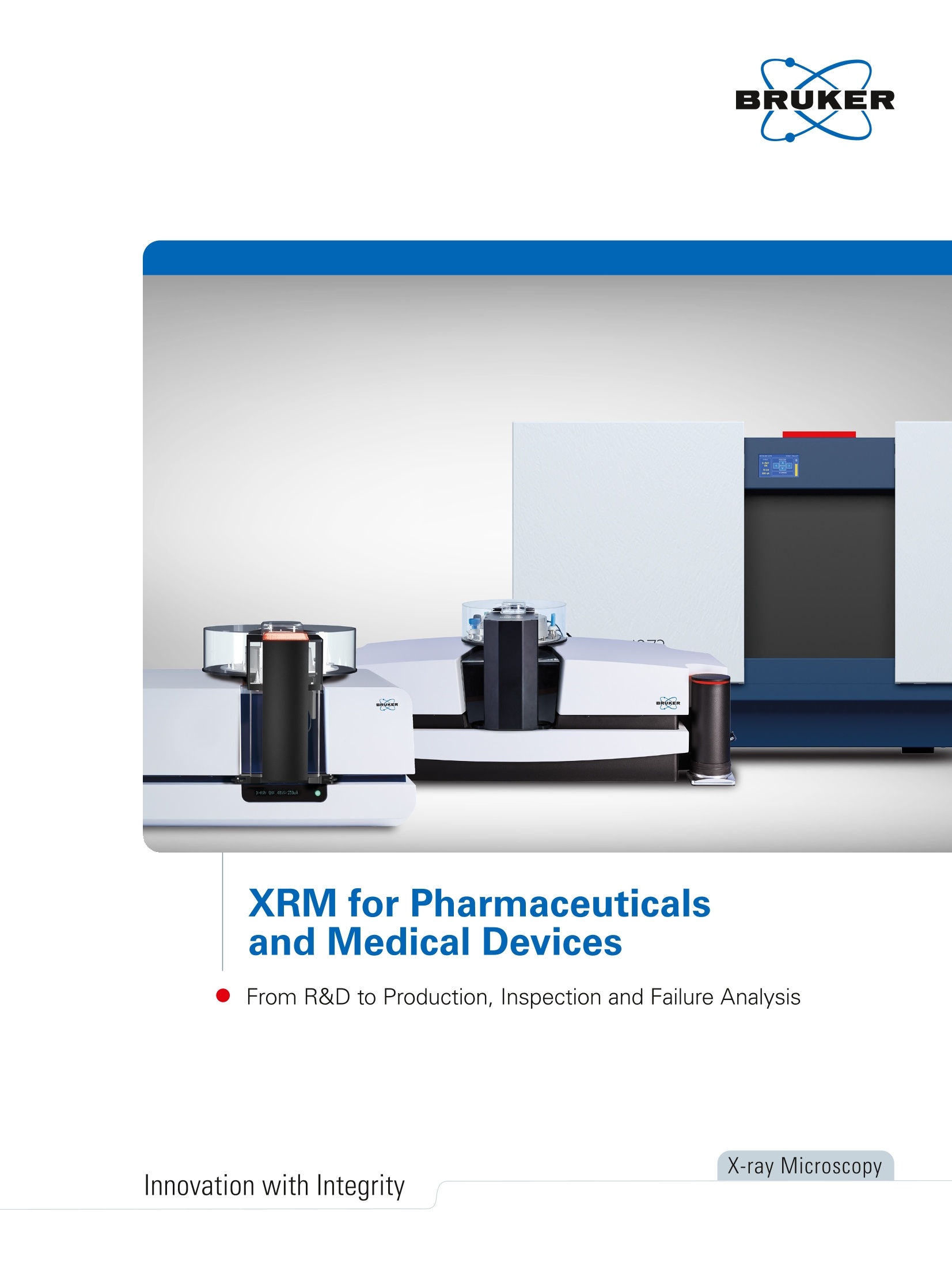

三维X射线显微镜是当前获取样品内部三维结构最有力的工具之一,而且作为无损的非破坏成像技术,它适用于各种形态的样品,无需包埋,镀层或切片等复杂的样品前处理。布鲁克skyscan系列三维X射线纤维成像系统,包含稳定易用的高分辨率成像设备,功能强大的软件套装,可为不同领域的应用提供完善的解决方案。

