Abstract:In practical rubber processing the compounds will be subjectedto high shear rates. Hence in order to optimize processing con-ditions and also to guarantee a constant quality of the com-pounds it''s a mus! to lest processibility of rubber compounds inthe shear rate range of practical processing. Processibility ofrubber compounds is predominantly determined by its viscositythat''s balanced by two effects; viscosity of these materials de-creases drastically with increasing shear rate (pseudoplasticity)hut increases markedly with the onset and development of cur-ing. The rheovulkameter has been developped especially to takecare of these effects and allowing to measure easily and fastprocessibility of rubber compounds under conditions of practicalprocessing. It can be used like a capillary rheometer hut like aninjection molding tester as weil. Rheovulkameter tests given in-formation about both: j/owing (Rheo-) and curing (Vulkameter)of rubber compounds and other curing systems, too.

方案详情

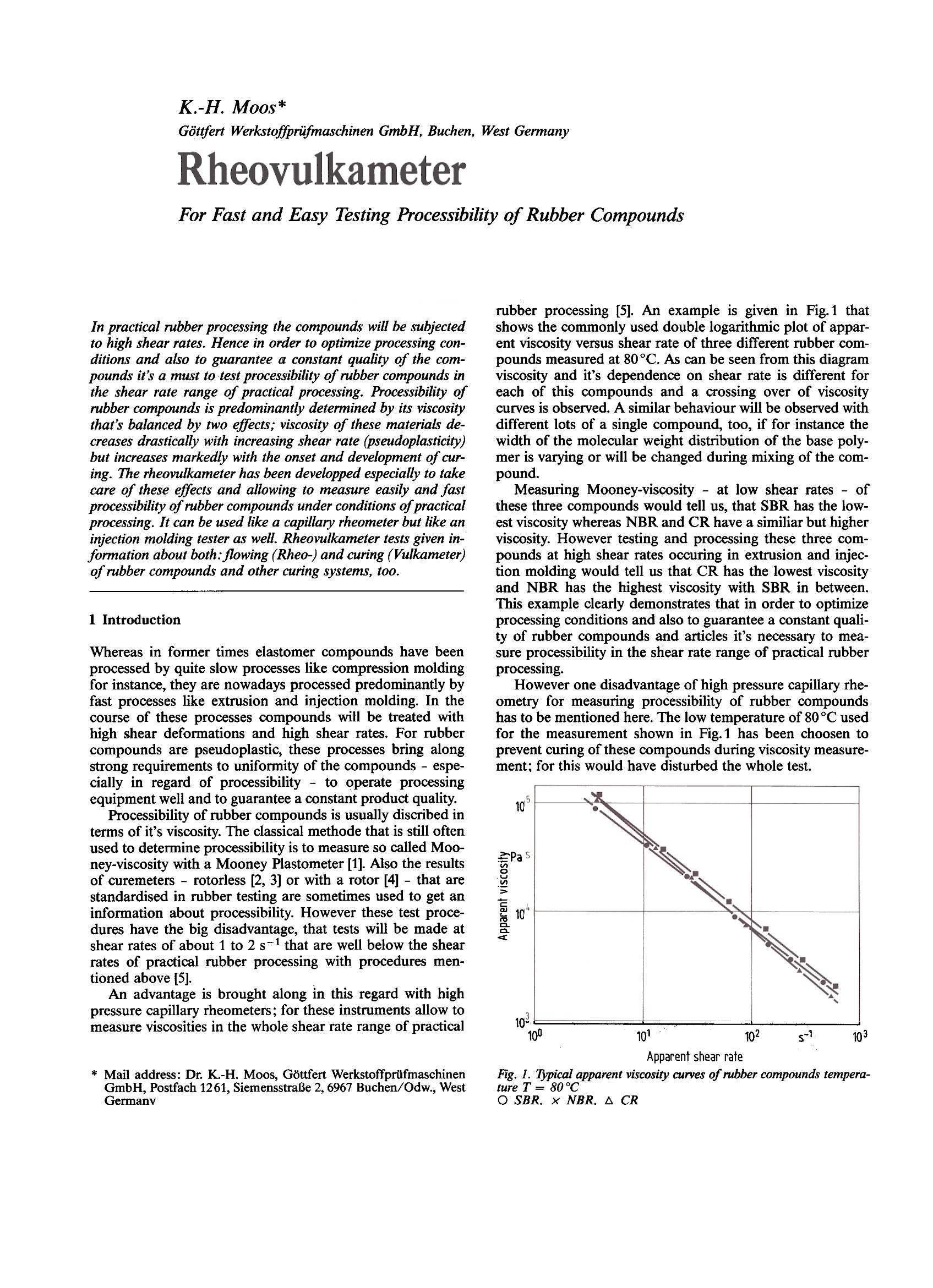

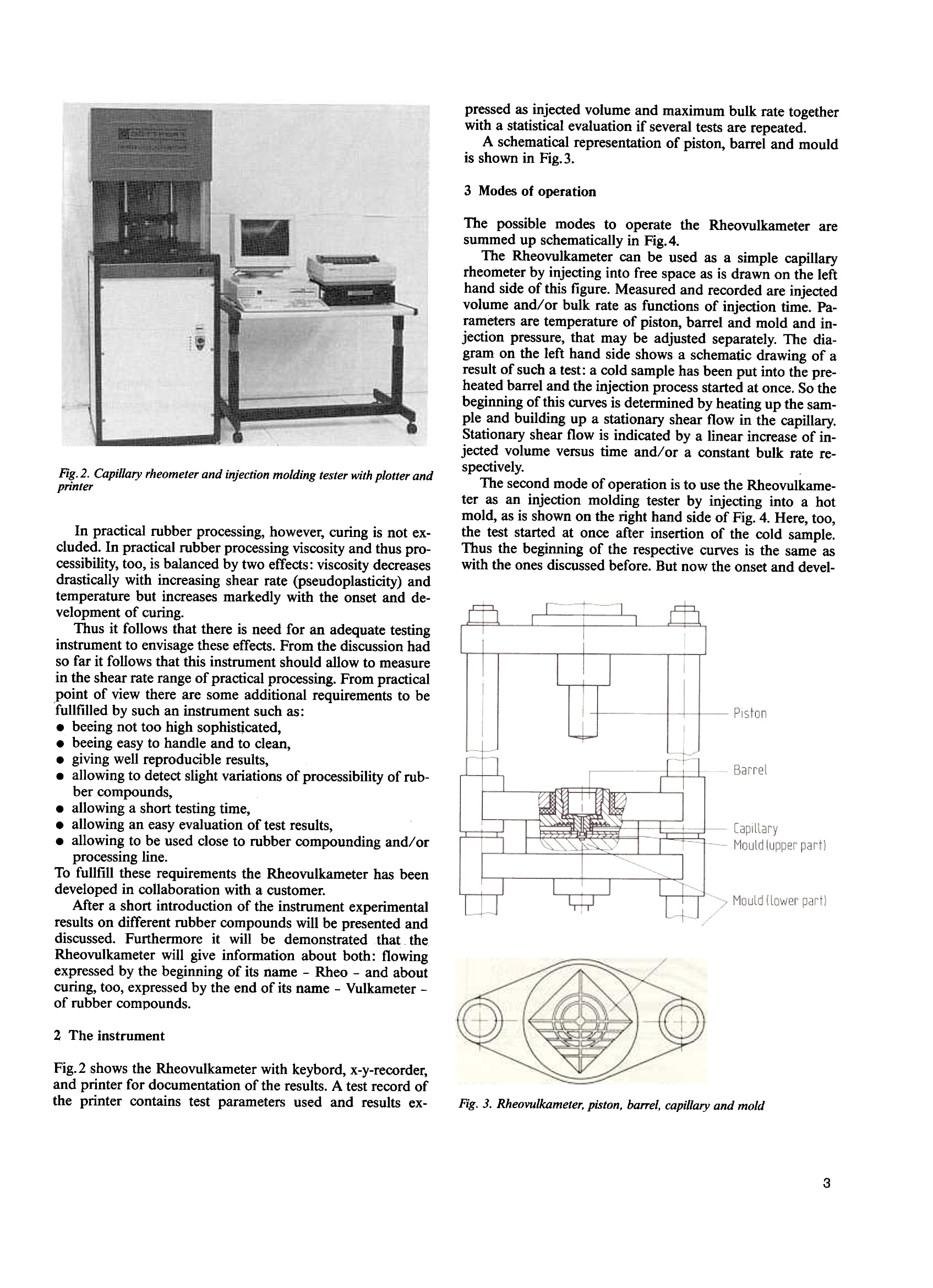

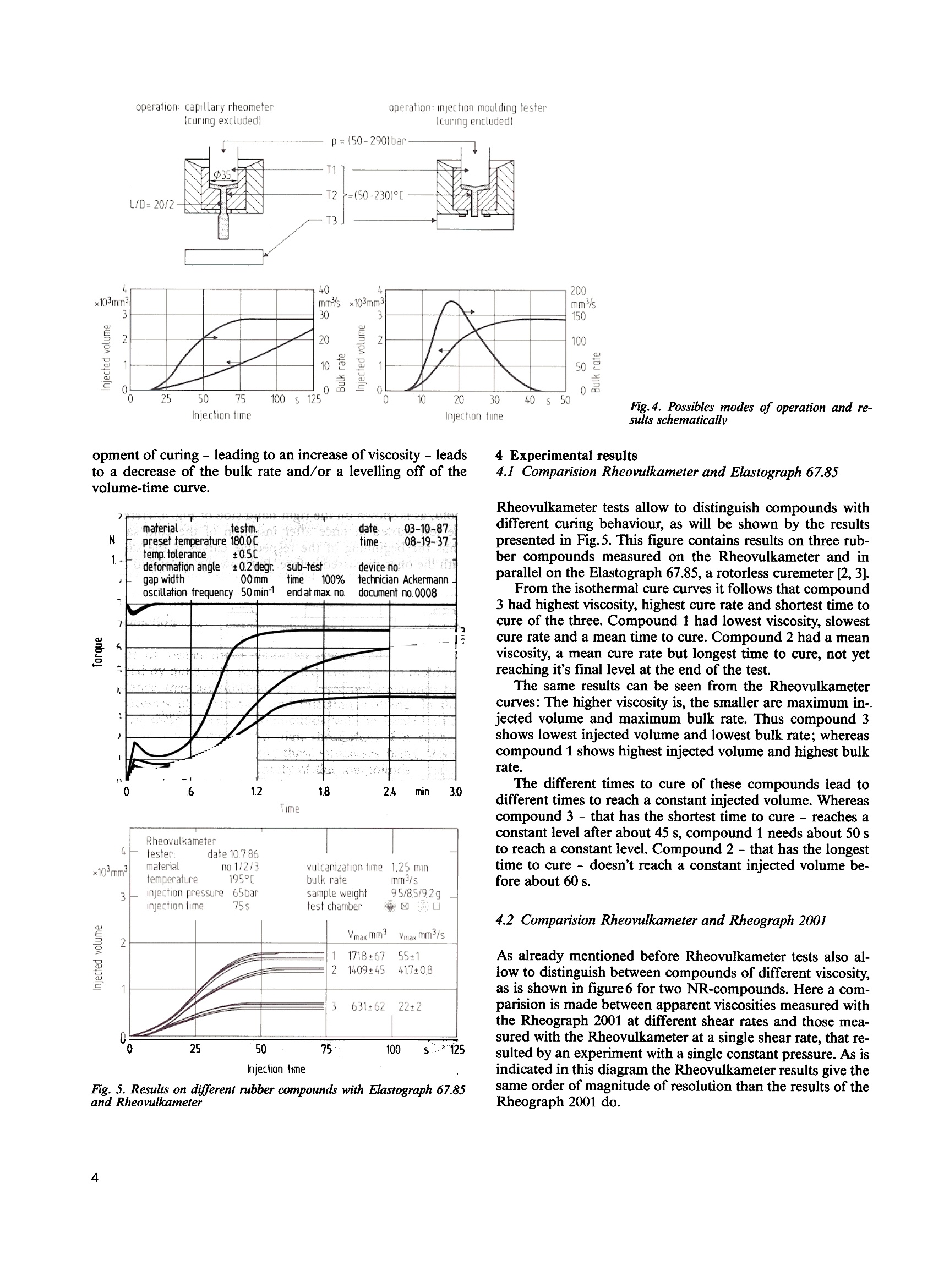

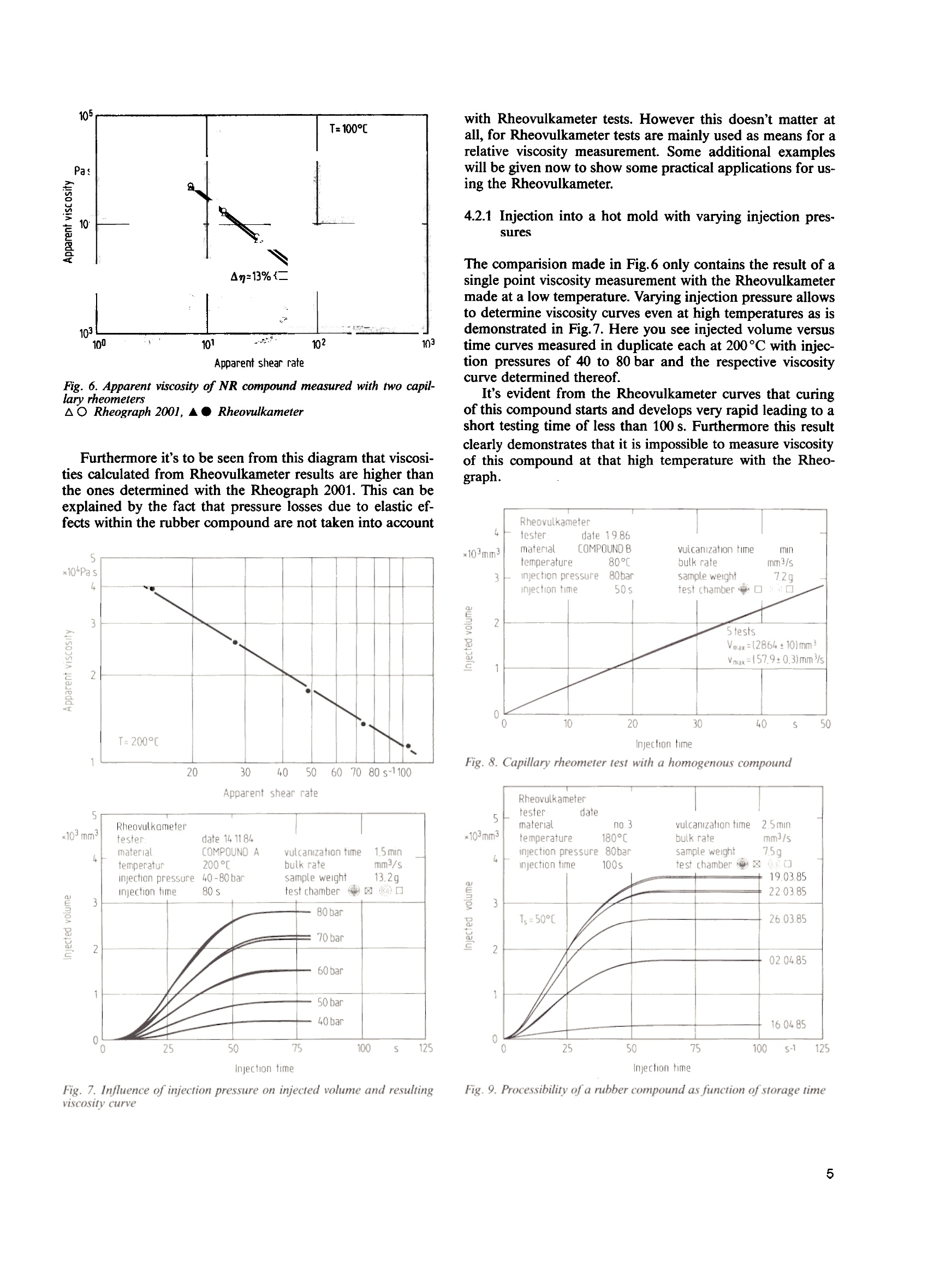

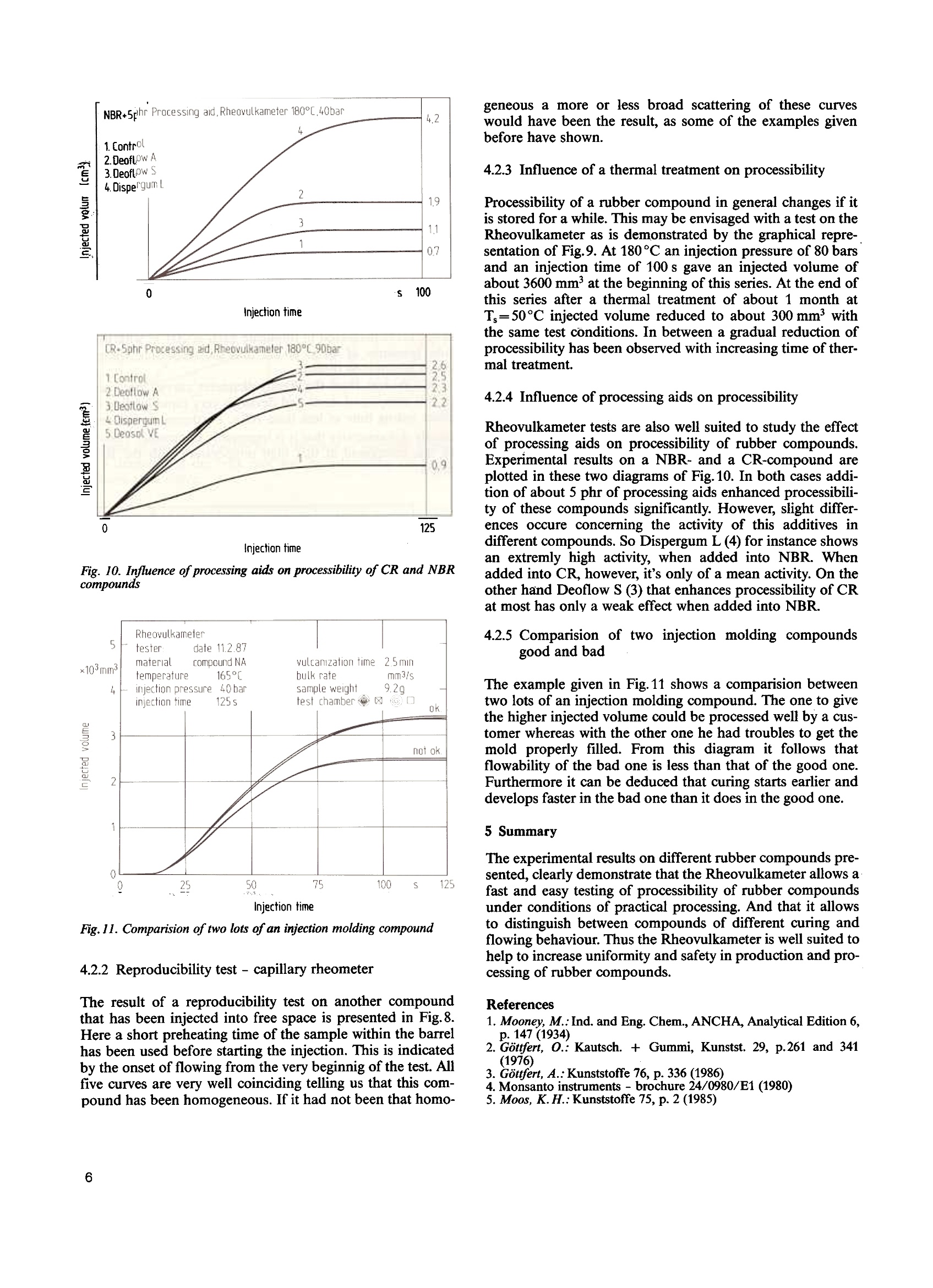

K.-H. Moos*Gottfert Werkstoffpriifmaschinen GmbH, Buchen, West Germany Rheovulkameter For Fast and Easy Testing Processibility ofRubber Compounds In practical rubber processing the compounds will be subjectedto high shear rates. Hence in order to optimize processing con-ditions and also to guarantee a constant quality of the com-pounds it's a must to test processibility ofrubber compounds inthe shear rate range of practical processing. Processibility ofrubber compounds is predominantly determined by its viscositythat’s balanced by two effects; viscosity of these materials de-creases drastically with increasing shear rate (pseudoplasticity)but increases markedly with the onset and development of cur-ing. The rheovulkameter has been developped especially to takecare of these effects and