Fluid materials, by definition, are systems which flow when subjected to stress. How they respond to an input stress is the heart of rheological testing and may be a complex issue. There are many types of fluids: pure substances, mixtures, dispersions and solutions, falling into the categories of either simple or structured fluids. Each has its own unique behavior when subjected to stress. In general, when a material has a uniform phase, such as a solution or pure substance, it is referred to as a simple fluid. Materials which contain more than one phase, such as solid particles dispersed in a liquid, gas particles in foam or an emulsion of immiscible liquids are considered structured fluids since their rheological behavior is in general dominated by the interactions of the constituents.

方案详情

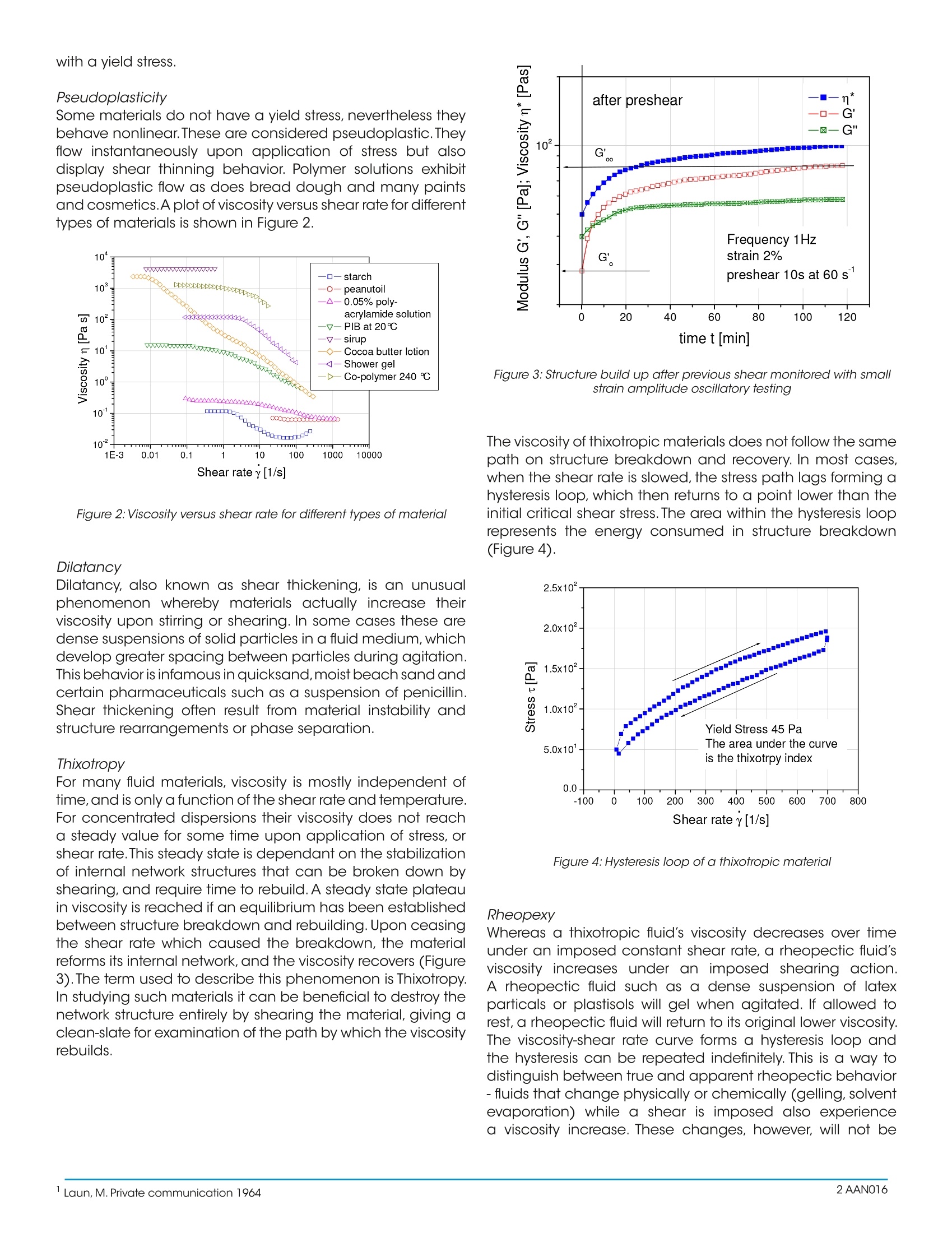

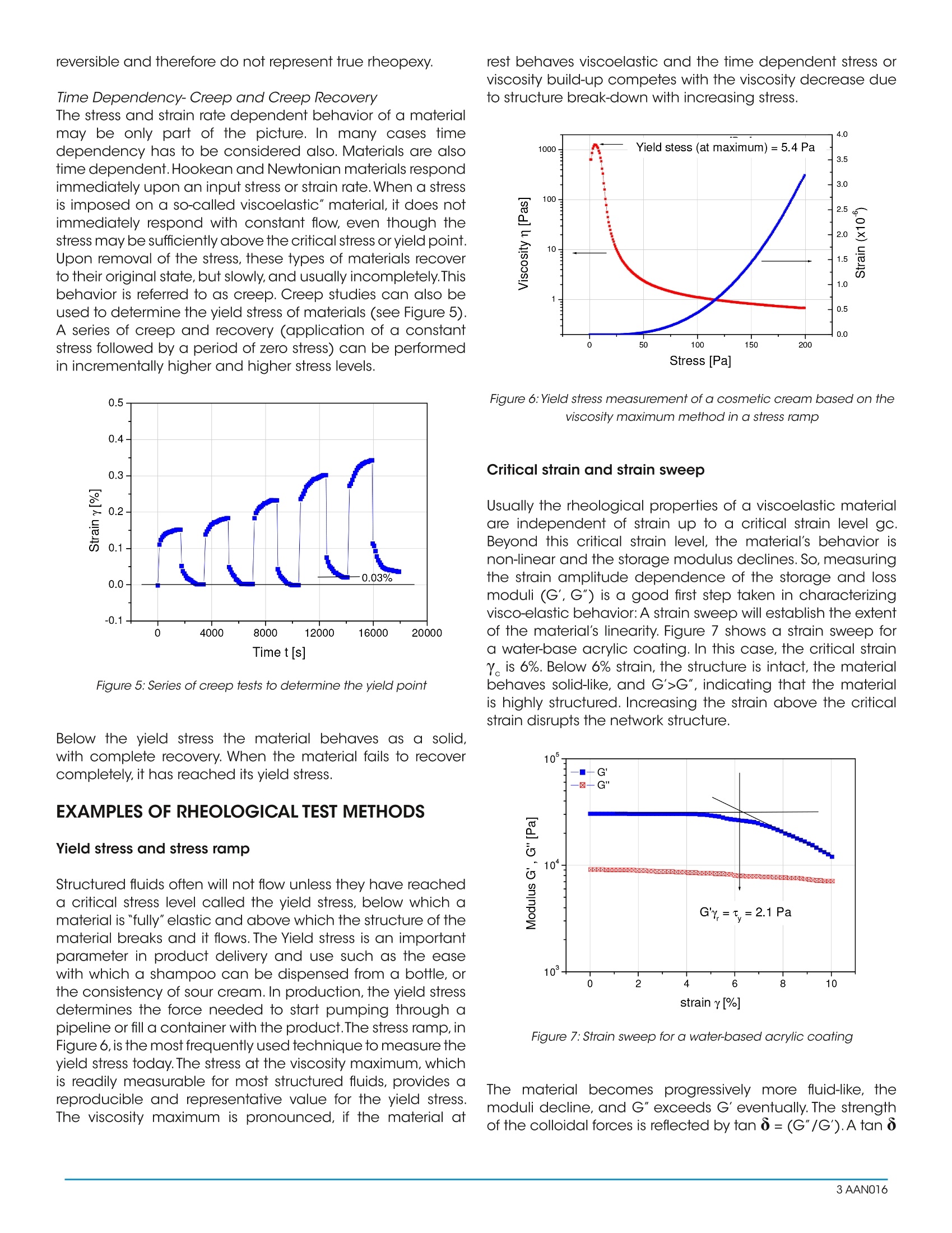

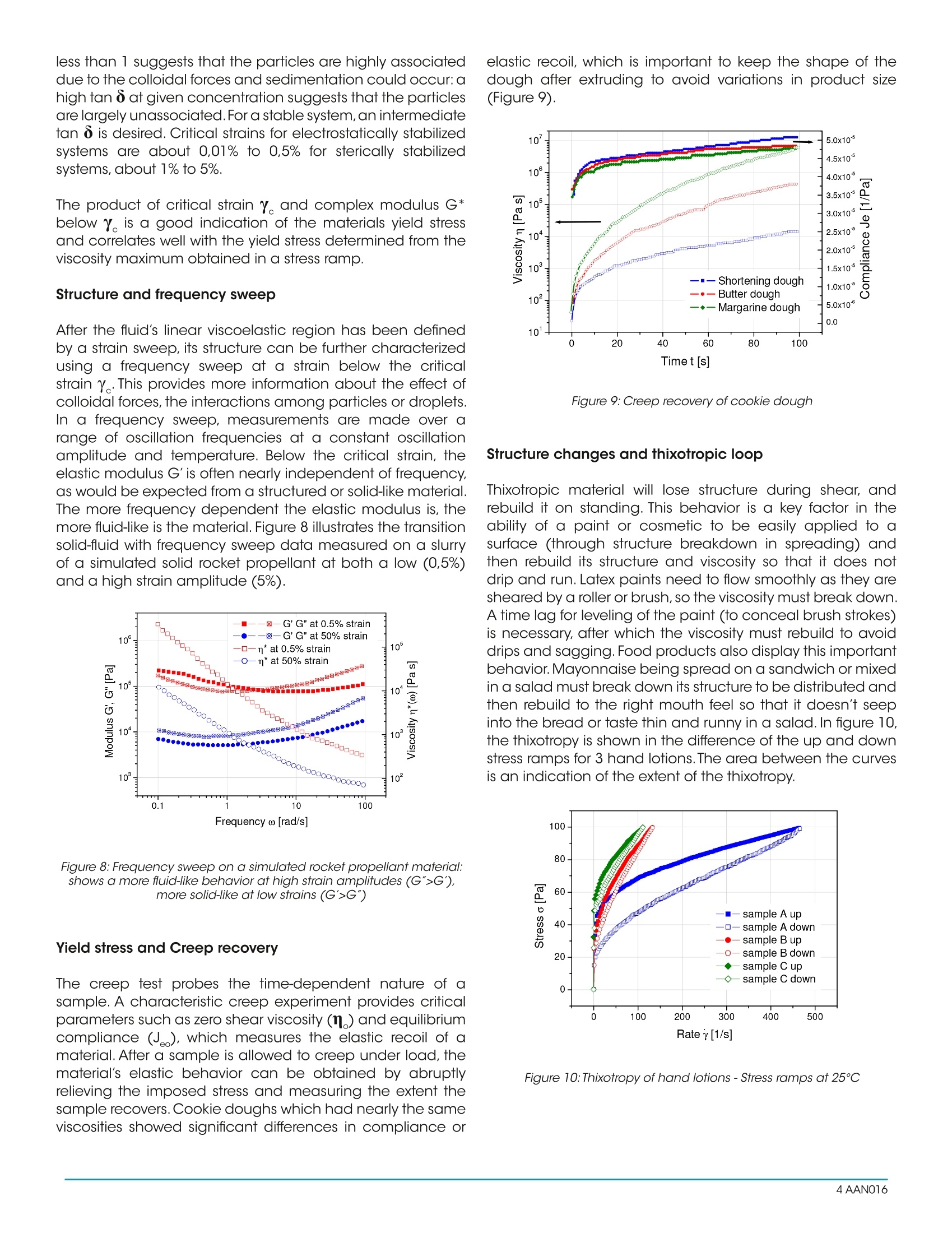

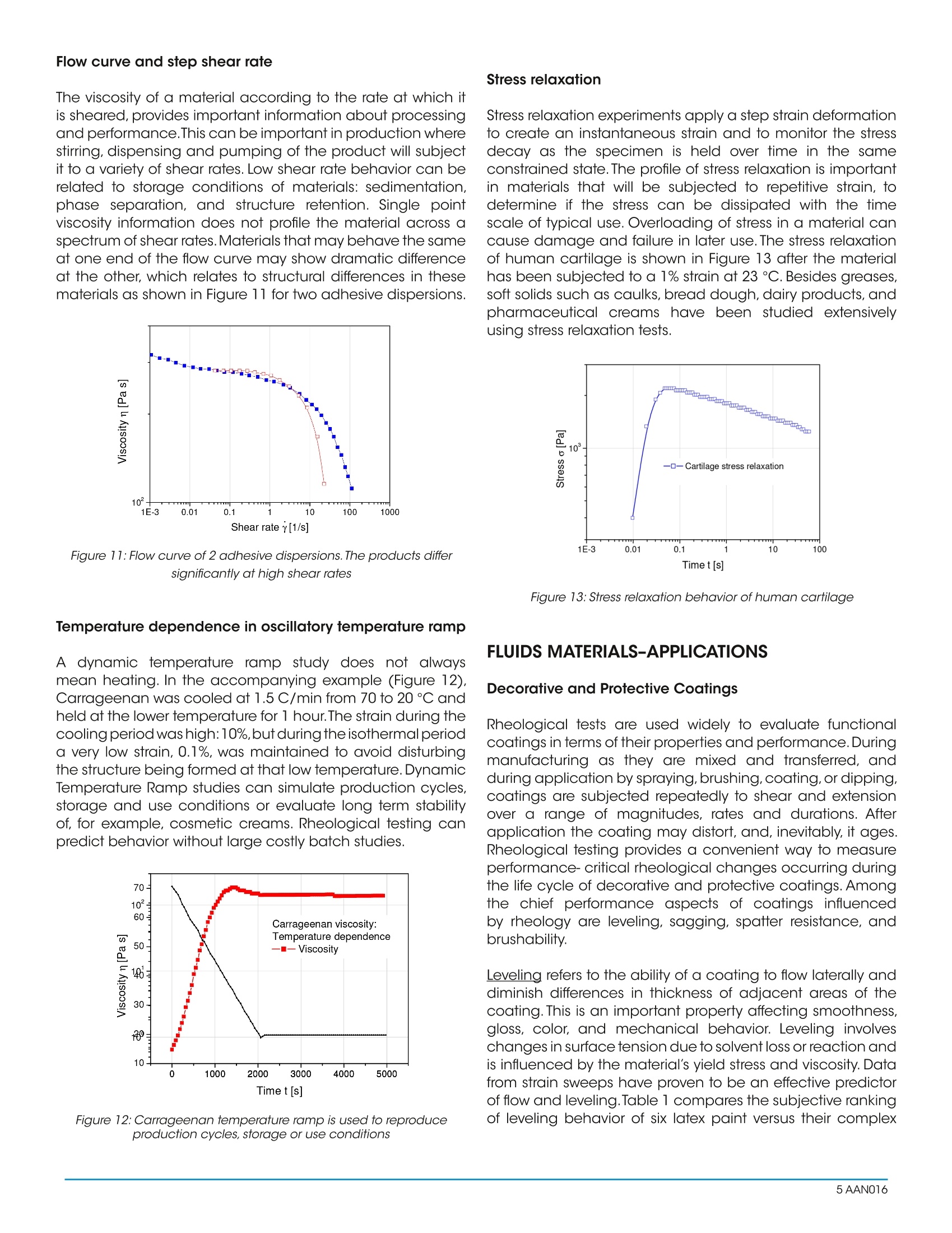

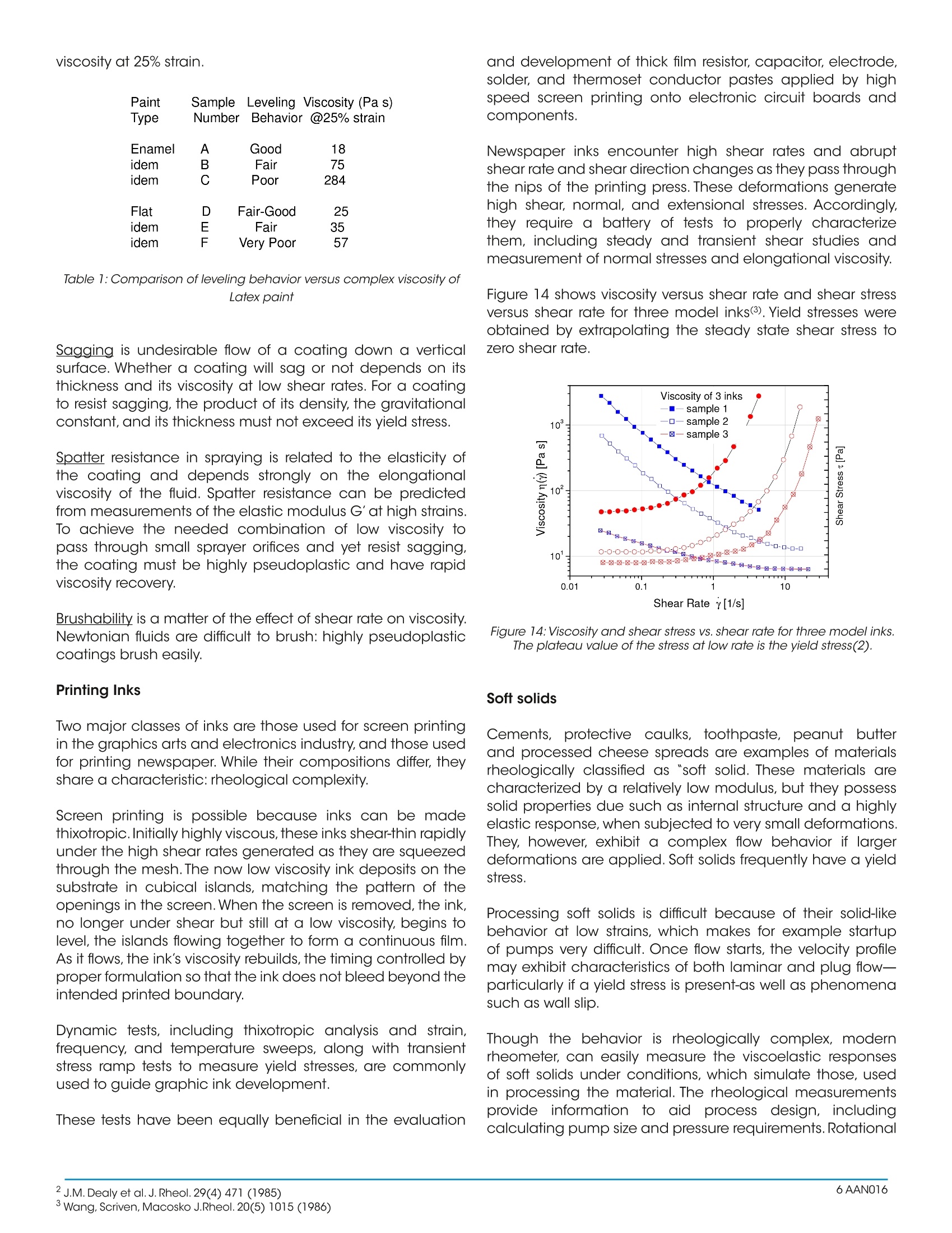

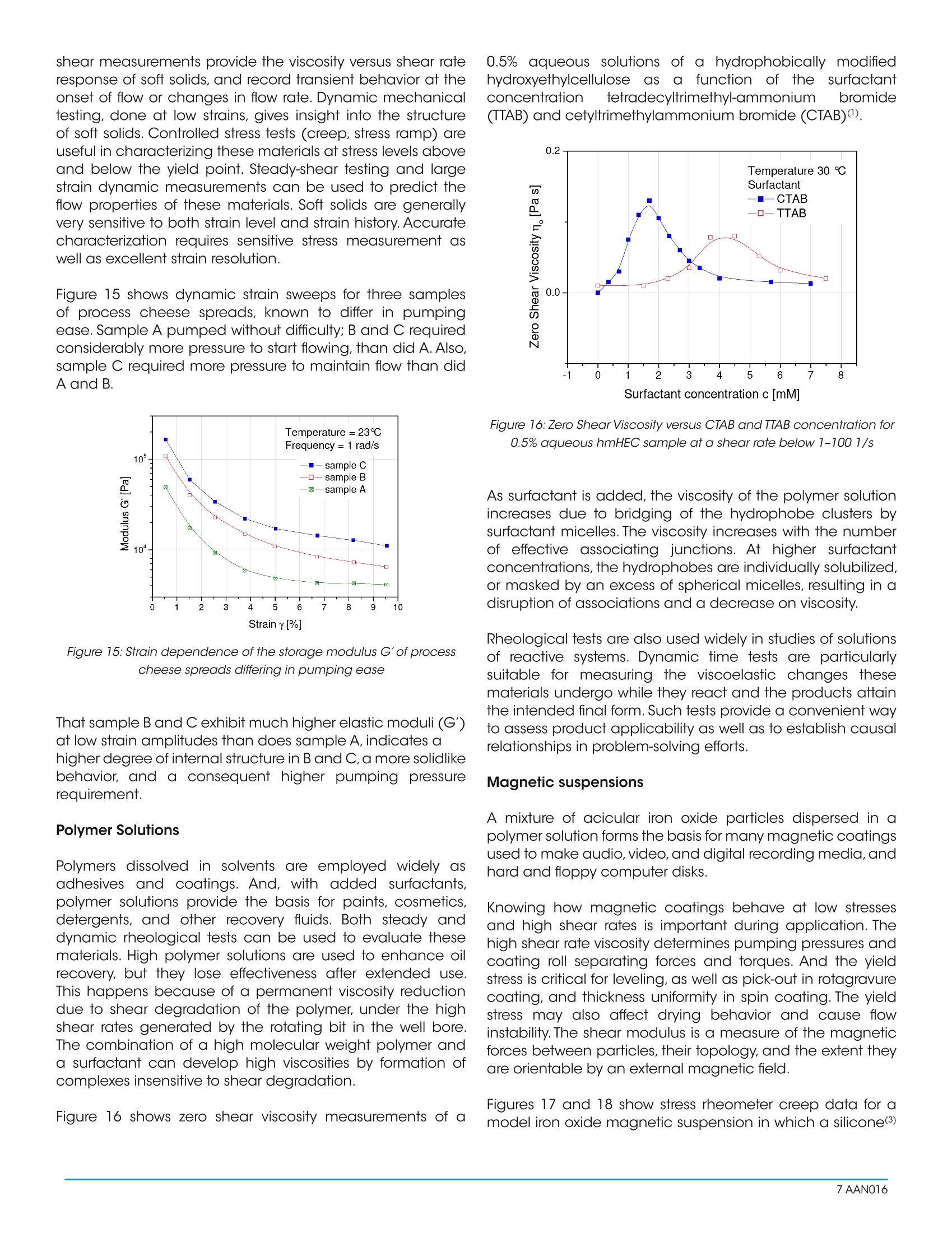

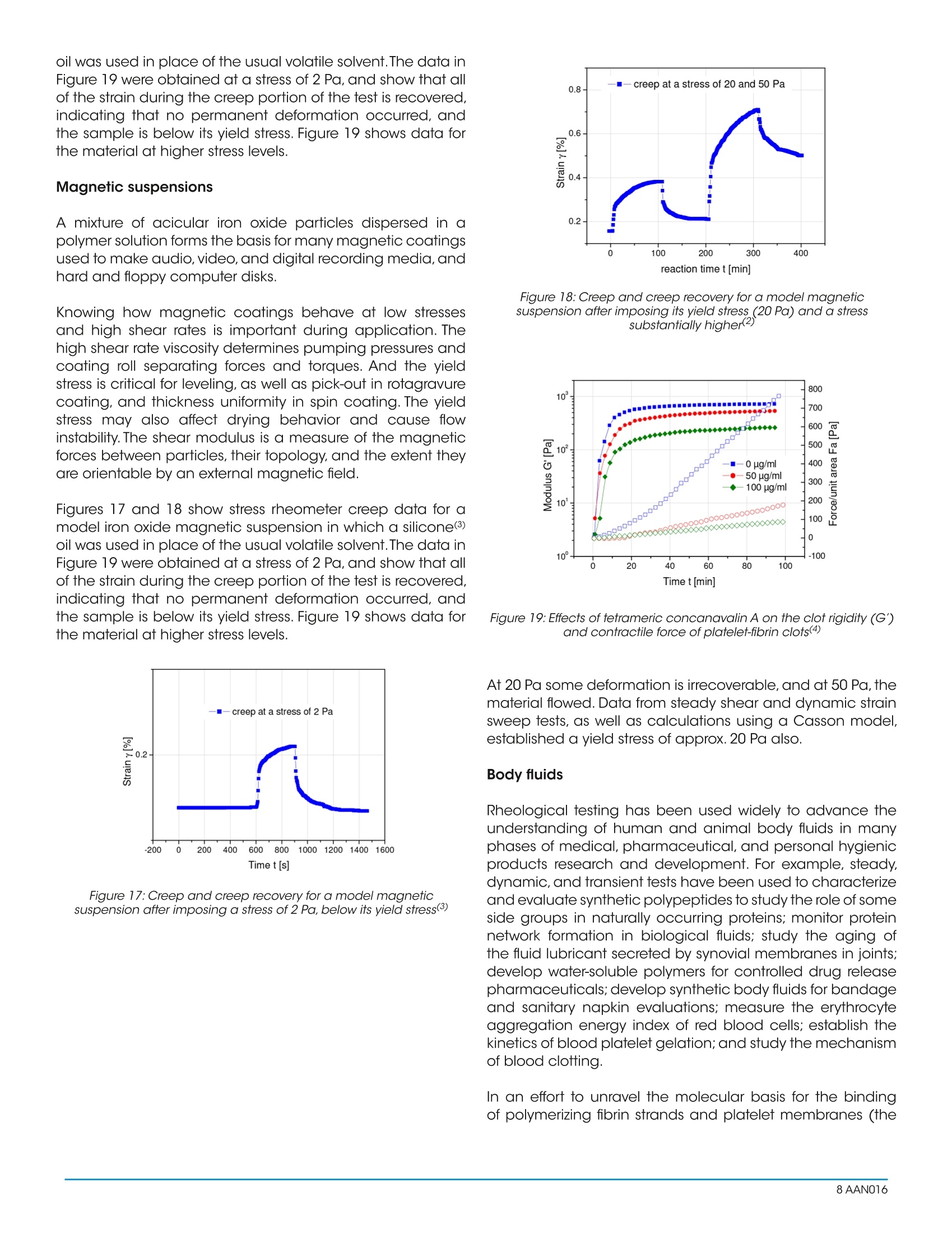

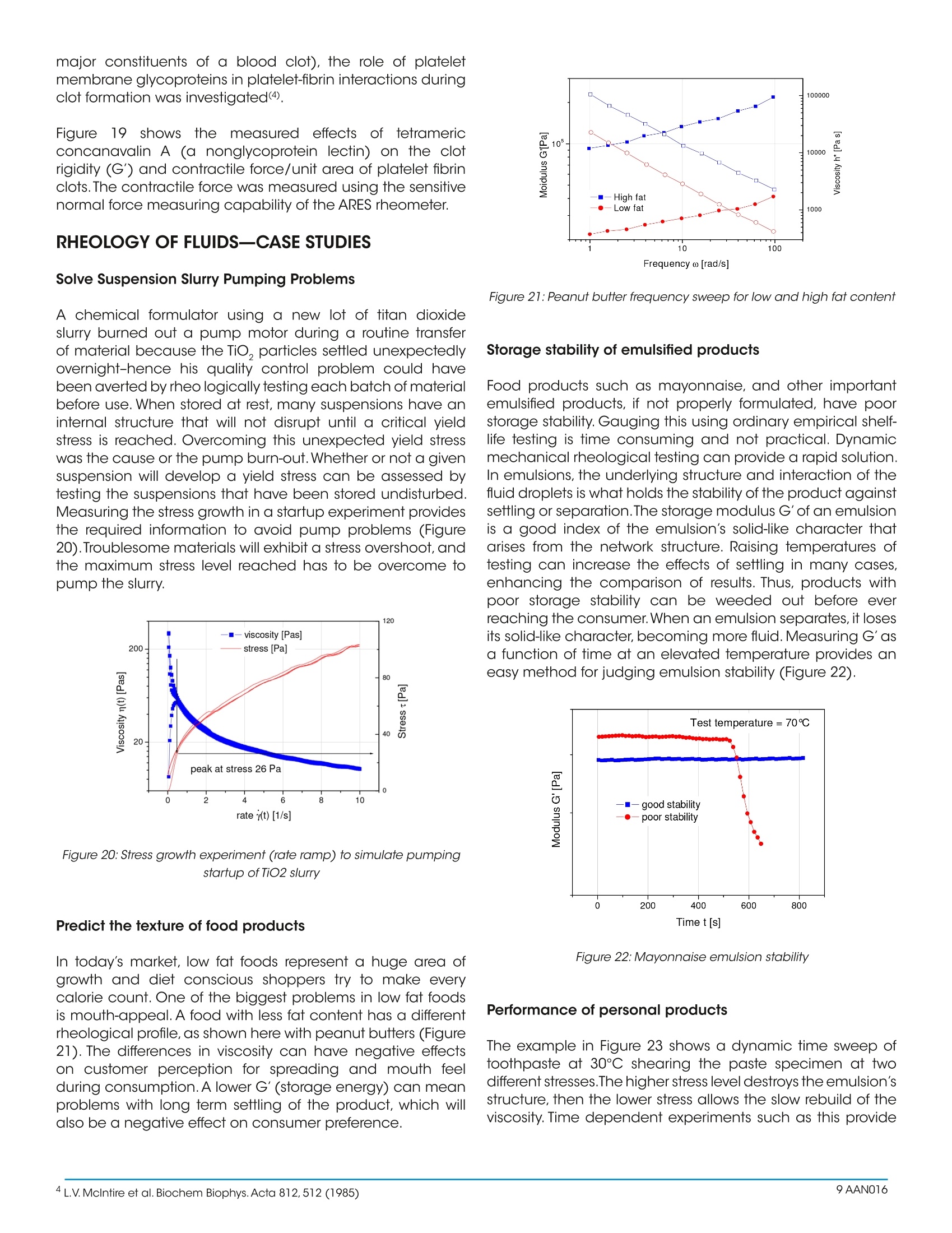

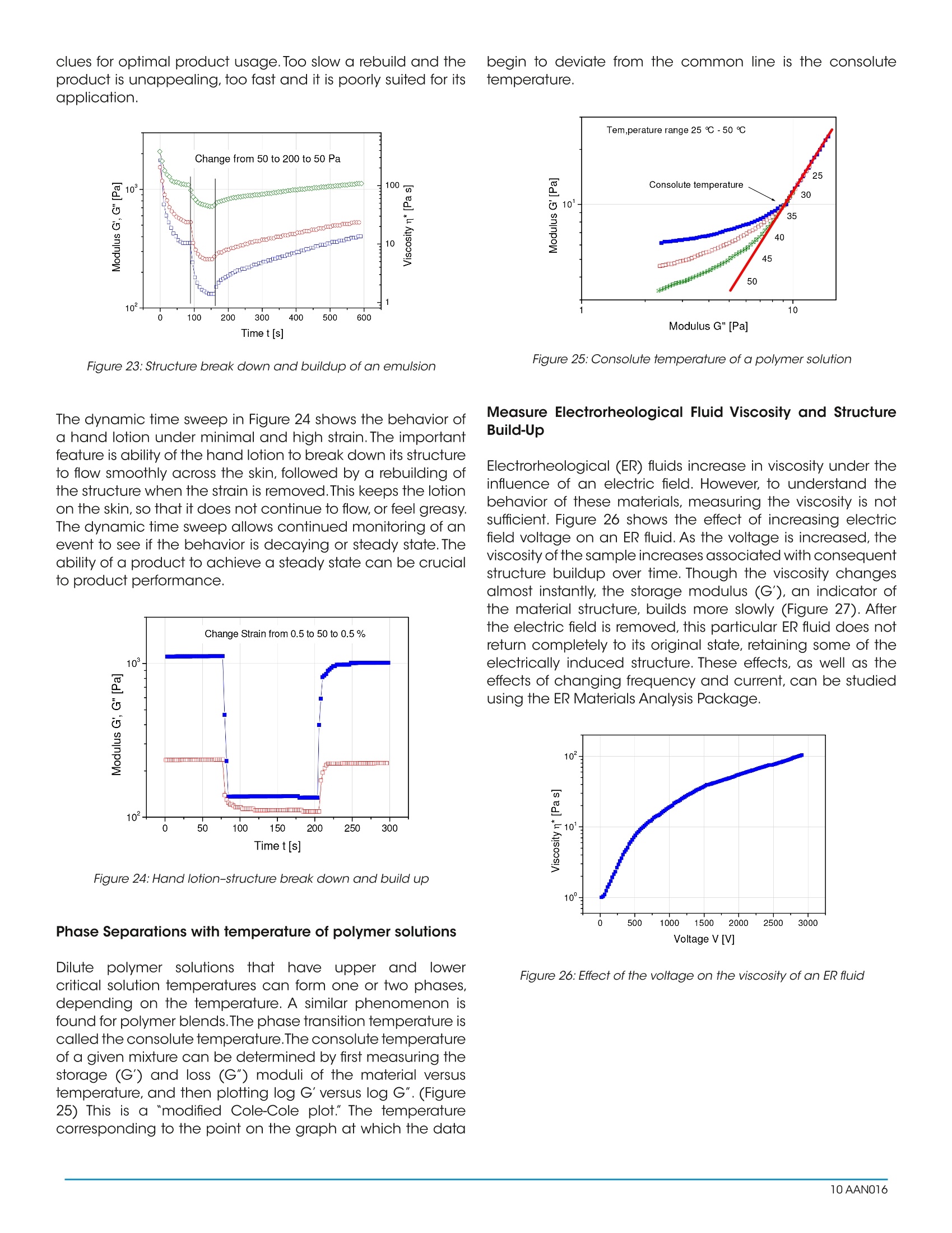

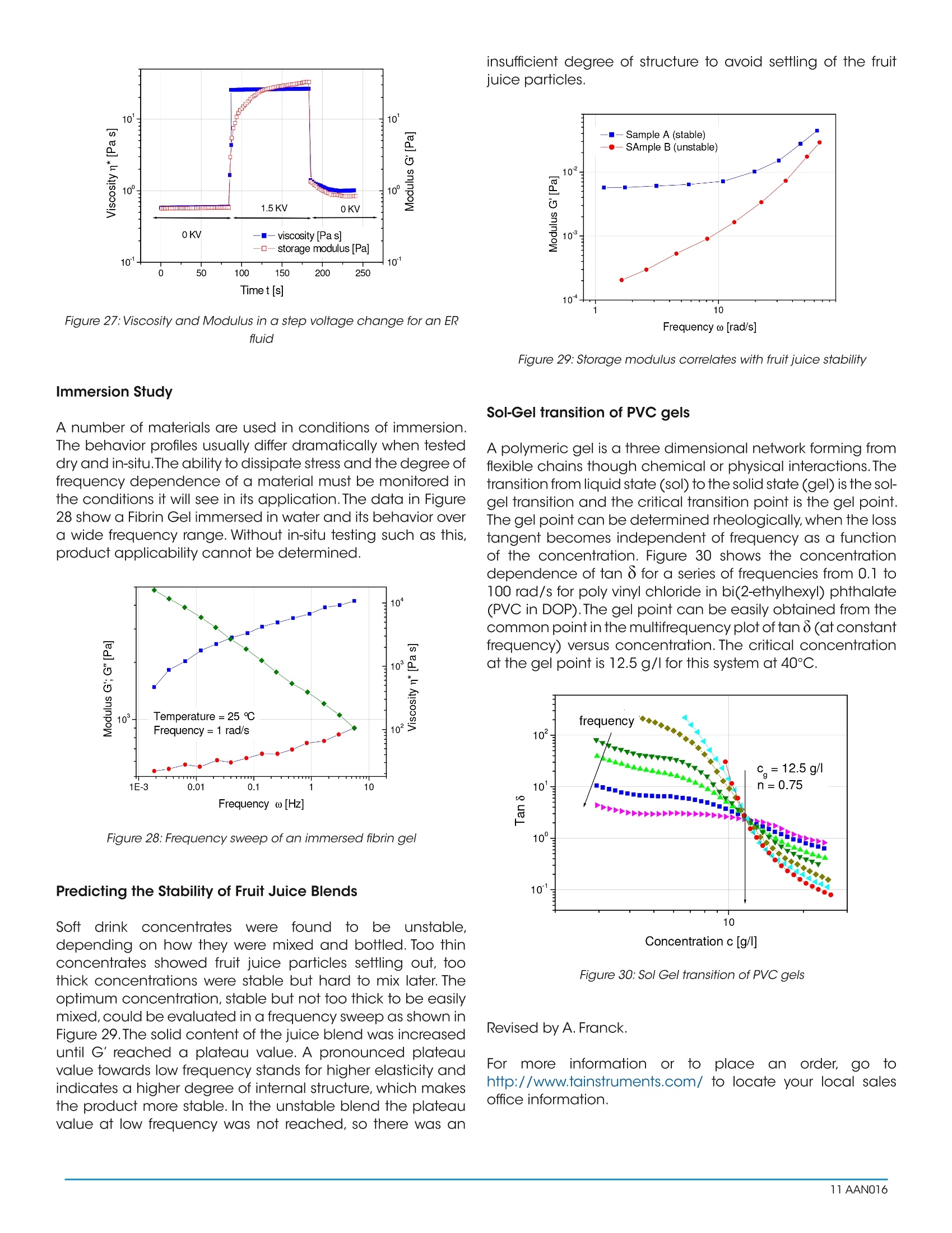

reversible and therefore do not represent true rheopexy. Flow curve and step shear rate Understanding Rheology of Structured Fluids Keywords: structured fluids, sol gel transition, solution, yield stress, thixotropy, viscosity, mechanical stability, AAN016shelf life, flow curve, inks, cosmetics, dispersions, food GENERAL CONSIDERATIONS Fluids: Simple or Structured Fluid materials, by definition, are systems which flow whensubjected to stress. How they respond to an input stress is theheart of rheological testing and may be a complex issue.There are many types of fluids: pure substances, mixtures,dispersions and solutions, falling into the categories of eithersimple or structured fluids. Each has its own unique behaviorwhen subjected to stress. In general, when a material hasa uniform phase, such as a solution or pure substance, it isreferred to as a simple fluid. Materials which contain morethan one phase,such as solid particles dispersed in a liquid,gas particles in foam or an emulsion of immiscible liquidsare considered structured fluids since their rheologicalbehavior is in general dominated by the interactions of theconstituents. Structured fluids Many of the materials we use each day are structured fluids.Most foods, cosmetics, pharmaceuticals and paints containparticles or droplets of an immiscible fluid suspended in acarrier liquid. A number of soft semisolid materials also fallunder the category of structured fluids since they have amultiphase structure and exhibit complex flow behavior.Some examples would be cheeses, lipstick, caulk, and breaddough. Many factors affect the stability of structured fluids. Theviscosity of the liquid phase in dispersions usually playsan important role on the flow properties of the material.Dispersions have wide variations in performance dependingon particle size, shape, concentration, and any attractionwith the continuous phase in which they are suspended.When there is a repulsive electrostatic or steric force betweenparticles they end not to settle rapidly, instead forminga network structure which will stabilize the suspension ifundisturbed.Shearing or even Brownian motion can destroythis delicate structure and break down the fluids viscosity, Structured fluids do not obey a simple linear relationshipbetween applied stress and flow (Newtonian fluid behavior)as shown in Figure 1 for suspensions of latex particles withincreasing volume fraction in water. Figure 7:Viscosity of a structured fluid as a function of shear rate andparticle concentration' Nearly all these materials have a viscosity that drops at higherrates of shear velocityresp,stress. This is the phenomenon ofshear thinning which becomes progressively larger as thevolume concentration of solid particles increases. At highconcentration of solid content,the low shear rate viscosityregion disappears completely, the material l iiss yielding.Some materials show after the shear thinning region withincreasing rate or stress, an increase of the viscosity, usuallydue to structure rearrangements as a result of the appliedshear. This is referred to as flow induced shear thickening. Characteristic flow parameters and functions Bingham Flow Eugene Bingham, a colloid chemist, first coined the term"Rheology." He also showed that for many real fluids acritical level of stress must be attained in order to initiateflow. Below this critical stress, ty, the material behaves as asolid, absorbing the stress energy without flowing. Once thethreshold of critical stress has been reached, the materialyields to flow, hence the term, yield stress.The yield stress is thereason, why you need to shake or tap a bottle to make theketchup flow. Materials which exhibit Newtonian flow beyondthe yield bear the name