1.可信赖性 Reliable

2.高性能 High Performance

3.安全性 Safety

4.为客户着想的理念 For Customer Benefit

方案详情

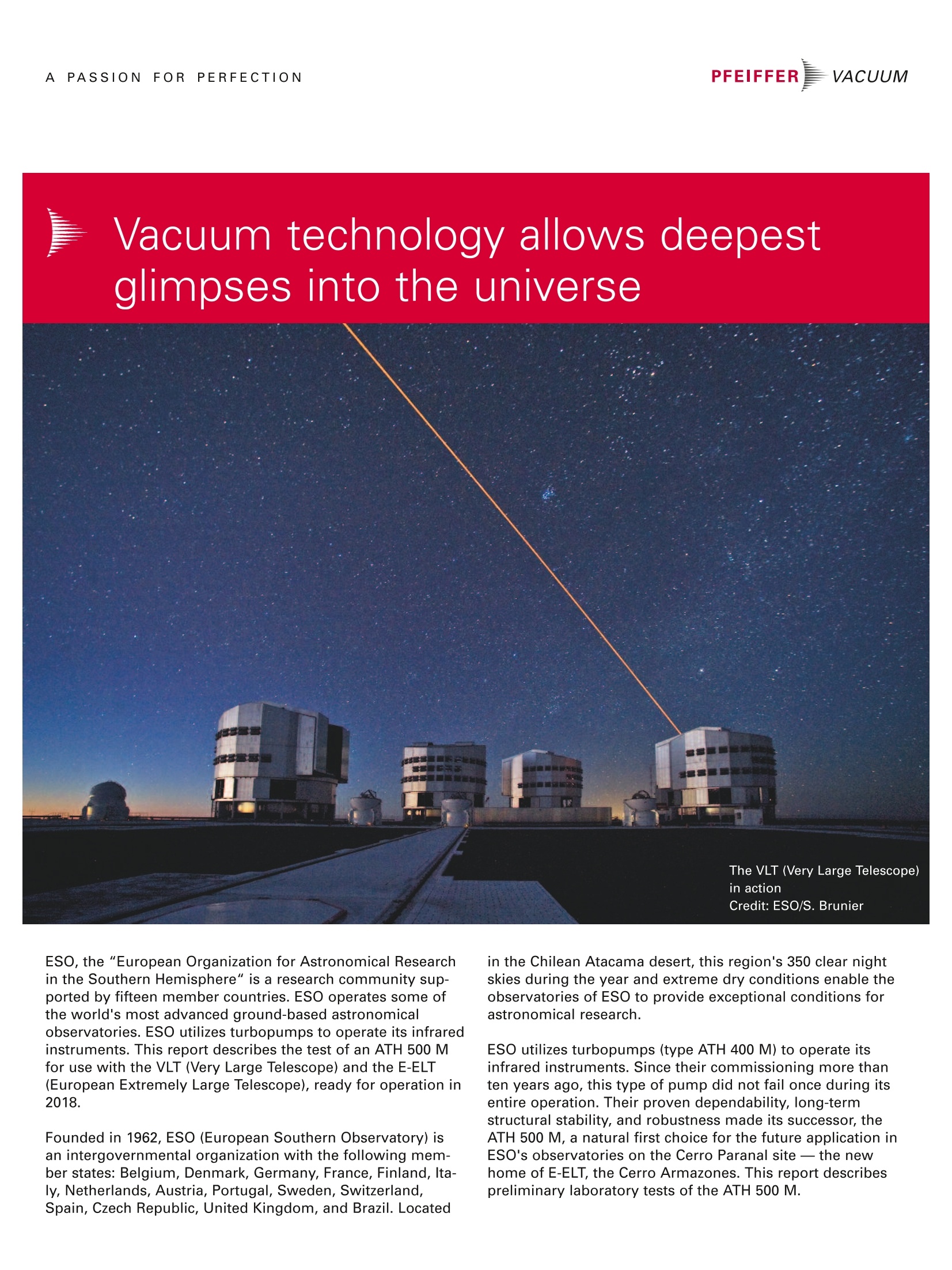

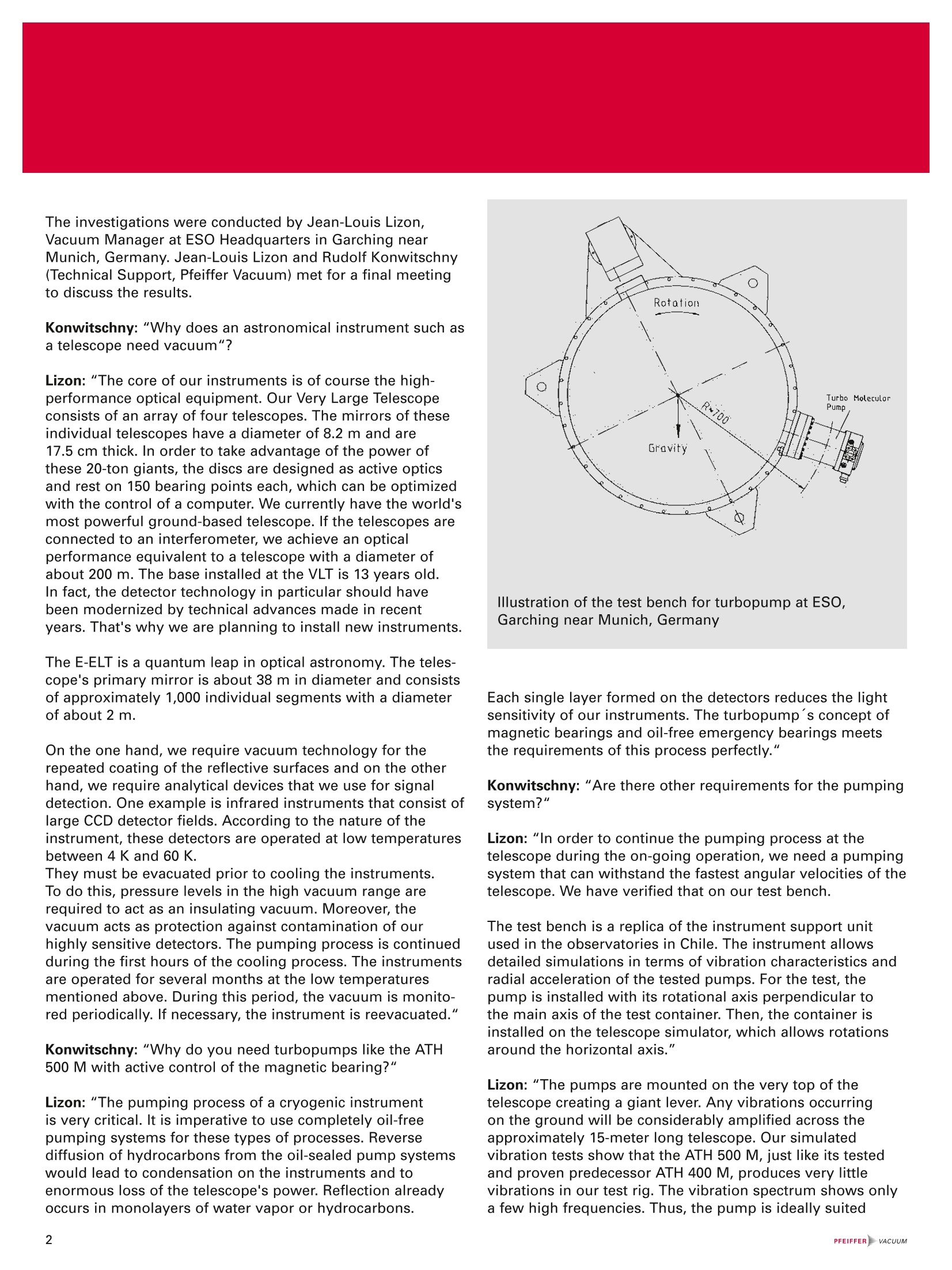

PFEIFFERVACUUMA PASSIONFOR PERFECTION Vacuum technology allows deepest ESO, the"European Organization for Astronomical Researchin the Southern Hemisphere" is a research community sup-ported by fifteen member countries. ESO operates some ofthe world's most advanced ground-based astronomicalobservatories. ESO utilizes turbopumps to operate its infraredinstruments. This report describes the test of an ATH 500 Mfor use with the VLT (Very Large Telescope) and the E-ELT(European Extremely Large Telescope), ready for operation in2018. Founded in 1962, ESO (European Southern Observatory) isan intergovernmental organization with the following mem-ber states: Belgium, Denmark, Germany, France, Finland, Ita-ly, Netherlands, Austria, Portugal, Sweden, Switzerland,Spain, Czech Republic, United Kingdom, and Brazil. Located in the Chilean Atacama desert, this region's 350 clear nightskies during the year and extreme dry conditions enable theobservatories of ESO to provide exceptional conditions forastronomical research. ESO utilizes turbopumps (type ATH 400 M) to operate itsinfrared instruments. Since their commissioning more thanten years ago, this type of pump did not fail once during itsentire operation. Their proven dependability, long-termstructural stability, and robustness made its successor, theATH 500 M, a natural first choice for the future application inESO's observatories on the Cerro Paranal site一 the newhome of E-ELT, the Cerro Armazones. This report describespreliminary laboratory tests of the ATH 500 M. The investigations were conducted by Jean-Louis Lizon,Vacuum Manager at ESO Headquarters in Garching nearMunich, Germany. Jean-Louis Lizon and Rudolf Konwitschny(Technical Support, Pfeiffer Vacuum) met for a final meetingto discuss the results. Konwitschny:“Why does an astronomical instrument such asa telescope need vacuum"? Lizon:“The core of our instruments is of course the high-performance optical equipment. Our Very Large Telescopeconsists of an array of four telescopes. The mirrors of theseindividual telescopes have a diameter of 8.2 m and are17.5 cm thick. In order to take advantage of the power ofthese 