将人参用可变速高速旋转粉碎机P14粉碎后,为测定其组分及质量特性,需用激光粒度仪A22 NanoTec测定其粒径,A22以其宽的测量范围,高分辨率和准确度,很好的对人参粉粒径进行了分析,为后续试验分析给予了准确的实验数据。

方案详情

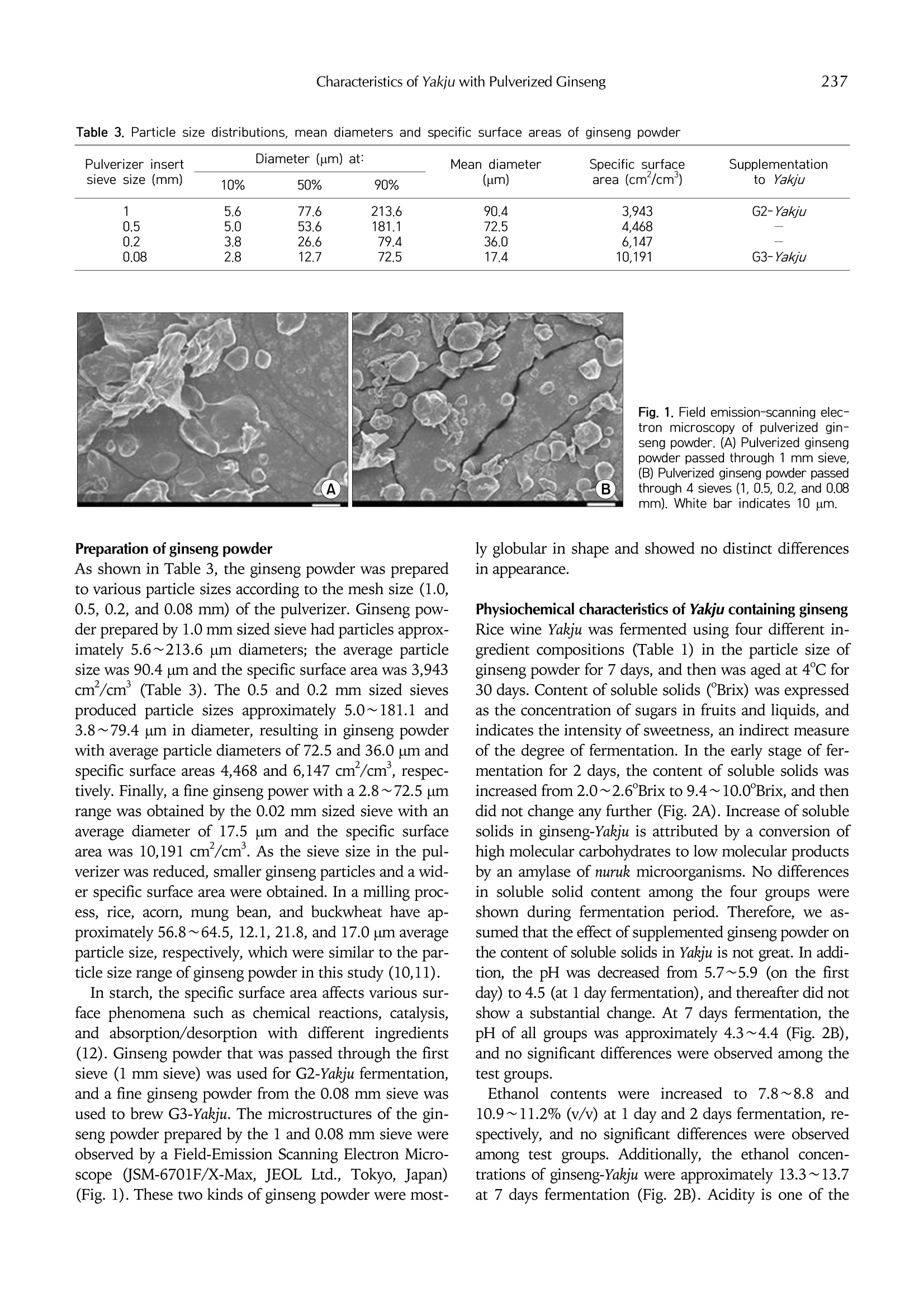

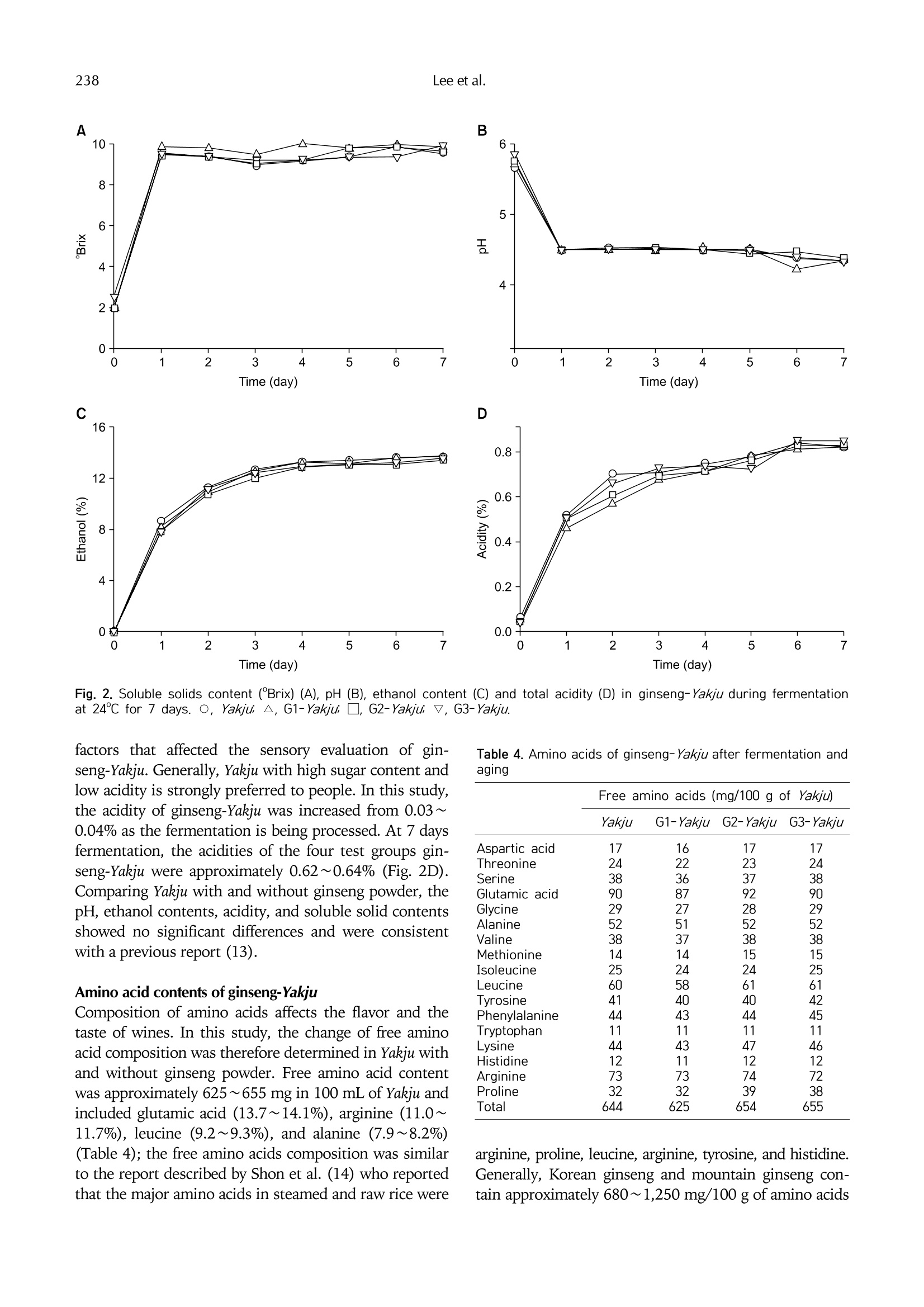

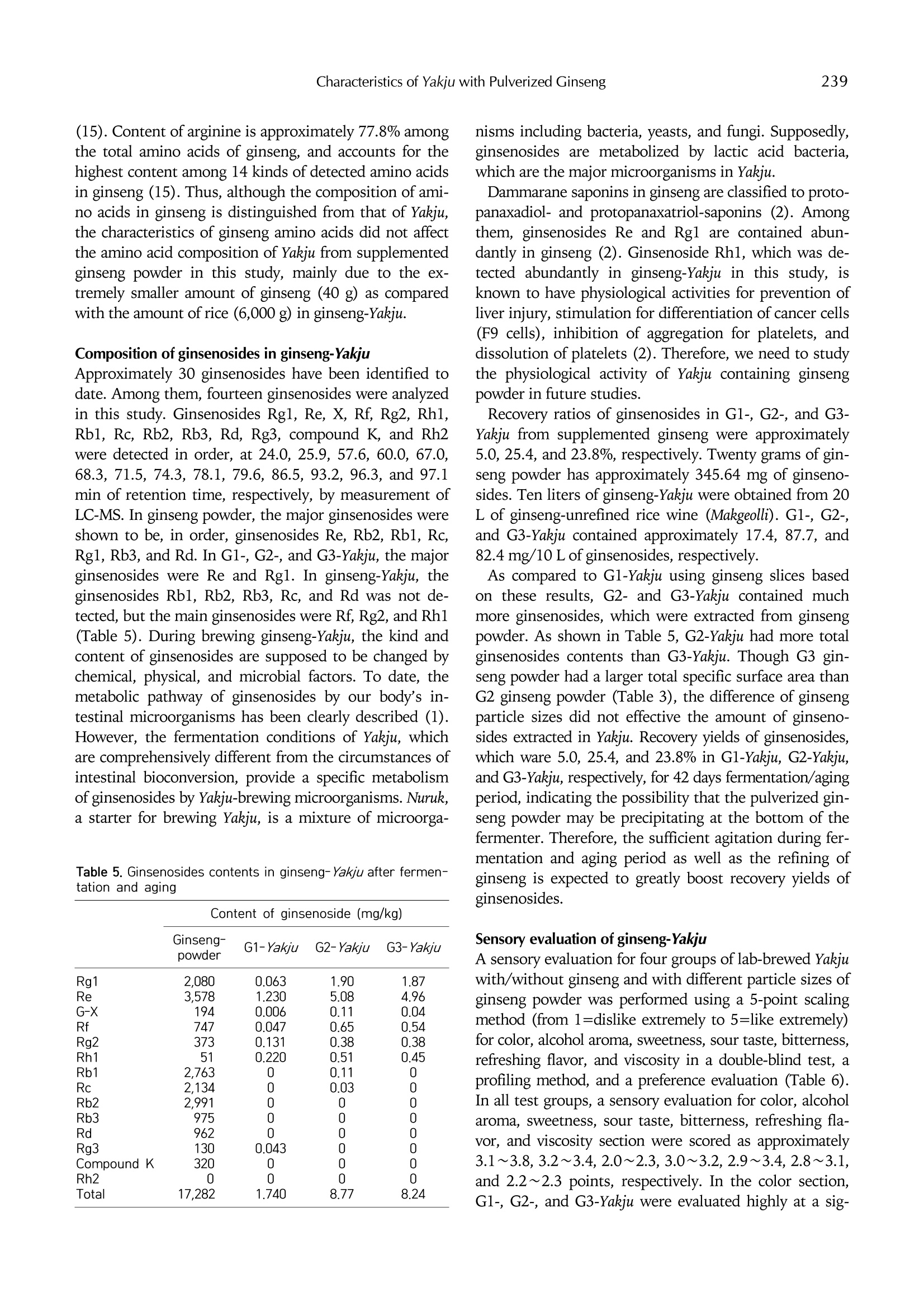

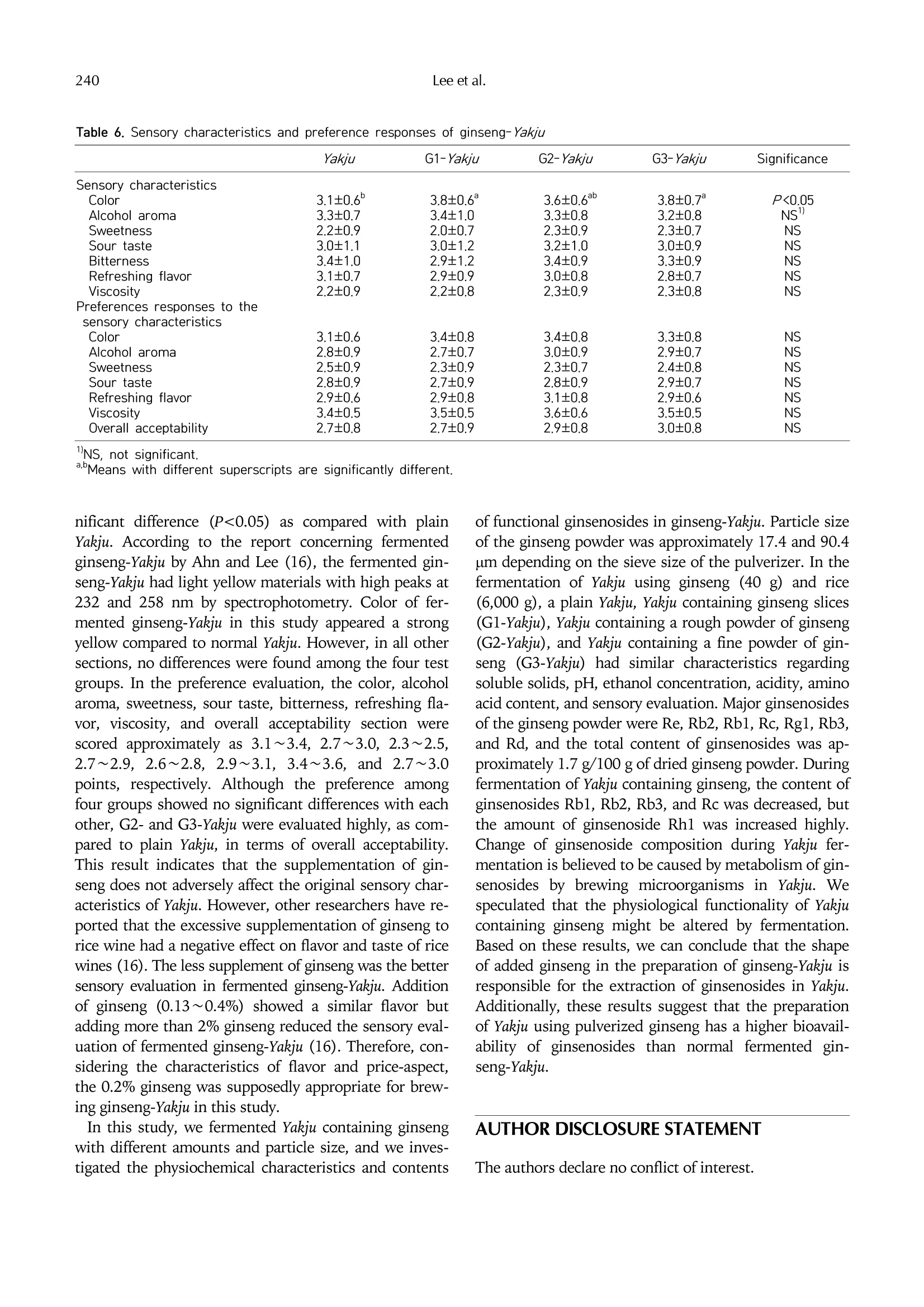

Prev. Nutr. Food Sci. 2013;18(4):234-241http://dx.doi.org/10.3746/pnf.2013.18.4.234pISSN 2287-1098·elSSN 2287-8602 Characteristics of Yakju with Pulverized Ginseng235 Quality Characteristics and Ginsenosides Composition ofGinseng-Yakju According to the Particle Size of Ginseng Powder Je-Hyuk Lee, Kang Hyun Choi,Eun-Hwa Sohn, and Ki-Hyo Jang’ 'Department of Food and Nutrition, Kongju National University, Chungnam 340-702,Korea Department of Food and Nutrition and Department of Herbal Medicine Resource, Kangwon National University, Gangwon 245-710, Korea ABSTRACT: The aim of this study was to develop rice wine (Yakju) containing various amounts and particle sizes of gin-seng powder and to analyze the physicochemical characteristics and content of ginsenosides in ginseng-Yakju. Soluble sol-id content, pH, ethanol concentration, acidity, amino acid content, and evaluation of preference showed no difference be-tween four kinds of Yakju groups, regardless of ginseng supplementation and particle size of the ginseng powder. Duringfermentation of Yakju containing ginseng, the contents of ginsenosides Rbl, Rb2, Rb3, and Rc were decreased. Other-wise, the content of ginsenoside Rhl was increased highly by brewing microorganisms in Yakju. Recovery ratios of ginse-nosides in ginseng-Yakju were approximately 25.4%(coarse ginseng power) and 23.8% (fine ginseng powder), whichwere superior to the recovery ratio of ginsenosides in Yakju containing ginseng slices (5%). Keywords: finely pulverized ginseng, ginsenoside, ginsenoside Rhl, Yakju INTRODUCTION Increased incomes and rising interest in personal healthhave led to greater consumption of health-enhancingfoods with specific physiological activities. Ginseng andred ginseng products are representative health-enhanc-ing foods, and have physiological activities for anti-fa-tigue, anti-stress, improvement of immunity, and anti-carcinogenesis (1). Ginsenosides are saponins and the ma-jor pharmaceutical ingredient in ginseng. Approximately 30different ginsenosides have been identified chemicallyand their pharmaceutical activities have been proved sci-entifically (2). The compositions and amounts of ginsenosides arechanged by processing procedures such as heating andhydrolysis. In our body, the ginsenosides are metabo-lized and modified chemically by intestinal micro-organisms (1-4). Ginsenosides Rbl, Rb2, and Re aremetabolized to ginsenosides Rd, Rgl, Rg2, Rhl, Fl, andF2 by intestinal microorganisms, including Bacteroidessp., Eubacterium sp., Fusobacterium sp., and Bifidobacteriumsp., and are converted to 20(S)-protopanaxadiol and pro-topanaxatriol (1). In addition, some intestinal lactic acidbacteria were involved in the metabolism of ginseno-sides Rbl, Rb2, Rc, and Rd to compound K through gin-senoside F2 (5). However, the individual differences for intestinal microflora cause metabolic and physiologicaldifferences of ginsenosides in the body (1,6). Therefore,the bioactive and easily uptakable ginsenosides are nec-essary to be produced in vitro before eating, and possiblycontribute to enhancing health. Yakju, one of the traditional alcohol beverages in Korea,is a refined rice wine, filtering milky Takju. Takju isbrewed by using rice and Nuruk as ingredients, whichhas a milky and turbid color due to the absence of clar-ification process after the fermentation. Starter Nurukcomes from the natural proliferation of wild micro-organisms on a starch substrate of crushed or wholewheat or barley and have been used as a starter for alco-hol fermentation (7). Nuruk contains various molds andyeasts, including mainly