硅橡胶片的导热系数测量 应用资料

硅橡胶是一种主要由硅树脂组成的类橡胶合成树脂。由于其优异的耐热性、耐水性、耐化学性,应用广泛,这里的快速导热系数测定仪采用硅橡胶块作为参考板。在本研究中,我们在[薄膜测量]模式下测量了厚度分别为2mm、3mm、5mm的硅橡胶片,以验证橡胶块的导热特性是否与橡胶片的导热特性相匹配。

方案详情

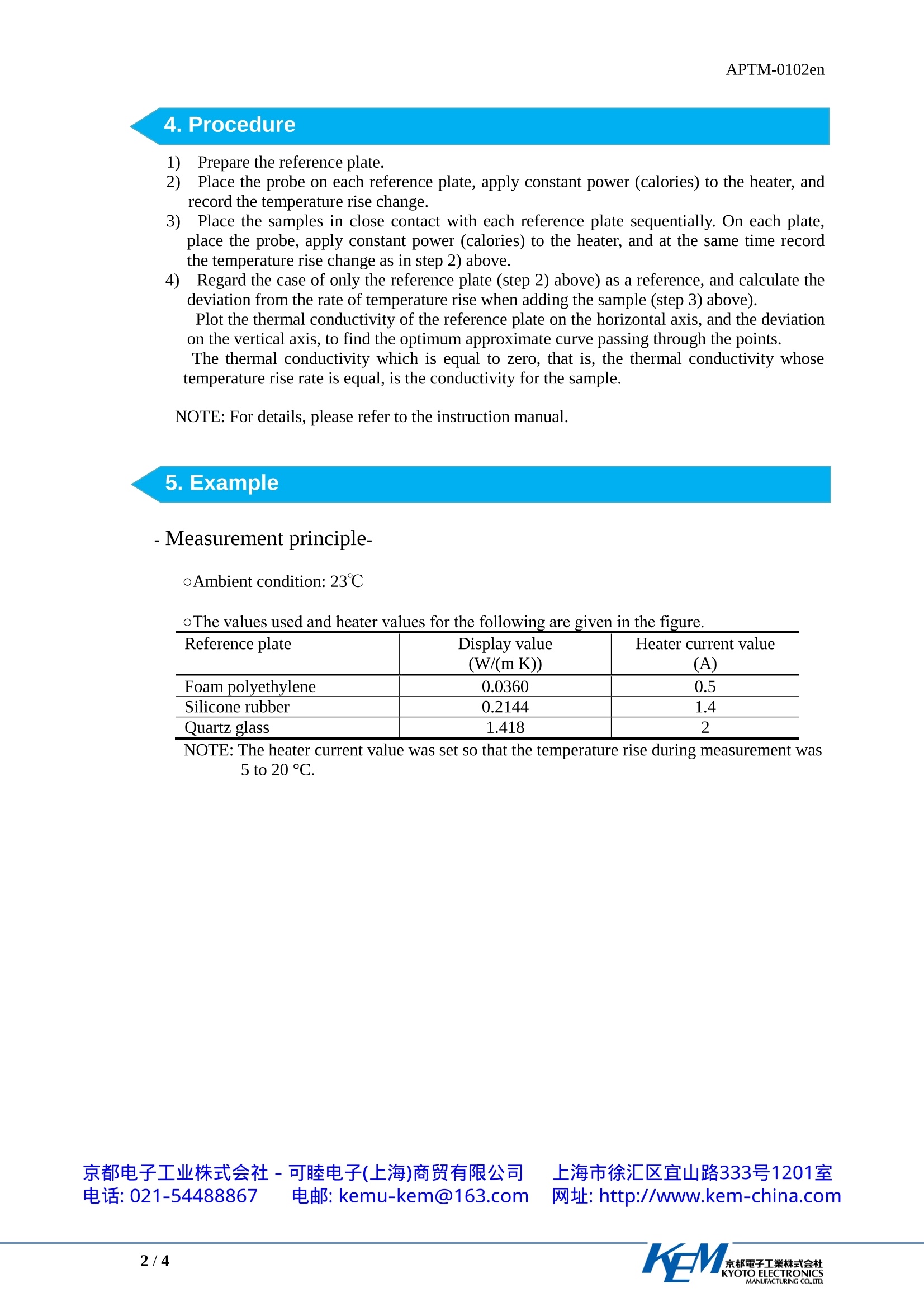

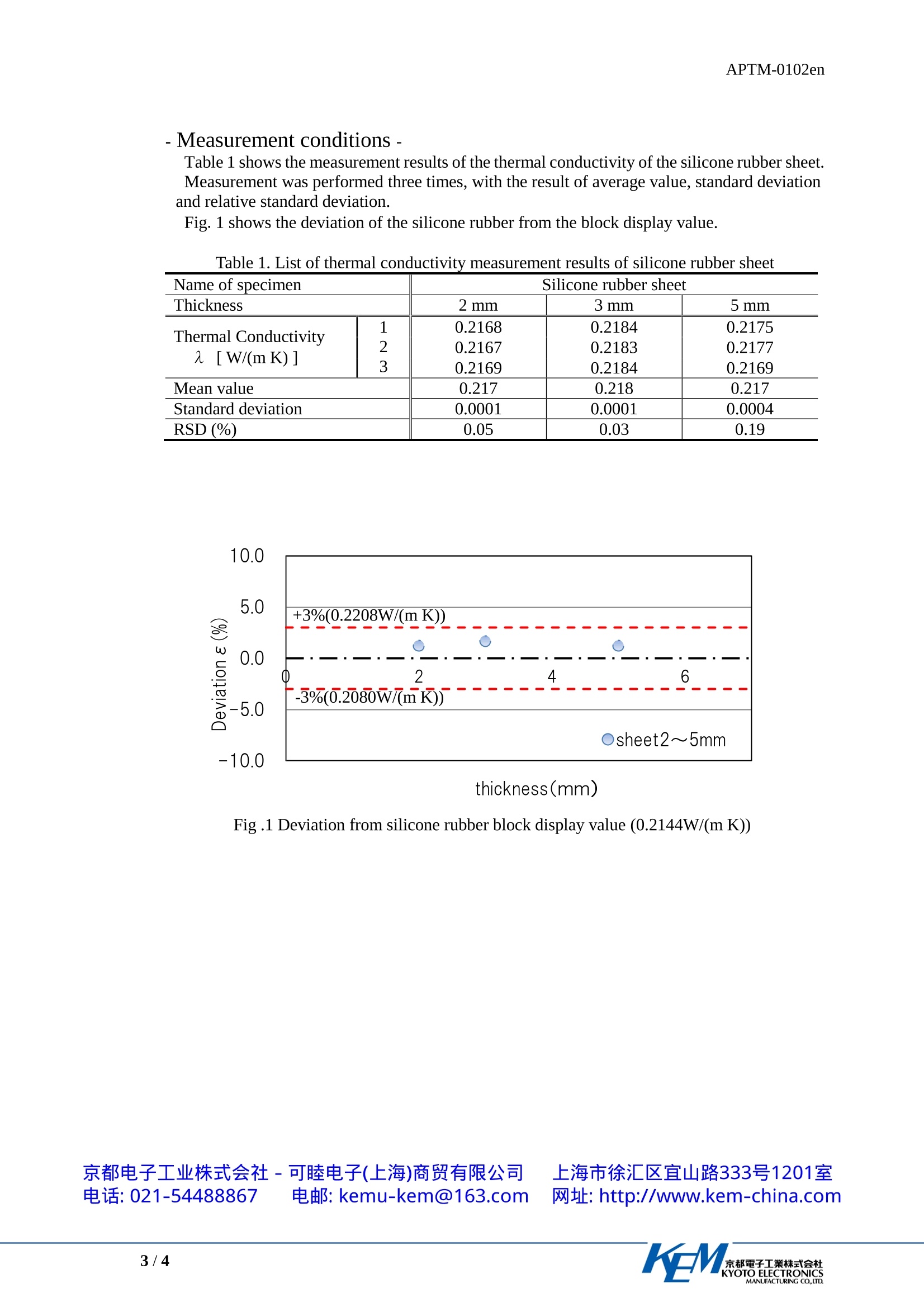

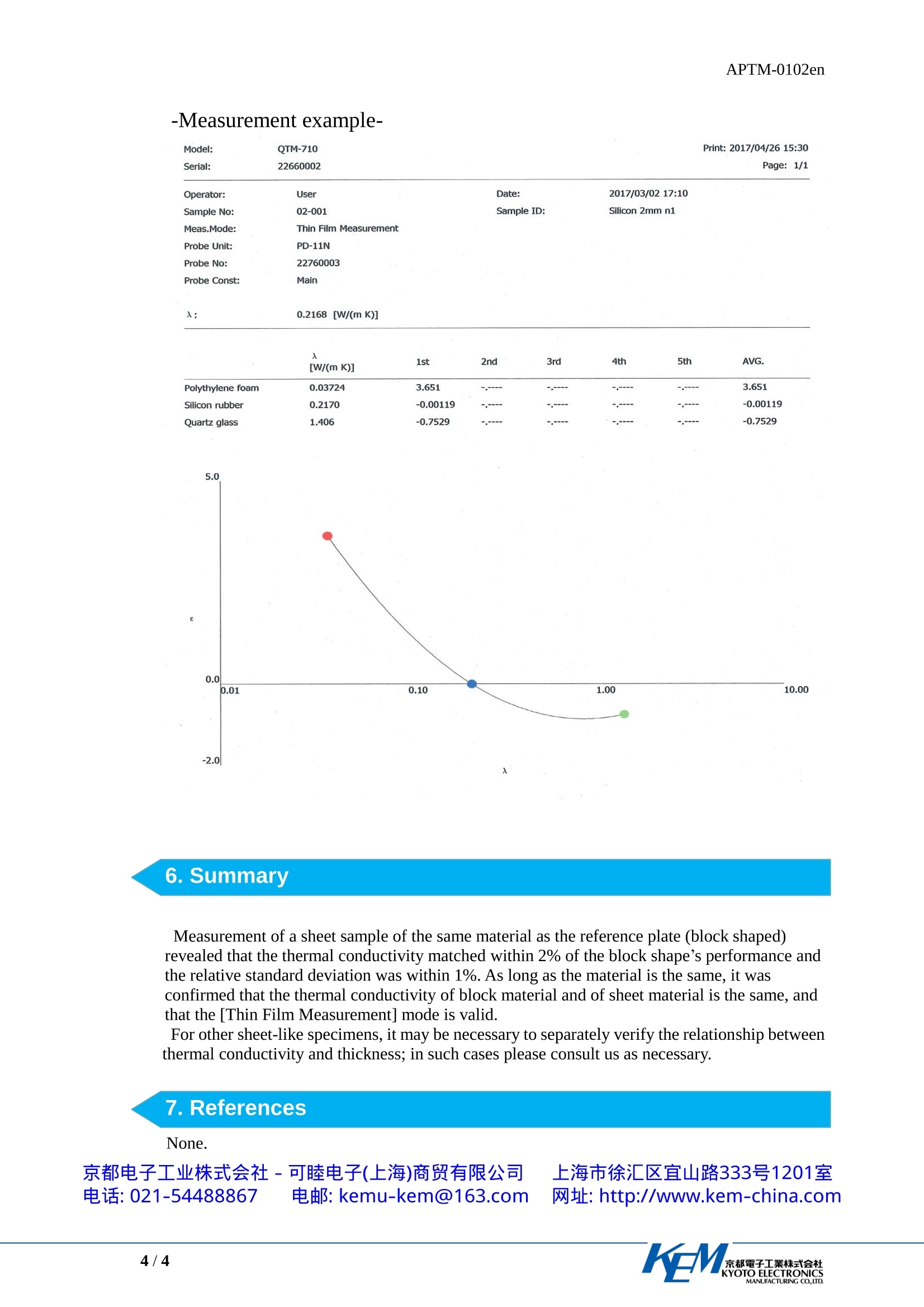

京都電子工業株式会社KYOTO ELECTRONICSMANUFACTURING CO.,LTD.APTM-0102en APTM-0102er Application Note Silicone Rubber Sheet Thermal Conductivity Measurement IndustryPlastic & rubberInstrumentQuick Thermal Conductivity MeterMeasurement method:Hot wire comparative methodStandard 1.Scope Silicone rubber is a rubber-like synthetic resin mainly composed of silicone. Because of its excellent heat resistance, water resistance and chemical resistance, it is used inmany applications, and here, the Quick Thermal Conductivity Meter has adopted silicone rubberblock as the reference plate. In this study, we measured silicone rubber sheet with thicknesses of 2mm, 3 mm, 5 mm in the [Thin Film Measurement] mode, to verify whether the thermalconductivity characteristics of the rubber block match with those of the rubber sheet. 2.Precautions Avoid trapping air between the sample and the probe when setting. If pockets of air exist, they will affect the thermal conductivity measurement result. · Prepare a flat specimen with no irregularities or undulations on the sample surface. · If there is dust on the sample surface or