方案详情

文

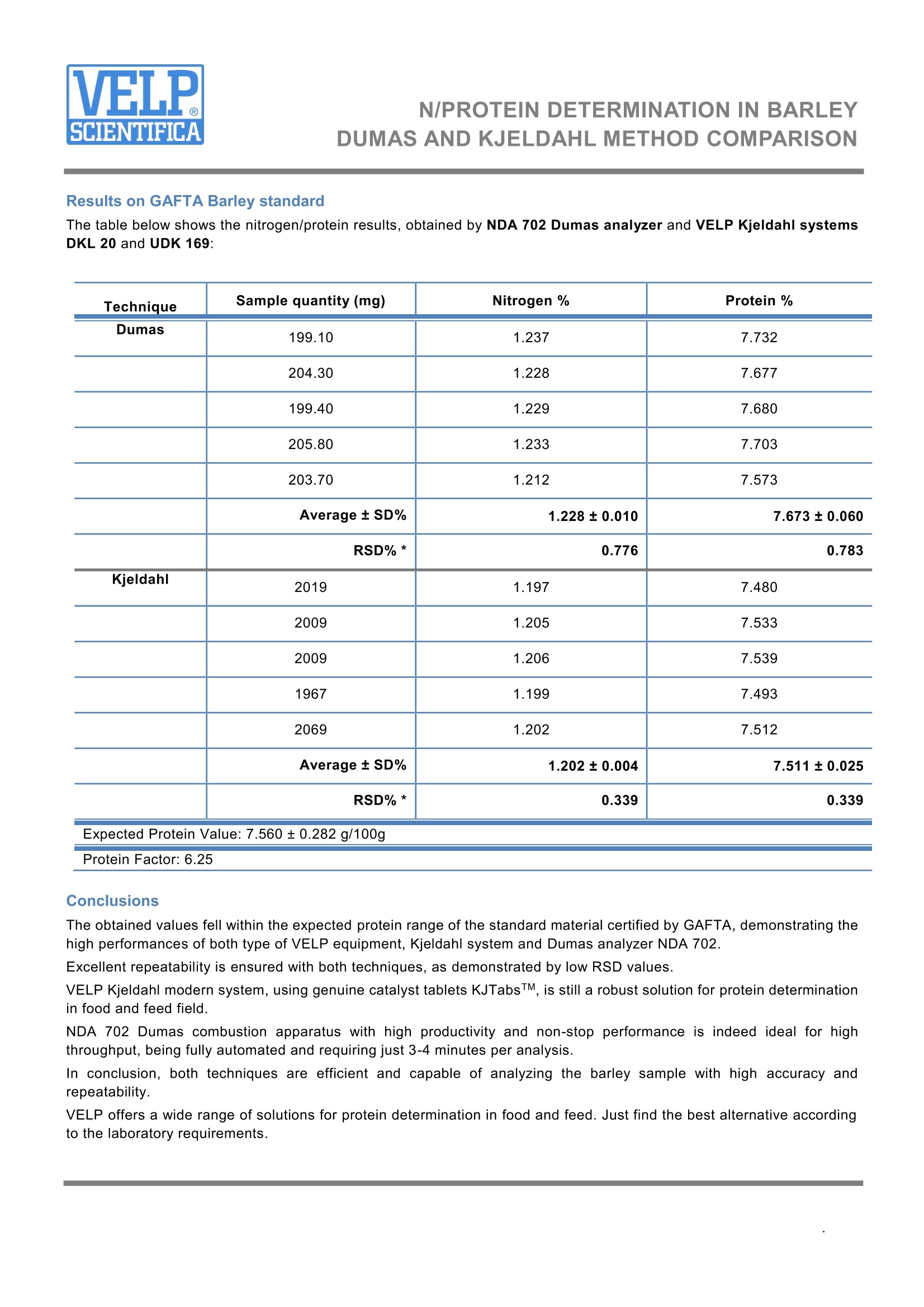

采用杜马斯法与凯氏定氮法分析大麦中N/蛋白质含量,所得的蛋白质值在GAFTA认证的标准材料的预期蛋白质范围内,这证明了两种VELP设备备、凯氏定氮系统和Dumas分析仪NDA702的高性能。这两种技术都保证了优良的重复性,低RSD值就是证明。

方案详情

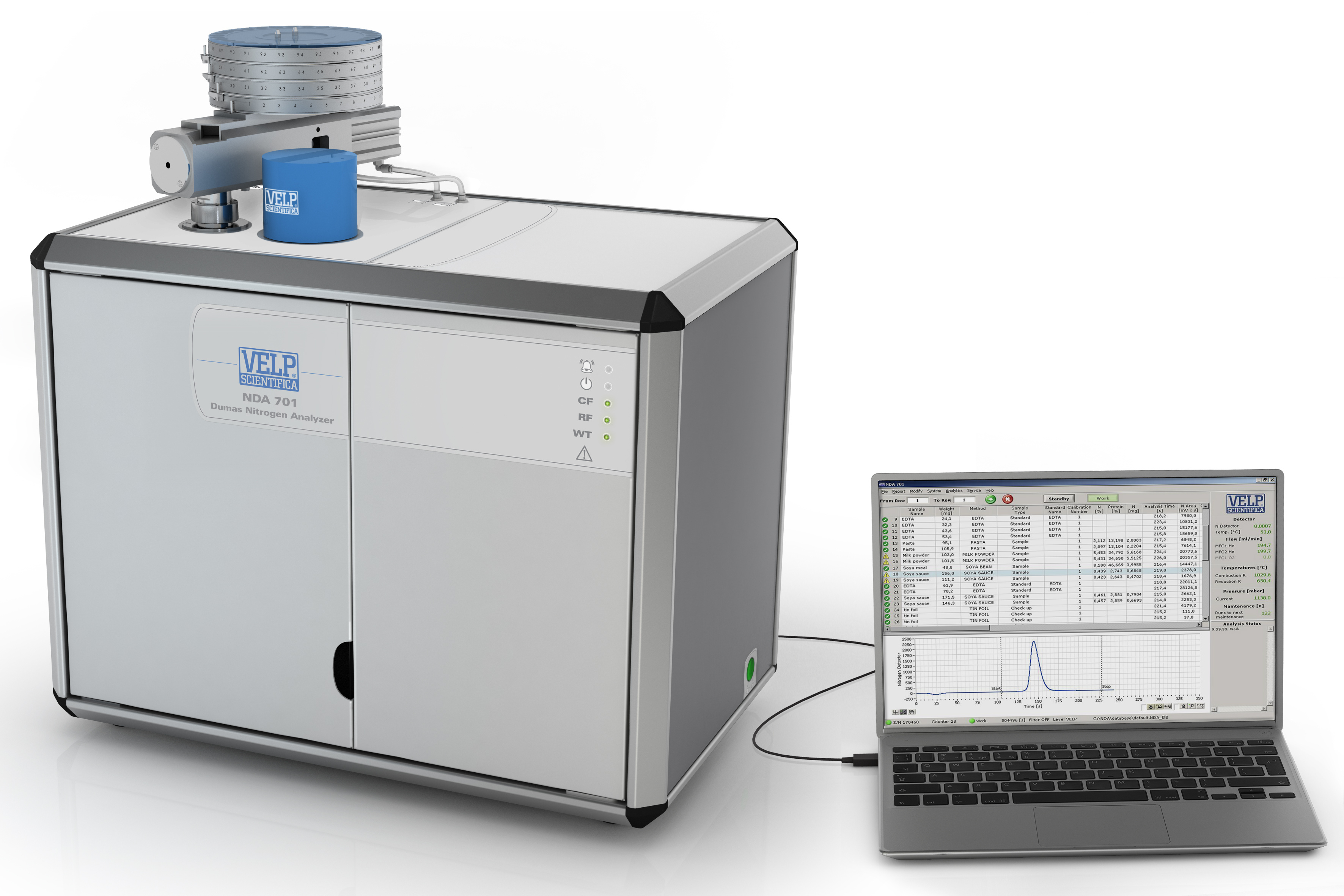

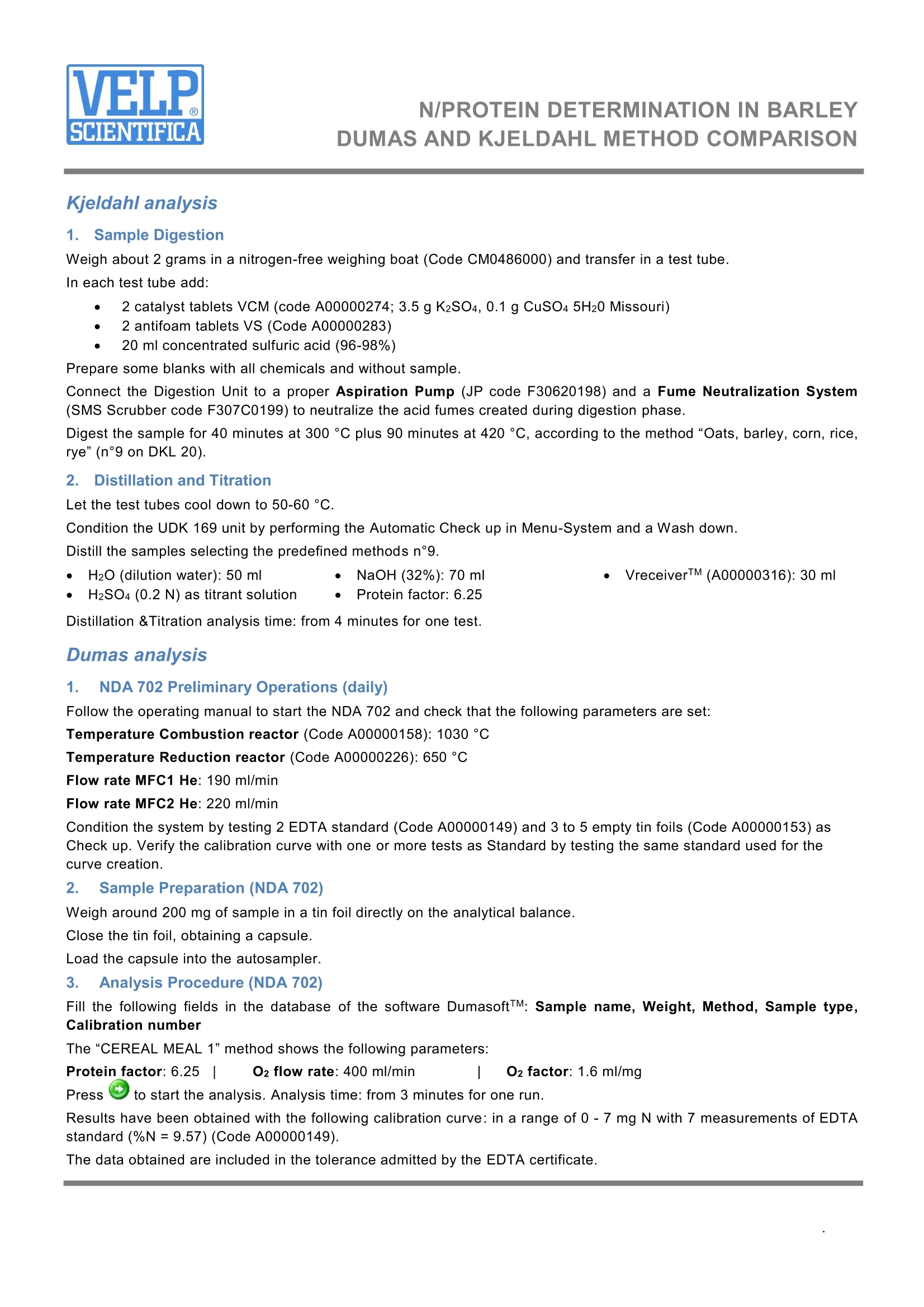

APPLICATION NOTEF&F-D-003-2017/A1 DUMAS AND KJELDAHL METHOD COMPARISON N/Protein Determination in BarlevDumas and Kjeldahl method comparison Kjeldahl reference: AOAC 979.09 Protein in Grains; AACC 46.11 A, ASBC Barley7A Dumas reference: AOAC 992.23 Crude Protein in Cereal Grains and Oilseeds, AACC 46-30.01, ASBC Barley 7C Tested with VELP Scientifica DKL 20 Automatic Kjeldahl Digestion Unit (Code S30100210) UDK 169 Automatic Kjeldahl Analyzer with AutoKjel Autosampler (Code S30200160) and VELP Scientifica NDA 702 Dual Carrier Gas Dumas Nitrogen Analyzer (Code F30800080) N/PROTEIN DETERMINATION IN BARLEY Introduction Protein content of malting barley is important because it affects malting, brewing, and their end products. Kjeldahldetermination is the commonly accepted method of protein estimation in barley, based on traditional wet chemistry.An alternative to the classical Kjeldahl method is the Dumas combustion technique, innovative dry chemistry,easy to useand highly accurate. Both the techniques are officially approved for the determination of the nitrogen and protein content in barley. Protein Determination in GAFTA Barley This application note compares the nitrogen/protein determination in barley by using NDA 702 Dumas Nitrogen Analyzerand