方案详情

文

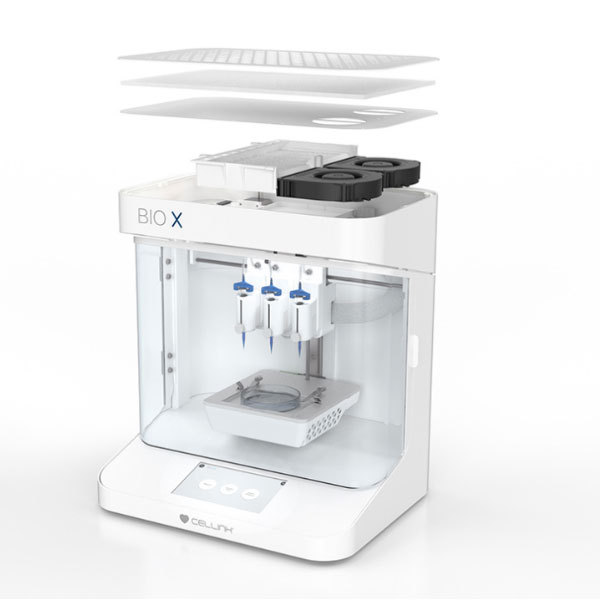

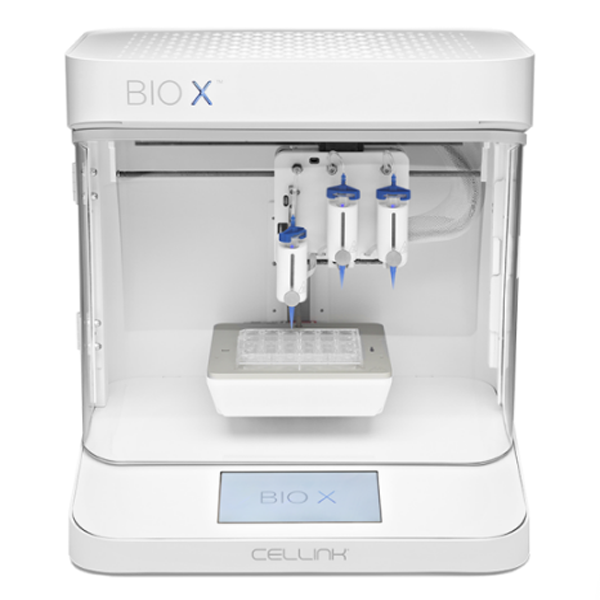

在基于挤压的3D生物打印中,使用胶原蛋白等软材料,这是一个复杂的挑战,因为它们在挤压后无法保持缺失的形状。一种解决方案是悬浮水凝胶(新鲜),这是一种生物制造方法,提供临时支持,防止生物打印过程中结构的坍塌或变形。生命支持™,一种常用的凝胶式新鲜生物打印蛋白基支持浴, 提供了一个额外的优势,即它可以很容易地实现 打印后移除。本研究旨在进行优化 几种流行的生物酸盐的新鲜生物打印 里亚尔斯使用生命支持浴缸提供BIO X用户 已有既定的印刷协议。显示 新鲜生物打印的多功能性,我们选择了三个 具有不同凝胶机械的软生物材料 镍钛合金(热自组装,照片和离子)。 所有的生物材料都进行了流变学表征, 优化的打印和,最后,生物打印与 细胞

