方案详情

文

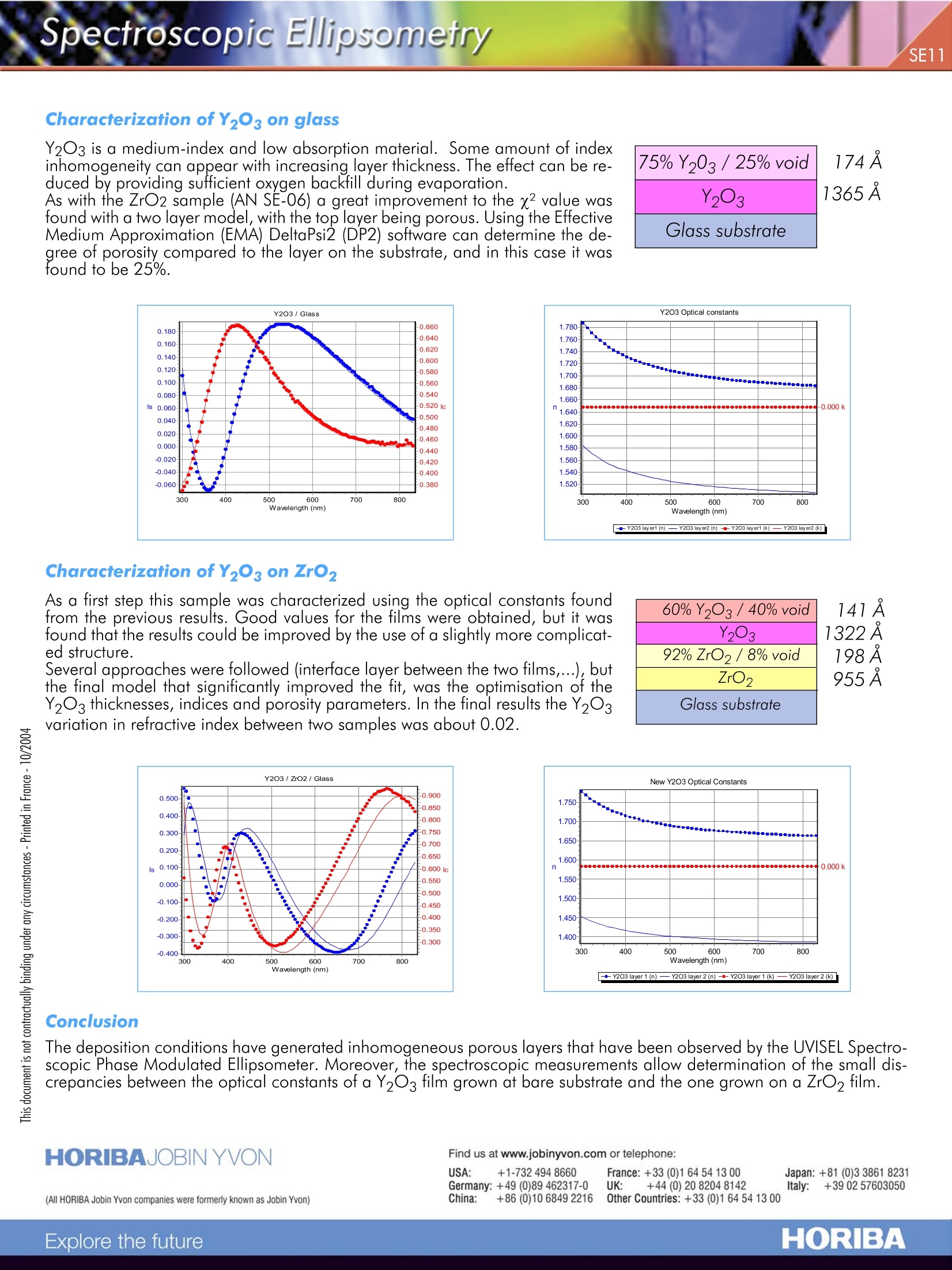

The deposition conditions have generated inhomogeneous porous layers that have been observed by the UVISEL Spectroscopic Phase Modulated Ellipsometer. Moreover, the spectroscopic measurements allow determination of the small discrepancies between the optical constants of a Y2O3 film grown at bare substrate and the one grown on a ZrO2 film.