probe, wipe it off. For the amount of heat applied to the sample, determine the heater current value so that thetemperature rise during measurement is 5 to 20 °C. Set the heater current value from [HEATER] on the main unit and select the heater current valueto be used according to the sample.Excessive heating may cause breakage of samples andreferences. Refer to the instruction manual for current value guidelines. Measure the sample by allowing it to fully conform to the measurement environmentaltemperature. 3.Apparatus Main unit Quick Thermal Conductivity Meter (Thin Film Measurement) Probe PD-11N(Box type probe) Reference plate Polyethylene foam, Silicone rubber , Quartz glass 4. Procedure Prepare the reference plate. Place the probe on each reference plate, apply constant power (calories) to the heater, andrecord the temperature rise change. 3)Place the samples in close contact with each reference plate sequentially. On each plate,place the probe, apply constant power (calories) to the heater, and at the same time recordthe temperature rise change as in step 2) above. 4) Regard the case of only the reference plate (step 2) above) as a reference, and calculate thedeviation from the rate of temperature rise when adding the sample (step 3) above). Plot the thermal conductivity of the reference plate on the horizontal axis, and the deviationon the vertical axis, to find the optimum approximate curve passing through the points. The thermal conductivity which is equal to zero, that is, the thermal conductivity whosetemperature rise rate is equal, is the conductivity for the sample. NOTE: For details, please refer to the instruction manual. 5.Example -Measurement principle- oAmbient condition: 23℃ oThe values used and heater values for the following are given in the figure. Reference plate Display value(W/(m K)) Heater current value (A) Foam polyethylene 0.0360 0.5 Silicone rubber 0.2144 1.4 Quartz glass 1.418 2 NOTE: The heater current value was set so that the temperature rise during measurement was5 to 20 °C. -Measurement conditions - Table 1 shows the measurement results ofthe thermal conductivity of the silicone rubber sheet.Measurement was performed three times, with the result of average value, standard deviationand relative standard deviation. Fig. 1 shows the deviation of the silicone rubber from the block display value. Table 1. List of thermal conductivity measurement results of silicone rubber sheet Name of specimen Silicone rubber sheet Thickness 2mm 3mm 5 mm Thermal Conductivity 123 0.2168 0.2167 0.2184 0.2175 0.2177 a[W/(mK)] 0.2169 0.2183 0.2184 0.2169 Mean value 0.217 0.218 0.217 Standard deviation 0.0001 0.0001 0.0004 RSD (%) 0.05 0.03 0.19 thickness(mm) Fig .1 Deviation from silicone rubber block display value (0.2144W/(mK)) 京都电子工业株式会社-可睦电子(上海)商贸有限公司电话: 