钢铁等金属样品中碳、硫元素检测方案(红外碳硫仪)

钢铁材料中的碳、硫是确定钢铁产品规格和质量的重要元素,钢中含碳量增加,屈服点和抗拉强度升高,但塑性和冲击性降低,当碳量0.23%超过时,钢的焊接性能变坏。此外,碳能增加钢的冷脆性和时效敏感性。 典型的例子是低碳钢、高碳钢、高碳钢力学性能变化。

硫在通常情况下也是有害元素。使钢产生热脆性,降低钢的延展性和韧性,在锻造和轧制时造成裂纹。硫对焊接性能也不利,降低耐腐蚀性。所以通常要求硫含量小于0.055%,优质钢要求小于0.040%。在钢中加入0.08-0.20%的硫,可以改善切削加工性,通常称易切削钢。

那么针对于钢铁中的碳、硫元素我们应该通过怎样的方法来检测呢?在GB_T20123-2006规定了高频燃烧红外吸收法为标准方法,那这个方法是如何实现的呢?

检测样品:

粗钢

检测项:

含量分析

艾力蒙塔贸易(上海)有限公司

查看联系电话

前往展位

铁素体不锈钢晶粒中细化及耐腐蚀性研究检测方案(电化学工作站)

本文介绍了在工业纯铁和0Cr17铁素体不锈钢中加入不同含量的强碳氮化合

物形成元素钛,并加入适量的硅、锰、铝,利用钛与C、N原子的强烈亲和作用,来固定C、N等间隙原子,生产含钛铁素体不锈钢。包括试验钢的化学成分设计,冶炼、锻造及普通的轧制工艺设计。采用了金相显微镜、透射电子显微镜等显微分析手段和力学性能、电化学试验等试验方法,观察和分析了试验钢的组织、晶界、析出物的特点,考察了钛对试验钢的强韧性的影响,研究了试验钢的耐腐蚀性能,并对不锈钢的微合金化问题进行了较为全面的探讨。

通过对试验钢的力学性能和显微分析后可以认为,当材料在低于奥氏体再结

晶温度而高于Ar3相变温度时变形,能够促使相变在较高的温度下发生,并且能得到较小半径的临界核胚。要想得到超细晶铁素体组织,必须对钢铁材料进行较大程度的变形。强碳氮化合物形成元素钛可以通过其碳氮化合物在均热时阻止奥氏体晶粒的长大,热轧过程中阻止奥氏体再结晶及钢中存在的细小未溶的钛的碳氮化合物促进γ→α转变这几个方面来细化铁素体晶粒。试验结果表明,钛可以细化0Cr13铁素体不锈钢晶粒,提高其强度,改善其韧性,使之具有较好的加工性能。钛的添加量有一最佳范围,过多过少都不能获得理想的强化效果,当钛的含量为碳含量的6~9倍时具有较好的效果。分析计算表明,第二相析出粒子Ti(C,N)粒子对铁素体晶界的拖曳力主要取决于其大小及所占体积分数。Ti(C,N)粒子越小,所占体积分数越大,越能有效地细化铁素体晶粒,从而提高钢铁材料的综合性能。通过对沉淀析出第二相粒子的热力学与动力学分析可知,Ti(C,N)析出粒子越细小,越容易粗化,因而要得到极细的第二相析出粒子比较困难。通过实验室的电化学试验结果分析,表明:普通的0Cr13型铁素体不锈钢耐晶间腐蚀的能力较差。引入钛之后,钢中的碳与强碳氮化合物形成元素钛可以生成很稳定的钛碳化物,(Fe,Cr)7C3在晶界上的析出受到抑制。钛元素的引入,消除了钢中的C、N间隙原子,抑制了珠光体组织的生成,净化了铁素体晶界,提高了铁素体组织的均匀性,使其耐腐蚀性能显著提高。

检测样品:

粗钢

检测项:

可靠性能

天津市兰力科化学电子高技术有限公司

查看联系电话

前往展位

电渣冶金用含氟渣系对夹杂物的影响研究

本文以 MoSi2电阻炉为熔炼设备,以电渣重熔过程常用的几种渣系与支承辊用钢进行了渣金平衡实验,分别利用金相显微镜、SEM-EDS 对不同时刻所取试样进行了数量、尺寸及形貌、成分的测定,得出 S4 渣及 S5 渣的变形渣 S6 渣(即保持 S5 渣其它组元成分比例不变,将 MgO 含量提升到 13%)冶炼过程中夹杂物面积百分比相对于其它渣系均较低;在钢液凝固过程后钢中易氧化元素重新与钢中溶解[O]结合形成相应非金属夹杂物,并伴随钢液的凝固常有 Ti、V 的氮化物、碳化物夹杂生成,采用三七渣冶炼,终点钢样中夹杂物多成塑性夹杂,而采用五元渣系冶炼,终点钢样中夹杂物呈向塑性夹杂转变的趋势。