方案详情

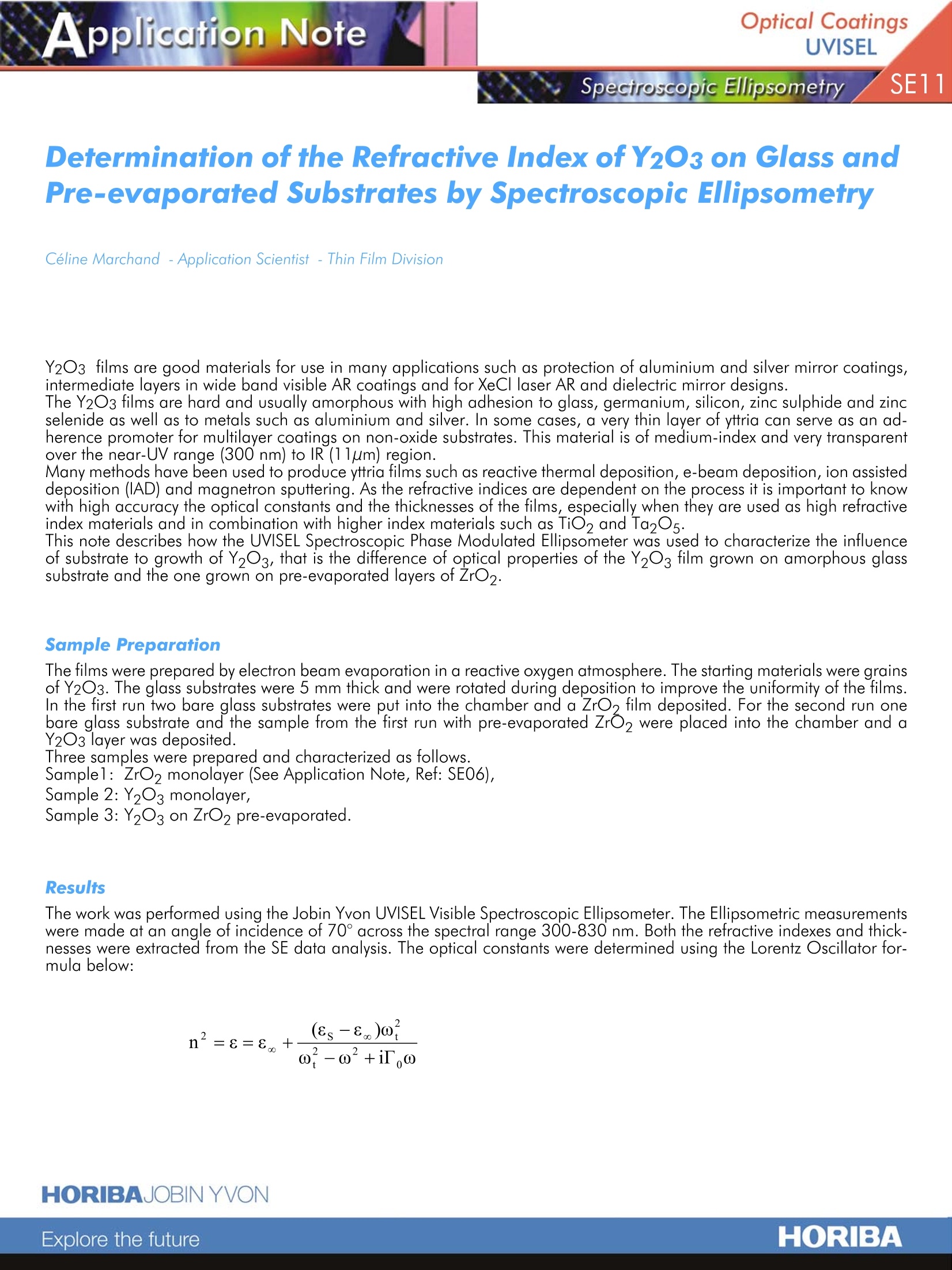

Application NoteOptical CoatingsUVISELSE11Spectroscopic Ellipsometry Spectroscopic Ellipsometry Celine Marchand - Application Scientist - Thin Film Division Y2O3 films are good materials for use in many applications such as protection of aluminium and silver mirror coatings,intermediate layers in wide band visible AR coatings and for XeCI laser AR and dielectric mirror designs. The Y2O3 films are hard and usually amorphous with high adhesion to glass, germanium, silicon, zinc sulphide and zincselenide as well as to metals such as aluminium and silver. In soSmeo cmases, a very thin layer of yttria can serve as an ad-herence promoter for multilayer coatings on non-oxide substrates. This material is of medium-index and very transparentover the near-UV range (300 nm) to IR (11um) region. Many methods have been used to produce yttria films such as reactive thermal deposition, e-beam deposition, ion assisteddeposition (IAD) and magnetron sputtering. As the refractive indices are dependent on the process it is important to knowwith high accuracy the optical constants and the thicknesses of the films, especially when they are used as high refractiveindex materials and in combination with higher index materials such as TiO2 and Ta2O5. This note describes how the UVISEL Spectroscopic Phase Modulated Ellipsometer was used to characterize the influenceof substrate to growth of Y2O3, that is the difference of optical properties of the Y2O3 film grown on amorphous glasssubstrate and the one grown on pre-evaporated layers of ZrO2. Sample Preparation The films were prepared by electron beam evaporation in a reactive oxygen atmosphere. The starting materials were grainsof Y2O3. The glass substrates were 5 mm thick and were rotated during deposition to improve the uniformity of the films.In the first run two bare glass substrates were put into the chamber and a ZrO2 film deposited. For the second run onebare glass substrate and the sample from the first run with pre-evaporatedZrO2 were placed into the chamber and aY2O3 layer was deposited. Three samples were prepared and characterized as follows. Sample1: ZrO2 monolayer (See Application Note, Ref: SE06), Sample 2:YO3 monolayer, Sample 3: Y2O3 on ZrO2 pre-evaporated. Results The work was performed using the Jobin Yvon UVISEL Visible Spectroscopic Ellipsometer. The Ellipsometric measurementswere made at an angle of incidence of 70° across the spectral range 300-830 nm. Both the refractive indexes and thick-nesses were extracted from the SE data