allowing to measure easily and fastprocessibility ofrubber compounds under conditions of practicalprocessing. It can be used like a capillary rheometer but like aninjection molding tester as well. Rheovulkameter tests given in-formation about both: flowing (Rheo-) and curing (Vulkameter)of rubber compounds and other curing systems, too. 1 Introduction Whereas in former times elastomer compounds have beenprocessed by quite slow processes like compression moldingfor instance, they are nowadays processed predominantly byfast processes like extrusion and injection molding. In thecourse of these processes compounds will be treated withhigh shear deformations and high shear rates. For rubbercompounds are pseudoplastic, these processes bring alongstrong requirements to uniformity of the compounds - espe-cially in regard of processibility - to operate processingequipment well and to guarantee a constant product quality.V. Processibility of rubber compounds is usually discribed interms of it’s viscosity. The classical methode that is still oftenused to determine processibility is to measure so called Moo-ney-viscosity with a Mooney Plastometer [1]. Also the resultsof curemeters - rotorless [2, 3] or with a rotor [4] - that arestandardised in rubber testing are sometimes used to get aninformation about processibility. However these test proce-dures have the big disadvantage, that tests will be made atshear rates of about 1 to 2 s-1 that are well below the shearrates of practical rubber processing with procedures men-tioned above [5]. An advantage is brought along in this regard with highpressure capillary rheometers; for these instruments allow tomeasure viscosities in the whole shear rate range of practical ( * Mail address: Dr.K.