我们为大家带来桌面型三维X射线显微镜在药物与医疗器械领域的应用介绍。

方案详情

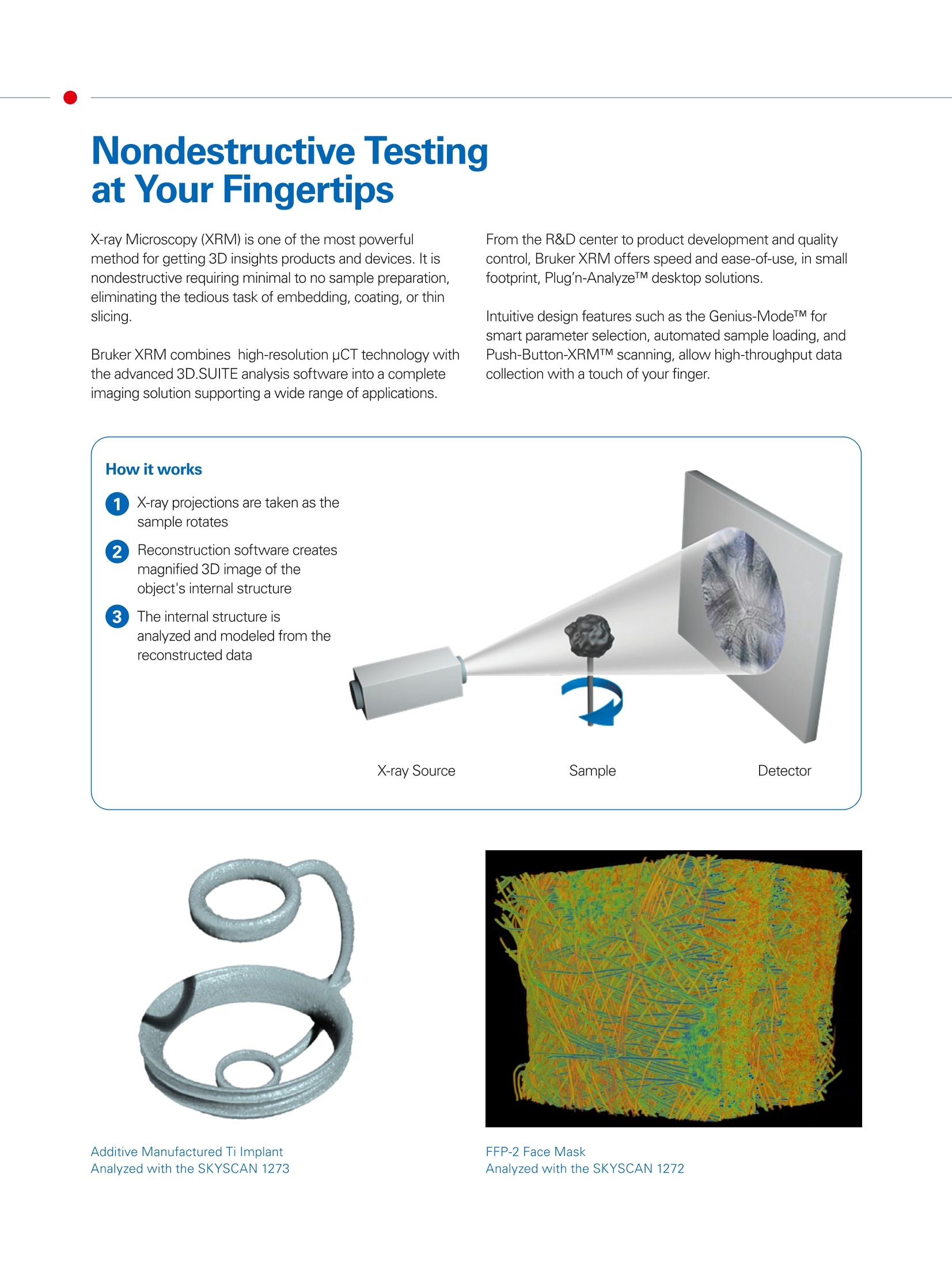

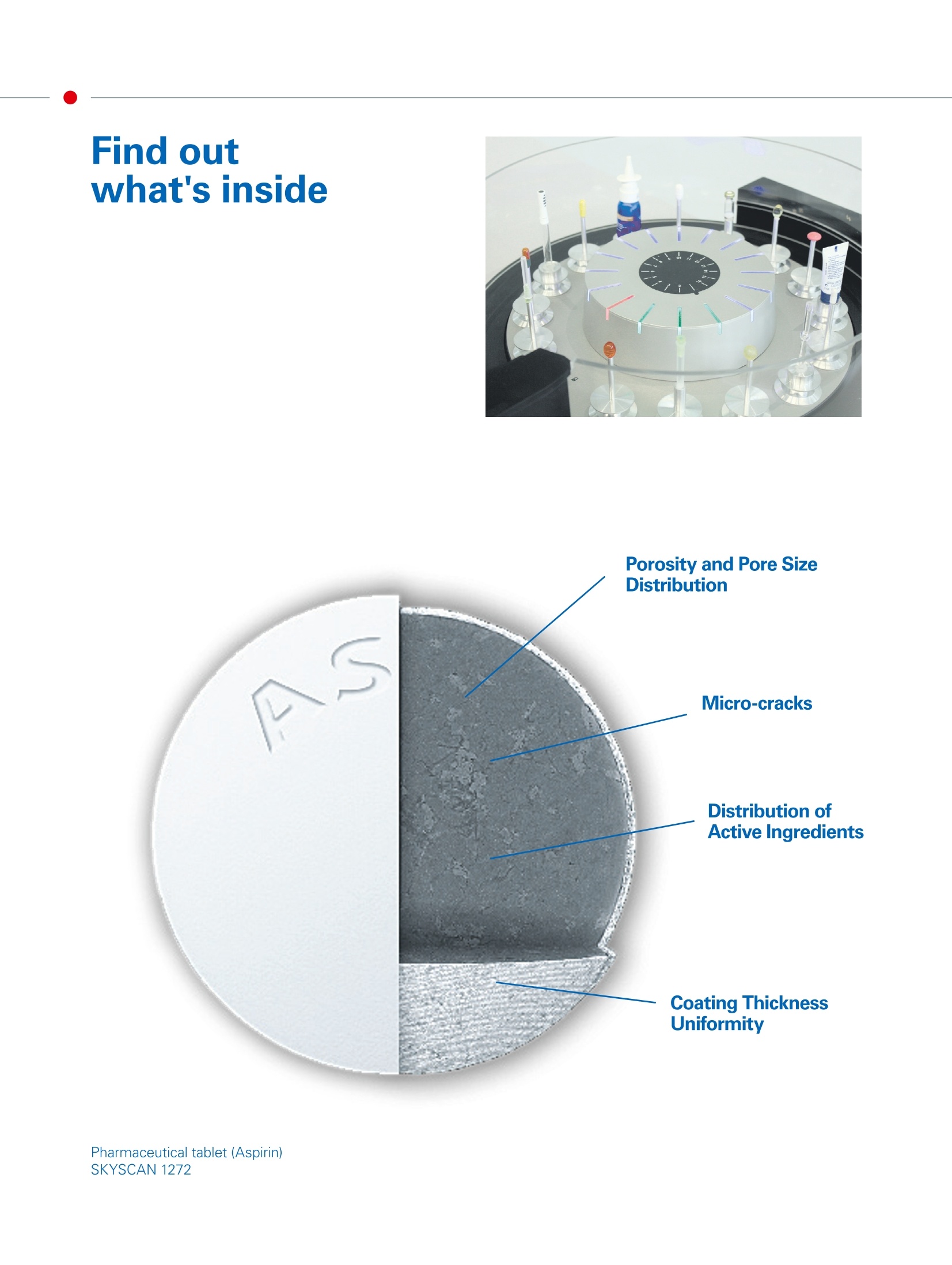

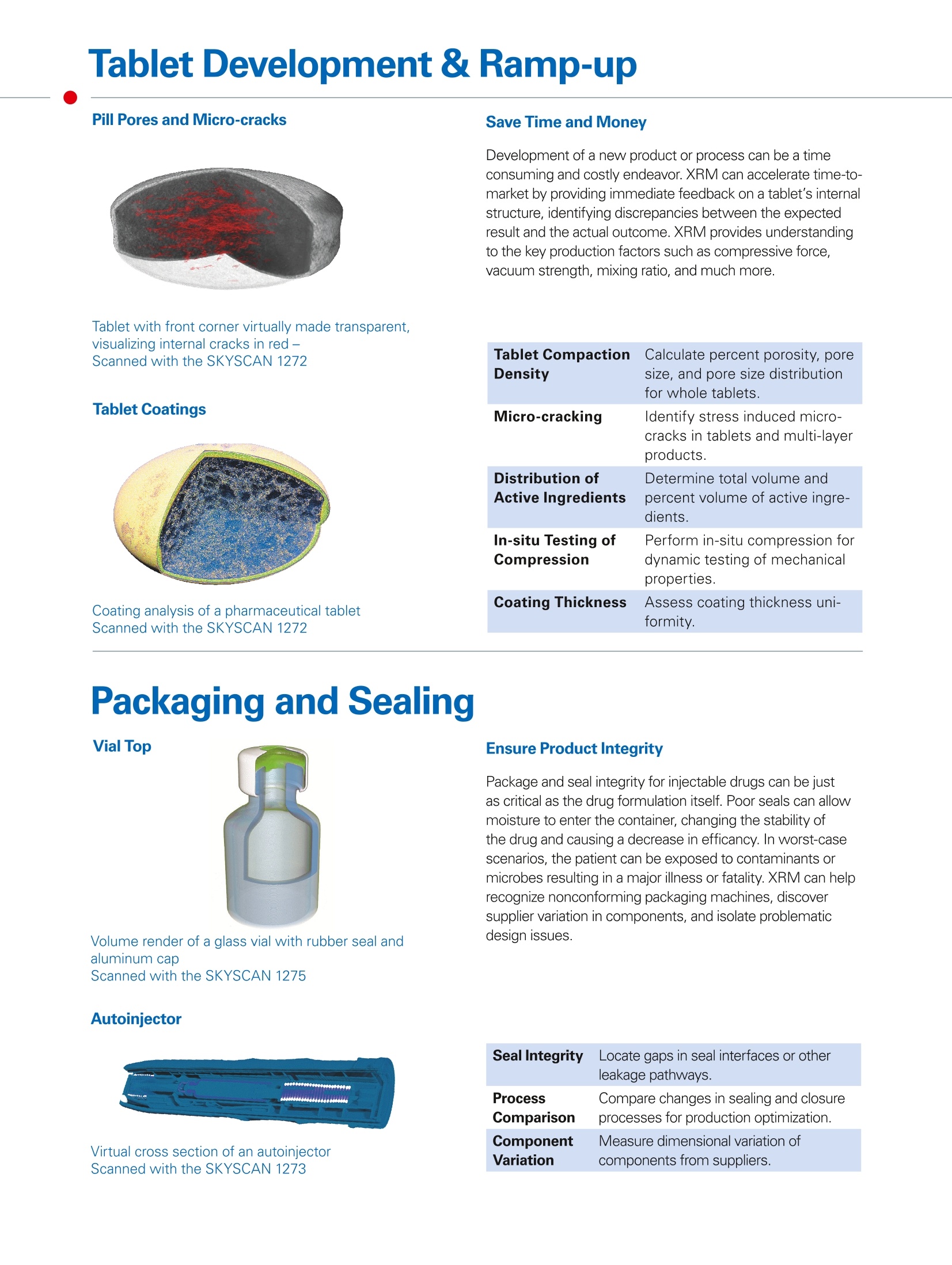

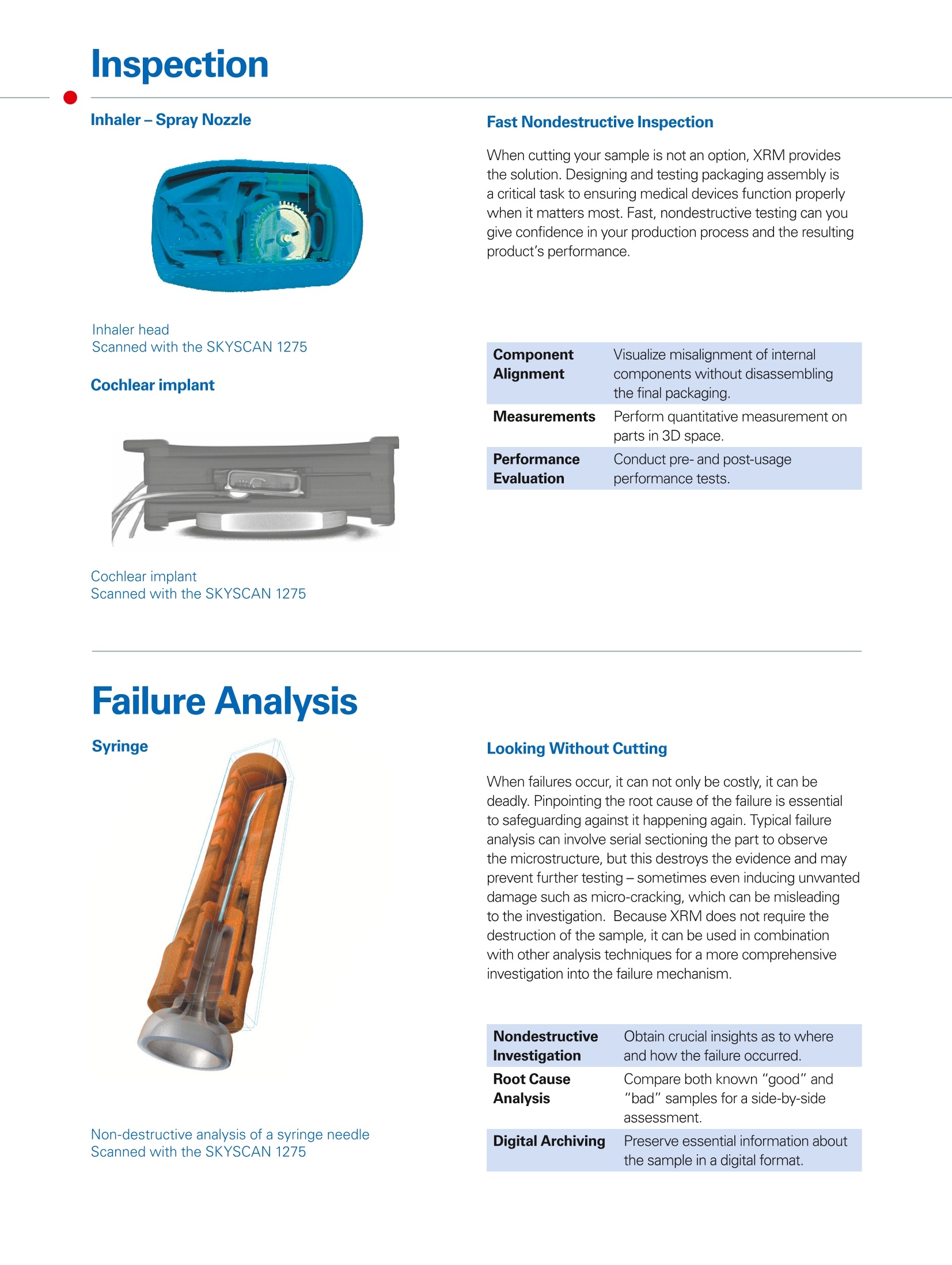

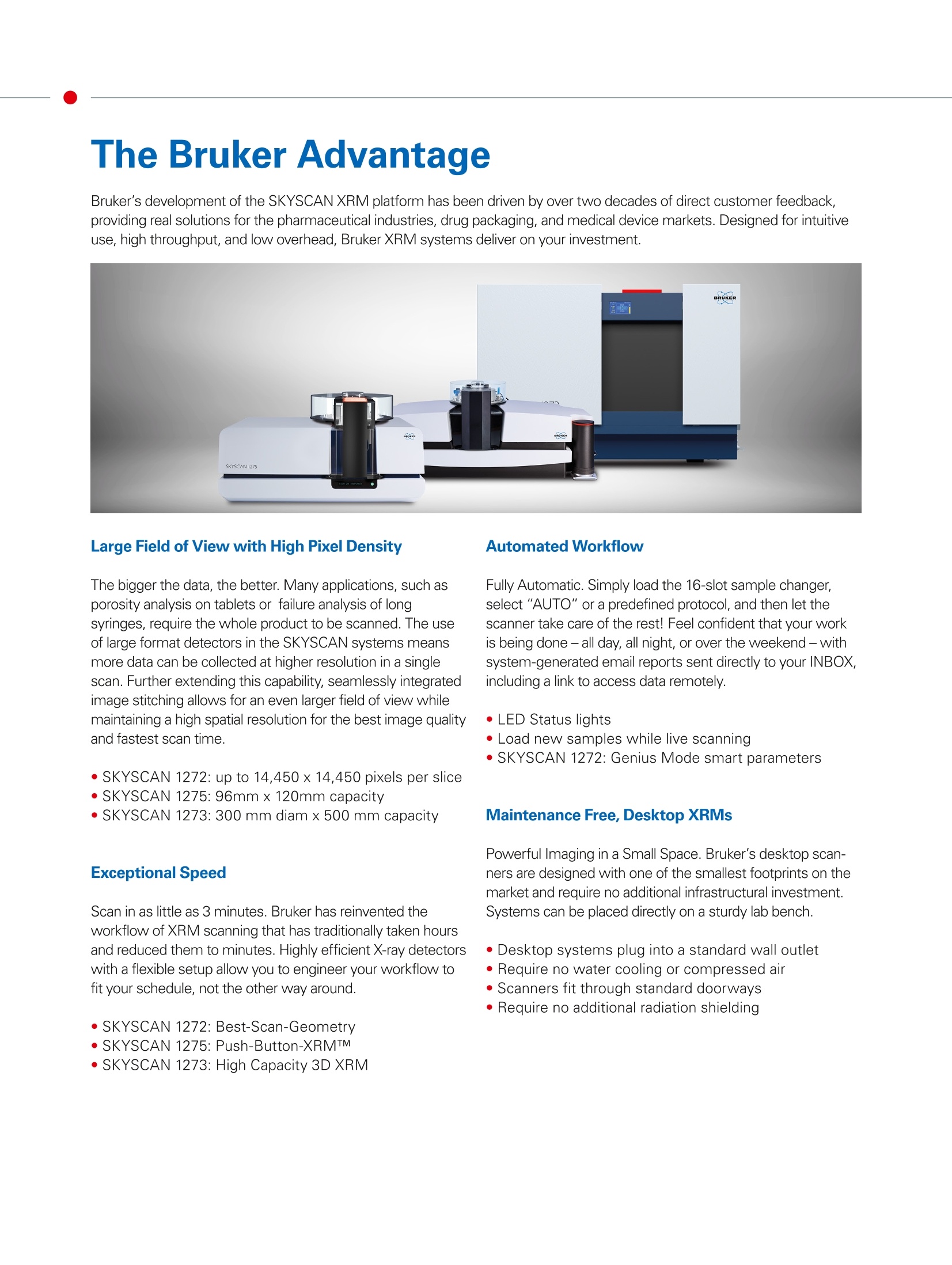

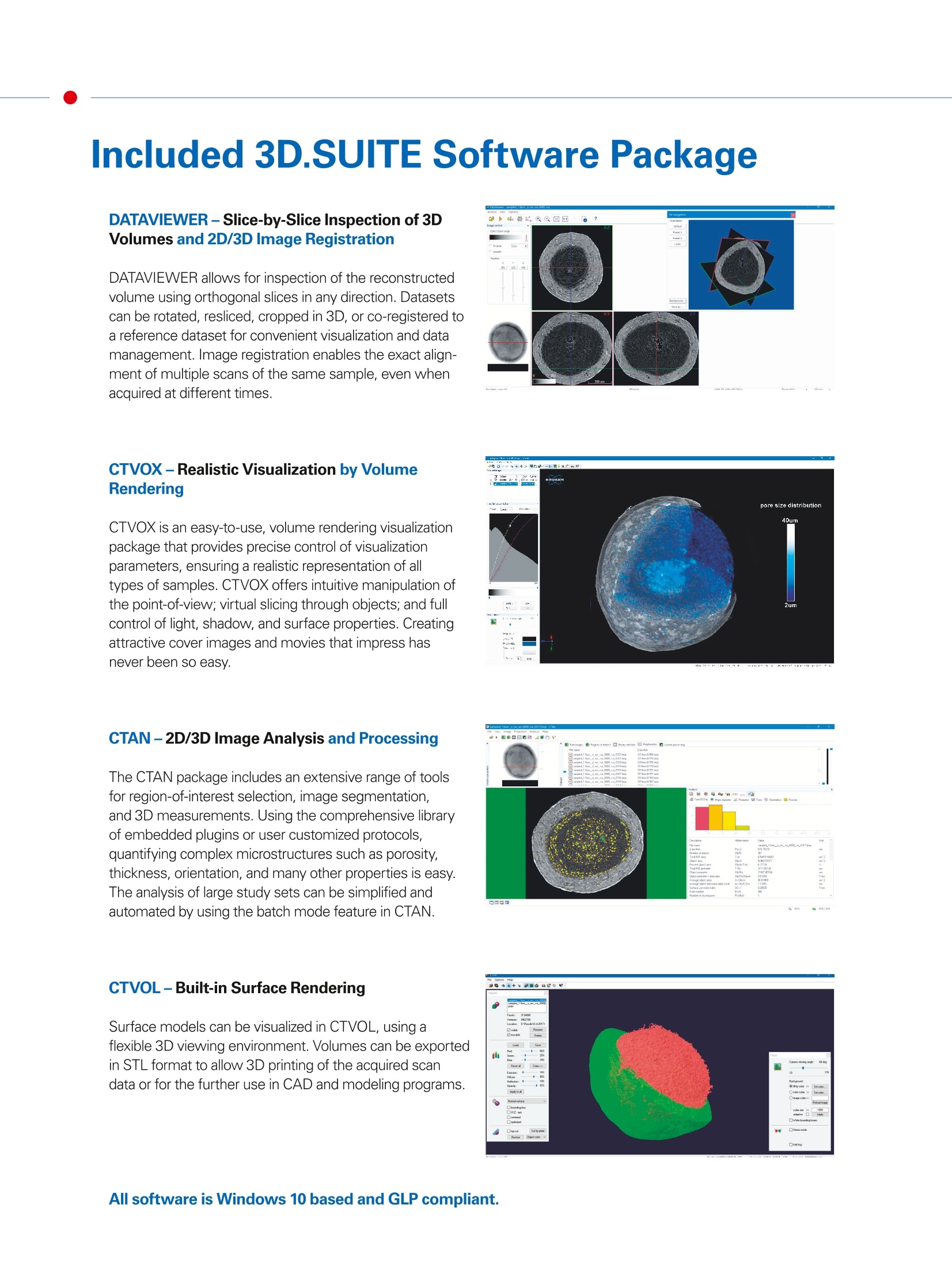

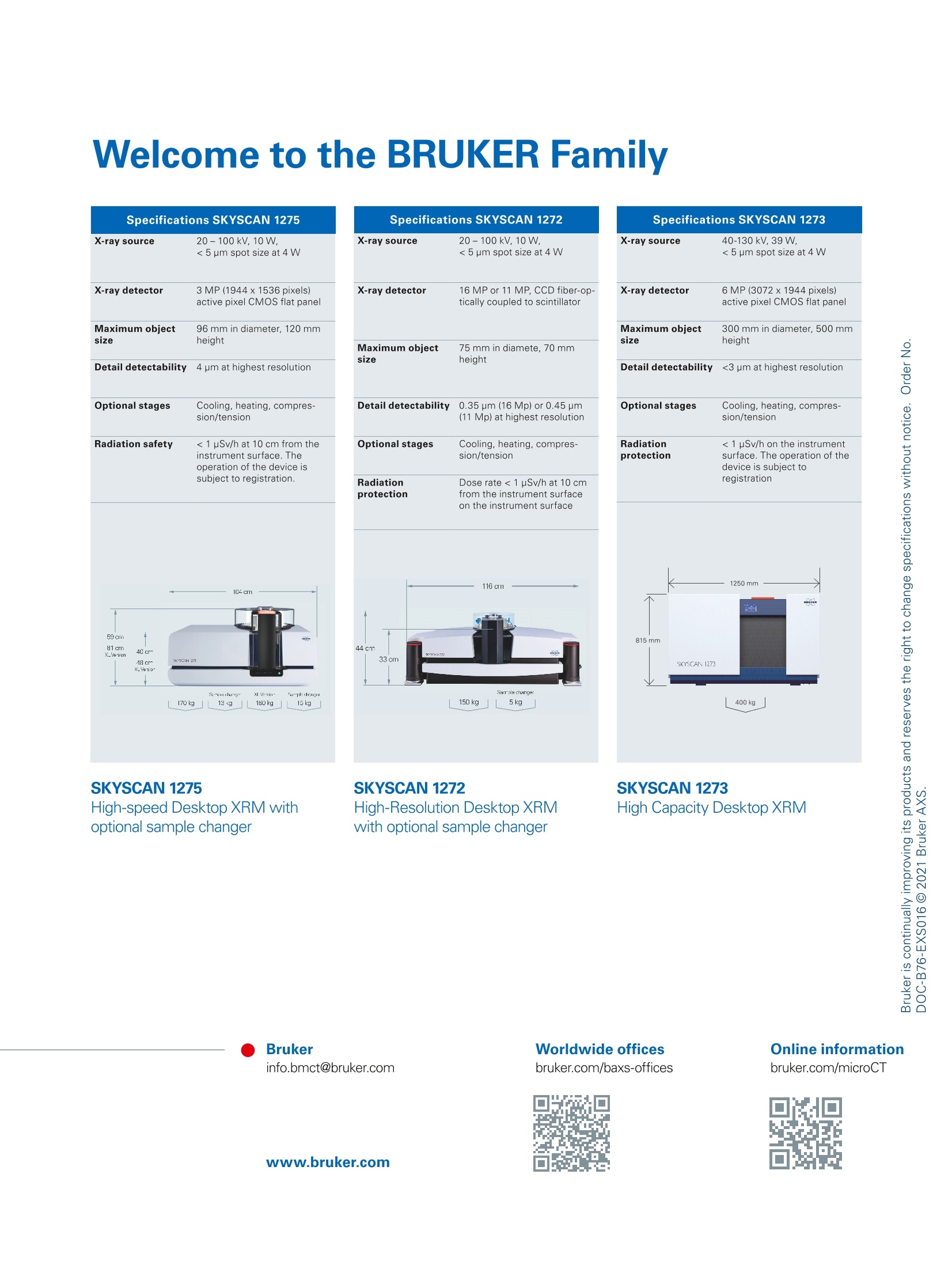

Tablet Development & Ramp-up Oe BROKER ON: 43kW/250UA XRM for Pharmaceuticalsand Medical Devices From R&D to Production, Inspection and Failure Analysis Nondestructive Testingat Your Fingertips X-ray Microscopy (XRM) is one of the most powerfulmethod for getting 3D insights products and devices. It isnondestructive requiring minimal to no sample preparation,eliminating the tedious task of embedding, coating, or thinslicing. Bruker XRM combines high-resolution pCT technology withthe advanced 3D.SUITE analysis software into a completeimaging solution supporting a wide range of applications. From the R&D center to product development and qualitycontrol, Bruker XRM offers speed and ease-of-use, in smallfootprint, Plug'n-AnalyzeTM desktop solutions. Intuitive design features such as the Genius-ModeTM forsmart parameter selection, automated sample loading, andPush-Button-XRMTM scanning, allow high-throughput datacollection with a touch of your finger. Additive Manufactured Ti ImplantAnalyzed with the SKYSCAN 1273 FFP-2 Face Mask Analyzed with the SKYSCAN 1272 Find outwhat's