Bingham Fluids. Plastic Flow Most materials do not exhibit Newtonian flow after the yield,but have a viscosity that decreases (shear thinning) until aplateau is reached.Lipsticks, drilling muds and toothpaste aregood examples of shear thinning non-Newtonian materials Pseudoplasticity Some materials do not have a yield stress, nevertheless theybehave nonlinear. These are considered pseudoplastic.Theyflow instantaneously upon application of stress but alsodisplay shear thinning behavior. Polymer solutions exhibitpseudoplastic flow as does bread dough and many paintsand cosmetics.A plot of viscosity versus shear rate for differenttypes of materials is shown in Figure 2. Figure 2: Viscosity versus shear rate for different types of material Dilatancy Dilatancy, also known as shear thickening, is an unusualphenomenon whereby materials actually increase theirviscosity upon stirring or shearing. In some cases these aredense suspensions of solid particles in a fluid medium, whichdevelop greater spacing between particles during agitation.This behavior is infamous in quicksand,moist beach sand andcertain pharmaceuticals such as a suspension of penicillin.Shear thickening often result from material instability andstructure rearrangements or phase separation. Thixotropy For many fluid materials, viscosity is mostly independent oftime,and is only a function of the shear rate and temperature.For concentrated dispersions their viscosity does not reacha steady value for some time upon application of stress, orshear rate.This steady state is dependant on the stabilizationof internal network structures that can be broken down byshearing, and require time to rebuild. A steady state plateauin viscosity is reached if an equilibrium has been establishedbetween structure breakdown and rebuilding. Upon ceasingthe shear rate which caused the breakdown, the materialreforms its internal network, and the viscosity recovers (Figure3). The term used to describe this phenomenon is Thixotropy.In studying such materials it can be beneficial to destroy thenetwork structure entirely by shearing the material, giving aclean-slate for examination of the path by which the viscosityrebuilds. Figure 3: Structure build up after previous shear monitored with smallstrain amplitude oscillatory testing The viscosity of thixotropic materials does not follow the samepath on structure breakdown and recovery. In most cases,when the shear rate is slowed, the stress path lags forming anysteresis loop, which then returns to a point lower than theinitial critical shear stress. The area within the hysteresis looprepresents the energy consumed in structure breakdown(Figure 4). Figure 4: Hysteresis loop of a thixotropic material Rheopexy Whereas a thixotropic fluid’s viscosity decreases over timeunder an imposed constant shear rate, a rheopectic fluid'sviscosity increases under an imposed shearing action.A rheopectic fluid such as a dense suspension of latexparticals or plastisols will gel when agitated. If allowed torest, a rheopectic fluid will return to its original lower viscosity.The viscosity-shear rate curve forms a hysteresis loop andthe hysteresis can be repeated indefinitely. This is a way todistinguish between true and apparent rheopectic behavior- fluids that change physically or chemically (gelling, solventevaporation) while a shear is imposed also experiencea viscosity increase. These changes, however, will not be Time Dependency-Creep and Creep Recovery The stress and strain rate dependent behavior of a materialmay be only part of the picture. In many cases timedependency has to be considered also. Materials are alsotime dependent.Hookean and Newtonian materials respondimmediately upon an input stress or strain rate.When a stressis imposed on a so-called viscoelastic" material, it does notimmediately respond with constant flow, even though thestress may be sufficiently above the critical stress or yield point.Upon removal of the stress, these types of materials recoverto their original state, but slowly, and usually incompletely.Thisbehavior is referred to as creep.Creep studies can also beused to determine the yield stress of materials (see Figure 5).A series of creep and recovery (application of a constantstress followed by a period of zero stress) can be performedin incrementally higher and higher stress levels. Figure 5: Series of creep tests to determine the yield point Below the yield stress the material behaves as a solid,with complete recovery. When the material fails to recovercompletely, it has reached its yield stress. EXAMPLES OF RHEOLOGICAL TEST METHODS Yield stress and stress ramp Structured fluids often will not flow unless they have reacheda critical stress level called the yield stress, below which amaterial is "fully" elastic and above which the structure of thematerial breaks and it flows. The Yield stress is an importantparameter in product delivery and use such as the easewith which a shampoo can be dispensed