UDK169 Automatic Kjeldahl Analyzer with AutoKjel Autosampler. The specific methods used in this study are summarized briefly here: Kjeldahl method The modern Kjeldahl method consists in a procedure of catalytically supported mineralization of organic material in aboiling mixture of sulfuric acid and sulfate salt at digestion temperatures higher than 400 °C. During the process the organically bonded nitrogen is converted into ammonium sulfate. Alkalizing the digested solutionliberates ammonia which is quantitatively steam distilled and determined by titration. Dumas method The Dumas method starts with a combustion furnace (CF) to burn thesample, obtaining elemental compounds. Water is removed by a first physical trap (WT1 -DriStepTM), placed afterthe combustion, and a second chemical one (WT2). Between the two, theelemental substances passed through a reduction furnace (RF). The auto-regenerative CO2 absorbers (CO2) let pass only the elementalnitrogen that is detected by the LoGas TM innovative Thermal ConductivityDetector (TCD) with no requirement for a reference gas. The NDA 702 is controlled via PC through the intuitive DUMASoftTM. Performances of VELP Kjeldahl system and Dumas unit were evaluated by determining the protein content of a GAFTA(The Grain and Feed Trade Association) reference sample, tested with both techniques by over 250 laboratories, in 53countries. The obtained results (as % Protein) were compared with the GAFTA assigned value. Sample Un-milled barley Sample ID: 2016:G2 Protein