方案详情

文

Spectroscopic ellipsometry is a powerful technique to characterize the thickness and optical constants of encapsulated OLED devices.

For the case of non-transparent encapsulation thecombination of ellipsometric measurements via the glass substrate and the powerful modelling features of DeltaPsi2 software make it possible to analyze “this reverse sample”.

Ellipsometric investigation of a 1-month aging process for an α-NPD film show a significant decrease of the refractive index, suggesting a decrease in the material density.

方案详情

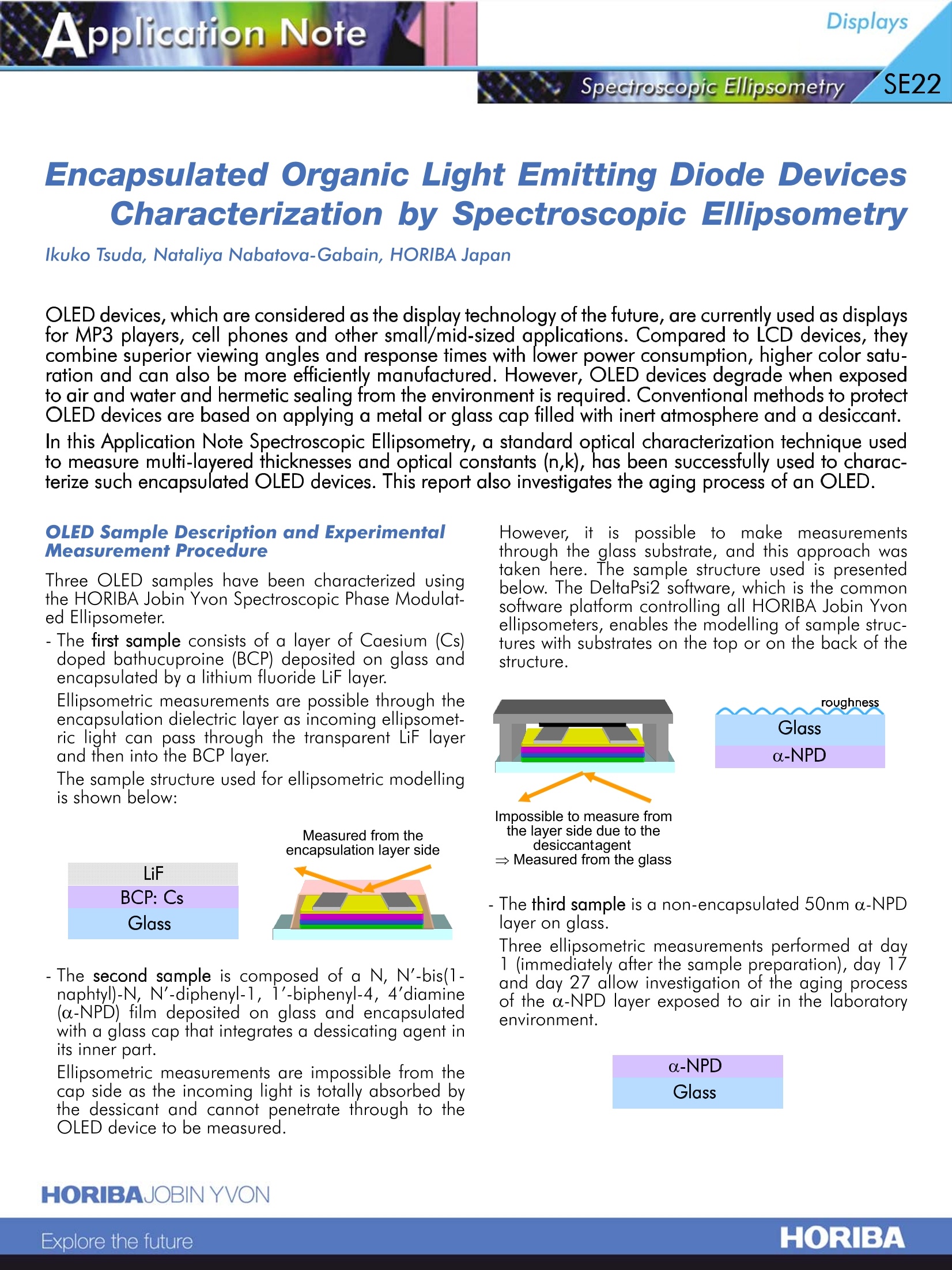

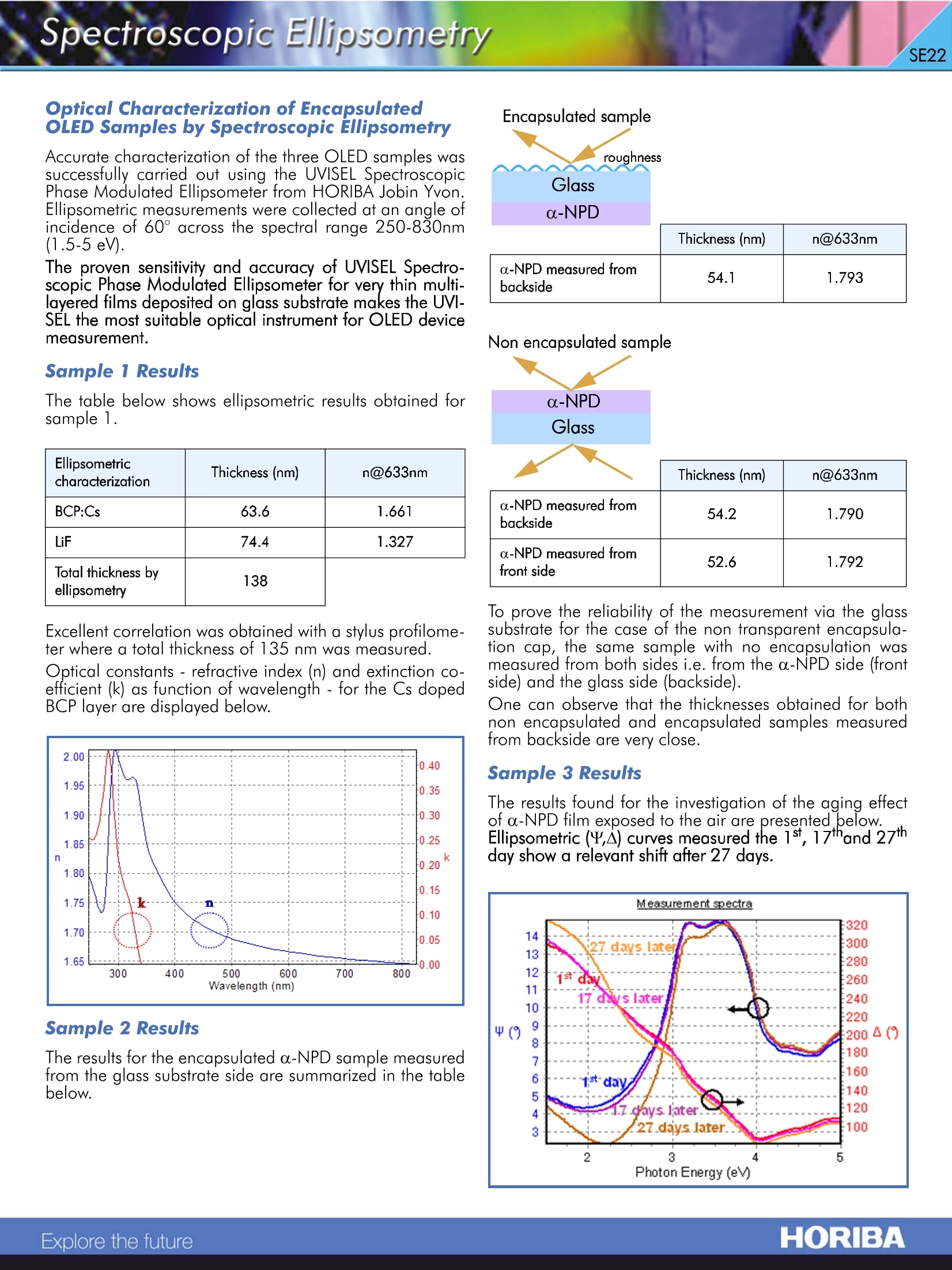

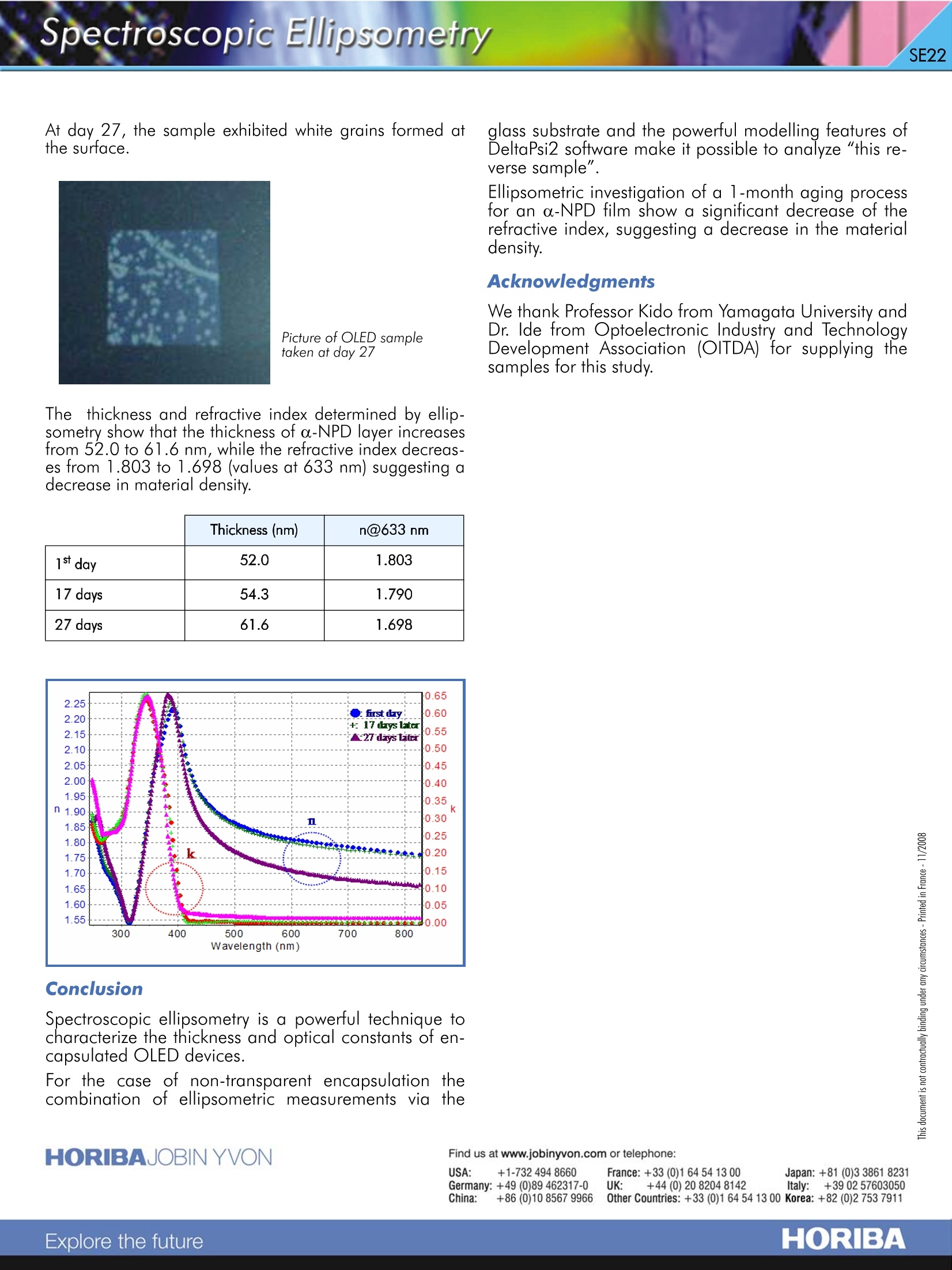

wApplication NofeDisplaysSpectroscopic Ellipsometry SE22 Spectroscopic Ellipsometry Encapsulated Organic Light Emitting Diode DevicesCharacterization by Spectroscopic Ellipsometry Ikuko Tsuda, Nataliya Nabatova-Gabain, HORIBA Japan OLED devices, which are considered as the display technology of the future, are currently used as displaysfor MP3 players, cell phones and other small/mid-sized applications. Compared to LCD devices, theycombine superior viewing angles and response times with lower power consumption, higher color satu-ration and can also be more efficiently manufactured. However, OLED devices degrade when exposedto air and water and hermetic sealing from the environment is required. Conventional methods to protectOLED devices are based on applying a metal or glass cap filled with inert atmosphere and a desiccant. In this Application Note Spectroscopic Ellipsometry, a standard optical characterization technique usedto measure multi-layered thicknesses and optical constants (n,k), has been successfully used to charac-terize such encapsulated OLED devices. This report also investigates the aging process of an OLED. OLED Sample Description and ExperimentalMeasurement Procedure Three OLED samples