-H. Moos, Gottfert WerkstoffprufmaschinenGmbH, Postfach 1261, SiemensstraBe 2, 6967 Buchen/Odw., West Germanv ) rubber processing [5]. An example is given in Fig. 1 thatshows the commonly used double logarithmic plot of appar-ent viscosity versus shear rate of three different rubber com-pounds measured at 80°C. As can be seen from this diagramviscosity and it’s dependence on shear rate is different fofrareach of this compounds and a crossing over of viscositycurves is observed. A similar behaviour will be observed withdifferent lots of a single compound, too, if for instance thewidth of the molecular weight distribution of the base poly-mer is varying or will be changed during mixing of the com-pound. Measuring Mooney-viscosity - at low shear rates -ofthese three compounds would tell us, that SBR has the low-est viscosity whereas NBR and CR have a similiar but higherviscosity. However testing and processing these three com-pounds at high shear rates occuring in extrusion and injec-tion molding would tell us that CR has the lowest viscosityand NBR has the highest viscosity with SBR in between.This example clearly demonstrates that in order to optimizeprocessing conditions and also to guarantee a constant quali-ty of rubber compounds and articles it’s necessary to mea-sure processibility in the shear rate range of practical rubberprocessing. However one disadvantage of high pressure capillary rhe-ometry for measuring processibility of rubber compoundshas to be mentioned here. The low temperature of 80°C usedfor the measurement shown in Fig. 1 has been choosen toprevent curing of these compounds during viscosity measure-ment; for this would have disturbed the whole test. Fig. 1. Typical apparent viscosity curves ofrubber compounds tempera-ture T= 80℃O SBR. × NBR. A CR Fig.2. Capillary rheometer and injection molding tester with plotter andprinter In practical rubber processing, however, curing is not ex-cluded. In practical rubber processing viscosity and thus pro-cessibility, too, is balanced by two effects: viscosity decreasesdrastically with increasing shear rate (pseudoplasticity) andtemperature but increases markedly with the onset and de-velopment of curing. Thus it follows that there is need for an adequate testinginstrument to envisage these