assigned value: 7.560±0.282 g/100g The sample has been grinded by using a laboratory cereal mill (particle size 1mm). Kjeldahl analysis 1. Sample Digestion Weigh about 2 grams in a nitrogen-free weighing boat (Code CM0486000) and transfer in a test tube.In each test tube add: ● 2 catalyst tablets VCM (code A00000274;3.5 g K2SO4, 0.1 g CuSO4 5H20 Missouri) ● 2 antifoam tablets VS (Code A00000283) ● 20 ml concentrated sulfuric acid (96-98%) Prepare some blanks with all chemicals and without sample. Connect the Digestion Unit to a proper Aspiration Pump (JP code F30620198) and a Fume Neutralization System(SMS Scrubber code F307C0199) to neutralize the acid fumes created during digestion phase.Digest the sample for 40 minutes at 300°C plus 90 minutes at 420 °C, according to the method“Oats, barley, corn, rice,rye”(n°9 on DKL 20). 2. lDistillation and Titration Let the test tubes cool down to 50-60°C. Condition the UDK 169 unit by performing the Automatic Check up in Menu-System and a Wash down. Distill the samples selecting the predefined methods n°9. ●HH2O (dilution water): 50 ml ·NNaOH(32%): 70 ml VreceiverTM (A00000316): 30 ml ●HH2SO4 (0.2 N) as titrant solution FProtein factor: 6.25 Distillation &Titration analysis time: from 4 minutes for one test. Dumas analysis 1. NDA 702 Preliminary Operations (daily) Follow the operating manual to start the NDA 702 and check that the following parameters are set: Temperature Combustion reactor (Code A00000158): 1030°C Temperature Reduction reactor (Code