方案详情

文

耐驰DMA242E为模块化设计,可以配备冷却系统,种类丰富的样品支架,还有更多的特殊配置可选,这使得它可以适应非常宽广的应用范围,成为材料研究人员的理想选择。

方案详情

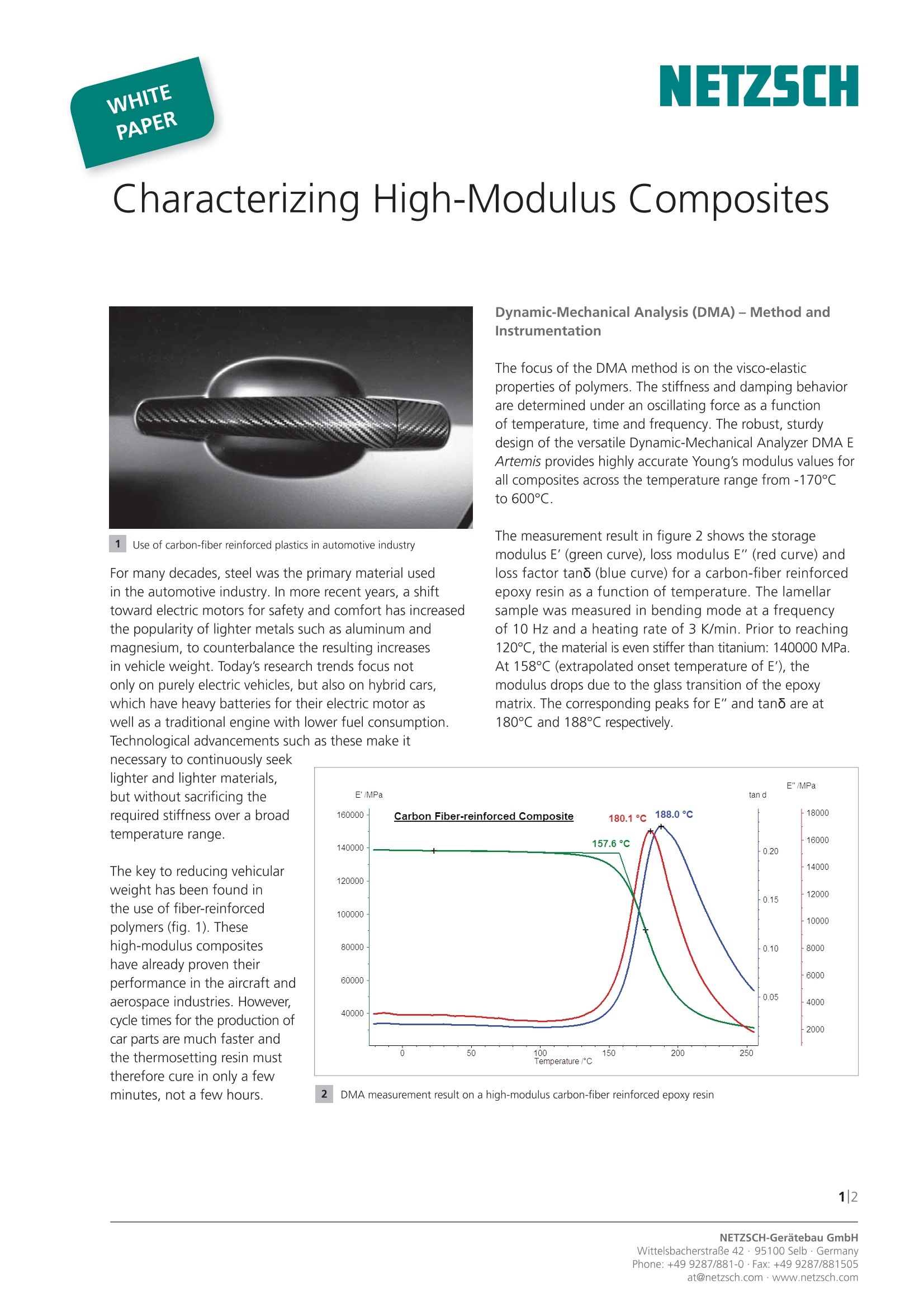

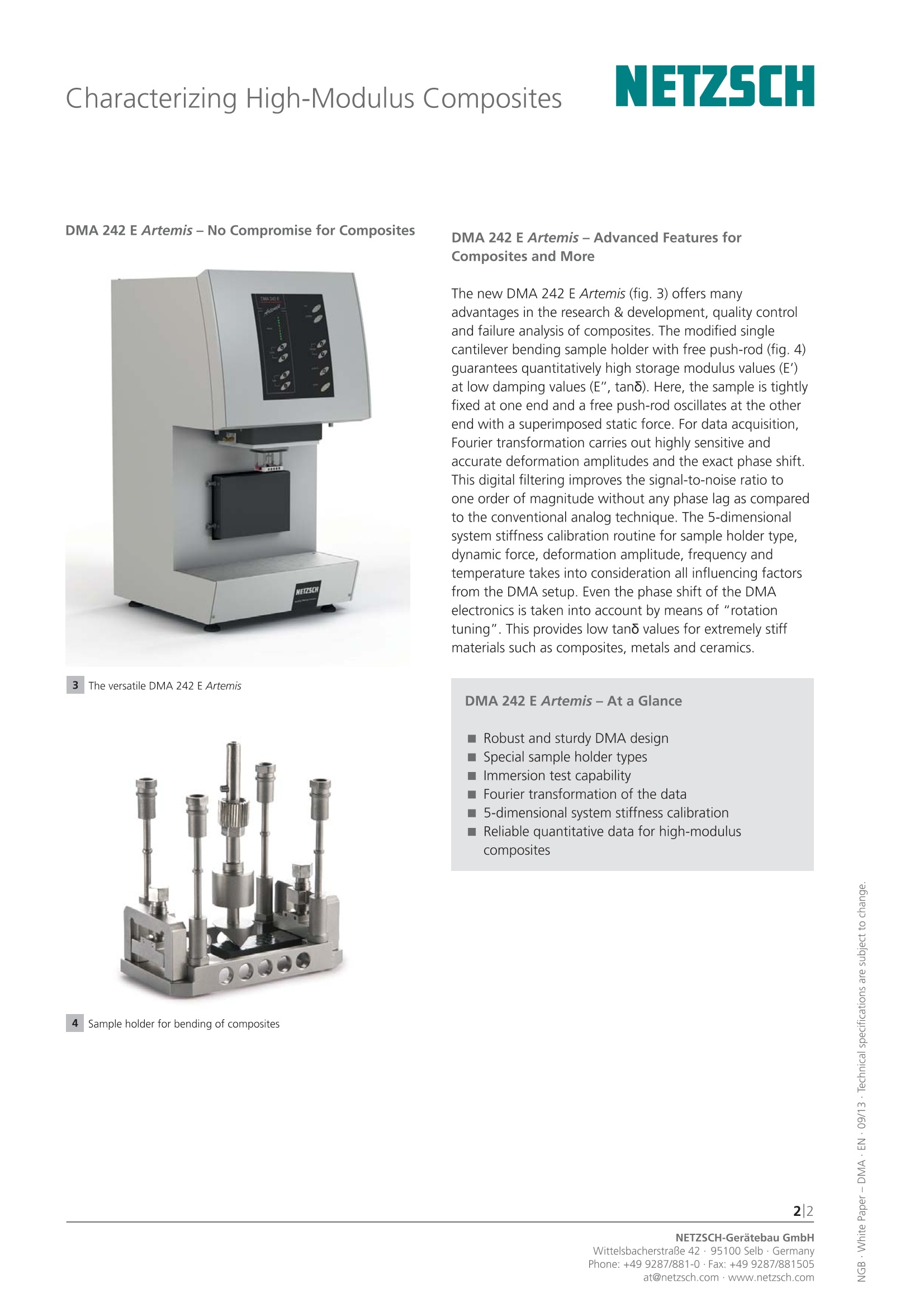

NETZSCHWHITEPAPER Characterizing High-Modulus Composites 1Use of carbon-fiber reinforced plastics in automotive industry For many decades, steel was the primary material usedin the automotive industry. In more recent years, a shifttoward electric motors for safety and comfort has increasedthe popularity of lighter metals such as aluminum andmagnesium, to counterbalance the resulting increasesin vehicle weight. Today's research trends focus notonly on purely electric vehicles, but also on hybrid cars,which have heavy batteries for their electric motor aswell as a traditional engine with lower fuel consumption.Technological advancements such as these make it necessary to continuously seek Dynamic-Mechanical Analysis (DMA)-Method andInstrumentation The focus of the DMA method is on the visco-elasticproperties of polymers. The stiffness and damping behaviorare determined under an oscillating force as a functionof temperature, time and frequency.The robust, sturdydesign of the versatile Dynamic-Mechanical Analyzer DMA EArtemis provides highly accurate Young's modulus values forall composites across the temperature range from -170℃to 