Aspergillus sp., Mucor sp., Rhizopussp., Saccharomyces sp., and Pichia sp. (8). As the interestsfor health-enhancing functions of Yakju increases, Yakjucontaining various fruits, berries, herbs, and medicinalplants has been developed. In this study, we investigated the physicochemicalcharacteristics of Yakju brewed using various shaped gin-seng, and we studied the change of ginsenoside compo-sitions and extraction yield in Yakju, according to theshape of added ginseng. This result is anticipated to pro-vide fundamental information concerning the shape ofadded ginseng in the preparation of ginseng-Yakju. ( Correspondence to Ki-Hyo Jang, Tel:+82-33-540-3312, E-mail: kihyojang@kangwon.ac.kr ) Copyright @ 2013 by The Korean Society of Food Science and Nutrition. All rights Reserved. ( @ This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License ( http://creativecommons.org/licenses/by-nc/3.0) which permits u nrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited. ) Fermentation materials Rice was harvested in Samcheok, Kangwon during Octo-ber 2011. Korean ginseng was purchased from an agri-cultural cooperative's joint market in August 2011 inSamcheok, Kangwon, Korea. Water for fermentation waspurchased from Dongwon F&B Co., Ltd. (Gyeonggi,Korea). Bionuruk, which is a mixture of Saccharomycescerevisiae and Nuruk microorganisms, was obtained fromKorea Enzyme Inc. (Gyeonggi, Korea) and was used forYakju fermentation as a fermentation starter. Nuruk is astarter containing a mixture of microorganisms, includingAspergillus oryzae, Aspergillus niger, and Rhizopus oryzae. Drying and measuring free water content in ginseng Ginseng was washed with water, and 0.5 cm slices ofginseng were dried with hot air in a sealed drier at 40℃for 72 h. Water content in ginseng was expressed as aweight after drying at 104℃ for 16 h. Dry matter ratiowas calculated by the following formula based on dryweight: Preparation of ginseng powder Dried ginseng slices were crushed mechanically by a pul-verizer (Variable-Speed Rotor Mill Pulverisette 14, FritschGmbH, Idar-Oberstein, Germany). Working conditionswere as follows: impact force; feed size, ~5 mm; samplequantity, 50 g; throughout, 10 g/min; sieve insert, 0.08,0.2, 0.5, and 1.0 mm; feeding, batchwise process; rotorspeed, 10,000 rpm; rotor type, 12 ribs (stainless steel).Crushed ginseng was isolated with 1.0 mm sieve insert,and coarse ginseng powders were grinded by a pulver-izer equipped with 0.5, 0.2, and 0.08 mm sieve insert.Fine ginseng powder was defined as ginseng powderpassed through size 0.08 mm sieve insert. In addition,some dried ginseng slices were not crushed and wereused for preparation of Yakju (G1-Yakju) containing sli-ces of ginseng. Size of ginseng powder was analyzed by aparticle size analyzer (Analysette-22 NanoTec, FritschGmbH). Distribution ratio of particle diameter, averageparticle diameter, and specific surface area were meas- ured in a range of 0.3~300 um particle diameter. Field emission scanning electron microscope (FE-SEM)For observation of ginseng powder by FE-SEM, ginsengpowder was coated with a gold plasma layer by ion sputtercoater for 60 s in a vacuum condition. Microstructure offine ginseng powder was observed with a FE-SEM at 5kV. Preparation of Yakju supplemented with ginseng powder Rice(600 g) was washed and prepared for steamed rice.The hard-streamed rice, 120 g of Bionurukstarter, and60 g of yeasts were mixed in a 20 L of fermentation jar,and water was added to 20 L volume for basal Yakju. Fora comparison, Yakju containing 0.2% of ginseng slices(G1-Yakju), Yakju containing 0.2% ginseng powder with1.0 mm particle size (G2-Yakju), and Yakju containing 0.2%ginseng powder with 0.08 mm particle size (G3-Yakju)were used (Table 1). Material mixture for ginseng-Yakjuwas fermented in a fermentation jar equipped with air-lock apparatus for 7 days at 24℃, and was mixed