from a bottle, orthe consistency of sour cream. In production, the yield stressdetermines the force needed to start pumping through apipeline or fill a container with the product.The stress ramp,inFigure6, is the most frequently used technique to measure theyield stress today. The stress at the viscosity maximum, whichis readily measurable for most structured fluids, provides areproducible and representative value for the yield stress.The viscosity maximum is pronounced, if the material at rest behaves viscoelastic and the time dependent stress orviscosity build-up competes with the viscosity decrease dueto structure break-down with increasing stress. Figure 6: Yield stress measurement of a cosmetic cream based on theviscosity maximum method in a stress ramp Critical strain and strain sweep Usually the rheological properties of a viscoelastic materialare independent of strain up to a critical strain level gc.Beyond this critical strain level, the material's behavior isnon-linear and the storage modulus declines. So, measuringthe strain amplitude dependence of the storage and lossmoduli (G', G") is a good first step taken in characterizingvisco-elastic behavior: A strain sweep will establish the extentof the material's linearity. Figure 7 shows a strain sweep fora water-base acrylic coating. In this case, the critical strainY is 6%. Below 6% strain, the structure is intact, the materialbehaves solid-like, and G'>G",indicating that the materialis highly structured. Increasing the strain above the criticalstrain disrupts the network structure. Figure 7: Strain sweep for a water-based acrylic coating The material becomes progressively more fluid-like, themoduli decline, and G" exceeds G'eventually. The strengthof the colloidal forces is reflected by tan 8= (G"/G'). A tan 8 less than 1 suggests that the particles are highly associateddue to the colloidal forces and sedimentation could occur: ahigh tan 8 at given concentration suggests that the particlesare largely unassociated. For a stable system, an intermediatetan 8 is desired. Critical strains for electrostatically stabilizedsystems are about 0,01% to 0,5% for sterically stabilizedsystems, about 1% to 5%. The product of critical strain Y, and complex modulus G*below Y, is a good indication of the materials yield stressand correlates well with the yield stress determined from theviscosity maximum obtained in a stress ramp. Structure and frequency sweep After the fluid's linear viscoelastic region has been definedby a strain sweep, its structure can be further characterizedusing a frequency sweep at a strain below the criticalstrain y.This provides more information about the effect ofcolloidal forces, the interactions among particles or droplets.In a frequency sweep, measurements are made over arange of oscillation frequencies at a constant oscillationamplitude and temperature. Below the critical strain, theelastic modulus G' is often nearly independent of frequency,as would be expected from a structured or solid-like material.The more frequency dependent the elastic modulus is, themore fluid-like is the material. Figure 8 illustrates the transitionsolid-fluid with frequency sweep data measured on a slurryof a simulated solid rocket propellant at both a low (0,5%)and a high strain amplitude (5%). Figure 8: Frequency sweep on a simulated rocket propellant material:shows a more fluid-like behavior at high strain amplitudes (G">G),more solid-like at low strains (G'>G") Yield stress and Creep recovery The creep test probes the time-dependent nature of asample. A characteristic creep experiment provides criticalparameters such as zero shear viscosity(n。) and equilibriumcompliance (). which measures the elastic recoil of amaterial. After a sample is allowed to creep under load, thematerial's elastic behavior can be obtained by abruptlyrelieving the imposed stress and measuring the extent thesample recovers. Cookie doughs which had nearly the sameviscosities showed significant differences in compliance or elastic recoil, which is important to keep the shape of thedough after extruding to avoid variations in product size(Figure 9). Figure 9: Creep recovery of cookie dough Structure changes and thixotropic loop Thixotropic material will lose structure during shear, andrebuild it on standing. This behavior is a key factor in theability of a paint or cosmetic to be easily applied to asurface (through structure breakdown in spreading) andthen rebuild its structure and viscosity so that it does notdrip and run. Latex paints need to flow smoothly as they aresheared by a roller or brush, so the viscosity must break down.A time lag for leveling of the paint (to conceal brush strokes)is necessary, after which the viscosity must rebuild to avoiddrips and sagging. Food products also display this importantbehavior. Mayonnaise being spread on a sandwich or mixedin a salad must break down its structure to be distributed andthen rebuild to the right mouth feel