方案详情

文

气化焦碳的特性-德国筛选活动的结果CHARACTERISTICS OF GASIFICATION CHARS – RESULTS FROM A SCREENING CAMPAIGN IN GERMANY

方案详情

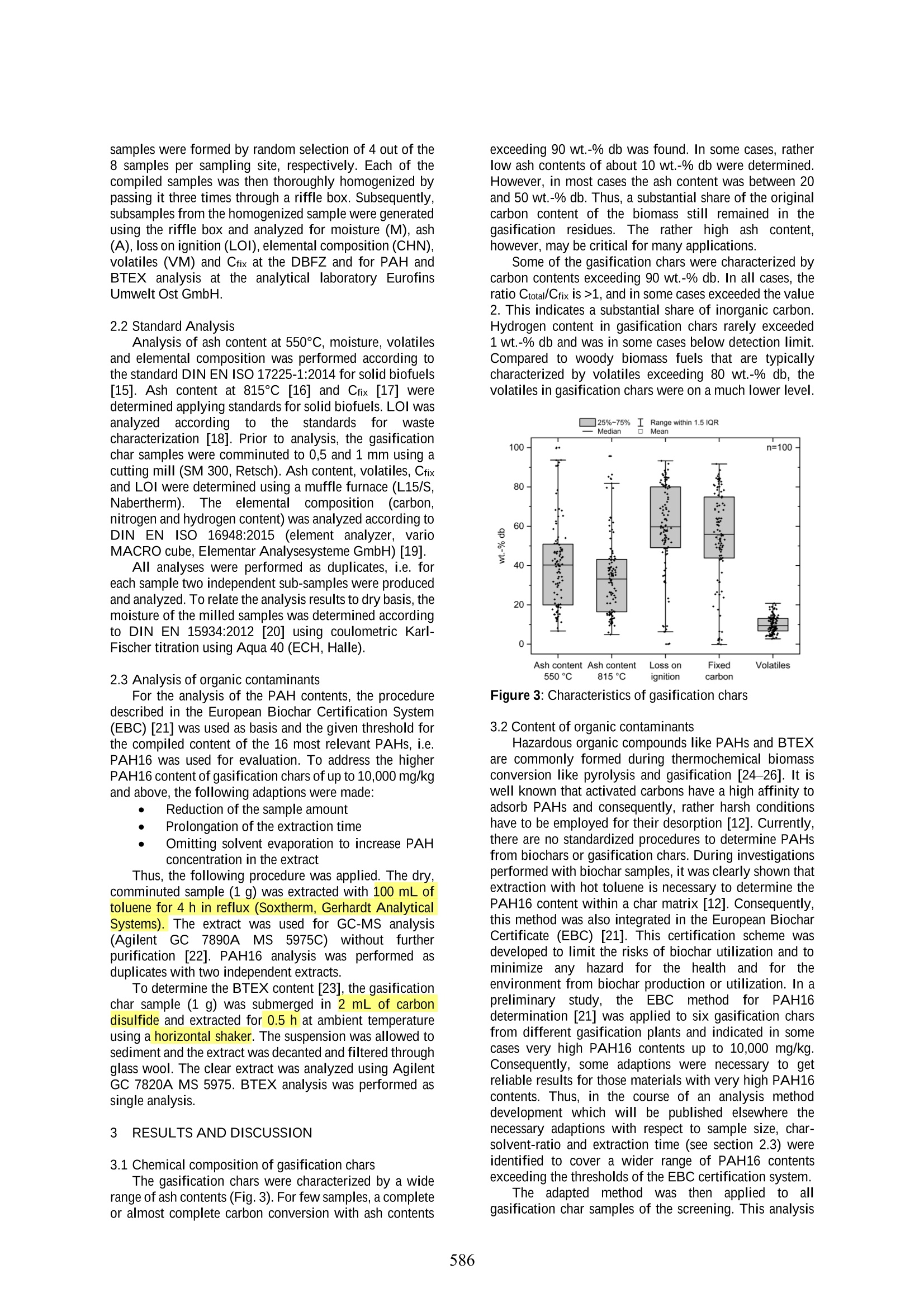

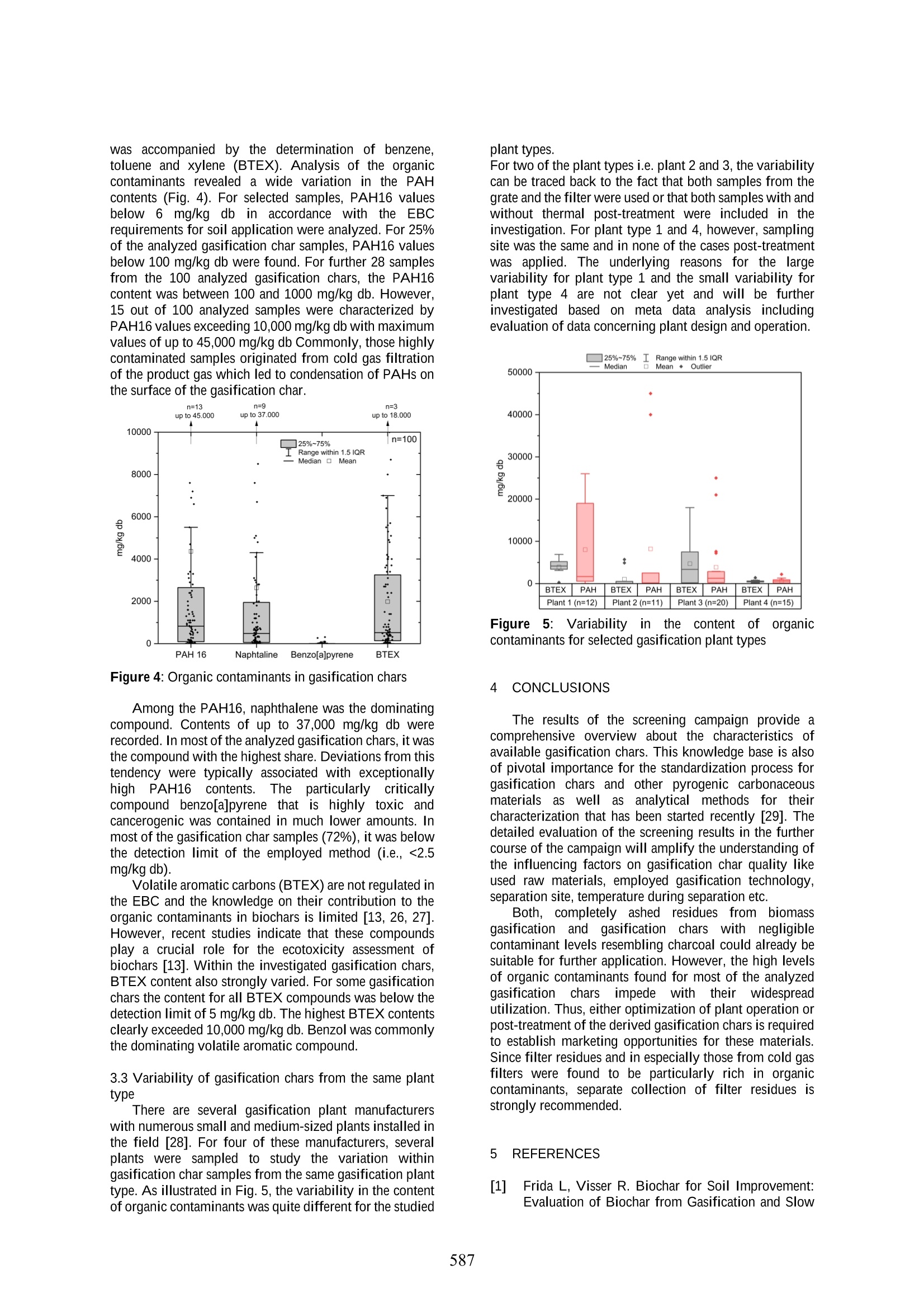

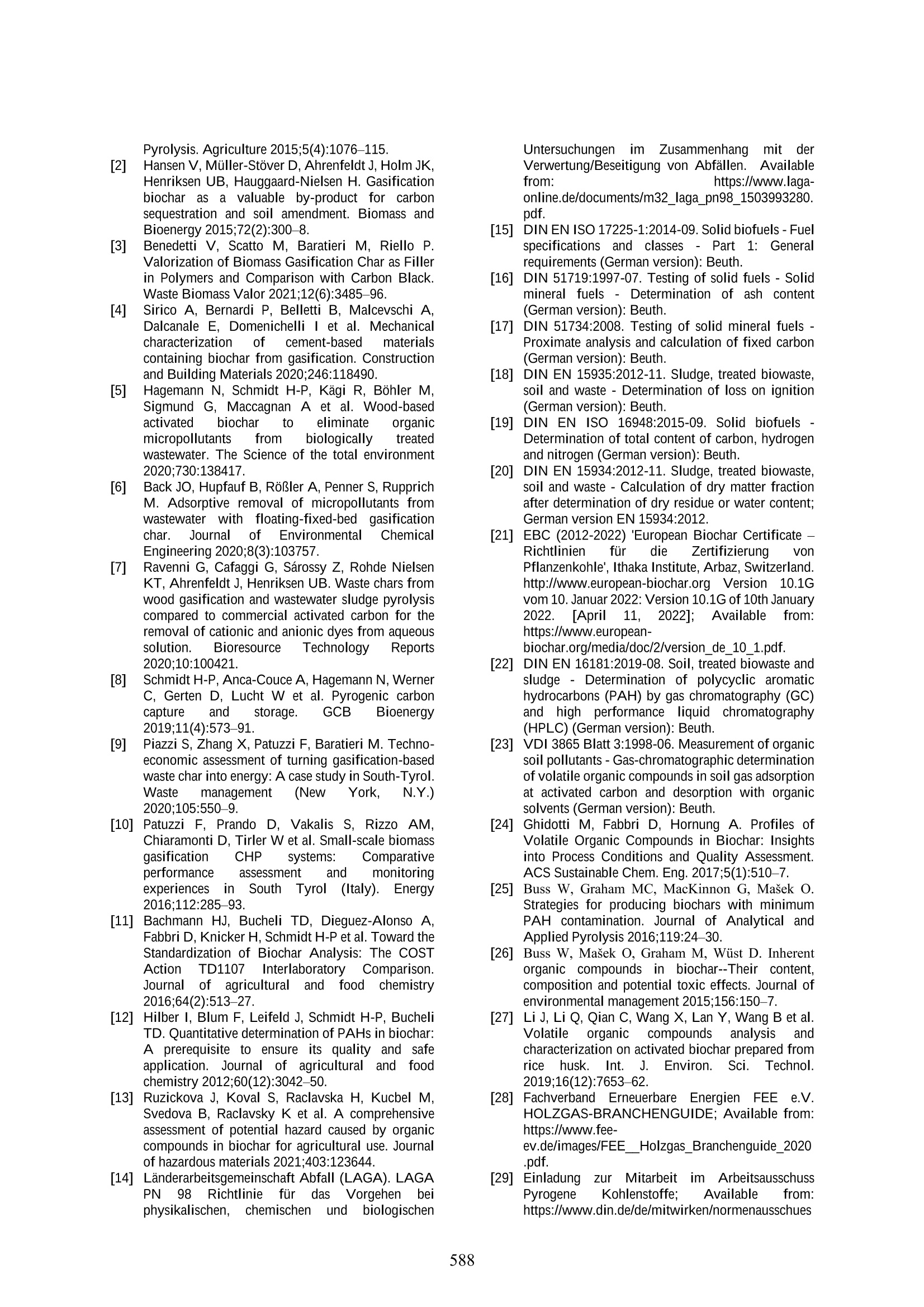

气化焦碳的特性-德国筛选活动的结果CHARACTERISTICS OF GASIFICATION CHARS – RESULTS FROM A SCREENING CAMPAIGN IN GERMANY30th European Biomass Conference and Exhibition, 9-12 May 2022, Online 气化焦碳的特性-德国筛选活动的结果 CHARACTERISTICS OF GASIFICATION CHARS-RESULTS FROM A SCREENING CAMPAIGNIN GERMANY Annett Pollexl, Sabine Bandemer , Axel Ulbricht, Thomas Zeng ', Krist i na Herrmann’, Dieter Brakow3 1. Deutsches Biomasseforschungszentrum gemeinnitzige GmbH (DBFZ), Torgauer StraBe 116, 04347 Leipzig, Germany 欧陆分析 2Eurof i ns Umwelt Ost GmbH, LindenstraBe 11, 09627 Bobritzsch-Hilbersdorf, Germany 3 Fordergesellschaft Erneuerbare Energien (FEE) e.V.,EUREF-Campus 16, 10829 Berlin ABSTRACT : Despite severa l interesting characteris t ics like high carbon content, large BET surface area and narrow par t icles size distribution, the solid residues from wood gasification, i.e. gasification chars, are rarely used and commonly considered as wastes. Furthermore, marketing of these materials i s hampered by a limited knowledge base on the actual characteristics of gasification chars from different conversion technologies, an incomplete understanding on i nfluencing factors and a l ack of standardization both for t he material i t self and the analytical procedures that have to be employed for their characterization. To provide a basis for standardization and future utilization perspectives, a screening was performed covering a wide range of gas i ficat i on technologies. The samples were analyzed for ash content, moisture, volatiles, fixed carbon and elemental composition (carbon, hydrogen, nitrogen) as well as the content of polycyclic aromatic hydrocarbons and volat i le aromatic hydrocarbons . In total , analysis data o f 100 gasification char samples from 14 different gasification technologies have been evaluated. The results indicate a wide variation in the characteristics of gasification chars both with respect to ash and carbon content and level of organic contaminants.Keywords: biomass gasification, gasi f ication char, screening, analysis, PAH content, carbon sequestration Biomass gasification on small and medium-scale (i .e.30-500 kWel) will play a crucial role to stabilize a future electricity supply dominated by fluctuating energy sources l i ke solar and wind energy. The process generates a product gas which is used for combined heat and electricity production. Typically, a solid residue wi t h a high carbon content is formed as residual material for which t he t erm,,gasification char" is used i n t he following.At the moment, this residual material is commonly considered as waste and disposed or internally used for heat