com-pletely twice a day. Samples (50 mL) were taken duringfermentation and stored at -20℃ for analysis. After aprimary fermentation, a fermented mixture (Yakju) wasstored at 4℃ for 30 days for precipitation of the lees,and 10 L of Yakju, the supernatant layer, was isolatedand used for analysis of ginsenoside and amino acidscomposition. Analysis of total sugar content, pH, and acidity Total sugar content of fermentation mixture was de-tected using 50 pL of filtered sample by a hand-held re-fractometer (model N-1o, ATAGO, Tokyo,Japan). ThepH of fermentation mixture was measured by a pH me-ter (model 725p, Istek Inc., Seoul, Korea). Total titrat-able acidity (TTA) was analyzed by a titration method.Briefly, the fermentation mixture was spun by a cen-trifuge (5819R, Eppendorf, Hamburg, Germany)at3,000 rpm and 4℃ for 10 min, and the supernatant wasfiltered with a 0.45 um syringe filter. One or two dropsof phenolphthalein was added to a filtered sample (10mL) and mixed with magnetic stirrer (model PC-420,Corning, Corning, NY, USA). NaOH (0.1N) was addedcarefully to sample until color of sample became pink.End point of titration was defined as sample keeping a Table 1. Composition of fermentation materials of ginseng-Yakju Yakju G1-Yakju G2-Yakju G3-Yakju Ginseng, sliced (g) 40 —— Ginseng, coarse powder (g) 40 — Ginseng, fine powder (g) 40 Rice (g) 6,000 6,000 6,000 6,000 Water (mL) 13,580 13,540 13,540 13,540 Bionuruk"((g) 300 300 300 300 Yeast (g) 120 120 120 120 pink color for 30 s, and TTA was calculated from 0.1 NNaOH volume (mL) consumed to the end point usingthe following equation: Total titratable acidity (TTA, %)=0.1 N NaOH (mL)×factor of N NaOHxtartaric acid coefficient×100/volume of sample (mL), where tartaric acid coefficient is 0.075. Analysis of ethanol content Fermentation sample was centrifuged at 3,000 rpm and4℃ for 10 min, and the supernatant was filtered with a0.45 um syringe filter. Ethanol content in fermentationsample was quantitated by Alcolyzer (Anton Paar GmbH,Graz, Austria). Range for a confident concentration was0~20% (v/v) and accuracy was approximately 0.1%. Analysis of amino acids For analysis of amino acid, a centrifuged sample was fil-tered with the 0.45 um syringe filter and injected intothe amino acid analyzer (L-8800, Hitachi, Tokyo, Japan)with ion exchange column (4.6 mmx60 mm). Columnoven temperature, injection volume, flow rate, and re-action coil temperature were 30℃, 20 pL, 0.35 mL/min,and 135℃, respectively. Isolated amino acids from samplepassed through the column were converted to coloredcompound by reaction with ninhydrin at high tem-peratures. Intensity of color was measured at 570 (forproline measurement) and 440 nm (for other aminoacids) by the spectrophotometer. Content of free aminoacids in sample was quantitated based on the intensityof color. Analysis of ginsenosides Ginseng powder (50 g) was added to 50 mL of methanoland extracted by ultrasonicator (JAC 2010, Jinwoo,Seoul, Korea) at 50℃ for 1 h. Methanol extract was fil-tered with a 0.45 um syringe filter, and 5 pL of filteredsample was analyzed by LC-MS (micromass ZQ de-tector, Waters, Milford, MA, USA) with a C18 column(3.5 um, 2.1×150 mm, XTerra, Waters). In addition,Yakju sample was mixed with equal volume of methanoland filtered with a 0.45 um syringe filter, and the super-natant was analyzed by HPLC. Mobile phases were cre- ated by a gradient solvent system using 18% acetonitrile(solvent A) and acetonitrile (solvent B). Gradient ratioof mobile phase was programed to hold at 100:0 (A: B,v/v) at 0~32 min, changed to 80:20 at 32~65 min,hold at 80:20 at 65~80 min, changed to 0:100 at80~98 min, and kept at 0:100 (A :B, v/v) at 98~103min at a 0.25 mL/min flow rate. Then, the gradient ratioof mobile phase was changed to 100:0 in 103~105 minand kept going to 110 min. Sensory evaluation Four different ginseng-Yakju samples (plain Yakju, G1-Yakju, G2-Yakju, and G3-Yakju) were brewed and storedfor 18 h. A 19-student sensory evaluation panel from theDepartment of Food and Nutrition were pre-educatedwith purpose of study and characteristics of quality forginseng-Yakju. SensSo0r1y evaluation was performed usinga five-point scaling method (1=dislike extremely to5=like extremely) for color, alcohol aroma, sweetness,bitterness, refreshing flavor, and viscosity of sample, ac-ceptability, and preference using double blind test. Statistical analysis All results were analyzed by one-way analysis of variance(ANOVA) statistically (9), and were expressed as themean±standard deviation. RESULTS AND DISCUSSION Drying of ginseng slices After ginseng slices were dried in a sealed dryer at 40℃for 72 h, the weight change of the slices was measured,as shown in Table 2. After 24 h of drying, the weight ofginseng slices was reduced to approximately 30.7% ofthe control, which was the weight before drying (P<0.001). Then the ginseng slices were dried slowly andhad approximately 27.4% of the control weight for 48-hdrying. In addition, the ginseng had approximately 25.8%of the control weight for 16 h-drying at 104℃ (data notshown). Generally, the process of food drying is com-posed of a settling down, a constant rate drying, and afalling rate drying period. In the case of drying ginseng,the falling rate drying period was reached within 24 h. Ina subsequent study, we used 72 h-dried ginseng slices. Table 2. Weight changes of sliced ginseng by drying process at 40℃ 0 h 12 h 24h 48 h 72 h P-value 100±0a1 57.0±4.2° 30.7±1.4 27.4±0.7 27.3±0.7° 0.001 "Percentage (%) weight values are expressed as a ratio to the weight obtained at O h. Means with different superscripts are significantly different. Table 3. Particle size distributions, mean diameters and specific surface areas of ginseng powder Pulverizer insert Diameter (um) at: Mean diameter Specific surface Supplementation sieve size (mm) 10% 50% 90% (um) area (cm/cm) to Yakju 1 5.6 77.6 213.6 90.4 3,943 G2-Yakju 0.5 5.0 53.6 181.1 72.5 4,468 0.2 3.8 26.6 79.4 36.0 6,147 0.08 2.8 12.7 72.5 17.4 10,191 G3-Yakju Preparation of ginseng powder As shown in Table 3, the ginseng powder was preparedto various particle sizes according to the mesh size (1.0,0.5, 0.2, and 0.08 mm) of the pulverizer. Ginseng pow-der prepared by 1.0 mm sized sieve had particles approx-imately 5.6~213.6 um diameters; the average particlesize was 90.4 um and the specific surface area was 3,943cm /cm’ (Table 3). The 0.5 and 0.2 mm sized sievesproduced particle sizes approximately 5.0~181.1 and3.8~79.4 um in diameter, resulting in ginseng powderwith average particle diameters of 72.5 and 36.0 um andspecific surface areas 4,468 and 6,147 cm/cm’, respec-tively. Finally, a fine ginseng power with a 2.8~72.5 umrange was obtained by the 0.02 mm sized sieve with anaverage diameter of 17.5 um and the specific surfacearea was 10,191 cm /cm. As the sieve size in the pul-verizer was reduced, smaller ginseng particles and a wid-er specific surface area were obtained. In a milling proc-ess, rice, acorn, mung bean, and buckwheat have ap-proximately 56.8~64.5, 12.1, 21.8, and 17.0 um averageparticle size, respectively, which were similar to the par-ticle size range of ginseng powder in this study (10,11). In starch, the specific surface area affects various sur-face phenomena such as chemical reactions, catalysis,and absorption/desorption with different ingredients(12). Ginseng powder that was passed through the firstsieve (1 mm sieve) was used for G2-Yakju fermentation,and a fine ginseng powder from the 0.08 mm sieve wasused to brew G3-Yakju. The microstructures of the gin-seng powder prepared by the l and 0.08 mm sieve wereobserved by a Field-Emission Scanning Electron Micro-scope (JSM-6701F/X-Max, JEOL Ltd., Tokyo, Japan)(Fig. 1). These two kinds of ginseng powder were