so that it doesn't seepinto the bread or taste thin and runny in a salad. In figure 10,the thixotropy is shown in the difference of the up and downstress ramps for 3 hand lotions. The area between the curvesis an indication of the extent of the thixotropy. Figure 10: Thixotropy of hand lotions - Stress ramps at 25℃ The viscosity of a material according to the rate at which itis sheared, provides important information about processingand performance.This can be important in production wherestirring, dispensing and pumping of the product will subjectit to a variety of shear rates. Low shear rate behavior can berelated to storage conditions of materials: sedimentation,phase separation, and structure retention. Single pointviscosity information does not profile the material across aspectrum of shear rates.Materials that may behave the sameat one end of the flow curve may show dramatic differenceat the other, which relates to structural differences in thesematerials as shown in Figure 11 for two adhesive dispersions. Figure 11: Flow curve of 2 adhesive dispersions. The products differsignificantly at high shear rates Temperature dependence in oscillatory temperature ramp A dynamic temperature ramp study does not alwaysmean heating. In the accompanying example (Figure 12),Carrageenan was cooled at 1.5 C/min from 70 to 20℃ andheld at the lower temperature for 1 hour. The strain during thecooling period was high:10%,but during the isothermal perioda very low strain, 0.1%, was maintained to avoid disturbingthe structure being formed at that low temperature.DynamicTemperature Ramp studies can simulate production cycles,storage and use conditions or evaluate long term stabilityof, for example,cosmetic creams. Rheological testing canpredict behavior without large costly batch studies. Figure 12: Carrageenan temperature ramp is used to reproduceproduction cycles, storage or use conditions Stress relaxation experiments apply a step strain deformationto create an instantaneous strain and to monitor the stressdecay as the specimen is held over time in the sameconstrained state. The profile of stress relaxation is importantin materials that will be subjected to repetitive strain, todetermine if the stress can be dissipated with the timescale of typical use.Overloading of stress in a material cancause damage and failure in later use. The stress relaxationof human cartilage is shown in Figure 13 after the materialhas been subjected to a 1% strain at 23 ℃. Besides greases,soft solids such as caulks, bread dough, dairy products, andpharmaceutical creamshave been studied extensivelyusing stress relaxation tests. Figure 13: Stress relaxation behavior of human cartilage FLUIDS MATERIALS-APPLICATIONS Decorative and Protective Coatings Rheological tests are used widely to evaluate functionalcoatings in terms of their properties and performance.Duringmanufacturing as they are mixed and transferred, andduring application by spraying, brushing, coating, or dipping,coatings are subjected repeatedly to shear and extensionover a range of magnitudes, rates and durations. Afterapplication the coating may distort, and, inevitably, it ages.Rheological testing provides a convenient way to measureperformance- critical rheological changes occurring duringthe life cycle of decorative and protective coatings. Amongthe chief performance aspects of coatings influencedby rheology are leveling, sagging, spatter resistance, andbrushability. Leveling refers to the ability of a coating to flow laterally anddiminish differences in thickness of adjacent areas of thecoating. This is an important property affecting smoothness,gloss, color, and mechanical behavior. Leveling involveschanges in surface tension due to solvent loss or reaction andis influenced by the material’s yield stress and viscosity. Datafrom strain sweeps have proven to be an effective predictorof flow and leveling.Table 1 compares the subjective rankingof leveling behavior of six latex paint versus their complex viscosity at 25% strain. Type Number E Behavior @25% strain Enamel Good idem Fair idem Poor 284 Flat Fair-Good idem Fair idem Very Poor Table 1: Comparison of leveling behavior versus complex viscosity ofLatex paint Sagging is undesirable flow of a coating down a verticalsurface. Whether a coating will sag or not depends on itsthickness and its viscosity at low shear rates. For a coatingto resist sagging, the product of its density, the gravitationalconstant, and its thickness must not exceed its yield stress. Spatter resistance in spraying is related to the elasticity ofthe coating and depends strongly on the elongationalviscosity of the fluid. Spatter resistance can be predictedfrom measurements of the elastic modulus G'at high strains.To achieve the needed combination of low viscosity topass through small sprayer orifices and yet resist sagging,the coating must be highly pseudoplastic and have rapidviscosity recovery. Brushability is a matter of the effect