analysis. The optical constants were determined using the Lorentz Oscillator for-mula below: Characterization of Y203 on glass Y2O3 is a medium-index and low absorption material. Some amount of indexinhomogeneity can appear with increasing layer thickness. The effect can be re-duced by providing sufficient oxygen backfill during evaporation. As with the ZrO2 sample (AN SE-06) a great improvement to the x2 value wasfound with a two layer model, with the top layer being porous. Using the EffectiveMedium Approximation (EMA) DeltaPsi2 (DP2) software can determine the de-gree of porosity compared to the layer on the substrate, and in this case it wasfound to be 25%. Characterization of Y203 on ZrO2 As a first step this sample was characterized using the optical constants foundfrom the previous results. Good valuueess ffor the films were obtained, but it wasfound that the results could be improved by the use of a slightly more complicat-ed structure. Several approaches were followed (interface layer between the two films,…..), butthe final model that significantly improved the fit, was the optimisation of theY2O3 thicknesses, indices and porosity parameters. In the final results the Y2O3variation in refractive index between two samples was about 0.02. 60%Y03 / 40% void YO3 92% ZrO,/ 8%void ZrO2 Conclusion The deposition conditions have generated inhomogeneous porous layers that have been observed by the UVISEL Spectro-scopic Phase Modulated Ellipsometer. Moreover, the spectroscopic measurements allow determination of the small dis-crepancies between the optical constants of a Y2O3 film grown at bare substrate and the one grown on a ZrO2 film. HORIBAJOBIN YVON USA:+1-732 4948660France:+33 (0)1 64 54 1300Japan: +81 (0)3 3861 8231 Germany:+49 (0)89 462317-0 UK: +44 (0) 20 8204 8142 Italy: +390257603050China: +86(0)106849 2216 Other Countries: +33 (0)1 64 54 1300 HORIBAJOBIN YVONHORIBAExplore the future Find us at www.jobinyvon.com or telephone:(All HORIBA Jobin Yvon companies were formerly known as Jobin Yvon)HORIBAExplore the future The deposition conditions have generated inhomogeneous porous layers that have been observed by the UVISEL Spectroscopic Phase Modulated Ellipsometer. Moreover, the spectroscopic measurements allow determination of the small discrepancies between the optical constants of a Y2O3 film grown at bare substrate and the one grown on a ZrO2 film.

确定

还剩1页未读,是否继续阅读?

HORIBA(中国)为您提供《玻璃和预蒸镀基底中光学常数检测方案(椭偏仪)》,该方案主要用于玻璃中光学常数检测,参考标准--,《玻璃和预蒸镀基底中光学常数检测方案(椭偏仪)》用到的仪器有HORIBA UVISEL Plus研究级经典型椭偏仪

推荐专场

相关方案

更多

该厂商其他方案

更多