most- ly globular in shape and showed no distinct differences1n appearance. Physiochemical characteristics of Yakju containing ginsengRice wine Yakju was fermented using four different in-gredient compositions (Table 1) in the particle size ofginseng powder for 7 days, and then was aged at 4℃ for30 days. Content of soluble solids (Brix) was expressedas the concentration of sugars in fruits and liquids, andindicates the intensity of sweetness, an indirect measureof the degree of fermentation. In the early stage of fer-mentation for 2 days, the content of soluble solids wasincreased from 2.0~2.6°Brix to 9.4~10.0°Brix, and thendid not change any further (Fig. 2A). Increase of solublesolids in ginseng-Yakju is attributed by a conversion ofhigh molecular carbohydrates to low molecular productsby an amylase of nuruk microorganisms. No differencesin soluble solid content among the four groups wereshown during fermentation period. Therefore, we as-sumed that the effect of supplemented ginseng powder onthe content of soluble solids in Yakju is not great. In addi-tion, the pH was decreased from 5.7~5.9 (on the firstday) to 4.5 (at 1 day fermentation), and thereafter did notshow a substantial change. At 7 days fermentation, thepH of all groups was approximately 4.3~4.4 (Fig.2B),and no significant differences were observed among thetest groups. Ethanol contents were increased to 7.8~8.8and10.9~11.2% (v/v) at 1 day and 2 days fermentation, re-spectively, and no significant differences were observedamong test groups. Additionally, the ethanol concen-trations of ginseng-Yakju were approximately 13.3~13.7at 7 days fermentation (Fig. 2B). Acidity is one of the Fig. 2. Soluble solids content (Brix) (A), pH (B), ethanol content (C) and total acidity (D) in ginseng-Yakju during fermentationat 24℃ for 7 days. O, Yakju A, G1-Yakju, G2-Yakju. V, G3-Yakju. factors that affected the sensory evaluation of gin-seng-Yakju. Generally, Yakju with high sugar content andlow acidity is strongly preferred to people. In this study,the acidity of ginseng-Yakju was increased from 0.03~0.04% as the fermentation is being processed. At 7 daysfermentation, the acidities of the four test groups gin-seng-Yakju were approximately 0.62~0.64% (Fig. 2D).Comparing Yakju with and without ginseng powder, thepH, ethanol contents, acidity, and soluble solid contentsshowed no significant differences and were consistentwith a previous report (13). Amino acid contents of ginseng-Yakju Composition of amino acids affects the flavor and thetaste of wines. In this study, the change of free aminoacid composition was therefore determined in Yakju withand without ginseng powder. Free amino acid contentwas approximately 625~655 mg in 100 mL of Yakju andincluded glutamic acid (13.7~14.1%), arginine (11.0~11.7%), leucine (9.2~9.3%), and alanine (7.9~8.2%)(Table 4); the free amino acids composition was similarto the report described by Shon et al. (14) who reportedthat the major amino acids in steamed and raw rice were Table 4. Amino acids of ginseng-Yakju after fermentation andaging Yakju G1-Yakju G2-Yakju /( G3-Yakju Aspartic acid 17 16 17 17 Threonine 24 22 23 24 Serine 38 36 37 38 Glutamic acid 90 87 92 90 Glycine 29 27 28 29 Alanine 52 51 52 52 Valine 38 37 38 38 Methionine 14 14 15 15 Isoleucine 25 24 24 25 Leucine 60 58 61 61 Tyrosine 41 40 40 42 Phenylalanine 44 43 44 45 Tryptophan 11 11 11 11 Lysine 44 43 47 46 Histidine 12 11 12 12 Arginine 73 73 74 72 Proline 32 32 39 38 Total 644 625 654 655 arginine, proline, leucine, arginine, tyrosine, and histidine.Generally, Korean ginseng and mountain ginseng con-tain approximately 680~1,250 mg/100 g of amino acids (15). Content of arginine is approximately 77.8% amongthe total amino acids of ginseng, and accounts for thehighest content among 14 kinds of detected amino acidsin ginseng (15). Thus, although the composition of ami-no acids