A00000226):650°C Flow rate MFC1 He: 190 ml/min Flow rate MFC2 He: 220 ml/min Condition the system by testing 2 EDTA standard (Code A00000149) and 3 to 5 empty tin foils (Code A00000153) asCheck up. Verify the calibration curve with one or more tests as Standard by testing the same standard used for thecurve creation. 2. Sample Preparation (NDA 702) Weigh around 200 mg of sample in a tin foil directly on the analytical balance. Close the tin foil, obtaining a capsule. Load the capsule into the autosampler. 3. Analysis Procedure (NDA 702) Fill the following fields in the database of the software DumasoftTM: Sample name, Weight, Method, Sample type,Calibration number The "CEREAL MEAL 1"method shows the following parameters: Protein factor: 6.25 O2 flow rate: 400 ml/min O2 factor: 1.6 ml/mg Press to start the analysis. Analysis time: from 3 minutes for one run. Results have been obtained with the following calibration curve: in a range of 0 - 7 mg N with 7 measurements of EDTAstandard (%N=9.57) (Code A00000149). The data obtained are included in the tolerance admitted by the EDTA certificate. Results on GAFTA Barley standard The table below shows the nitrogen/protein results, obtained by NDA 702 Dumas analyzer and VELP Kjeldahl systemsDKL 20 and UDK 169: Technique Sample quantity (mg) Nitrogen % Protein% Dumas 199.10 1.237 7.732 204.30 1.228 7.677 199.40 1.229 7.680 205.80 1.233 7.703 203.70 1.212 7.573 Average±SD% 1.228±0.010 7.673±0.060 RSD%* 0.776 0.783 Kjeldahl 2019 1.197 7.480 2009 1.205 7.533 2009 1.206 