600°C. The measurement result in figure 2 shows the storagemodulus E’ (green curve), loss modulus E" (red curve) andloss factor tano (blue curve) for a carbon-fiber reinforcedepoxy resin as a function of temperature. The lamellarsample was measured in bending mode at a frequencyof 10 Hz and a heating rate of 3 K/min. Prior to reaching120℃, the material is even stiffer than titanium: 140000 MPa.At 158C (extrapolated onset temperature of E'), themodulus drops due to the glass transition of the epoxymatrix. The corresponding peaks for E" and tano are at180℃ and 188℃ respectively. lighter and lighter materials,but without sacrificing therequired stiffness over a broadtemperaturerange. The key to reducing vehicularweight has been found inthe use of fiber-reinforcedpolymers (fig.1). Thesehigh-modulus compositeshave already proven theirperformance in the aircraft andaerospace industries.However,cycle times for the production ofcar parts are much faster andthe thermosetting resin musttherefore cure in only a fewminutes, not a few hours. 2DMA measurement result on a high-modulus carbon-fiber reinforced epoxy resin Characterizing High-Modulus Composites DMA 242 E Artemis -No Compromise for Composites 3The versatile DMA 242 E Artemis DMA 242 E Artemis -Advanced Features forComposites and More The new DMA 242 E Artemis (fig. 