generation. However, based on t he interesting properties of these residues, e.g. high carbon content and narrow particle size distribution, there are various potential ut i lization options presupposed that qual i ty criteria for the respective application are met, e.g. as soi l enhancer [1, 2], as additive for polymers [3] as wel l as brick, concrete or asphalt production [4], as adsorbent for waste water treatment [5-7]or for r carbon sequestration nwhich providear opportunity y to reduce greenhouse gas levels in the atmospheree [8]. Nevertheless, there are hardly any establ i shed market i ng opportunities for gasi f ication chars yet [9]. This is mainly the consequence of a limited knowledge t base on n the e actualcharacteristics of gasif i cation chars from different technologies [10], a l i mited understanding on i nfluencing factors and a lack of standardization both for the material itself and the analytical procedures that have to be employed for their characterization [11, 12]. To establish utilization options,it is mandatory that gasification chars fulfill quality requirements for their save application and that negative impacts on human health or environment are avoided. Of particular interest is the content of hazardous organic compounds like polycyclic aromatic hydrocarbons (PAHs) and volatile aromatic carbons (BTEX) [13]. To provide a basis for standardization and future utilization perspectives, a screening was performed covering a wide range of gasi f ication technologies. In total, analysis data of 100 gasification char samples obtained from 14 different gasi f ication tech n ologies have been evaluated. 2.1 Gasi f ication cha r samples Samples were obtained between March 2020 and December 2021 directly from operators of gasification plants.The e samples originate from 14different technologies and cover both samples from the grate, from the product gas filter (hot or cold gas cleaning) or miscel l aneous sources. Apart from the few completely ashed samples which were characterized by a brownish grey color, al l samples were characterized by a black color.The majority of samples resembled a powder with few larger particles. However, some of t he gasification chars were also rather coarse or reminded of charcoal (Fig. 1). Figure 1: Powdery (lef t ), coarse (middle) and charcoal-like appearance of gasi f ication chars (right) The gasification char samples were gathered according to the technical regulat i on for waste sampl i ng LAGA PN98 [14] (Fig.2). Thus, 8 samples of 0,5 L each were obtained from the gasification char produced over one day ortwo consecutive days depending on the gasification plant size.If possible, t he samples were taken from the mov i ng stream. Alternatively, evenly distributed grab samples were obtained from daily production. Two compiled samples were formed by random selec t ion of 4 out