方案详情

在几年的时间里,3D生物打印已经成为最流行的技术之一,精确地将生物材料和细胞放置在三维空间中,以重建复杂生物系统的结构和功能,从细胞到器官的规模(Shiwarski,2021)。尽管许多不同的技术和生物打印策略已经被提出用于具有非常高分辨率的复杂组织的生物打印,但基于挤压的生物打印由于其多功能性、低成本和易用性仍然是最受欢迎的。 不幸的是,由于重力和随后的打印保真度的损失,软液体样生物材料(如胶原蛋白或脱细胞的细胞外基质)的复杂结构的基于挤压的3D生物打印是困难的。为了克服这一问题,研究人员开发了光交联、温度敏感和流变修饰的生物材料,以对抗重力的影响,并实现在空气中进行三维生物打印(Adib,2020;Heid,2020)。然而,这些方法通常需要在生物特性和严格的生物打印参数方面进行妥协(Hazur,2020)。悬浮水凝胶的自由形式可逆嵌入(新鲜)方法已被开发为一种解决方案,通过提供一个临时的支撑结构(在下文中称为支撑浴),以防止打印过程中结构的坍塌和变形(Hinton,2015)。支撑槽具有宾厄姆塑性特性,使支撑槽在低剪应力下表现为硬体,在高剪应力下表现为粘性流体。通过这种方式,打印头喷嘴可以在打印过程中在整个浴缸中移动,并在创建的空白空间中挤压生物材料(Wu,2011)。经过新鲜的生物打印后,支撑浴被融化,结构被释放。新鲜生物打印允许使用多种具有不同凝胶机制的生物材料,可以在市场上广泛的支持浴(基于明胶、海藻酸盐、卡波尔、琼脂糖、结冷胶、透明质酸等)中打印。其中,以明胶为基础的生物相容性、低成本和热可逆性,以及热可逆性,使得在室温下打印结构并在生理下熔融浴 印刷后的温度。这是一个非常温和的过程,可以与细胞和蛋白质兼容,这意味着即使是非常软的支架也可以成功地打印出来,然后释放出来,而不会失去基本的生物特性。 本研究旨在优化三种不同的低粘度软生物材料的三维生物打印,采用先进生物基质提供的基于无菌明胶的支持浴。(李,2019;Jeon,2019)。优化过程包括流变学表征、印刷参数的调整和概念验证单元研究。CELLINK冷A BICO COMPANYAPPLICATION NOTE APPLICATION NOTE FRESH Bioprinting of Soft Biomaterials Franca Scocozza1, MSc, Milena Savioli Lopes?, PhD, Volodymyr Kuzmenko2, PhD, Itedale Namro Redwan2, PhD 1Dept. of Civil Engineering and Architecture, University of Pavia, Italy 2CELLINK, Gothenburg, Sweden Abstract In extrusion-based 3D bioprinting, working withsoft materials, like collagen, presents a com-plex challenge given their inability to retain a de-sired shape following extrusion. One solution isfreeform reversibleembedding of suspendedhydrogels (FRESH), a method of biofabricationwhich provides a temporary support and preventsthe collapse or deformation of a construct duringbioprinting. LifeSupportM, a commonly used gel-atin-based support bath for FRESH bioprinting, offers the added advantage that it can be easilyremoved after printing. This study aims to optimizethe FRESH bioprinting of several popular biomate-rials using LifeSupport bath to provide BIO Xuserswith established printing protocols. To show theversatility of FRESH bioprinting, we chose threesoft biomaterials with different gelation mecha-nisms (thermal self-assembly, photo, and ionic).All biomaterials were rheologically characterized,optimized for printing and, finally, bioprinted withcells. In the span of a few years, 3D bioprinting hasbecome one of the most popular techniques forprecisely placing biomaterials and cells in 3D space tobiofabricate constructs that recreate the structureand function of complex biological systems, fromcellular to organ scale (Shiwarski, 2021). AlthoughmanyCdifferent technologiesSand bioprintingstrategiess havee been proposed for bioprintingcomplex tissues with very high resolution, extrusion-based bioprinting remains the most popular thanksto its versatility, low cost, and ease of use. Unfortunately, extrusion-based 3DD上bioprintingof complex structures is difficult with soft liquid-like biomaterials((eg, collagen or decellularizedextracellular matrix) due to gravity and subsequentloss of print fidelity. To overcome this, researchershave developed photo-crosslinkable, temperature-sensitive, and rheologically modified biomaterialsto counter the effects of gravity and enable 3Dbioprinting in the air (Adib, 2020; Heid, 2020).However, these approachesoften requirecompromises in terms of biological properties andstringent bioprinting parameters (Hazur, 2020). Freeformmrreversible embedding ofsuspendedhydrogels (FRESH) method has been developedas a solution to this issue by providing a temporarysupport structure (referred to in the followingtext as a support bath) to prevent the collapseand deformation of the constructs during printing(Hinton,2015). The support bath has Bingham plasticproperties that make the support bath behaveas a hard body under low shear stresses and