in ginseng is distinguished from that of Yakju,the characteristics of ginseng amino acids did not affectthe amino acid composition of Yakju from supplementedginseng powder in this study, mainly due to the ex-tremely smaller amount of ginseng (40 g) as comparedwith the amount of rice (6,000 g) in ginseng-Yakju. Composition of ginsenosides in ginseng-Yakju Approximately 30 ginsenosides have been identified todate. Among them, fourteen ginsenosides were analyzedin this study. Ginsenosides Rgl, Re, X, Rf, Rg2, Rhl,Rb1, Rc, Rb2, Rb3, Rd, Rg3, compound K, and Rh2were detected in order, at 24.0, 25.9,57.6,60.0,67.0,68.3, 71.5,74.3,78.1,79.6,86.5,93.2, 96.3, and 97.1min of retention time, respectively, by measurement ofLC-MS. In ginseng powder, the major ginsenosides wereshown to be, in order, ginsenosides Re, Rb2, Rb1, Rc,Rg1, Rb3, and Rd. In G1-, G2-, and G3-Yakju, the majorginsenosides were Re and Rg1. In ginseng-Yakju, theginsenosides Rbl, Rb2, Rb3, Rc, and Rd was not de-tected, but the main ginsenosides were Rf,Rg2, and Rh1(Table 5). During brewing ginseng-Yakju, the kind andcontent of ginsenosides are supposed to be changed bychemical, physical, and microbial factors. To date, themetabolic pathway of ginsenosides by our body’s in-testinal microorganisms has been clearly described (1).However, the fermentation conditions of Yakju, whichare comprehensively different from the circumstances ofintestinal bioconversion, provide a specific metabolismof ginsenosides by Yakju-brewing microorganisms. Nuruk,a starter for brewing Yakju, is a mixture of microorga- Table 5. Ginsenosides contents in ginseng-Yakju after fermen-tation and aging Ginseng- powder G1-Yakju G2-Yakju G3-Yakju 2,080 0.063 1.90 1.87 3,578 1.230 5.08 4.96 194 0.006 0.11 0.04 747 0.047 0.65 0.54 373 0.131 0.38 0.38 51 0.220 0.51 0.45 2,763 0.11 2,134 0.03 2,991 975 962 130 320 0.043 17,282 1.740 8.77 8.24 nisms including bacteria, yeasts, and fungi. Supposedly,ginsenosides are metabolized by lactic acid bacteria,which are the major microorganisms in Yakju. Dammarane saponins in ginseng are classified to proto-panaxadiol- and protopanaxatriol-saponins (2). Amongthem, ginsenosides Re and Rgl are contained abun-dantly in ginseng (2). Ginsenoside Rhl, which was de-tected abundantly in ginseng-Yakju in this study, isknown to have physiological activities for prevention ofliver injury, stimulation for differentiation of cancer cells(F9 cells), inhibition of aggregation for platelets, anddissolution of platelets (2). Therefore, we need to studythe physiological activity of Yakju containing ginsengpowder in future studies. Recovery ratios of ginsenosides in G1-, G2-, and G3-Yakju from supplemented ginseng were approximately5.0, 25.4, and 23.8%, respectively. Twenty grams of gin-seng powder has approximately 345.64 mg of ginseno-sides. Ten liters of ginseng-Yakju were obtained from 20L of ginseng-unrefined rice wine (Makgeolli). G1-, G2-,and G3-Yakju contained approximately 17.4, 87.7, and82.4 mg/10 L of ginsenosides, respectively. As compared to Gl-Yakju using ginseng slices basedon these results, G2- and G3-Yakju contained muchmore ginsenosides, which were extracted from ginsengpowder. As shown in Table 5, G2-Yakju had more totalginsenosides contents than G3-Yakju. Though G3 gin-seng powder had a larger total specific surface area thanG2 ginseng powder (Table 3), the difference of ginsengparticle sizes did not effective the amount of ginseno-sides extracted in Yakju. Recovery yields of ginsenosides,which ware 5.0, 25.4, and 23.8% in G1-Yakju, G2-Yakju,and G3-Yakju, respectively, for 42 days fermentation/agingperiod, indicating the possibility that the pulverized gin-seng powder may be precipitating at the bottom of thefermenter. Therefore, the sufficient agitation during fer-mentation and aging period as well as the refining ofginseng is expected to greatly boost recovery