have been characterized usingthe HORIBA Jobin Yvon Spectroscopic Phase Modulat-ed Ellipsometer. - The first sample consists of a layer of Caesium (Cs)doped bathucuproine (BCP) deposited on glass andencapsulated by a lithium fluoride LiF layer. Ellipsometric measurements are possible through theencapsulation dielectric layer as incoming ellipsomet-ric light can pass through the transparent LiF layerand then into the BCP layer. The sample structure used for ellipsometric modellingis shown below: Measured from theencapsulation layer side LiFBCP: CsGlass -The second sample is composed of a N, N'-bis(1-naphtyl)-N,N'-diphenyl-1, 1'-biphenyl-4, 4'diamine(a-NPD) film deposited on glass and encapsulatedwith a glass cap that integrates a dessicating agent in Ellipsometric measurements are impossible from thecap side as the incoming light is totally absorbed bythe dessicant and cannot penetrate through to theOLED device to be measured. owever it ispossiblee to makemeasurementsthrough the glass substrate, and this approach wastaken here. The sample structure used is presentedbelow. The DeltaPsi2 software, which is the commonsoftware platform controlling all HORIBA Jobin Yvonellipsometers, enables the modelling of sample struc-tures with substrates on the top or on the back of thestructure. =Measured from the glass -The third sample is a non-encapsulated 50nm α-NPDlayer on glass. Three ellipsometric measurements performed at day1 (immediately after the sample preparation), day 17and day 27 allow investigation of the aging processof the a-NPD layer exposed to air in the laboratoryenvironment. a-NPDGlass Optical Characterization of EncapsulatedOLED Samples by Spectroscopic Ellipsometry Accurate characterization of the three OLED samples wassuccessfully carried out using the UVISEL SpectroscopicPhase Modulated Ellipsometer from HORIBA Jobin Yvon.Ellipsometric measurements