as aviscous fluid under high shear stresses. In this way,the printhead nozzle can move throughout the bathduring printing and extrude biomaterial in the emptyspace created (Wu, 2011). After FRESH bioprinting,the support bath is melted away and the constructreleased. FRESHbioprintinggallowsLusinggCa varietybiomaterials with different gelation mechanismsthat can be printed in the wide range of supportbaths available on the market (based on gelatin,alginate, Carbopol, agarose, gellan gum, hyaluronicacid, etc.). Among these, gelatin-based support bathis one of the most used for FRESH bioprinting thanksto biocompatibility, low cost, and thermoreversibleproperties that make it possible to print constructs atroom temperature and melt the bath at physiological temperature after printing. This is a very gentleprocess that is compatible with cells and proteins,meaning that even extremely soft scaffolds can beprinted successfully and then released without losingessential biological properties. This study aims to optimize the 3D bioprinting ofthree different low viscosity soft biomaterials withdifferent gelation mechanisms using the FRESHbioprinting method with LifeSupport, a sterile gelatinbased support bath provided by AdvancedBioMatrix.(Lee, 2019; Jeon, 2019). The optimization processincluded rheological characterization, adjustmentof printing parameters and a proof-of-concept cellstudy with established bioprinting protocols AnnestablisheddprotocolWas used for thepreparation of the LifeSupport bath (AdvancedBioMatrix, 5244): i) add 40 mL of cold (4℃)suspension media (eg, PBS, crosslinker solution,cell medium) to a 2 g of LifeSupport, ii) vortexand shake the solution, iii) let stand for 15 minutesat 4℃ to allow LifeSupport to fully rehydrate,iv)centrifuge the rehydrated LifeSupport twice for1.5 minutes at 1500 rpm, v) pour off the liquidsupernatant, vi) settle the LifeSupport in theprinting substrate (eg, Petri dish or well plate).For the detailed preparation protocol, one canrefer to the LifeSupport webpage.For thisstudy, we selected soft biomaterials with threedifferent gelation mechanisms: collagen withthermal self-assembly, methacrylated collagenwith photocrosslinking, and sodium alginate withionic crosslinking. For printing with collagens, thesuspension medium for the bath was PBS, and forprinting with alginate, the suspension medium forthe bath contained 0.1%(w/v) CaCl2. with cells, the deionized water was replaced withcell medium. For more details, access the FRESHBioprinting Protocol: TeloCol-10. PhotoCol (Advanced BioMatrix, 5198) is a lyo-philized methacrylated type l collagen that can bethermally crosslinked at 37°℃ (mild crosslinking)and subsequently photocrosslinked for completemechanical stabilization. First, the lyophilizedPhotoCol@ biomaterial was reconstituted using 20mM acetic acid to a concentration of 10 mg/mL.To prepare 1 mL of 6 mg/mL PhotoCol solution forprinting, 600 pL of 10 mg/mL stock solution wastransferred into a sterile Eppendorf using a positivedisplacement pipette.The photoinitiator LAP(AdvancedBioMatrix, 5205) was dissolved in theneutralization solution to achieve a concetrationof 0.25%(w/v) in the final bioink. To neutralize 600pL of 10 mg/mL, 45 pL of neutralization solution/LAP was used to reach the physiologic pH of 7.2.355 pL of deionized water was added to reachthe final concentration of 6 mg/mL. For printingwith cells, the deionized water was replaced withcell medium. For more details, access the FRESHBioprinting Protocol: PhotoCol. Alginate Lyophilizate (CELLINK, VLB000000201)provides a medium viscosity alginate solution sta-ble at room temperature and ionically crosslink-able with