yields ofginsenosides. Sensory evaluation of ginseng-Yakju A sensory evaluation for four groups of lab-brewed Yakjuwith/without ginseng and with different particle sizes ofginseng powder was performed using a 5-point scalingmethod (from 1=dislike extremely to 5=like extremely)for color, alcohol aroma, sweetness, sour taste, bitterness,refreshing flavor, and viscosity in a double-blind test, aprofiling method, and a preference evaluation (Table 6).In all test groups, a sensory evaluation for color, alcoholaroma, sweetness, sour taste, bitterness, refreshing fla-vor, and viscosity section were scored as approximately3.1~3.8,3.2~3.4,2.0~2.3,3.0~3.2,2.9~3.4,2.8~3.1,and 2.2~2.3 points, respectively. In the color section,G1-, G2-, and G3-Yakju were evaluated highly at a sig- Table 6. Sensory characteristics and preference responses of ginseng-Yakju Yakju G1-Yakju G2-Yakju G3- Yakju Significance Sensory characteristics Color 3.1±0.6° 3.8±0.6° 3.6±0.6 3.8±0.7° P<0.05 Alcohol aroma 3.3±0.7 3.4±1.0 3.3±0.8 3.2±0.8 Ns" Sweetness 2.2±0.9 2.0±0.7 2.3±0.9 2.3±0.7 NS Sour taste 3.0±1.1 3.0±1.2 3.2±1.0 3.0±0.9 NS Bitterness 3.4±1.0 2.9±1.2 3.4±0.9 3.3±0.9 NS Refreshing flavor 3.1±0.7 2.9±0.9 3.0±0.8 2.8±0.7 NS Viscosity 2.2±0.9 2.2±0.8 2.3±0.9 2.3±0.8 NS Preferences responses to the sensory characteristics Color 3.1±0.6 3.4±0.8 3.4±0.8 3.3±0.8 NS Alcohol aroma 2.8±0.9 2.7±0.7 3.0±0.9 2.9±0.7 NS Sweetness 2.5±0.9 2.3±0.9 2.3±0.7 2.4±0.8 NS Sour taste 2.8±0.9 2.7±0.9 2.8±0.9 2.9±0.7 NS Refreshing flavor 2.9±0.6 2.9±0.8 3.1±0.8 2.9±0.6 NS Viscosity 3.4±0.5 3.5±0.5 3.6±0.6 3.5±0.5 NS Overall acceptability 2.7±0.8 2.7±0.9 2.9±0.8 3.0±0.8 NS NS, not significant. nificant difference (P<0.05) as compared with plainYakju. According to the report concerning fermentedginseng-Yakju by Ahn and Lee (16), the fermented gin-seng-Yakju had light yellow materials with high peaks at232 and 258 nm by spectrophotometry. Color of fer-mented ginseng-Yakju in this study appeared a strongyellow compared to normal Yakju. However, in all othersections, no differences were found among the four testgroups. In the preference evaluation, the color, alcoholaroma, sweetness, sour taste, bitterness, refreshing fla-vor, viscosity, and overall acceptability section werescored approximately as 3.1~3.4,2.7~3.0,2.3~2.5,2.7~2.9,2.6~2.8,2.9~3.1,3.4~3.6, and 2.7~3.0points, respectively. Although the preference amongfour groups showed no significant differences with eachother, G2-and G3-Yakju were evaluated highly, as com-pared to plain Yakju, in terms of overall acceptability.This result indicates that the supplementation of gin-seng does not adversely affect the original sensory char-acteristics of Yakju. However, other researchers have re-ported that the excessive supplementation of ginseng torice wine had a negative effect on flavor and taste of ricewines (16). The less supplement of ginseng was the bettersensory evaluation in fermented ginseng-Yakju. Additionof ginseng (0.13~0.4%) showed a similar flavor butadding more than 2% ginseng reduced the sensory eval-uation of fermented ginseng-Yakju (16). Therefore, con-sidering the characteristics of flavor and price-aspect,the 0.2% ginseng was supposedly appropriate for brew-ing ginseng-Yakju in this study. In this study, we fermented Yakju containing ginsengwith different amounts and particle size, and we inves-tigated the physiochemical characteristics and contents of functional ginsenosides in ginseng-Yakju. Particle sizeof the ginseng powder was approximately 17.4 and 90.4um depending on the sieve size of the pulverizer. In thefermentation of Yakju using ginseng (40 g) and rice(6,000 g), a plain Yakju, Yakju containing ginseng slices(Gl-Yakju), Yakju containing a rough powder of ginseng(G2-Yakju), and Yakju containing a fine powder of gin-seng (G3-Yakju) had similar characteristics regardingsoluble solids, pH, ethanol