of t he 8 samples per sampl i ng site e ,, I respectively. Each of the compiled samples was then thoroughly homogenized by passing it three t i mes through a riffle box. Subsequently,subsamples from the homogenized sample were generated using the riffle box and analyzed for mois t ure (M), ash (A), loss on ignition (LOI), elemental composition (CHN),volati l es (VM) and Cf i x at the DBFZ and for PAH and BTEX analysis at the analytical laboratory Eurofins Umwel t Ost GmbH. 2.2 Standard Analysis Analysis of ash content at 550°C, moisture, volatiles and elemental composition was performed according to the standard DIN EN ISO 17225-1:2014 for solid biofuels [15]. Ash content at 815℃ [16] and C f ix [17] were determined applying standards f or solid biofuels. LOI was analyzed according to the standards for waste characterization [18]. Prior to analysis, t he gasification char samples were comminuted to 0,5 and 1 mm using a cutting mil l (SM 300, Retsch). Ash content, volatiles, C f ix and LOI were determined using a muffle furnace (L15/S,Nabertherm). The elemental composition (carbon,nitrogen and hydrogen content) was analyzed according to DIN EN ISO 16948:2015 (element analyzer, vario MACRO cube, Elementar Analysesysteme GmbH) [19]. All analyses were performed as duplicates, i.e. for each sample two independent sub-samples were produced and analyzed. To relate the analysis results to dry basis,the moisture of the mi l led samples was determined according to DIN EN 15934:2012 [20] using coulometric Karl-Fischer t itration using Aqua 40 (ECH, Halle). 2.3 Analysis of organic contaminants For the analysis of the PAH contents, the procedure described i n the European Biochar Certification System (EBC) [21] was used as basis and the given threshold for the compiled content of the 16 most relevant PAHs, i.e.PAH16 was used for evaluation. To address the higher PAH16 content of gasification chars of up to 10,000 mg/kg and above, the following adaptions were made: ● Reduction of the sample amount ● Prolongation o f the extract i on t ime Omitting solvent evaporation to increase PAH concentration in the extract Thus, the following procedure was applied. The dry,comminuted sample (1 g) was extracted with 100 mL of toluene for 4 h in reflux (Soxtherm, Gerhardt Analytical Systems). The extract was used for GC-MS analysis (Agi l ent GC 7890AMMS 55975C)without further purification [22]. PAH16 analysis was performed as duplicates with two i ndependent extracts. To determine the BTEX content [23], the gas i fication char sample (1 g) was submerged in 2 mL of carbon disulfide and extracted for 0.5 h at ambient temperature using a horizonta l shaker. The suspension was allowed to sediment and t he extract was decanted and f i l tered through glass wool. The c l ear extract was analyzed using Agilent GC 7820A MS 5975. BTEX analysis was performed as single analysis. RESULTS AND DISCUSSION 3.1 Chemical composition of gasification chars The gas if ication chars were characterized by a wide range of ash contents (Fig.3). For few samples, a complete or almost complete carbon conversion with ash contents exceeding 90 wt.