of shear rate on viscosity.Newtonian fluids are difficult to brush: highly pseudoplasticcoatings brush easily. Printing Inks Two major classes of inks are those used for screen printingin the graphics arts and electronics industry, and those usedfor printing newspaper. While their compositions differ, theyshare a characteristic: rheological complexity. Screen printing is possible because inks can be madethixotropic. Initially highly viscous, these inks shear-thin rapidlyunder the high shear rates generated as they are squeezedthrough the mesh.The now low viscosity ink deposits on thesubstrate in cubical islands, matching the pattern of theopenings in the screen. When the screen is removed, the ink,no longer under shear but still at a low viscosity, begins tolevel, the islands flowing together to form a continuous film.As it flows, the ink’s viscosity rebuilds, the timing controlled byproper formulation so that the ink does not bleed beyond theintended printed boundary. Dynamic tests, including thixotropic analysis and strain,frequency, and temperature sweeps, along with transientstress ramp tests to measure yield stresses, are commonlyused to guide graphic ink development. These tests have been equally beneficial in the evaluation and development of thick film resistor, capacitor, electrode,solder, and thermoset conductor pastes applied by highspeed screen printing onto electronic circuit boards andcomponents. Newspaper inks encounter high shear rates and abruptshear rate and shear direction changes as they pass throughthe nips of the printing press. These deformations generatehigh shear, normal, and extensional stresses. Accordingly,they require a battery of tests to properly characterizethem, including steady and transient shear studies andmeasurement of normal stresses and elongational viscosity. Figure 14 shows viscosity versus shear rate and shear stressversus shear rate for three model inks(3), Yield stresses wereobtained by extrapolating the steady state shear stress tozero shear rate. Figure 14: Viscosity and shear stress vs. shear rate for three model inks.The plateau value of the stress at low rate is the yield stress(2). Soft solids Cements, protective caulks, toothpaste, peanut tbutterand processed cheese spreads are examples of materialsrheologically classified as "soft solid. These materials arecharacterized by a relatively low modulus, but they possesssolid properties due such as internal structure and a highlyelastic response, when subjected to very small deformations.They, however, exhibit a complex flow behavior if largerdeformations are applied. Soft solids frequently have a yieldstress. Processing soft solids is difficult because of their solid-likebehavior at low strains, which makes for example startupof pumps very difficult. Once flow starts, the velocity profilemay exhibit characteristics of both laminar and plug flow-particularly if a yield stress is present-as well as phenomenasuch as wall slip. Though the behavior is rheologically complex, modernrheometer, can easily measure the viscoelastic responsesof soft solids under conditions, which simulate those, usedin processing the material. The rheological measurementsprovide information to aidprocessdesign, includingcalculating pump size and pressure requirements. Rotational shear measurements provide the viscosity versus shear rateresponse of soft solids, and record transient behavior at theonset of flow or changes in flow rate. Dynamic mechanicaltesting, done at low strains, gives insight into the structureof soft solids. Controlled stress tests (creep, stress ramp) areuseful in characterizing these materials at stress levels aboveand below the yield point. Steady-shear testing and largestrain dynamic measurements can be used to predict theflow properties of these materials. Soft solids are generallyvery sensitive to both strain level and strain history. Accuratecharacterization requires sensitive stress measurement aswell as excellent strain resolution. Figure 15 shows dynamic strain sweeps for three samplesof process cheese spreads, known to differ in pumpingease. Sample A pumped without difficulty; B and C requiredconsiderably more pressure to start flowing, than did A. Also,sample C required more pressure to maintain flow than didA and B. Figure 15: Strain dependence of the storage modulus G'of processcheese spreads differing in pumping ease That sample B and C exhibit much higher elastic moduli (G')at low strain amplitudes than does sample A, indicates ahigher degree of internal structure in B and C, a more solidlikebehavior, and a consequent higher pumping pressurerequirement. Polymer Solutions Polymers dissolved in solvents are employed widely asadhesives and coatings. And, with added surfactants,polymer solutions provide the basis for paints, cosmetics,detergents, and other recovery fluids. Both steady anddynamic rheological tests can be used to evaluate thesematerials. High polymer solutions are used to enhance oilrecovery, but they lose effectiveness after extended use.This happens because of a permanent viscosity reductiondue to shear degradation of the polymer, under the highshear rates generated by the rotating bit in the well bore.The combination of a high molecular weight polymer anda surfactant can develop high viscosities by formation ofcomplexes insensitive to shear degradation. 