concentration, acidity, aminoacid content, and sensory evaluation.Major ginsenosidesof the ginseng powder were Re, Rb2, Rb1, Rc, Rgl, Rb3,and Rd, and the total content of ginsenosides was ap-proximately 1.7 g/100 g of dried ginseng powder. Duringfermentation of Yakju containing ginseng, the content ofginsenosides Rbl, Rb2, Rb3, and Rc was decreased, butthe amount of ginsenoside Rhl was increased highly.Change of ginsenoside composition during Yakju fer-mentation is believed to be caused by metabolism of gin-senosides by brewing microorganisms in Yakju. Wespeculated that the physiological functionality of Yakjucontaining ginseng might be altered by fermentation.Based on these results, we can conclude that the shapeof added ginseng in the preparation of ginseng-Yakju isresponsible for the extraction of ginsenosides in Yakju.Additionally, these results suggest that the preparationof Yakju using pulverized ginseng has a higher bioavail-ability of ginsenosides than normal fermented gin-seng-Yakju. AUTHOR DISCLOSURE STATEMENT The authors declare no conflict of interest. REFERENCES 1. Kim DH. 2009. Metabolism of ginsenosides to bioactivecompounds by intestinal microflora and its industrial appli-cation. J Ginseng Res 33:165-176. 2. Park CK, Jeon BS, YangJW. 2003. The chemical componentsof Korean ginseng. Food Industry and Nutrition 8: 10-23. 3. Lee DH, Kang HY, Lee YS, Cho CH, Kim SJ. 2011. Effect ofmicrowave treated-wild ginseng on the quality of Koreantraditional Yakju. Korean J Food Sci Technol 43:742-746. Yang SJ, Woo KS, YooJS, Kang TS, Noh YH, Lee JS, Jeong HS.2006. Change of Korean ginseng components with hightemperature and pressure treatment. Korean J Food Sci Technol38:521-525. 5. Bae EA, Kim NY, Han MJ, Choo MK, Kim DH.2003.Transformation of ginsenosides to compound K(IH-901) bylactic acid bacteria of human intestine. J Microbiol Biotechnol13:9-14. 6. Wakabayashi C, Hasegawa H, Murata J, Saiki I. 1997. In vivoantimetastatic action of ginseng protopanaxadiol saponins isbased on their intestinal bacterial metabolites after oraladministration. Oncol Res 9: 411-417. 7. LeeJH, Choi KH, Jang KH. 2013. Evaluation of silicon intakethrough consumption of Takju, Soju, and wine. Food SciBiotechnol 22:249-255. 8. Kim HR, Kim JH, Bae DH, Ahn BH. 2010. Characterization of Yakju brewed from glutinous rice and wild-type yeaststrains isolated from Nuruks. J Microbiol Biotechnol 20: 1702-1710. 9. Albright SC, Winston WL, Zappe C. 1999. Data analysis anddecision making with microsoft excel. Brooks/Cole PublishingCo., Pacific Grove, CA, USA. p 945-999. 10. Cho SA, Kim SK. 2000. Particle size distribution, pastingpattern and texture of gel of acorn, mungbean and buck-wheat starches. Korean J Food Sci Technol 32: 1291-1297. l1. Yoon MR, Chun AR, Oh SK, Ko SH, Kim DJ, Hong HC, ChoiIS, Lee JH. 2011. Physicochemical properties of endospermstarch and bread making quality of rice cultivars. Korean ICrop Sci 56: 219-225. 12. Han MR, Chang MG, Kim MH. 2007. Investigation ofphysical property change in modified rice starch by ultra finepulverization. J Korean Soc Appl Biol Chem 50: 160-166. 13. Yoon YJ, Kim NY, Rhee YK, Han MJ. 2007. Quality charac-teristics and biological activities of traditionally fermentedginseng wine. Food Sci Biotechnol 16: 198-204. 14. Shon SK, Rho YH, Kim HJ, Bae MS. 1990. Takju brewing ofuncooked rice starch using Rhizopus koji. Korean J ApplMicrobiol Biotech 18: 506-510. 15. Lee HJ, Yoo BS, Byun SY.2000. Differences in free aminoacids between Korean ginsengs and mountain ginsengs.Korean J Biotechnol Bioeng 15:323-328. 16. Ann YG, Lee SK. 1996. Studies on the ginseng wine. KoreanI Food 8 Nutr 9: 151-159.

确定

还剩6页未读,是否继续阅读?

北京飞驰科学仪器有限公司为您提供《人参粉粒度中皂苷类化合物组成及质量特性检测方案(激光粒度仪)》,该方案主要用于其他食品中皂苷类化合物组成及质量特性检测,参考标准--,《人参粉粒度中皂苷类化合物组成及质量特性检测方案(激光粒度仪)》用到的仪器有德国FRITSCH(飞驰)A22大量程纳米激光粒度仪、德国FRITSCH P4 可变速率比行星式球磨机/仪

推荐专场

相关方案

更多

该厂商其他方案

更多