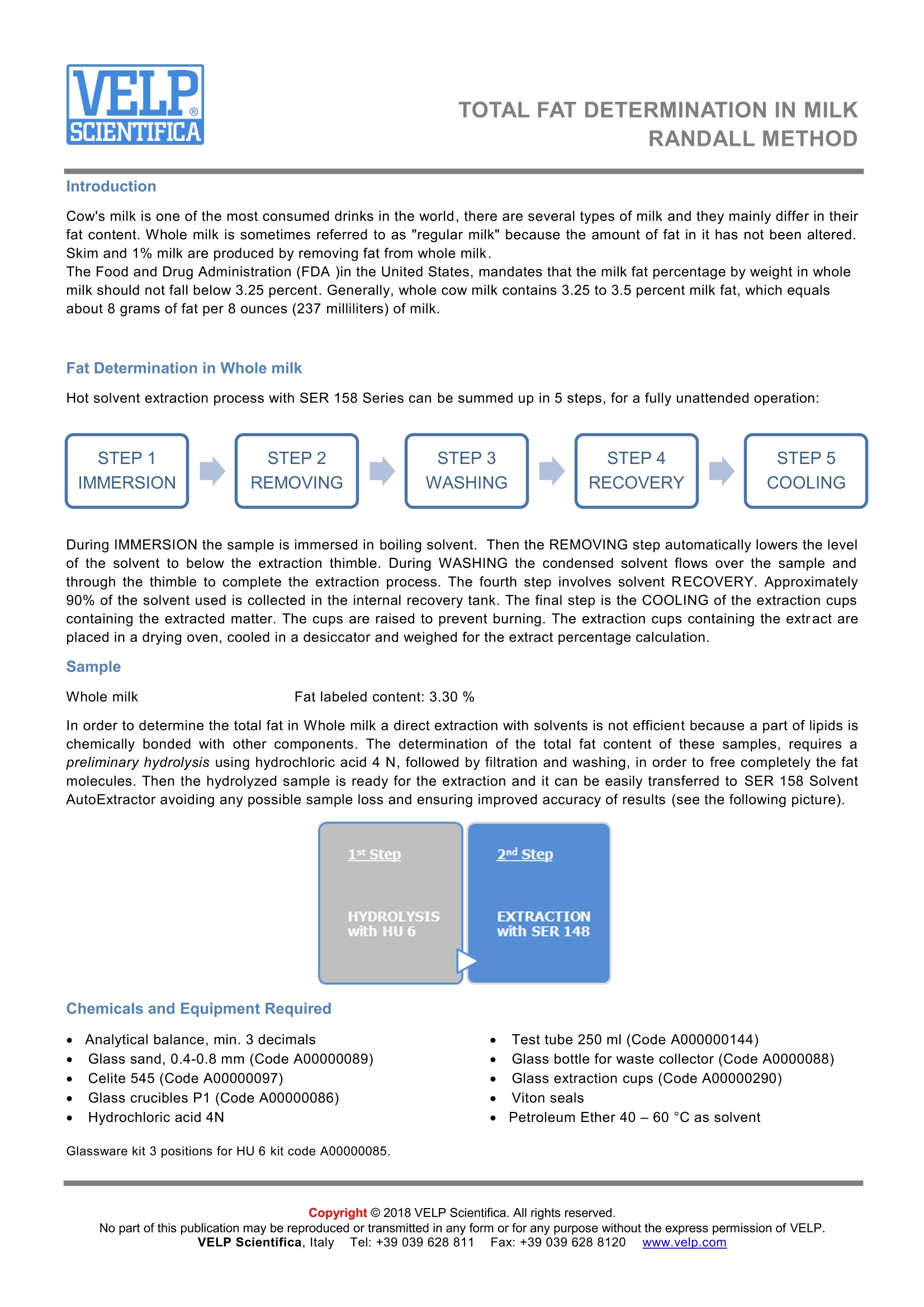

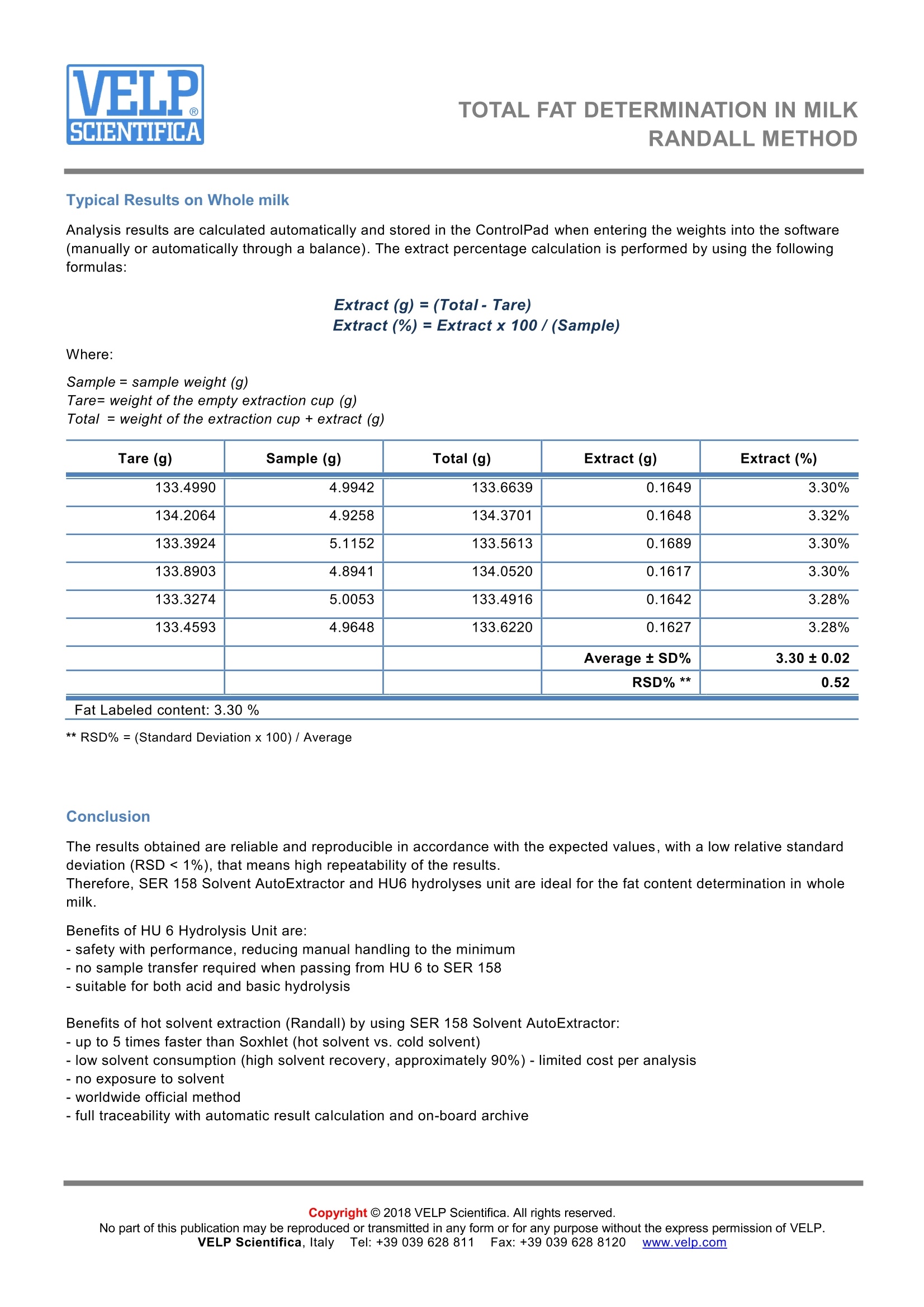

APPLICATION NOTEF&F-S-003-2018/A1 TOTAL FAT DETERMINATION IN MILKRANDALL METHOD Total Fat Determination in Milkaccording to the Randall method Reference: VELP Procedure for Total Fat Determination in Whole Milk Tested with VELP Scientifica SER 158/6 Solvent AutoExtractor (Code S303A0380) and HU6 Hydrolysis Unit(Code F30300110) Introduction Cow’s milk is one of the most consumed drinks in the world, there are several types of milk and they mainly differ in theirfat content. Whole milk is sometimes referred to as "regular milk" because the amount of fat in it has not been altered.Skim and 1% milk are produced by removing fat from whole milk. The Food and Drug Administration (FDA )in the United States, mandates that the milk fat percentage by weight in wholemilk should not fall below 3.25 percent. Generally, whole cow milk contains 3.25 to 3.5 percent milk fat, which equalsabout 8 grams of fat per 8 ounces (237 milliliters) of milk. Fat Determination in Whole milk Hot solvent extraction process with SER 158 Series can be summed up in 5 steps, for a fully unattended operation: During IMMERSION the sample is immersed in boiling solvent. Then the REMOVING step automatically lowers the levelof the solvent to below the extraction thimble. During WASHING the condensed solvent flows over the sample andthrough the thimble to complete the extraction process. The fourth step involves solvent RECOVERY. Approximately90% of the solvent used is collected in the internal recovery tank. The final step is the COOLING of the extraction cupscontaining the extracted matter. The cups are raised to prevent burning. The extraction cups containing the extract areplaced in a drying oven, cooled in a desiccator and weighed for the extract percentage calculation. Sample Whole milk Fat labeled content: 3.30% In order to determine the total fat in Whole milk a direct extraction with solvents is not efficient because a part of lipids ischemically