20-ton giants, the discs are designed as active opticsand rest on 150 bearing points each, which can be optimizedwith the control of a computer. We currently have the world'smost powerful ground-based telescope. If the telescopes areconnected to an interferometer, we achieve an opticalperformance equivalent to a telescope with a diameter ofabout 200 m. The base installed at the VLT is 13 years old.In fact, the detector technology in particular should havebeen modernized by technical advances made in recentyears. That's why we are planning to install new instruments. The E-ELT is a quantum leap in optical astronomy. The teles-cope's primary mirror is about 38 m in diameter and consistsof approximately 1,000 individual segments with a diameterof about 2 m. On the one hand, we require vacuum technology for therepeated coating of the reflective surfaces and on the otherhand, we require analytical devices that we use for signaldetection. One example is infrared instruments that consist oflarge CCD detector fields. According to the nature of theinstrument, these detectors are operated at low temperaturesbetween 4 K and 60 K. They must be evacuated prior to cooling the instruments.To do this, pressure levels in the high vacuum range arerequired to act as an insulating vacuum. Moreover, thevacuum acts as protection against contamination of ourhighly sensitive detectors. The pumping process is continuedduring the first hours of the cooling process. The instrumentsare operated for several months at the low temperaturesmentioned above. During this period, the vacuum is monito-red periodically. If necessary, the instrument is reevacuated." Konwitschny:“Why do you need turbopumps like the ATH500 M with active control of the magnetic bearing?" Lizon:"The pumping process of a cryogenic instrumentis very critical. It is imperative to use completely oil-freepumping systems for these types of processes.Reversediffusion of hydrocarbons from the oil-sealed pump systemswould lead to condensation on the instruments and toenormous loss of the telescope's power. Reflection alreadyoccurs in monolayers of water vapor or hydrocarbons. Illustration of the test bench for turbopump at ESO,Garching near Munich, Germany Each single layer formed on the detectors reduces the lightsensitivity of our instruments. The