effects. From the discussion hadso far it follows that this instrument should allow to measurein the shear rate range of practical processing. From practicalpoint of view there are some additional requirements to befullfilled by such an instrument such as: beeing not too high sophisticated, beeing easy to handle and to clean, ● giving well reproducible results, allowing to detect slight variations of processibility of rub-ber compounds, allowing a short testing time, · allowing an easy evaluation of test results, ●allowing to be used close to rubber compounding and/orprocessing line. To fullfill these requirements the Rheovulkameter has beendeveloped in collaboration with a customer. After a short introduction of the instrument experimentalresults on different rubber compounds will be presented anddiscussed. Furthermore it will be demonstrated that theRheovulkameter will give information about both: flowingexpressed by the beginning of its name - Rheo- and aboutcuring, too, expressed by the end of its name - Vulkameter -of rubber compounds. 2 The instrument Fig.2 shows the Rheovulkameter with keybord, x-y-recorder,and printer for documentation of the results. A test record ofthe printer contains test parameters used and results ex- pressed as injected volume and maximum bulk rate togetherwith a statistical evaluation if several tests are repeated. A schematical representation of piston, barrel and mouldis shown in Fig.3. 3 Modes of operation The possible modes to operate the Rheovulkameter aresummed up schematically in Fig.4. The Rheovulkameter can be used as a simple capillaryrheometer by injecting into free space as is drawn on the lefthand side of this figure. Measured and recorded are injectedvolume and/or bulk rate as functions of injection time. Pa-rameters are temperature of piston, barrel and mold and in-jection pressure, that may be adjusted separately. The dia-gram on the left hand side shows a schematic drawing of aresult of such a test: a cold sample has been put into the