CaCl_. Lyophilized alginate was reconsti-tuted to 2% (w/v) using Reconstitution Agent M(CELLINK, IK200000050). For cell printing, algi-nate solution was mixed with cell suspension in cellmedium with a volume ratio of 9:1. For more details,access the FRESH Bioprinting Protocol: Alginate. RHEOLOGY Rheological measurements of LifeSupport andcollagen biomaterials were performed using anoscillatory shear mode on a rotational DiscoveryHR-10 Rheometer (TAInstruments)with analuminum 20 mm parallel plate setup with a 0.5mm gap. Temperature ramps were evaluated from5℃ to 37°℃ for collagen materials and from 10°℃to 37℃ for LifeSupport bath, with a ramp rateof 1'C/min, constant shear strain of 0.5%, andfrequency of 1 Hz for all tests. The final stiffnessof both collagen materials was measured underconstant shear strain and frequency of 0.5% and1 Hz, respectively, after loading the samples intoa 5℃ plate and instantaneously increasing thetemperature to 37°℃ for thermal crosslinking. ForPhotoCol, an additional step was introduced byexposing the sample to photocrosslinking for 30 seconds, using an external LED lamp with near-UVlight wavelength (405nm). OPTIMIZATION OF FRESH BIOPRINTINGPROCESS FRESH bioprinting with LifeSupport involves dif-ferent steps shown in Figure 1. The process startswith adding a suspension medium (water, PBS,crosslinking solution, etc.) to the gelatin powder(Figure 1A). The solution is mixed and centrifugedto form the LifeSupport bath (Figure 1B), whichis used to fill up a well plate (Figure 1C) or Petridish. After printing (Figure 1D), the well plate isplaced into an incubator at 37°℃ for 30 minutes forLifeSupport melting (Figure 1E) and the release ofprinted construct (Figure 1F). To optimize FRESH bioprinting, one must selectan appropriate needle size and adjust printingparameters such as pressure and speed. In ourstudy, the printing optimization was performedusing both 22 G and 25 G 1-inch length needles(CELLINK,NZ5221005001 and NZ5251005001).Tooptimize the printability of materials in the bath,3-layer cylindrical grid constructs (d=10 mm) were3D printed. TeloCol and PhotoCol were transferred to 3 cccartridgesS(CELLINK, CSC010300502) using Figure 1. FRESH bioprinting process: A) suspension mediumaddition to the gelatin powder; B) ready-to-use gelatin-basedsupport bath; C) well plate filled with LifeSupport; D) printing ofa biomaterial inside the bath; E) LifeSupport melting at 37℃; F)release of a printed construct. Figure 2. Rheological evaluation of the support bath and collagen biomaterials. A) Material stability within 5℃ to 37℃ range. B) Finalstiffness of TeloCol and PhotoCol after crosslinking. a positivedisplacement七Ppipetteeftor viscousmaterials. The alginate solution was transferredto 3 cc cartridges using female/female Luer locks(CELLINK, OH000000010). The cartridge wasthen connected to the selected tip needle (1-inchlength) and mounteddonto thelemperature-controlled Printhead (CELLINK, OOO000020346).BiomaterialswerePprinted using theBIOXbioprinter (CELLINK,D16110020717) with print bedand printhead temperatures set at 10℃ and 5℃,respectively, for TeloCol and PhotoCol. Ambientconditions were used for alginate printing. Afterprinting, the well plate was incubated for 30minutes at 37°℃(5%CO,and 95%relativehumidity)for thermal crosslinking of collagen materials andthe melting of LifeSupport bath. After thermalcrosslinking, PhotoCol samples were exposed tophotocrosslinking at 405 nm light for 30 seconds.To avoid premature self-assembly of both collagenbiomaterials, consumables and printhead used inthe printing were pre-chilled in the freezer. Aftermelting of LifeSupport, alginate constructs