bonded with other components. The determination of the total fat content of these samples, requires apreliminary hydrolysis using hydrochloric acid 4 N, followed by filtration and washing, in order to free completely the fatmolecules. Then the hydrolyzed sample is ready for the extraction and it can be easily transferred to SER 158 SolventAutoExtractor avoiding any possible sample loss and ensuring improved accuracy of results (see the following picture). Chemicals and Equipment Required ●Analytical balance, min. 3 decimals Test tube 250 ml (Code A000000144) Glass sand, 0.4-0.8 mm (Code A00000089) Glass bottle for waste collector (Code A0000088) .CCelite 545 (Code A00000097) Glass extraction cups (Code A00000290) . Glass crucibles P1 (Code A00000086) Viton seals Hydrochloric acid 4N Petroleum Ether 40-60°C as solvent Glassware kit 3 positions for HU 6 kit code A00000085. VELP Scientifica, Italy Tel:+39039628811 Fax: +39 039 628 8120 www.velp.com Sample Preparation ●HHydrolysis Crucibles Preparation Put 25 g of glass sand in glass crucibles P1 and 3g of Celite 545: the two layers resulting have not be mixed togetherotherwise the phase in Celite may bypass the crucible negatively affecting the end result. Sample Preparation in the Test Tube Put under stirring the Whole milk, weigh 5 g of under stirring sample (Msample) and 2 g of Celite 545 in the test tube. Ineach test tube add 50 ml of 4N hydrochloric acid,shake gently and carefully, and finally add a further 50 ml hydrochloricacid in order to rinse the sample residue that may remain on the walls of the test tube. ● Glass Extraction Cups Preparation Keep the empty glass extraction cups in oven at 105°℃ for 1 hour. Cool them in a dessicator and record the accurateweight of the tare (Mtare). Hydrolysis Procedure with HU 6 Place 6 crucibles P1 on the HU6 and connect the aspirating tubes: one side needs to be placed on the sealing ring ofthe crucible and the other one has to be in contact with the corresponding test tube. Set 170 °C for 30 minutes. Place the 