were collelected at an angle ofincidence of 60°across the spectral range 250-830nm(1.5-5 eV). The proven sensitivity and accuracy of UVISEL Spectro-scopic Phase Modulated Elliippsometer for very thin multi-layered films deposited on gass substrate makes the UVI-SEL the most suitable optical instrument for OLED devicemeasurement. Sample 1 Results The table below shows ellipsometric results obtained forsample 1. Ellipsometriccharacterization Thickness (nm) n@633nm BCP:Cs 63.6 1.661 LiF 74.4 1.327 Total thickness byellipsometry 138 Excellent correlation was obtained with a stylus profilome-ter where a total thickness of 135 nm was measured. Optical constants - refractive index (n) and extinction co-efficient (k) as function of wavelength - for the Cs dopedBCP layer are displayed below. Sample 2 Results The results for the encapsulated o-NPD sample measuredtrom the glass substrate side are summarized in the tablebelow. Encapsulated sample Thickness (nm) n@633nm a-NPD measured from backside 54.1 1.793 Non encapsulated sample a-NPD Glass Thickness (nm) n@633nm a-NPD measured frombackside 54.2 1.790 a-NPD measured fromfront side 52.6 1.792 To prove the reliability of the measurement via the glasssubstrate for the case of the non transparent encapsula-tion cap, the same sample with no encapsulation wasmeasured from both sides i.e. from the a-NPD side (frontside) and the glass side (backside). One can observe that the thicknesses obtained for bothnon encapsulated and encapsulated samples measuredtrom backside are very close. Sample 3 Results The results found for the investigation of the aging effectof a-NPD film exposed to the air are presenteddpelow.Ellipsometric (,A) curves measured the 1st, 17hhand 27thday show a relevant shift after 27 days. Measurement spectra 320 27 days later300 280 17 days later 260-240 220 day// :17 days later At day 27, the sample exhibited