maysubstantially decrease in size due to the shrinkingphenomenon caused by prolonged crosslinking inCaClz (typically lasting 5 to 10 minutes). CELL PREPARATION Human mesenchymal stem cells (MSCs) wereused for evaluating the influence of the FRESHbioprinting process on cell viability. Cells wereexpanded in 2D T175 flasks before bioprinting.Throughout七theculture,Dulbecco'smodifiedeagle medium (DMEM) with high glucose (Gibco,11965092) supplemented with 10% fetal bovineserum (FBS, Gibco, 10270-106) and Antibiotic-Antimycotic (Gibco, 15240096) was used. Beforebioprinting, cells in passage 28 were detached fromthe flask and a cell suspension was prepared withcell viability of 95%. FRESH 3D BIOPRINTING OF MSCS The BIOXwas prepared by cooling the Temperature-controlled Printhead anddprint bed accordingtopreviously describeddsettings. Biomaterialswere mixed with the cell suspension for a finalconcentration of 2 million MSCs/mL. In particular,the cells were added to TeloCol and PhotoCol usinga pipette and mixed within the Eppendorf, while theaddition of cells to alginate 2% (w/v) solution wasdone using two 3 mLsyringes connected with a Luerlock. The homogeneous solutions were transferredinto cartridges and capped with a 22 G1-inch needlethat was chosen as optimal for printing with cells.The following conditions were used for the BIO Xbioprinting setup: STL file with cylindrical grid of 5mm diameter and 1 mm height with one perimeter,infill = 30%, printing speed = 3.5 mm/s, pressure of10 kPa for the TeloCol and PhotoCol, and 20 kPafor the alginate. The constructs were bioprintedinto an untreated 24-well plate (VWR, 7342779)and placed in the incubator at 37°℃ for 30 minutesto thermally crosslink the constructs and melt theLifeSupport bath. The melted LifeSupport wascarefully removed by replacing it with cell culturemedium to avoid damaging the printed constructs.Cell culture media were replenished three times aweek during the 14-day culturing period. CELL ANALYSIS On days 1, 7 and 14 after bioprinting, the viability ofthe MSCs was assessed using calcein AM (InvitrogeneBioscience, 15560597) and propidium iodide (SigmaAldrich, 81845-25mg). Cell viability was determined byfluorescent imaging of the constructs with green andred channels. Images were analyzed using ImageJsoftware to merge live and dead channel images.For constructs, DAPI stain (Thermo Fisher Scientific,62248) was added on day 14. The protocol for Liveand Dead Assay can be found on CELLINK's website. Table 1. Filament thickness obtained using optimized printing parameters for FRESH bioprinting. TELOCOL PHOTOCOL ALGINATE Needle size (G) 22 25 22 25 22 25 Pressure (kPa) 8-10 12-15 5-15 12-15 20 70 Speed (mm/s) 3.5 Filament thickness (mm) 0.4±0.03 0.25±0.02 0.41±0.04 0.26±0.03 0.29±0.04 0.2±0.05 Rheological tests were performed to check thestability of the temperature-sensitive LifeSupportand collagen biomaterials and ensure satisfactorytemperature control during printing. LifeSupportis stable up to 15℃, showing a slight decreaseinSstoragemodulus above thistemperature.TeloCol and PhotoCol both showed rapid thermalcrosslinking above =18℃ and =23℃, respectively(Figure 2A), indicating a need to keep them coldduring the printing process to avoid prematurecollagen network formation and nozzle clogging. Additionally the final stiffness ofcollagenbiomaterials was assessed (Figure 2B). TeloColand PhotoCol showed similar storage modulusvalues of 920 kPa and 996 kPa, respectively, afterthermal self-assembly at 37℃. However, PhotoColconstructs became much stiffer (ie, 1551kPa) whenthey were additionally exposed to photocrosslinkingafter the melting of the LifeSupport bath. FRESH