6 test tubes in the heating block, lower the glassware and activate the vacuum pump. In case of foam, add 4 N hydrochloric acid drop by drop inside the test tubes. At the end of the procedure, switch off and allow aspiration of the content of the test tubes in the crucible.Raise the glassware to its maximum point and secure it, by tightening the knob. Then, add hot water (40-50°C, about 250 ml) slowly, in order to aspirate all the residues of hydrolysis in the test tubes.Remove the aspirating tubes and the crucibles containing the sample after the washing: mix the layer of hydrolyzed sample with the layer of Celite by using a spatula in order to break any clot. Take care to not damage the layer of glass sand. This operation helps the sample drying, which must take place in an oven at 105°C. If dried test portions will not be immediately extracted, put them in a desiccator, or let the crucibles cool to roomtemperature and then, mix the layer of hydrolyzed sample and Celite with a spatula to obtain apowdery hydrolyzed. Take care not damage the layer of glass sand. Extraction Procedure with SER 158 Fix the crucibles with the crucible holders (Code A00000293). The extraction cups containing the crucibles can now beplaced on the ultra-fast heating plate of SER 158. On the ControlPad select “Analysis", and then method“Total fat in milk Powder”including the following parameters: ●· Immersion Time: 55 minutes ●Recovery Time 30 minutes ●RRemoving Time: 10 minutesCooling Time:5 minutes●VWashing Time: 55 minutesPetroleum Ether 40-60°C, 100 ml Close the safety guard and add the solvent using the automatic solvent dispensing system SolventXpress TM to minimizeexposure to the solvent ensuring operator safety. Press START to begin the extraction process. At the end of analysis position the extraction cups containing the extractin a drying oven (1 hour at 105°C), cool them in a desiccator to room temperature and record the accurate weight (Mtot). Typical Results on Whole milk Analysis results are calculated