-% db was found. In some cases, rather low ash contents of about 10 wt.-% db were determined.However, in most cases the ash content was between 20and 50 wt .-% db. Thus , a substantia l share of t he original carbon content of the biomass still remained in the gasi f ication residues. The rather high ashh content.however, may be critical for many applications. Some of the gasif i cation chars were characterized by carbon contents exceeding 90 wt.-% db. In all cases, the ratio Ctotal /C f ix is >1, and in some cases exceeded the value 2. This indicates a substantial share of inorganic carbon.Hydrogen content i n gasification chars rarely exceeded 1 wt.-% db and was in some cases below detection limi t .Compared to woody biomass fuels that are typically characterized by volat i les exceeding 80 wt.-% db, the volatiles in gasification chars were on a much lower level. Figure 3: Characteristics of gasi f ication chars 3.2 Content of organic contaminants Hazardous organic compounds l ike PAHs and BTEX are commonly formed during thermochemical biomass conversion l i ke pyrolysis and gas if ication [24-26]. It is wel l known that activated carbons have a high affinity to adsorb PAHs and consequently, rather harsh conditions have to be employed for their desorption [12]. Currently,there are no standardized procedures to determine PAHs from biochars or gasi f ication chars. During investigations performed with biochar samples, it was clearly shown that extraction with hot toluene is necessary to determine the PAH16 content within a char matrix [12]. Consequently,this method was also integrated in the European Biochar Certificate (EBC) [21]. This certi f ication scheme was developed to limi t the risks of biochar uti l ization and to minimize any hazard for the health and for the environment from biochar production or uti l ization. In a preliminary study, the EBC method for PAH16determination [21] was applied to six gasification chars from di f ferent gasi f i cation plants and indicated in some cases very high PAH16 contents up to 10,000 mg/kg.Consequent l y, some adaptions were necessary to get rel i able results for those materials with very high PAH16contents. Thus, in the course of an analysis method development which wil l be publ i shed elsewhere the necessary adaptions wi t h respect to sample size, char-solvent-ratio and extraction time (see section 2.3) were identified to cover a wider range of PAH16 contents exceeding the thresholds of the EBC certification system. TThe adapted method was t hen applied ttoal gasi f ication char samples of the screening. This analysis