方案详情

文

聚氯乙烯(PVC)是最常见的聚合物之一。聚氯乙烯(PVC)中增塑剂含量需要在一定范围内,从而确保产品在使用中有合适的硬度和韧性。 MQC+ 台式核磁共振分析仪提供了无需溶剂的替代检测方案。该方法检测快速、易于操作和校准,更大程度简化了样品制备工作。

方案详情

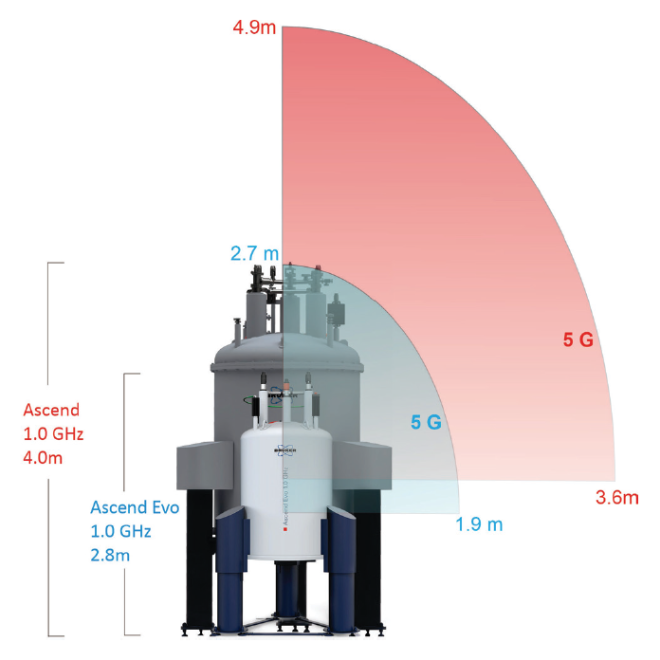

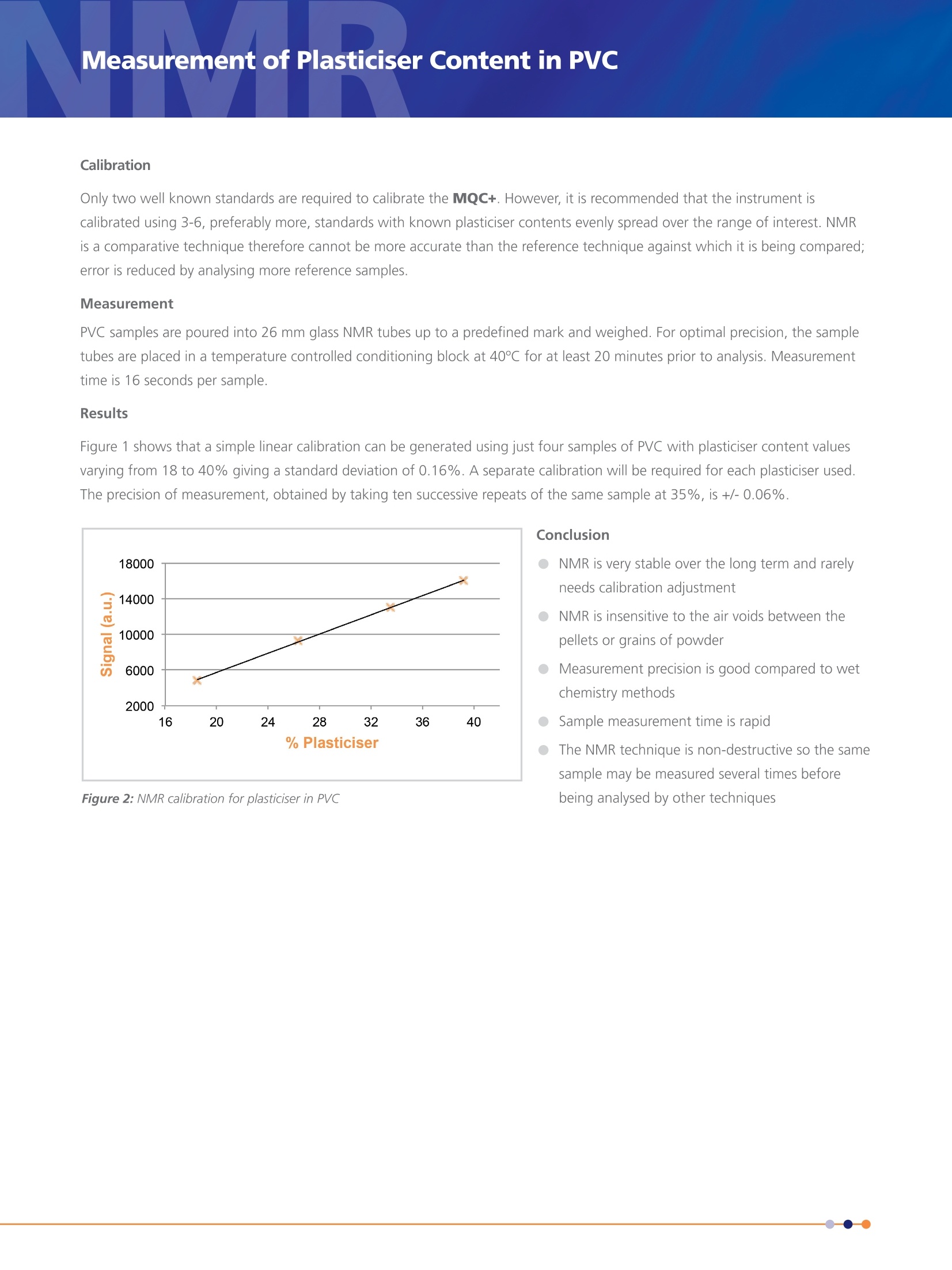

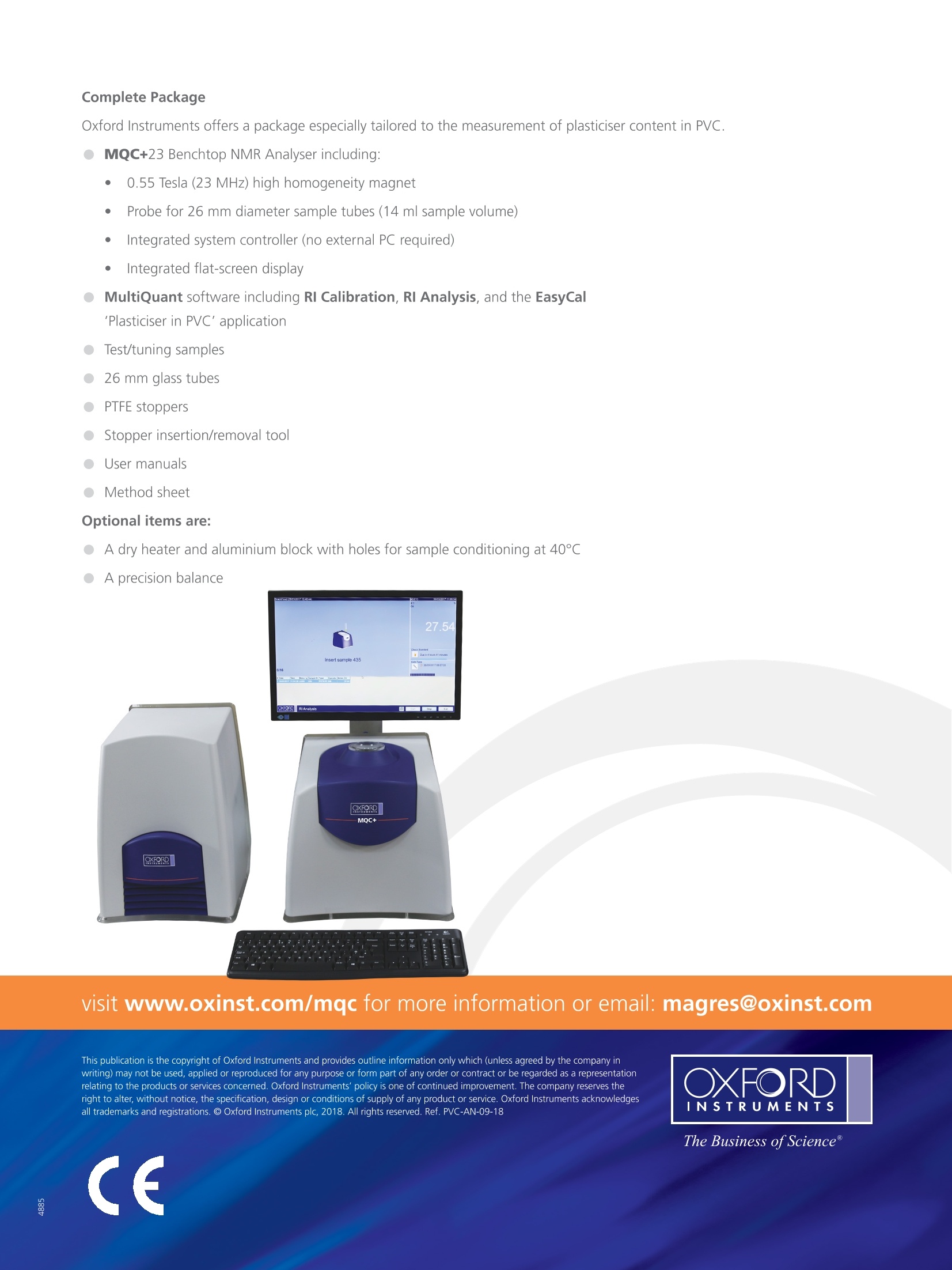

Measurement of Plasticiser Content in PVC Application Note 23 Application Polyvinyl chloride (PVC) is a versatile thermoplastic which isused for construction, bottles, packaging, floor coverings,coatings and tubing. It can be rigid or flexible, dependingon the amount of additives, plasticisers, fillers and pigmentsadded. Each particular type of PVC is the product of blendingthe PVC resin and defined quantities of selected additives. It is very important that the plasticiser content is withinspecification limits to ensure that the product has the correcthardness and flexibility for its end use. The MQC+ benchtopanalyser can determine plasticiser content rapidly andaccurately without using environmentally unfriendly solventsor complicated chemometrics. Advantages of NMR The traditional method of testing is to dissolve the plasticiser inorganic solvent and then to determine the amount of dissolvedoil in the solvent either by gravimetric analysis (followingdistillation),infrared spectroscopy or gas chromatography.These methods can be time consuming, require skilledoperators and the use of hazardous solvents. Alternatively,the plasticiser content may be determined indirectly byNear Infrared (combined with chemometric analysis) or bymechanical testing of the flexibility or hardness of the product. The MQC+ benchtop Nuclear Magnetic Resonance (NMR)analyser provides an alternative method which is quick andeasy to perform, simple to calibrate, and requires minimalsample preparation. As such it is ideal for routine operationeither in a laboratory or production environment without anyrequirement for additional chemicals and specialist operatortraining. Method Benchtop NMR is able to distinguish between signals fromsolid (dense, ordered