automatically and stored in the ControlPad when entering the weights into the software(manually or automatically through a balance). The extract percentage calculation is performed by using the followingformulas: Where: Sample = sample weight (g) Tare= weight of the empty extraction cup (g) Total = weight of the extraction cup +extract (g) Tare (g) Sample (g) Total (g) Extract (g) Extract (%) 133.4990 4.9942 133.6639 0.1649 3.30% 134.2064 4.9258 134.3701 0.1648 3.32% 133.3924 5.1152 133.5613 0.1689 3.30% 133.8903 4.8941 134.0520 0.1617 3.30% 133.3274 5.0053 133.4916 0.1642 3.28% 133.4593 4.9648 133.6220 0.1627 3.28% Average±SD% 3.30±0.02 RSD% ** 0.52 Fat Labeled content: 3.30 % Fat Labeled content: 3.30 % **RSD%=(Standard Deviation x 100) / Average Conclusion The results obtained are reliable and reproducible in accordance with the expected values, with a low relative standarddeviation (RSD<1%), that means high repeatability of the results. Therefore, SER 158 Solvent AutoExtractor and HU6 hydrolyses unit are ideal for the fat content determination in wholemilk. Benefits of HU 6 Hydrolysis Unit are: -safety with performance, reducing manual handling to the minimum -no sample transfer required when passing from HU 6 to SER 158 -suitable for both acid and basic hydrolysis Benefits of hot solvent extraction (Randall) by using SER 158 Solvent AutoExtractor: -up to 5 times faster than Soxhlet (hot solvent vs. cold solvent) -low solvent consumption (high solvent recovery, approximately 90%)-limited cost per analysis - no exposure to solvent -worldwide official method -full traceability with automatic result calculation and on-board archive Copyright C VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel: + Fax: + www.velp.com 意大利VELP公司SER 158进行牛奶中的总脂肪测定:■ 传统方法测定牛奶中的总脂肪较为耗时,SER 158可以缩短实验实验,同时确保结果的可靠性。■ 在对牛奶进行水解后进行浸提,移除,洗涤,回收和冷凝几个萃取步骤。■最终通过称重计算总脂肪的含量。

确定

还剩2页未读,是否继续阅读?

意大利VELP公司为您提供《牛奶中总脂肪含量检测方案(抽提萃取)》,该方案主要用于液体乳中营养成分检测,参考标准--,《牛奶中总脂肪含量检测方案(抽提萃取)》用到的仪器有VELP SER 158 全自动脂肪测定仪(索式抽提仪)

推荐专场

相关方案

更多

该厂商其他方案

更多