0.5% aqueous solutions of a hydrophobically modifiedhydroxyethylcellulose as ca1function ofthe surfactantconcentration tetradecyltrimethyl-ammonium bromide(TTAB) and cetyltrimethylammonium bromide (CTAB)0). Figure 16:Zero Shear Viscosity versus CTAB and TTAB concentration for0.5% aqueous hmHEC sample at a shear rate below 1-100 1/s As surfactant is added, the viscosity of the polymer solutionincreases due to bridging of the hydrophobe clusters bysurfactant micelles. The viscosity increases with the numberof effective associating junctions. At higher surfactantconcentrations, the hydrophobes are individually solubilized,or masked by an excess of spherical micelles, resulting in adisruption of associations and a decrease on viscosity. Rheological tests are also used widely in studies of solutionsof reactive systems. Dynamic time tests are particularlysuitable for measuring the viscoelastic changes thesematerials undergo while they react and the products attainthe intended final form. Such tests provide a convenient wayto assess product applicability as well as to establish causalrelationships in problem-solving efforts. Magnetic suspensions A mixture of acicular iron oxide particles dispersed in apolymer solution forms the basis for many magnetic coatingsused to make audio,video, and digital recording media, andhard and floppy computer disks. Knowing how magnetic coatings behave at low stressesand high shear rates is important during application. Thehigh shear rate viscosity determines pumping pressures andcoating roll separating forces and torques. And the yieldstress is critical for leveling, as well as pick-out in rotagravurecoating, and thickness uniformity in spin coating. The yieldstress may also affect drying behavior and cause flowinstability. The shear modulus is a measure of the magneticforces between particles, their topology, and the extent theyare orientable by an external magnetic field. Figures 17 and 18 show stress rheometer creep data for amodel iron oxide magnetic suspension in which a silicone(3) oil was used in place of the usual volatile solvent.The data inFigure 19 were obtained at a stress of 2 Pa, and show that allof the strain during the creep portion of the test is recovered,indicating that no permanent deformation occurred, andthe sample is below its yield stress. Figure 19 shows data forthe material at higher stress levels. Magnetic suspensions A mixture of acicular iron oxide particles dispersed in apolymer solution forms the basis for many magnetic coatingsused to make audio, video, and digital recording media, andhard and floppy computer disks. Knowing how magnetic coatings behave at low stressesand high shear rates is important during application. Thehigh shear rate viscosity determines pumping pressures andcoating roll separating forces and torques. And the yieldstress is critical for leveling, as well as pick-out in rotagravurecoating, and thickness uniformity in spin coating. The yieldstress may also affect drying behavior and cause flowinstability. The shear modulus is a measure of the magneticforces between particles, their topology, and the extent theyare orientable by an external magnetic field. Figures 17 and 18 show stress rheometer creep data for amodel iron oxide magnetic suspension in which a silicone(3)oil was used in place of the usual volatile solvent.The data inFigure 19 were obtained at a stress of 2 Pa, and show that allof the strain during the creep portion of the test is recovered,indicating that no permanent deformation occurred, andthe sample is below its yield stress. Figure 19 shows data forthe material at higher stress levels. Figure 17: Creep and creep recovery for a model magneticsuspension after imposing a stress of 2 Pa, below its yield stress(3) Figure 18: Creep and creep recovery for a model magneticsuspension after imposing its yield stress (20 Pa) and a stresssubstantially higher() Figure 19: Effects of tetrameric concanavalin A on the clot rigidity (G)and contractile force of platelet-fibrin clots(4) At 20 Pa some deformation is irrecoverable, and at 50 Pa,thematerial flowed. Data from steady shear and dynamic strainsweep tests, as well as calculations using a Casson model,established a yield stress of approx.20 Pa also. Body fluids Rheological testing has been used widely to advance theunderstanding of human and animal body fluids in manyphases of medical, pharmaceutical, and personal hygienicproducts research and development. For example, steady,dynamic, and transient tests have been used to characterizeand evaluate synthetic