pre-heated barrel and the injection process started at once. So thebeginning of this curves is determined by heating up the sam-ple and building up a stationary shear flow in the capillary.Stationary shear flow is indicated by a linear increase of in-jected volume versus time and/or a constant bulk rate re-spectively. The second mode of operation is to use the Rheovulkame-ter as an injection molding tester by injecting into a hotmold, as is shown on the right hand side of Fig. 4. Here, too,the test started at once after insertion of the cold sample.Thus the beginning of the respective curves is the same aswith the ones discussed before. But now the onset and devel- Fig. 3.Rheovulkameter, piston, barrel, capillary and mold opment of curing- leading to an increase of viscosity-leadsto a decrease of the bulk rate and/or a levelling off of the.volume-time curve. material testm. 03-10-87 Fig. 5. Results on different rubber compounds with Elastograph 67.85and Rheovulkameter 4 Experimental results 4.1 Comparision Rheovulkameter and Elastograph 67.85 Rheovulkameter tests allow to distinguish compounds withdifferent curing behaviour, as will be shown by the resultspresented in Fig.5. This figure contains results on three rub-ber compounds measured on the Rheovulkameter and inparallel on the Elastograph 67.85, a rotorless curemeter [2, 3]. From the isothermal cure curves it follows that compound3 had highest viscosity, highest cure rate and shortest time tocure of the three. Compound 1 had lowest viscosity, slowestcure rate and a mean time to cure. Compound 2 had a meanviscosity,a mean cure rate but longest time to cure, not yetreaching it’s final level at the end of the test. The same results can be seen from the Rheovulkametercurves: The higher viscosity is, the smaller are maximum in-.jected volume and maximum bulk rate. Thus compound 3shows lowest injected volume and lowest bulk rate; whereascompound 1 shows highest injected volume and highest bulkrate. The different times to cure of these