021-54488867 电邮: kemu-kem@163.com -Measurement example- Model: QTM-710 Operator: User Date: 2017/03/0217:10 Sample No: 02-001 Sample ID: Silicon 2mm n1 Meas.Mode: Thin Film Measurement Probe Unit: PD-11N Probe No: 22760003 Probe Const: Main 入: 0.2168 [W/(m K)] 入 1st4th[W/(m K)] 2nd 3rd 5th AVG. 6. Summarv Measurement of a sheet sample of the same material as the reference plate (block shaped)revealed that the thermal conductivity matched within 2% of the block shape’s performance andthe relative standard deviation was within 1%. As long as the material is the same, it wasconfirmed that the thermal conductivity of block material and of sheet material is the same, andthat the [Thin Film Measurement] mode is valid. For other sheet-like specimens, it may be necessary to separately verify the relationship betweenthermal conductivity and thickness; in such cases please consult us as necessary. 7.References None. 京都电子工业株式会社-可睦电子(上海)商贸有限公司电话:021-54488867 电邮:kemu-kem@163.com 上海市徐汇区宜山路333号1201室网址: http://www.kem-china.com 都電子工業株式会社KYOTO ELECTRONICSMANUFACTURING CO.,LTD. 硅橡胶片的导热系数测量 应用资料(英文版)硅橡胶是一种主要由硅树脂组成的类橡胶合成树脂。由于其优异的耐热性、耐水性、耐化学性,应用广泛,这里的快速导热系数测定仪采用硅橡胶块作为参考板。在本研究中,我们在[薄膜测量]模式下测量了厚度分别为2mm、3mm、5mm的硅橡胶片,以验证橡胶块的导热特性是否与橡胶片的导热特性相匹配。

确定

还剩2页未读,是否继续阅读?

可睦电子(上海)商贸有限公司-日本京都电子(KEM)为您提供《硅橡胶片中导热系数检测方案(导热仪)》,该方案主要用于硅橡胶中导热系数检测,参考标准--,《硅橡胶片中导热系数检测方案(导热仪)》用到的仪器有QTM-710/QTM-700快速导热系数测定仪

推荐专场

该厂商其他方案

更多