crystallites) and amorphous parts withinsamples because the solid signals decay rapidly (in the order ofa few tens of microseconds) whereas the amorphous signalsprevail for much longer (many hundreds of microseconds). The NMR signal from the amorphous parts increases with,therefore can be directly correlated to, the % plasticisercontent. In some instances, it is necessary to raise thetemperature to increase the plasticiser mobility and thereforethe signal-to-noise of the measurement. In addition, as themobility of the plasticiser phase is very temperature sensitive,it is essential to stabilise the temperature of the polymer priorto measurement; usually at 40℃, the same as the magnet. Figure 1: Typical NMRsignal from polymer Calibration Only two well known standards are required to calibrate the MQC+.However, it is recommended that the instrument iscalibrated using 3-6, preferably more, standards with known plasticiser contents evenly spread over the range of interest. NMRis a comparative technique therefore cannot be more accurate than the reference technique against which it is being compared;error is reduced by analysing more reference samples. Measurement PVC samples are poured into 26 mm glass NMR tubes up to a predefined mark and weighed. For optimal precision, the sampletubes are placed in a temperature controlled conditioning block at 40℃ for at least 20 minutes prior to analysis. Measurementtime is 16 seconds per sample. Results Figure 1 shows that a simple linear calibration can be generated using just four samples of PVC with plasticiser content valuesvarying from 18 to 40% giving a standard deviation of 0.16%. A separate calibration will be required for each plasticiser used.The precision of measurement, obtained by taking ten successive repeats of the same sample at 35%, is +/-0.06%. Conclusion Figure 2: NMR calibration for plasticiser in PVC ●NMR is very stable over the long term and rarelyneeds calibration adjustment ●NMR is insensitive to the air voids between thepellets or grains