检测样品:

粗钢

检测项:

北京欧波同光学技术有限公司

查看联系电话

前往展位

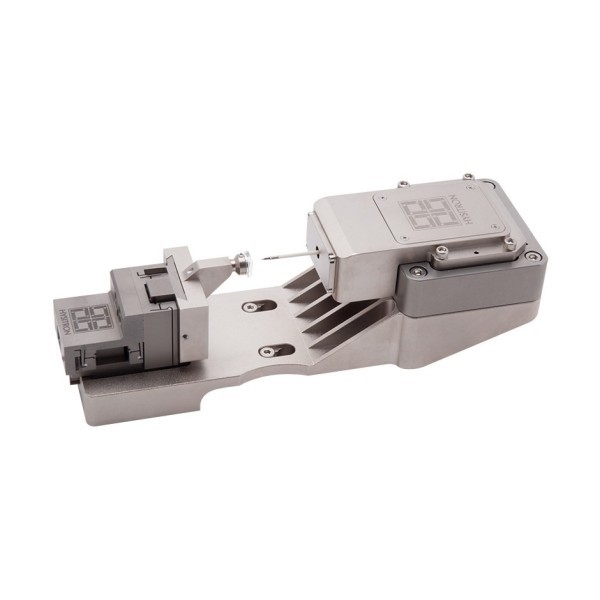

不锈钢中元素含量检测方案(电镜部件)

Using Bruker’s Hysitron PI 88 SEM PicoIndenter

equipped with tilt and rotation stages in conjunction with

the QUANTAX EBSD system enables a more robust

characterization of metallic materials by combining high

resolution phase and grain orientation mapping capabilities

with targeted nanomechanical property measurements.

This combination could also be used to extend the scope of

research related to other advanced textured, anisotropic, or

multi-phase materials.

检测样品:

粗钢

检测项:

含量分析

布鲁克电子显微纳米分析仪器部

查看联系电话

前往展位

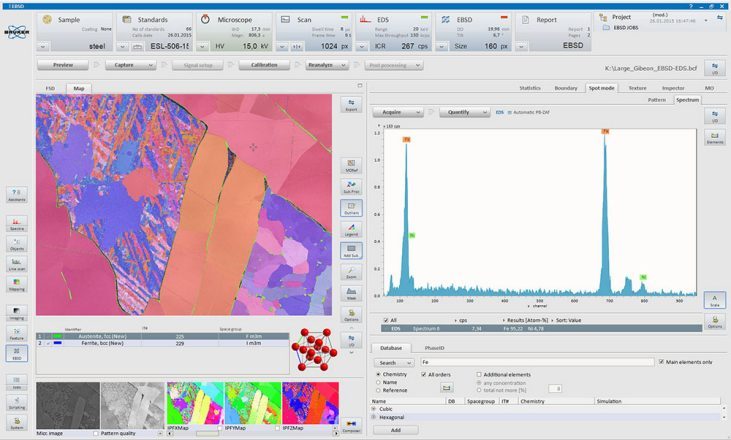

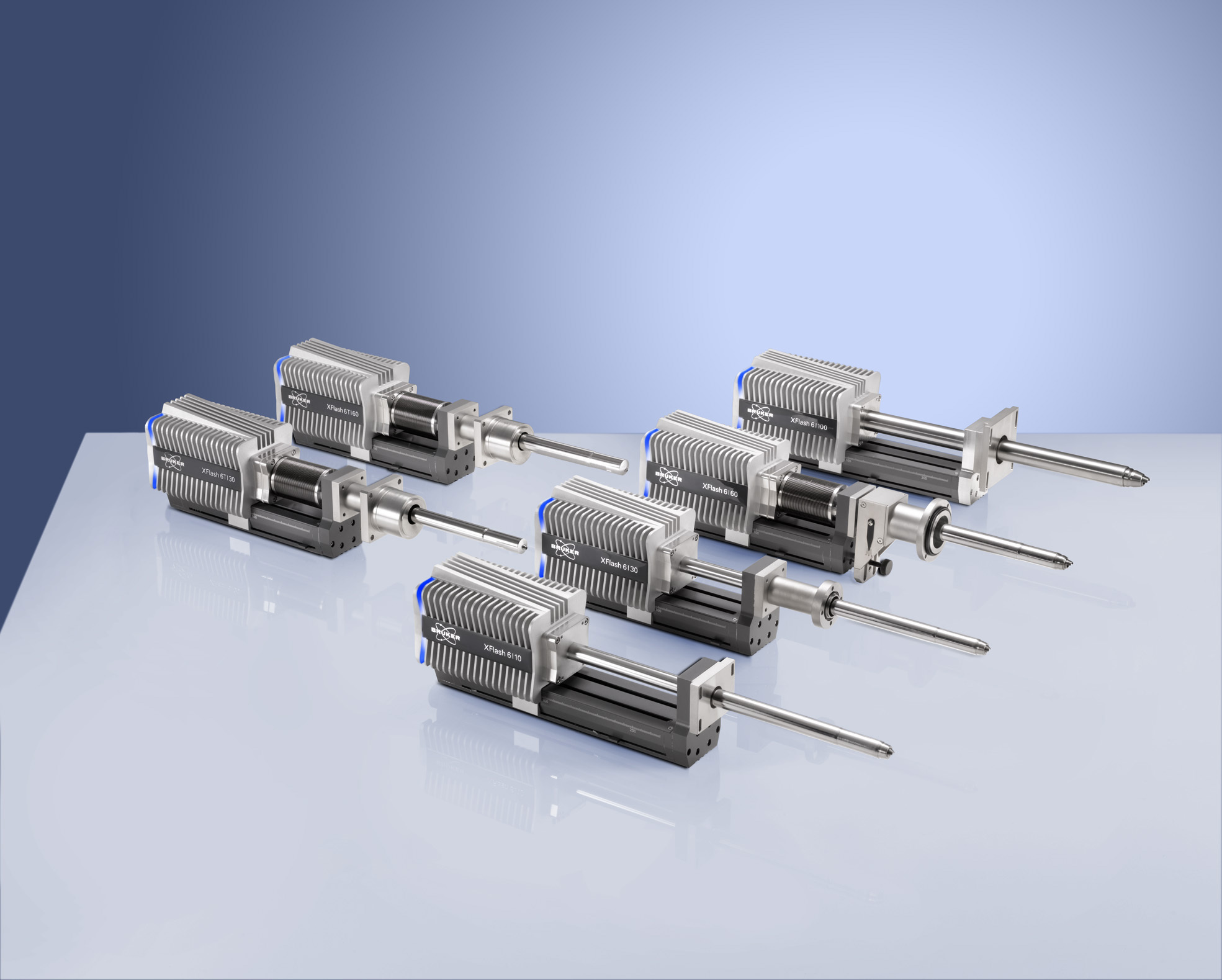

钢铁中元素含量检测方案(EBSD系统)

The evolution of texture and microstructure during plastic

deformation controls the bulk mechanical properties of

virtually all materials used to manufacture engineering

components and equipment. SEM based in-situ tensile/

compression testing allows investigating the onset of plastic

deformation as well as all intermediate deformation stages.

Microstructure and texture evolution can be quantified

when combining this technique with EBSD. The quantitative

results can then be used for refining the plastic deformation

theory as well as for confirming the existing simulation

models.

检测样品:

粗钢

检测项:

含量分析

布鲁克电子显微纳米分析仪器部

查看联系电话

前往展位

钢及其合金中S元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

碳钢中硅含量及硫化腐蚀检测方案(能散型XRF)

Niton XL3t GOLDD+分析仪可以快速检测从元素周期表中从镁(Mg)到铀(U)的元素。该仪器可以进行趋势分析,可以实时读取分析结果的平均值或将分析结果下载到电脑。Niton XL3t GOLDD+分析仪在苛刻的环境下依然可以提供快速,准确的元素分析结果。在炼油行业,使用 Niton XL3t GOLDD+分析仪的主要优点如下:

更快的分析速度和更低的检出限

无不伦比的准确性,可信的结果

轻元素检测(镁Mg,铝Al,硅Si,磷P,硫S)无须真空或充氦气(He)

可选充氦附件,用以加强轻元素的分析能力

实验室级别的现场便携式仪器

防水,防尘,坚固的外壳适用于恶劣环境

检测样品:

粗钢

检测项:

可靠性能

朗铎科技(北京)有限公司

查看联系电话

前往展位

钢及其合金中Cr元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中Al元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