polypeptides to study the role of someside groups in naturally occurring proteins; monitor proteinnetwork formation in biological fluids; study the aging ofthe fluid lubricant secreted by synovial membranes in joints;develop water-soluble polymers for controlled drug releasepharmaceuticals; develop synthetic body fluids for bandageand sanitary napkin evaluations; measure the erythrocyteaggregation energy index of red blood cells; establish thekinetics of blood platelet gelation; and study the mechanismof blood clotting. In an effort to unravel the molecular basis for the bindingof polymerizing fibrin strands and platelet membranes (the major constituents of a blood clot), the role of plateletmembrane glycoproteins in platelet-fibrin interactions duringclot formation was investigated(4). Figure 19 shows the measured effects of tetramericconcanavalin A (a nonglycoprotein lectin) on the clotrigidity (G') and contractile force/unit area of platelet fibrinclots.The contractile force was measured using the sensitivenormal force measuring capability of the ARES rheometer. RHEOLOGY OF FLUIDS-CASE STUDIES Solve Suspension Slurry Pumping Problems A chemical formulator using a new lot of titan dioxideslurry burned out a pump motor during a routine transferof material because the TiO, particles settled unexpectedlyovernight-hence his quality control problem could havebeen averted by rheo logically testing each batch of materialbefore use. When stored at rest, many suspensions have aninternal structure that will not disrupt until a critical yieldstress is reached. Overcoming this unexpected yield stresswas the cause or the pump burn-out.Whether or not a givensuspension will develop a yield stress can be assessed bytesting the suspensions that have been stored undisturbed.Measuring the stress growth in a startup experiment providesthe required information to avoid pump problems (Figure20). Troublesome materials will exhibit a stress overshoot, andthe maximum stress level reached has to be overcome topump the slurry. Figure 20: Stress growth experiment (rate ramp) to simulate pumpingstartup of TiO2 slurry Predict the texture of food products In today's market, low fat foods represent a huge area ofgrowth and diet conscious shoppers try to make everycalorie count. One of the biggest problems in low fat foodsis mouth-appeal. A food with less fat content has a differentrheological profile, as shown here with peanut butters (Figure21). The differences in viscosity can have negative effectson customer perception for spreading and mouth feelduring consumption. A lower G'(storage energy) can meanproblems with long term settling of the product, which willalso be a negative effect on consumer preference. Figure 21: Peanut butter frequency sweep for low and high fat content Storage stability of emulsified products Food products such as mayonnaise, and other importantemulsified products, if not properly formulated, have poorstorage stability. Gauging this using ordinary empirical shelf-life testing is time consuming and not practical. Dynamicmechanical rheological testing can provide a rapid solution.In emulsions, the underlying structure and interaction of thefluid droplets is what holds the stability of the product againstsettling or separation.The storage modulus G’ of an emulsionis a good index of the emulsion's solid-like character thatarises from the network structure. Raising temperatures oftesting can increase the effects of settling in many cases,enhancing the comparison of results. Thus, products withpoor storage stability can be weeded out before everreaching the consumer. When an emulsion separates, it losesits solid-like character, becoming more fluid. Measuring G'asa function of time at an elevated temperature provides aneasy method for judging emulsion stability (Figure 22). Figure 22:Mayonnaise emulsion stability Performance of personal products The example in Figure 23 shows a dynamic time sweep oftoothpaste at 30℃ shearing the paste specimen at twodifferent stresses.The higher stress level destroys the emulsion'sstructure, then the lower stress allows the slow rebuild of theviscosity.Time dependent experiments such as this provide Figure 23:Structure break down and buildup of an emulsion The dynamic time sweep in Figure 24 shows the behavior ofa hand lotion under minimal and high strain. The importantfeature is ability of the hand lotion to break down its structureto flow smoothly across the skin, followed by a rebuilding ofthe structure when the strain is removed.This keeps the lotionon the skin, so that it does not continue to flow, or feel greasy.The dynamic time sweep allows continued monitoring of anevent to see if the behavior is decaying or steady state. Theability of a product to achieve a steady state can be crucialto product performance. Figure 24: Hand lotion-structure break down and build up Phase Separations with temperature of polymer solutions Dilute polymer solutionsSthat have upper