compounds lead todifferent times to reach a constant injected volume. Whereascompound 3- that has the shortest time to cure - reaches aconstant level after about 45 s, compound 1 needs about 50 sto reach a constant level. Compound 2 - that has the longesttime to cure -doesn’t reach a constant injected volume be-fore about 60 s. 4.2 Comparision Rheovulkameter and Rheograph 2001 As already mentioned before Rheovulkameter tests also al-low to distinguish between compounds of different viscosity,as is shown in figure6 for two NR-compounds. Here a com-parision is made between apparent viscosities measured withthe Rheograph 2001 at different shear rates and those mea-sured with the Rheovulkameter at a single shear rate, that re-sulted by an experiment with a single constant pressure. As isindicated in this diagram the Rheovulkameter results give thesame order of magnitude of resolution than the results of theRheograph 2001 do Fig. 6. Apparent viscosity ofNR compound measured with two capil-lary rheometersAO Rheograph 2001, ▲●Rheovulkameter Furthermore it’s to be seen from this diagram that viscosi-ties calculated from Rheovulkameter results are higher thanthe ones determined with the Rheograph 2001. This can beexplained by the fact that pressure losses due to elastic ef-fects within the rubber compound are not taken into account with Rheovulkameter tests. However this doesn’t matter atall, for Rheovulkameter tests are mainly used as means for arelative viscosity measurement. Some additional exampleswill be given now to show some practical applications for us-ing the Rheovulkameter. 4.2.1 Injection into a hot mold with varying injection pres-sures The comparision made in Fig.6 only contains the result of asingle point viscosity measurement with the Rheovulkametermade at a low temperature. Varying injection pressure allowsto determine viscosity curves even at high temperatures as isdemonstrated in Fig.7. Here you see injected volume versustime curves measured in duplicate each at 200°C