inside Pill Pores and Micro-cracks Tablet with front corner virtually made transparent,visualizing internal cracks in red -Scanned with the SKYSCAN 1272 Tablet Coatings Coating analysis of a pharmaceutical tabletScanned with the SKYSCAN 1272 Save Time and Money Development of a new product or process can be a timeconsuming and costly endeavor. XRM can accelerate time-to-market by providing immediate feedback on a tablet's internalstructure, identifying discrepancies between the expectedresult and the actual outcome. XRM provides understandingto the key production factors such as compressive force,vacuum strength, mixing ratio, and much more. Tablet Compaction (Calculate percent porosity, pore Density size, and pore size distribution for whole tablets. Micro-cracking Identify stress induced micro-cracks in tablets and multi-layer products. Distribution of Determine total volume and Active Ingredients percent volume of active ingre- dients. In-situ Testing of Perform in-situ compression for Compression dynamic testing of mechanical properties. Coating Thickness Assess coating thickness uni- formity. Packaging and Sealing Vial Top Volume render of a glass vial with rubber seal andaluminum cap Scanned with the SKYSCAN 1275 Autoinjector Ensure Product Integrity Package and seal integrity for injectable drugs can be justas critical as the drug formulation itself. Poor seals can allowmoisture to enter the container, changing the stability ofthe drug and causing a decrease in efficancy. In worst-casescenarios, the patient can be exposed to contaminants ormicrobes resulting in a major illness or fatality. XRM can helprecognize nonconforming packaging machines, discoversupplier variation in components, and isolate problematicdesign issues. Seal Integrity Locate gaps in seal interfaces or otherleakagepathways. Compare changes in sealing and closureprocesses for production optimization. Inhaler-Spray Nozzle Inhaler head Scanned with the SKYSCAN 1275 Cochlear implant Cochlear implantScanned with the SKYSCAN 1275 Failure Analysis Syringe Non-destructive analysis of a syringe needleScanned with the SKYSCAN1275 Fast Nondestructive Inspection When cutting your sample is not an option, XRM providesthe solution. Designing and testing packaging assembly isa critical task to ensuring medical devices function properlywhen it matters most. Fast, nondestructive testing can yougive confidence in your production process and the resultingproduct's performance. Component Visualize misalignment of internal Alignment components without disassembling the final packaging. Measurements Perform quantitative measurement on parts in 3D space. Performance Conduct pre-and post-usage Evaluation performance tests. Looking Without Cutting When failures occur, it can not only be costly, it can bedeadly. Pinpointing the root cause