and lowercritical solution temperatures can form one or two phases,depending on the temperature. A similar phenomenon isfound for polymer blends.The phase transition temperature iscalled the consolute temperature.The consolute temperatureof a given mixture can be determined by first measuring thestorage (G') and loss (G") moduli of the material versustemperature, and then plotting log G' versus log G". (Figure25) This is a "modified Cole-Cole plot." The temperaturecorresponding to the point on the graph at which the data Figure 25:Consolute temperature of a polymer solution Measure Electrorheological Fluid Viscosity and StructureBuild-Up Electrorheological (ER) fluids increase in viscosity under theinfluence of an electric field. However, to understand thebehavior of these materials, measuring the viscosity is notsufficient. Figure 26 shows the effect of increasing electricfield voltage on an ER fluid. As the voltage is increased, theviscosity of the sample increases associated with consequentstructure buildup over time. Though the viscosity changesalmost instantly, the storage modulus (G), an indicator ofthe material structure, builds more slowly (Figure 27). Afterthe electric field is removed, this particular ER fluid does notreturn completely to its original state, retaining some of theelectrically induced structure. These effects, as well as theeffects of changing frequency and current, can be studiedusing the ER Materials Analysis Package. Figure 26: Effect of the voltage on the viscosity of an ER fluid Figure 27: Viscosity and Modulus in a step voltage change for an ERfluid Immersion Study A number of materials are used in conditions of immersion.The behavior profiles usually differ dramatically when testeddry and in-situ.The ability to dissipate stress and the degree offrequency dependence of a material must be monitored inthe conditions it will see in its application.The data in Figure28 show a Fibrin Gel immersed in water and its behavior overa wide frequency range. Without in-situ testing such as this,product applicability cannot be determined. Figure 28: Frequency sweep of an immersed fibrin gel Predicting the Stability of Fruit Juice Blends Soft drinkk concentratesWere 1found to be unstable,depending on how they were mixed and bottled. Too thinconcentrates showed fruit juice particles settling out, toothick concentrations were stable but hard to mix later. Theoptimum concentration, stable but not too thick to be easilymixed, could be evaluated in a frequency sweep as shown inFigure 29.The solid content of the juice blend was increaseduntil G’reached a plateau value.A pronounced plateauvalue towards low frequency stands for higher elasticity andindicates a higher degree of internal structure, which makesthe product more stable. In the unstableblend the plateauvalue at low frequency was not reached, so there was an Figure 29: Storage modulus correlates with fruit juice stability Sol-Gel transition of PVC gels A polymeric gel is a three dimensional network forming fromflexible chains though chemical or physical interactions.Thetransition from liquid state (sol) to the solid state (gel) is the sol-gel transition and the critical transition point is the gel point.The gel point can be determined rheologically, when the losstangent becomes independent of frequency as a functionof the concentration. Figure 30 shows the concentrationdependence of tan for a series of frequencies from 0.1 to100 rad/s for poly vinyl chloride in bi(2-ethylhexyl) phthalate(PVC in DOP).The gel point can be easily obtained from thecommon point in the multifrequency plot of tan 8 (at constantfrequency) versus concentration. The critical concentrationat the gel point is 12.5 g/l for this system at 40℃. Figure 30: Sol Gel transition of PVC gels Revised by A. Franck. For more:1information or to place an order, go tohttp://www.tainstruments.com/to locate your local salesoffice information. AAN AANaun,M. Private communication Fluid materials, by definition, are systems which flow when subjected to stress. How they respond to an input stress is the heart of rheological testing and may be a complex issue. There are many types of fluids: pure substances, mixtures, dispersions and solutions, falling into the categories of either simple or structured fluids. Each has its own unique behavior when subjected to stress. In general, when a material has a uniform phase, such as a solution or pure substance, it is referred to as a simple fluid. Materials which contain more than one phase, such as solid particles dispersed in a liquid, gas particles in foam or an emulsion of immiscible liquids are considered structured fluids since their rheological behavior is in general dominated by the interactions of the constituents.请关注我们微信公众账号

确定

还剩9页未读,是否继续阅读?

TA仪器为您提供《油墨、化妆品、食品中结构流体、屈服应力、粘度、触变性检测方案(流变仪)》,该方案主要用于其他中结构流体、屈服应力、粘度、触变性检测,参考标准--,《油墨、化妆品、食品中结构流体、屈服应力、粘度、触变性检测方案(流变仪)》用到的仪器有TA仪器ARES-G2 高级流变仪

推荐专场

相关方案

更多

该厂商其他方案

更多