turbopump's concept ofmagnetic bearings and oil-free emergency bearings meetsthe requirements of this process perfectly." Konwitschny:"Are there other requirements for the pumpingsystem?" Lizon: "In order to continue the pumping process at thetelescope during the on-going operation, we need a pumpingsystem that can withstand the fastest angular velocities of thetelescope. We have verified that on our test bench. The test bench is a replica of the instrument support unitused in the observatories in Chile. The instrument allowsdetailed simulations in terms of vibration characteristics andradial acceleration of the tested pumps. For the test, thepump is installed with its rotational axis perpendicular tothe main axis of the test container. Then, the container isinstalled on the telescope simulator, which allows rotationsaround the horizontal axis." Lizon: "The pumps are mounted on the very top of thetelescope creating a giant lever. Any vibrations occurringon the ground will be considerably amplified across theapproximately 15-meter long telescope. Our simulatedvibration tests show that the ATH 500 M, just like its testedand proven predecessor ATH 400 M, produces very littlevibrations in our test rig. The vibration spectrum shows onlya few high frequencies. Thus, the pump is ideally suited for our application. The natural frequency of our instrumentsis 14 hertz, and we can control the auxiliary mirror bycontrolling the accelerometers on the main mirrors. Ininterferometric applications, a so-called"delay line"compensates for all vibrations. Vibrations of vacuum pumpsno longer present a problem for us. Oil pressure pumps forthe bearings of the telescopes are much more critical. What we also like about the pump is its operational stabilityand reliability. To understand this, you must consider ouroperating conditions. We sit on a 2635-meter high mountainin the Atacama Desert, 130 km from the nearest city ofAntofagasta. In addition, several times during the year, weexperience earthquakes, and magnitudes of more than 5.4 onthe Richter scale are not uncommon. We were largely sparedfrom the big quake further south in Chile in February 2010;however, as a consequence of the aftershocks we had tofine-tune our optical equipment again." Konwitschny:"Previously,you mentioned tests on movingtelescope