with injec-tion pressures of 40 to 80 bar and the respective viscositycurve determined thereof. It's evident from the Rheovulkameter curves that curingof this compound starts and develops very rapid leading to ashort testing time of less than 100 s. Furthermore this resultclearly demonstrates that it is impossible to measure viscosityof this compound at that high temperature with the Rheo-graph. Fig. 8.Capillary rheometer test with a homogenous compound Injection time Fig. 10. Influence of processing aids on processibility of CR and NBRcompounds Fig. 11. Comparision of two lots of an injection molding compound 4.2.2 Reproducibility test -capillary rheometer The result of a reproducibility test on another compoundthat has been injected into free space is presented in Fig.8.Here a short preheating time of the sample within the barrelhas been used before starting the injection. This is indicatedby the onset of flowing from the very beginnig of the test. Allfive curves are very well coinciding telling us that this com-pound has been homogeneous. If it had not been that homo- geneous a more or less broad scattering of these curveswould have been the result, as some of the examples given. before have shown. 4.2.3 Influence of a thermal treatment on processibility Processibility of a rubber compound in general changes if itis stored for a while. This may be envisaged with a test on theRheovulkameter as is demonstrated by the graphical repre-sentation of Fig.9. At 180°℃ an injection pressure of 80 barsand an injection time of 100s gave an injected volume ofabout 3600 mm’ at the beginning of this series. At the end ofthis series after a thermal treatment of about 1 month atTs=50°℃ injected volume reduced to about 300 mm’withthe same test conditions. In between a gradual reduction ofprocessibility has been observed with increasing time of ther-mal treatment. 