BIOPRINTING PROCESS All biomaterials considered for this study weresuccessfully FRESH bioprinted with the extrusion-based BIO X 3D bioprinter. TeloCol printing,however, was challenging because of the needto keep the printhead at 5℃ to avoid prematureself-assembly. Optimized printing parameters forthe three biomaterials and their achieved filamentthickness are summarized in Table 1. Fixing printingparameters, the filament thickness for TeloColand PhotoCol is 0.4 mm and 0.25 mm for a 22 Gand 25 G needle, respectively. An excellent resultaiven that the theoretical minimum resolutionof a filament is defined by the nozzle diameter.Regarding the alginate printing, the filamentthickness is 0.29 mm and 0.2 mm for 22 G and 25 Gneedles, respectively, demonstrating the possibilityto print very thin features, especially with the 25 Gneedle. Since the relatively high pressure of 70 kPais not recommended for printing with cells, a 22 G1-inch needle was chosen for further bioprintingexperiments with cells. Finally, to show how FRESH helps print complexstructures, a hollow artery model with a bifurcation(Figure 3A) was 3D printed and perfused. This Figure 3. Complex structure of hollow arteryprinted with FRESH method. A) Hollow arteryCAD model. B) Printed construct. C) Perfusionof the artery. model was chosen because it is impossible toprint without a support bath or a sacrificial ink.Utilizing FRESH printing, this hollow artery witha bifurcation was printed (Figure 3B) successfully.The construct maintained its structure, and wasalso perfusable demonstrating the integrity of theprint (Figure 3C) CELL VIABILITY AND STRETCHING At day 1 (Figures 4A), MSCs were homogeneouslydistributed in the printed constructs, indicatingproper mixing of biomaterials with cells. Cellviability in TeloCol and PhotoCol constructs wasbetter than in alginate, which can be attributedto the higher printing pressure used for the moreviscous alginate bioink. These results show that FRESH bioprinting could negatively affect theviability of cells in viscous bioinks because ofthe stress imposed on cells from needle lengthand prolonged time without cell medium duringprinting. On day 7 (Figure 4B), there were manyMSCs stretching in all directions in TeloCol andPhotoCol constructs. While cells in the alginateconstructs were not able to stretch and remainedround, as expected for cell-neutral alginate. Day14 images (Figures 4C) highlight an increasednumber of stretched cells through the collagenbased constructs. There was however, an increasednumber of dead cells also observed at the center ofthe constructs. This increase could be attributed toa lack of oxygen and nutrients reaching these cells. TeloCol@ PhotoCol@ Alginate Figure 4. Representative images of the bioprinted MSCs stained with calcein AM (live cells) and propidium iodide (dead cells) at A) day1, B) day 7, and C) day 14 of culture. Magnification 4x. Conclusion In this study, we demonstrated the potential ofFRESH method using LifeSupport for printing softand liquid-like collagen and alginate biomaterialsusing extrusion-based 3D bioprinting. In particular,the proposed method enables printing complex structures without the need for sacrificial supportinks or ink modifiers to increase mechanicalstability, keeping the biological requirement of thebiomaterials. 1. Adamiak K, Sionkowska A. Current methods of collagen cross-linking: Review. International Journalof Biological Macromolecules. 2020;161:550-560.DOI:10.1016/j.ijbiomac.2020.06.075. 2. Adib AA, Sheikhi A, Shahhosseini M, et al. Direct-write 3D printing and characterization of a GelMA-based biomaterial for intracorporeal tissue engineering. Biofabrication. 