of the failure is essentialto safeguarding against it happening again. Typical failureanalysis can involve serial sectioning the part to observethe microstructure, but this destroys the evidence and mayprevent further testing-sometimes even inducing unwanteddamage such as micro-cracking, which can be misleadingto the investigation. Because XRM does not require thedestruction of the sample, it can be used in combinationwith other analysis techniques for a more comprehensiveinvestigation into the failure mechanism. Nondestructive Obtain crucial insights as to where Investigation and how the failure occurred. Root Cause Compare both known"good" and Analysis "bad" samples for a side-by-side assessment. Digital Archiving Preserve essential information about the sample in a digital format. The Bruker Advantage Bruker's development of the SKYSCAN XRM platform has been driven by over two decades of direct customer feedback,providing real solutions for the pharmaceutical industries, drug packaging, and medical device markets. Designed for intuitiveuse, high throughput, and low overhead, Bruker XRM systems deliver on your investment. The bigger the data, the better. Many applications, such asporosity analysis on tablets or failure analysis of longsyringes, require the whole product to be scanned. The useof large format detectors in the SKYSCAN systems meansmore data can be collected at higher resolution in a singlescan. Further extending this capability, seamlessly integratedimage stitching allows for an even larger field of view whilemaintaining a high spatial resolution for the best image qualityand fastest scan time. SKYSCAN 1272: up to 14,450x 14,450 pixels per sliceSKYSCAN 1275: 96mm x 120mm capacity SKYSCAN 1273: 300 mm diam x 500 mm capacity Scan in as little as 3 minutes. Bruker has reinvented the, workflow of XRM scanning that has traditionally taken hoursand reduced them to minutes. Highly efficient X-ray detectorswith a flexible setup allow you to engineer your workflow tofit your schedule, not the other way around. SKYSCAN 1272: Best-Scan-Geometrv SKYSCAN 1275: Push-Button-XRMTM SKYSCAN 1273: High Capacity 3D XRM Automated Workflow Fully Automatic. Simply load the 16-slot sample changer,select "AUTO" or a predefined protocol, and then let thescanner take care of the rest! Feel confident that your workis being done-all day, all night, or over the weekend - withsystem-generated email reports sent directly to your INBOX,including a link to access data remotely. ●' LED Status lights Load new samples while live scanning ' SKYSCAN 1272: Genius Mode smart parameters Maintenance Free, Desktop XRMs Powerful Imaging in a Small Space. Bruker's desktop scan-ners are designed with one of the smallest footprints on themarket and require no additional infrastructural investment.Systems can be placed