support beams. What experience have you gainedwith regard to these conditions?" Lizon:"These tests were conducted with different angularvelocities, ranging between 0.1 deg/min and 5 deg/sec.Typically, we move our telescopes very slowly if we follow anobject that we are currently interested in. We only switch tohigh speeds when we skip from one object to another. Themaximum angular acceleration tested so far was 1 deg/s2.This corresponds to about twice the speed reached inpractice. We repeated these tests ten times applying themost difficult parameters. The pump has coped with this ordeal without an adverse incident. Simply put, what we want from each component of ourtelescopes is optimal temperature stability. Any temperaturegradient produces a minute amount of convection, whichmay of course interfere with our optical observation.Therefore, we use only components in our applicationsthat meet our specification of a temperature stability of+1℃ to -3℃. We achieve this perfectly with water-cooledpumps. Once, an accidental water leakage caused a two-weekplant shutdown. That's why we prefer convectional coolingwhenever possible. When using this type of cooling, theelectronics in particular stay a bit warmer. However, weare responsible for the connection of the cooling watersupply. Basically, when compared to the previous version,the compact design of the ATH 500 M helps us with itsintegrated electronics and low surface temperatures." Konwitschny:"Mr. Lizon, thank you for this interview." The ATH 500 M is a turbopump with active control of themagnetic bearing that acts upon five axes in the inertialaxis of the pump. Authors: Jean-Louis Lizon a L'AllemandHead of the Integration andCryogenic GroupEuropean Southern Observatory Garching near Munich Leading.Dependable. Customer Friendly. Pfeiffer Vacuum stands for innovative and customvacuum solutions worldwide, for German engineering art,competent advice and reliable service. Ever since the invention of the turbopump, we havebeen setting standards in our industry and this claimto leadership will continue to drive us in the future. Are you looking for aperfect vacuum solution? Please contact us: FEIFFERVACuuM

确定

还剩2页未读,是否继续阅读?

普发真空技术(上海)有限公司为您提供《空气中其他检测方案 》,该方案主要用于空气中其他检测,参考标准--,《空气中其他检测方案 》用到的仪器有普发真空 HiPace® 300 H 涡轮分子泵

推荐专场

相关方案

更多