Al元素

安捷伦科技(中国)有限公司

查看联系电话

前往展位

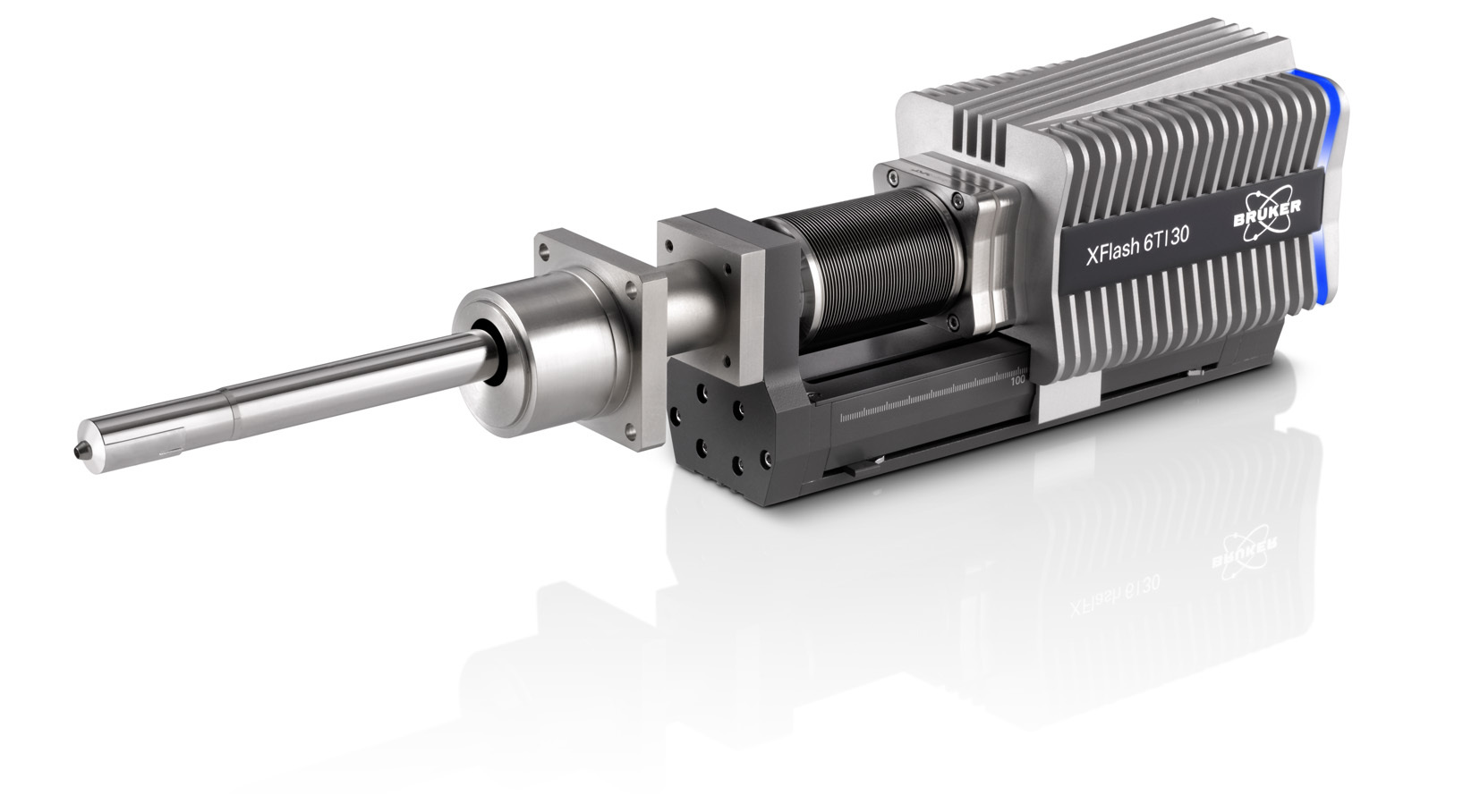

Cr-Ni钢中元素含量检测方案(X射线能谱仪)

The measurements discussed in this document relate to a

Cr-Ni-steel sample, the composition of which was originally

determined with XRF and S-OES. Steel analysis using EDS

generally deals with calculating the content of elements in

the intermediate atomic number range through evaluation of

the K-lines of the X-ray spectrum.

检测样品:

粗钢

检测项:

含量分析

布鲁克电子显微纳米分析仪器部

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供108篇粗钢检测方案,可分别用于,参考标准主要有《HJ 777-2015 空气和废气 颗粒物中金属元素的测定 电感耦合等离子体发射光谱法》等