was accompanied by the determination of benzene,toluene and xylene (BTEX). Analysis of the organic contaminants revealed a wide variation in the PAH contents (Fig. 4). For selected samples, PAH16 values below 6 mg/kg db in accordance wi t h the EBC requirements for soil application were analyzed. For 25%of the analyzed gasi f ication char samples, PAH16 values below 100 mg/kg db were found. For further 28 samples from the 100 analyzed gasification chars, the PAH16content was between 100 and 1000 mg/kg db. However,15 out of 100 analyzed samples were characterized by PAH16 values exceeding 10,000 mg/kg db with maximum values of up to 45,000 mg/kg db Commonly, t hose highly contaminated samples originated from cold gas f iltration of the product gas which led to condensation of PAHs on the surface of the gasi f ication char. Figure 4: Organic contaminants in gasification chars Among the PAH16, naphthalene was t he dominat i ng compound. Contents of up to 37,000 mg/kg db were recorded. In most of the analyzed gasificat i on chars, it was the compound with the highest share. Deviations from this tendency were typically associated with exceptional l y high PAH16contents.The particular l y critically compound benzo[a]pyrene that i s highly t oxic and cancerogenic was contained in much lower amounts. In most of t he gas i fication char samples (72%), i t was below the detection limit of the employed method (i.e., <2.5mg/kg db). Volat i le aromatic carbons (BTEX) are not regulated in the EBC and the knowledge on their contribution to the organic contaminants in biochars is limited [13, 26,27].However , recent studies indicate that these compounds play a crucial role for the ecotoxicity assessment of biochars [13]. Within the investigated gasi f ication chars,BTEX content also strongly varied. For some gasification chars the content for all BTEX compounds was below the detection limit of 5 mg/kg db. The highest BTEX contents clearly exceeded 10,000 mg/kg db. Benzol was commonly the dominating volat i le aromatic compound. 3.3 Variability of gasi f ication chars from the same plant type There are several gasi f ication plant manufacturers IIS with numerous small and medium-sized plants installed in the field [28]. For four of these manufacturers, several plants were sampled to study t he variation within gasif i cation char samples f rom t he same gas if icat i on plant type. As illustrated i n Fig. 5, the variability in t he content of organic contaminants was quite different for the studied plant types. For two of the plant types i .e. plant 2 and 3, the variability can be traced back to the fact that both samples from the grate and the fi l ter were used or tha t both samples with and wi t hout thermal post-treatment were i ncluded in the investigation. For plant type 1 and 4, however, sampling site was the same and in none of the cases