Abstract. This study investigates the changes in radial micro-texture via Kearn’s f-factors during single cold pilger reduction

of a titanium Ti-3-2.5 alloy as a result of strain path changes from tooling modifications. EBSD results confirm that the

texture intensity as well as the radial f-factors can be increased by modifications of pilgering tooling. In addition a switch

between the secondary prism planes which lie normal to the pilger direction in the starting tube to primary prism planes

after pilgering has been observed.

Material and Experimental

The tubes investigated were made from Ti alloy 3Al 2.5V, they were manufactured via hot extrusion and then cold pilgered.

The cold pilger process configuration is schematically shown in Figure 1. Two strain paths, shown in the ‘Q‘ factor chart in

Figure 2, were used in the manufactiure: texture minimised and texture maximised. They were annealed at 750oC before

being cold pilgered and for this investigation they were stress relieved at 530oC for 2 hours prior to EBSD examination.

Specimens were extracted from two regions either side of the reduced tube as shown in the schematic Figure 2, mounted

in conductive Bakelite and polished mechanically for EBSD examination. The final polish was carried out using vibratory

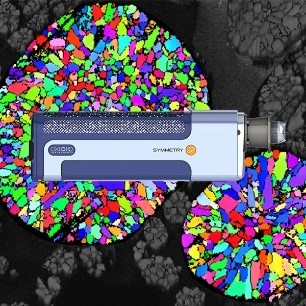

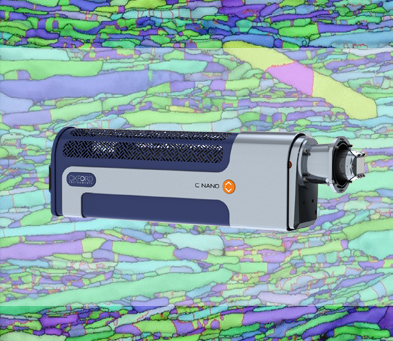

polishes using a mixture of 5:2 colloidal silica, hydrogen peroxide mixture. EBSD examination was conducted using a

FEGSEM and OI EBSD Nordlys detector and AZtec Software.

方案详情

www.oxford-instruments.comwww.finetubes.comThe Business of Science* An EBSD Study of Texture Variation alongPilger Reduced Titanium Alloy Tubes Harvinder Singh Ubhi, Andrew Houghton? and Janardhan Saithala Oxford Instruments, Halifax Road, High Wycombe HP12 3SE, UK1, Promet Consulting Ltd.Plymouth, UK?, Fine Tubes Ltd.Estover Works, Plymouth, Devon, PL6 7LG Abstract. This study investigates the changes in radial micro-texture via Kearn's f-factors during single cold pilger reductionof a titanium Ti-3-2.5 alloy as a result of strain path changes from t)reooling modifications. EBSD results confirm that thetexture intensity as well as the radial f-factors can be increased by modifications of pilgering tooling. In addition a switchbetween the secondary prism planes which lie normal to the pilger direction in the starting tube to primary prism planesafter pilgering has been observed. The tubes investigated were made from Ti alloy 3Al 2.5V, they were manufactured via hot extrusion and then cold pilgered.The cold pilger process configuration is schematically shown in Figure 1. Two strain paths, shown in the 'Q' factor chart inFigure2, were used in the manufactiure: texture minimised and texture maximised. They were annealed at 750℃ beforebeing cold pilgered and for this investigation they were stress relieved at 530°C for 2 hours prior to EBSD examination.Specimens were extracted from two regions either side of the reduced tube as shown in the schematic Figure 2, mountedin conductive Bakelite and polished mechanically for EBSD examination. The final polish was carried out using vibratorypolishes using a mixture of 5:2 colloidal silica, hydrogen peroxide mixture. EBSD examination was conducted using a 1.20 Die2 el work length mm Figure 2.Q’factor Chartshowing the two strain paths.Qfactor is measure ofthe relative amountofwallreductionto diameter reduction or the ratio of the wall strain todiameter strain for the reduction under consideration. Figure3. Schematic diagram showing the cone resultingfrom pilgering process. Texture minimised Texturemaximised Sample exit entry exit entry f-factors (0001) Fx tangential 0.405 0.465 0.360 0.460 Fy radial 0.558 0.493 0.605 0.490 Fz longitudinal 0.037 0.042 0.034 0.050 Pf intens ity 10.30 4.4 10.10 6.07 Mean Grain size(um) 0.6 4.4 0.6 4 Table 1. Summary of Kearn's f-factors, pole figureintensitites and grain sizes for the two tubes.. Figure 1. Schematic diagram showing pilgering pro-cess. Glen Stapleton, Cold Pilger Technology, Mannes-mann Demag Meer 1996. Figure 5. Typical SEM back-scattered image from thefinished (exit) end of the pilgered tube section showing adeformed non-uniform grain structure. Figure 7. Typical IPF Z coloured map from the exit tubesection. EBSD contoured pole figures before and after pilgering in Figures 8 and 9 clearly show the development of a prism fibre texture after pilgering. This also has the effect of switchingthe secondary prism intensity normal to the tube direction in the starting material to the primary prism after reduction. Figures 6-9 relate to the "texture maximized" sample and therewas little visual difference in the microstructures or pole figures between data from the two strain paths. However, from the (0001) Kearns f-factors given in Table 1, it is clear thatf-factors increase after reduction and that there are differences between the two samples. There could be a difference in through wall variation and this is to be investigated Conclusions . EBSD observations have confirmed that texture development can be manipulated in this product by altering the strainpath. This work aids the process of predicting textures ahead of tooling manufacture and this will be enhanced further bycorrelating results with observed strain modeled strain paths produced by non-linear finite element analysis. Acknowledgements The authors would like thank both Finetubes and Oxford Instruments for providing facilities and samples to conductthis work. Abstract. This study investigates the changes in radial micro-texture via Kearn’s f-factors during single cold pilger reductionof a titanium Ti-3-2.5 alloy as a result of strain path changes from tooling modifications. EBSD results confirm that thetexture intensity as well as the radial f-factors can be increased by modifications of pilgering tooling. In addition a switchbetween the secondary prism planes which lie normal to the pilger direction in the starting tube to primary prism planesafter pilgering has been observed.Material and ExperimentalThe tubes investigated were made from Ti alloy 3Al 2.5V, they were manufactured via hot extrusion and then cold pilgered.The cold pilger process configuration is schematically shown in Figure 1. Two strain paths, shown in the ‘Q‘ factor chart inFigure 2, were used in the manufactiure: texture minimised and texture maximised. They were annealed at 750oC beforebeing cold pilgered and for this investigation they were stress relieved at 530oC for 2 hours prior to EBSD examination.Specimens were extracted from two regions either side of the reduced tube as shown in the schematic Figure 2, mountedin conductive Bakelite and polished mechanically for EBSD examination. The final polish was carried out using vibratorypolishes using a mixture of 5:2 colloidal silica, hydrogen peroxide mixture. EBSD examination was conducted using aFEGSEM and OI EBSD Nordlys detector and AZtec Software.

确定

还剩1页未读,是否继续阅读?

牛津仪器科技(上海)有限公司为您提供《金属材料中微观结构检测方案(其它元素分析仪)》,该方案主要用于其他中理化分析检测,参考标准--,《金属材料中微观结构检测方案(其它元素分析仪)》用到的仪器有牛津仪器Azteclive能谱实时元素成像系统、电镜专用自动清洁度分析系统---牛津仪器AZtecFeature、EBSD探测器Symmetry S3 牛津仪器

推荐专场

相关方案

更多

该厂商其他方案

更多