3) offers manyadvantages in the research & development, quality controland failure analysis of composites. The modified singlecantilever bending sample holder with free push-rod (fig. 4)guarantees quantitatively high storage modulus values (E')at low damping values (E", tan). Here, the sample is tightlyfixed at one end and a free push-rod oscillates at the otherend with a superimposed static force. For data acquisition,Fourier transformation carries out highly sensitive andaccurate deformation amplitudes and the exact phase shift.This digital filtering improves the signal-to-noise ratio toone order of magnitude without any phase lag as comparedto the conventional analog technique. The 5-dimensionalsystem stiffness calibration routine for sample holder type,dynamic force, deformation amplitude, frequency andtemperature takes into consideration all influencing factorsfrom the DMA setup. Even the phase shift of the DMAelectronics is taken into account by means of "rotationtuning". This provides low tano values for extremely stiffmaterials such as composites,metals and ceramics. ETZSCH-Geratebau GmbHWittelsbacherstraBe Selb · GermanyPhone:+Fax: +

确定

还剩1页未读,是否继续阅读?

德国耐驰热分析为您提供《碳纤维增强塑料中模量、玻璃化转变温度、损耗因子检测方案(动态热机械)》,该方案主要用于其他中模量、玻璃化转变温度、损耗因子检测,参考标准--,《碳纤维增强塑料中模量、玻璃化转变温度、损耗因子检测方案(动态热机械)》用到的仪器有

相关方案

更多

该厂商其他方案

更多