post-treatment was applied. The underlying reasons for the l arge variabi l ity for plant type 1 and t he smal l variabil i ty for plant type 4 are not clear yet and wil l be further investigated based on meta data analysis including evaluation of data concerning plant design and operation . Figure 5: Variabi l i ty in the content of organic contaminants for selected gasi f ication plant types 4 CONCLUSIONS The results of the screening campaign provide a comprehensive overview about the characteristics of available gasification chars. This knowledge base is also of pivota l i mportance for the standardization process for gasif i cation chars and other pyrogenic carbonaceous materials as well asanalytical methods for their characterization t hat has been started recently [29]. The detai l ed evaluation of the screening results i n the further course of the campaign will amplify the understanding of the i nfluencing factors on gasif i cation char quality like used raw mater i als, employed gasification technology,separation site , temperature dur i ng separa t ion etc. Both, completely ashed residues from biomass gasi f ication and gasification chars with negligible contaminant levels resembling charcoal could already be suitable for further application. However, the high l evels of organic contaminants found for most of the analyzed ga s ification n C chars impedee with theirrwidespread ut i lization. Thus , either optimization of plant operation or post-treatment of the derived gasification chars is required to establish marketing opportuni t ies for these materials.Since filter residues and i n especially those from cold gas f il ters were found to be particularly rich in organic contaminants, separate collection of filter residues is strongly recommended. 5 REFERENCES [1] Frida L, Visser R. Biochar for Soi l Improvement:Evaluat i on of Biochar from Gasification and Slow Pyrolysis. Agriculture 2015;5(4):1076-115. [21 Hansen V, Muller-Stover D, Ahrenfeld t J, Holm JK,Henriksen UB, Hauggaard-Nielsen H. Gasi f ication biochar as avaluable by-product for carbon sequestration and soil amendment. Biomass and Bioenergy 2015;72(2):300-8. [3 Benedetti V, Scatto M, Baratieri M, Riello P.Valorization of Biomass Gasification Char as Filler in Polymers and Comparison with Carbon Black.Waste Biomass Valor 2021;12(6):3485-96. [4] Sirico A, Bernardi P, Belletti B, Malcevschi A,Dalcanale E, Domenichelli I et al. Mechanical characterization of cement-based materials containing biochar from gasification. Construction and Building Materials 2020;246:118490. [51 Hagemann N, Schmidt H-P, Kagi R, Bohler M,Sigmund G, Maccagnan A et al. Wood-based activated biochar to eliminate organic micropollutants from biologically treated wastewater. The Science of the total environment 2020;730:138417. 