white grains formed atthe surface. glass substrate and the powerful modelling features ofDeltaPsi2 software make it possible to analyze ‘“this re-verse sample. Ellipsometric investigation of a 1-month aging processfor an a-NPD film show a significant decrease of therefractive index, suggesting a decrease in the materialdensity. Acknowledgments Picture of OLED sample taken at day 27 We thank Professor Kido from Yamagata University andDr. Ide from Optoelectronic Industry and TechnologyDevelopment Association (OITDA) for supplying tthesamples for this study. The thickness and refractive index determined by ellip-sometry show that the thickness of a-NPD layer increasesfrom 52.0 to 61.6 nm, while the refractive index decreas-es from 1.803 to 1.698 (values at 633 nm) suggesting adecrease in material density. Thickness(nm) n@633 nm 1st day 52.0 1.803 17 days 54.3 1.790 27 days 61.6 1.698 Conclusion Spectroscopic ellipsometry is a powerful technique tocharacterize the thickness and optical constants of en-capsulated OLED devices. For the case of non-transparent encapsulation thecombination of ellipsometric measurements via the HORIBAExplore the future HORIBAExplore the future Spectroscopic ellipsometry is a powerful technique to characterize the thickness and optical constants of encapsulated OLED devices.For the case of non-transparent encapsulation thecombination of ellipsometric measurements via the glass substrate and the powerful modelling features of DeltaPsi2 software make it possible to analyze “this reverse sample”.Ellipsometric investigation of a 1-month aging process for an α-NPD film show a significant decrease of the refractive index, suggesting a decrease in the material density.

确定

还剩1页未读,是否继续阅读?

HORIBA(中国)为您提供《OLED封装器件中厚度,光学常数检测方案(椭偏仪)》,该方案主要用于光电器件中厚度,光学常数检测,参考标准--,《OLED封装器件中厚度,光学常数检测方案(椭偏仪)》用到的仪器有HORIBA UVISEL Plus研究级经典型椭偏仪

推荐专场

相关方案

更多

该厂商其他方案

更多