of powder ●Measurement precision is good compared to wetchemistry methods ●Sample measurement time is rapid ●The NMR technique is non-destructive so the samesample may be measured several times beforebeing analysed by other techniques Complete Package Oxford Instruments offers a package especially tailored to the measurement of plasticiser content in PVC. MQC+23 Benchtop NMR Analyser including: 0.55 Tesla (23 MHz) high homogeneity magnet Probe for 26 mm diameter sample tubes (14 ml sample volume) Integrated system controller (no external PC required) ● Integrated flat-screen display MultiQuant software including RI Calibration, RI Analysis, and the EasyCal'Plasticiser in PVC'application Test/tuning samples 26 mm glass tubes PTFE stoppers Stopper insertion/removal tool User manuals Method sheet Optional items are: A dry heater and aluminium block with holes for sample conditioning at 40°C A precision balance KFR visit www.oxinst.com/mqc for more information or email: magres@oxinst.com ( This publication is the copyright of Oxford Instruments and provides outline information on l y whic h (unle ss a gr ee d b y t h e company inwriting) may not be used, applied or reproduced for any purpose or form part of any orde r o r c on t r act or b e r e g a rded as a re p r e s e n t ati o nrelating to the products or services concerned.Oxford Instruments' policy is one of c ont in u ed imp ro ve ment. The c o m p an y rese r ves theright to alter, without notice, the specification, design or conditions of suppl y of any p rod uct o r s e r vic e . O xf or d I ns t rumen ts a c knowledgesall trademarks and registrations. @ Oxford Instruments plc, 2018. All r i gh t s r es e r ve d. Ref . PV C-AN-0 9 -1 8 ) 聚氯乙烯(PVC)是最常见的聚合物之一。聚氯乙烯(PVC)中增塑剂含量需要在一定范围内,从而确保产品在使用中有合适的硬度和韧性。 MQC+ 台式核磁共振分析仪提供了无需溶剂的替代检测方案。该方法检测快速、易于操作和校准,更大程度简化了样品制备工作。

确定

还剩1页未读,是否继续阅读?

牛津仪器科技(上海)有限公司为您提供《PVC中增塑剂检测方案(核磁共振)》,该方案主要用于其他中增塑剂检测,参考标准--,《PVC中增塑剂检测方案(核磁共振)》用到的仪器有牛津仪器MQC+台式磁共振分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多