6 Back JO, Hupfauf B, RoBler A, Penner S, Rupprich M. Adsorptive removal of micropollutants from wastewaterwith float i ng-f ixed-bed 1gasi f ication char. Journal of Environmental Chemical Engineering 2020;8(3):103757. [7] Ravenni G, Cafaggi G, Sárossy Z, Rohde Nielsen KT, Ahrenfeldt J, Henriksen UB. Waste chars from wood gasi f ication and wastewater sludge pyrolysis compared to commercial activated carbon for the removal of cationic and anionic dyes from aqueous solution. Bioresource Technology Reports 2020;10:100421. 8 Schmidt H-P, Anca-Couce A, Hagemann N, Werner C, Gerten D, Lucht W et al. Pyrogenic carbon capture and s t orage. GCB Bioenergy 2019;11(4):573-91. [9] Piazzi S, Zhang X, Patuzzi F, Barat i eri M. Techno-economic assessment of turning gasi f ication-based was t e char into energy: A case study i n South-Tyrol.Waste management (New York. N.Y.)2020;105:550-9. [10]上 Patuzzi F, Prando D, Vakalis S, Rizzo AM,Chiaramonti D, Tirler W et al. Small-scale biomass gasification CHP systems: Comparative performance assessment and monitoring experiences in South Tyrol (Italy).Energy 2016;112:285-93. [11]Bachmann HJ, Bucheli TD, Dieguez-Alonso A,Fabbri D, Knicker H, Schmidt H-P et al. Toward the Standardization of Biochar Analysis: The COST Action TD1107Interlaboratory Comparison.Journal of a a gricultural and food chemistry 2016;64(2):513-27. 12Hilber I, Blum F , Leifeld J, Schmidt H-P, Buchel i TD. Quant i tative determination of PAHs i n biochar:A prerequisite to ensure its qual i ty and safe application. JournalCof agricultural and food chemistry 2012;60(12):3042-50. [13]Ruzickova J, Koval S, Raclavska H, Kucbel M,Svedova B, Raclavsky K et al. A comprehensive assessment of potential hazard caused by organic compounds in biochar for agricul t ural use. Journal of hazardous materials 2021;403:123644. [14]I Landerarbeitsgemeinschaft Abfall (LAGA). LAGA PN 98 Richtlinie fur das Vorgehen bei physikalischen,C chemischen und biologischen Untersuchungen im n Zusammenhang n mit der Verwertung/Beseitigung von Abfallen.Available from: https://www.laga-onl i ne.de/documents/m32_laga _pn98_1503993280. pdf. [15]DIN EN ISO 17225-1:2014-09. Solid biofuels -Fuel speci f ications and classes -Part 1: General requirements (German version): Beuth. [16] DIN 51719:1997-07. Testing of sol i d fuels - Solid mineralfuels - Determination of ash content (German version): Beuth. [17]DIN 51734:2008. Testing of solid mineral fuels Proximate analysis and calculat i on of fixed carbon (German version): Beuth. [18]DIN EN 15935:2012-11. Sludge, treated biowaste,soi l and waste - Determination of loss on ignition (German version): Beuth. [19]DIN EN ISO 16948:2015-09. Solid biofuels Determination of total content of carbon, hydrogen and nitrogen (German version): Beuth. [20]DIN EN 15934:2012-11. S l udge, treated biowaste,soi l and waste - Calculation of dry ma t ter fraction after determination of dry residue or water