directly on a sturdy lab bench. Desktop systems plug into a standard wall outletRequire no water cooling or compressed airScanners fit through standard doorwaysRequire no additional radiation shielding Included 3D.SUITE Software Package DATAVIEWER-Slice-by-Slice Inspection of 3DVolumes and 2D/3D Image Registration DATAVIEWER allows for inspection of the reconstructedvolume using orthogonal slices in any direction. Datasetscan be rotated, resliced, cropped in 3D, or co-registered toa reference dataset for convenient visualization and datamanagement. Image registration enables the exact align-ment of multiple scans of the same sample, even whenacquired at different times. CTVOX-Realistic Visualization by VolumeRendering CTVOX is an easy-to-use, volume rendering visualizationpackage that provides precise control of visualizationparameters, ensuring a realistic representation of alltypes of samples. CTVOX offers intuitive manipulation ofthe point-of-view; virtual slicing through objects; and fullcontrol of light, shadow, and surface properties. Creatingattractive cover images and movies that impress hasnever been so easv. CTAN-2D/3D Image Analysis and Processing The CTAN package includes an extensive range of toolsfor region-of-interest selection, image segmentation,and 3D measurements. Using the comprehensive libraryof embedded plugins or user customized protocols,quantifying complex microstructures such as porosity,thickness, orientation, and many other properties is easy.The analysis of large study sets can be simplified andautomated by using the batch mode feature in CTAN. CTVOL-Built-in Surface Rendering Surface models can be visualized in CTVOL, using aflexible 3D viewing environment. Volumes can be exportedin STL format to allow 3D printing of the acquired scandata or for the further use in CAD and modeling programs. .. size SKYSCAN 1275 High-speed Desktop XRM withoptional sample changer Welcome to the BRUKER Family X-ray source 20-100 kV, 10 W, X-ray source < 5 pm spot size at 4 W X-ray detector 3 MP (1944x1536 pixels)active pixel CMOS flat panel size Maximum object 96 mm in diameter, 120 mm size height Detail detectability 4 pm at highest resolution Optional stages Cooling, heating, compres- Optional stages sion/tension Radiation safety <1 pSv/h at 10 cm from the protection instrument surface.The operation of the device is subject to registration. SKYSCAN 1272 High-Resolution Desktop XRMwith optional sample changer SKYSCAN 1273High Capacity Desktop XRM Worldwide officesbruker.com/baxs-offices Online informationbruker.com/microCT X-ray MicroscopyInnovation with Integrity Pharmaceutical tablet (Aspirin)SKYSCAN

确定

还剩6页未读,是否继续阅读?

布鲁克衍射荧光事业部(Bruker AXS)为您提供《药物与医疗器械中应用检测方案(工业CT)》,该方案主要用于其他中其他检测,参考标准--,《药物与医疗器械中应用检测方案(工业CT)》用到的仪器有布鲁克三维X射线显微镜 micro CT、布鲁克三维X射线显微镜 micro CT

推荐专场

相关方案

更多