4.2.4 Influence of processing aids on processibility Rheovulkameter tests are also well suited to study the effectof processing aids on processibility of rubber compounds.Experimental results on a NBR- and a CR-compound areplotted in these two diagrams of Fig.10. In both cases addi-tion of about 5 phr of processing aids enhanced processibili-ty of these compounds significantly. However, slight differ-ences occure concerning the activity of this additives indifferent compounds. So Dispergum L (4) for instance showsan extremly high activity, when added into NBR. Whenadded into CR, however, it’s only of a mean activity. On theother hand Deoflow S (3) that enhances processibility of CRat most has only a weak effect when added into NBR. 4.2.5 Comparision of two injection molding compoundsgood and bad The example given in Fig.11 shows a comparision betweentwo lots of an injection molding compound. The one to givethe higher injected volume could be processed well by a cus-tomer whereas with the other one he had troubles to get themold properly filled. From this diagram it follows thatflowability of the bad one is less than that of the good one.Furthermore it can be deduced that curing starts earlier anddevelops faster in the bad one than it does in the good one. 5 Summary The experimental results on different rubber compounds pre-sented, clearly demonstrate that the Rheovulkameter allows afast and easy testing of processibility of rubber compoundsunder conditions of practical processing. And that it allowsto distinguish between compounds of different curing andflowing behaviour. Thus the Rheovulkameter is well suited tohelp to increase uniformity and safety in production and pro-cessing of rubber compounds References 1. Mooney, M.:Ind. and Eng. Chem., ANCHA, Analytical Edition 6,p. 147 (1934) 2. Gottfert, O.: Kautsch. + Gummi, Kunstst. 29, p.261 and 341(1976) ( 3 . Gottfert, A.:Kunststoffe 76, p. 336 (1986) ) ( 4. Monsanto instruments- brochure 24/0980/E1 (1980) ) 5. Moos, K.H.: Kunststoffe 75, p. 2(1985)

确定

还剩3页未读,是否继续阅读?

仪尊科技有限公司为您提供《橡胶化合物中主要成分含量检测方案 》,该方案主要用于橡胶中主要成分含量检测,参考标准--,《橡胶化合物中主要成分含量检测方案 》用到的仪器有橡胶毛细管流变仪

相关方案

更多