In Formula 1 racing, there is a strong motive for reducing component weight and thereby

improving efficiency. This paper demonstrates the advantages Additive Manufacturing brings

to the production of hydraulic components. The Direct Metal Laser Sintering (DMLS)

production technique enables weight reductions to be attained by its geometric design

freedom coupled with this material’s attributes. The use of EOS Titanium Ti64 material for

hydraulic components has been assessed by a hydraulic soak test at 25 MPa and no

significant losses or failure occurred. The benefits to the efficiency of hydraulic flow have

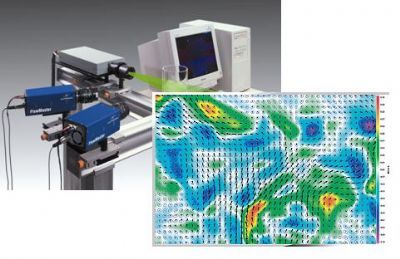

been measured using Particle Image Velocimetry (PIV) and the use of DMLS manufactured

geometry has improved flow characteristics by 250% over that of the currently used

techniques of manufacturing channels and bores.

方案详情

确定

该文件无法预览

北京欧兰科技发展有限公司为您提供《添加材料中利用添加材料制造技术改善产品性能检测方案(粒子图像测速)》,该方案主要用于其他饮料中食品添加剂检测,参考标准--,《添加材料中利用添加材料制造技术改善产品性能检测方案(粒子图像测速)》用到的仪器有德国LaVision PIV/PLIF粒子成像测速场仪、时间分辨粒子成像测速系统(TR-PIV)

推荐专场