2020; 12(4): 045006.DOI:10.1088/1758-5090/ab97a1. 3. Hazur J, Detsch R, Karakaya E, et al. Improving alginate printability for biofabrication:Establishment of a universal and homogeneous pre-crosslinking technique. Biofabrication. 2020;12(4): 045004.DOI:10.1088/1758-5090/ab98e5. 4. Heid S, Boccaccini AR. Advancing bioinks for 3D bioprinting using reactive fillers: A review. ActaBiomaterialia. 2020; 113: 1-22.DOI:10.1016/i.actbio.2020.06.040. 5. Hinton TJ,Jallerat Q, Palchesko NR, et al. Science Advances. 2015;1(9): e1500758.DOI:10.1126_sciadv.1500758. 6. Jeon O, Lee Y, Hinton T, Feinberg A, Alsberg E. Cryopreserved cell-laden alginate microgel bioinkfor 3D bioprinting of living tissues. Materials Today Chemistry. 2019; 12:61-70.DOI:10.1016/i.mtchem.2018.11.009. 7. Lee A, Hudson AR, Shiwarski DJ, et al. 3D bioprinting of collagen to rebuild components of thehuman heart. Science.2019;365:482-487.DOl:10.1126/science.aav90. 8. Shiwarski DJ, Hudson AR, Tashman JW, Feinberg AW. Emergence of FRESH 3D printingas a platform for advanced tissue biofabrication. APL Bioengineering. 2021;5(1):010904.DOI:10.1063/5.0032777. 9. Wu W, DeConinck A, Lewis JA. Omnidirectional printing of 3D microvascular networks. AdvancedMaterials. 2011;23(24): H178-H183.DOl:10.1002/adma.201004625. Read otherapplication notes @2022 BICO AB. All rights reserved. Duplication and/or reproduction of all or any portionof this document without the express written consent of BICO is strictly forbidden. Nothingcontained herein shall constitute any warranty, express or implied, as to the performance ofany products described herein. Any and all warranties applicable to any products are set forth inthe applicable terms and conditions of sale accompanying the purchase of such product. BICOprovides no warranty and hereby disclaims any and all warranties as to the use of any third-party products or protocols described herein. The use of products described herein is subject tocertain restrictions as set forth in the applicable terms and conditions of sale accompanyingthe purchase of such product. BICO may refer to the products or services offered by othercompanies by their brand name or company name solely for clarity and does not claim anyrights to those third-party marks or names. BICO products may be covered by one or morepatents. The use of products described herein is subject to BICO's terms and conditions of saleand such other terms that have been agreed to in writing between BICO and user. All productsand services described herein are intended FOR RESEARCH USE ONLY and NOT FOR USE INDIAGNOSTIC PROCEDURES. The use of BICO products in practicing the methods set forth herein has not been validatedby BICO, and such nonvalidated use is NOT COVERED BY BICO'S STANDARD WARRANTY,AND BICO HEREBY DISCLAIMS ANY AND ALL WARRANTIES FOR SUCH USE. Nothing in thisdocument should be construed as altering, waiving or amending in any manner BICO's termsand conditions of sale for the instruments, consumables or software mentioned, includingwithout limitation such terms and conditions relating to certain use restrictions, limitedlicense, warranty and limitation of liability, and nothing in this document shall be deemed to beDocumentation, as that term is set forth in such terms and conditions of sale. Nothing in thisdocument shall be construed as any representation by BICO that it currently or will at any timein the future offer or in any way support any application set forth herein.

确定

还剩6页未读,是否继续阅读?

上海迹亚国际商贸有限公司为您提供《FRESH Bioprinting of Soft Biomaterials》,该方案主要用于其他中胶原蛋白打印检测,参考标准--,《FRESH Bioprinting of Soft Biomaterials》用到的仪器有Cellink BIO X6 3D生物打印机

推荐专场

相关方案

更多

该厂商其他方案

更多