content;German version EN 15934:2012. [21]EBC (2012-2022) 'European Biochar Cer t ificate 一 Richtlinien fiir die Zertifizierung von Pflanzenkohle', Ithaka Institute, Arbaz, Switzerland.http://www.european-biochar.org Version n 10.1G vom 10. Januar 2022: Version 10.1G of 10th January 2022. [April 11, 2022]; Available from:https://www.european- biochar.org/media/doc/2/version _de _10_1.pdf. [22]DIN EN 16181:2019-08. Soil, treated biowaste and sludge -Determination of polycycl i c aromat i c hydrocarbons (PAH) by gas chromatography (GC)and dhigh performance e liquid C chromatography (HPLC) (German version): Beuth. [23]VDI 3865 Blatt 3:1998-06. Measurement of organic soil pollutants - Gas-chromatographic determination of volat i le organic compounds in soil gas adsorption at ac t ivated carbon and desorpt i on with organic solvents (German version): Beuth. [24]Ghidotti M, Fabbri D, Hornung A. Prof i les of Volat i le Organic Compounds in Biochar: Insights into Process Conditions and Quality Assessment.ACS Sustainable Chem. Eng. 2017;5(1):510-7. [25]Buss W, Graham MC, MacKinnon G, Masek O.Strategies for producing biochars with minimum PAH contamination. Journal of Analytical and Applied Pyrolysis 2016;119:24-30. [26]Buss W, Masek O, Graham M, Wust D. Inherent organic compounds in biochar--Their content,composition and potential toxic effects. Journal of environmental management 2015;156:150-7. [27]Li J, Li Q, Qian C, Wang X, Lan Y, Wang B et al.Volatile organic compounds analysis and characterization on activated biochar prepared from rice husk.Int.J. Environ. Sci . Technol .2019;16(12):7653-62. [28]Fachverband d Erneuerbare Energien FEE e.V.HOLZGAS-BRANCHENGUIDE; Available from:https://www.fee-ev .de/images/FEE _Holzgas _Branchenguide _2020.pdf. [29]Einladung zur Mitarbeit im Arbeitsausschuss Pyrogene Kohlenstoffe: Available from:https://www.din.de/de/mitwirken/normenausschues se/nmp/einladung-zur-mitarbeit-im-arbeitsausschuss-pyrogene-kohlenstoffe-na-062-02-85-aa--845266. [30]VergaFlex -Contribut i ng to an Enhanced Flexibi l ity of Biomass Gasification Plants by Utilization Options for Gas i fication Char; Available from:https://www.energetische-biomassenutzung.de/en/projects-partners/details/project/show/Project/VergaFlex 623. 6.ACKNOWLEDGEMENTS ■The recent study was performed in t he context of the WaSI funding program “Energet i sche Biomassenutzung (Biomass Energy Use) as part of the VergaF l ex project (funding number: 03KB157A-C) [30]. Financial support of this project by the Federal Ministry of Economic Affairs and Cl i mate Action is gratefully acknowledged. Suppor t ed b y:

确定

还剩3页未读,是否继续阅读?

产品配置单

中国格哈特为您提供《3种气化焦碳中多环芳烃(PAHs)含量的检测》,该方案主要用于固体废物中有机污染物检测,参考标准《HJ 950-2018 固体废物 多环芳烃的测定 气相色谱-质谱法》,《3种气化焦碳中多环芳烃(PAHs)含量的检测》用到的仪器有格哈特全自动快速溶剂萃取仪Sox416、格哈特快速干燥仪STL56、格哈特强力高重现振荡器LS500/RO500、德国加液器MM、棕色避光防紫外线萃取杯、玻璃滤筒、滤纸筒

相关方案

更多

该厂商其他方案

更多