7.539 1967 1.199 7.493 2069 1.202 7.512 Average±SD% 1.202±0.004 7.511±0.025 RSD%* 0.339 0.339 Expected Protein Value: 7.560±0.282 g/100g Protein Factor: 6.25 Conclusions The obtained values fell within the expected protein range of the standard material certified by GAFTA, demonstrating thehigh performances of both type of VELP equipment, Kjeldahl system and Dumas analyzer NDA 702. Excellent repeatability is ensured with both techniques, as demonstrated by low RSD values. VELP Kjeldahl modern system, using genuine catalyst tablets KJTabsTM, is still a robust solution for protein determinationin food and feed field.NDA 702 Dumas combustion apparatus with high productivity and non-stop performance is indeed ideal for highthroughput, being fully automated and requiring just 3-4 minutes per analysis. In conclusion, both techniques are efficient and capable of analyzing the barley sample with high accuracy andrepeatability. VELP offers a wide range of solutions for protein determination in food and feed. Just find the best alternative accordingto the laboratory requirements. 麦芽大麦的蛋白质含量很重要,因为它影响到麦芽酿造、酿造和最终产品。凯氏定氮法是一种基于传统湿化学的大麦蛋白质测定方法。经典凯氏定氮法的替代方法是杜马斯燃烧技术,创新的干化学,易于使用和高度准确。 这两种技术都被批准用于测定大麦中的氮和蛋白质含量。 实验样品:Un-milled barley Sample ID: 2016:G2Protein assigned value: 7.560 ± 0.282 g/100g样品用实验室谷物磨粉机(粒度1毫米)磨碎。实验仪器:DKL 20自动凯氏定氮消化装置,UDK 169全自动凯氏定氮分析仪, NDA 702双载气杜马斯定氮仪检测指标:麦芽大麦的蛋白质含量实验结果:下表显示了NDA 702 Dumas分析仪和VELP Kjeldahl系统得到的氮/蛋白结果 结 论:所得的蛋白质值在GAFTA认证的标准材料的预期蛋白质范围内,这证明了两种VELP设备、凯氏定氮系统和Dumas分析仪NDA 702的高性能。这两种技术都保证了优良的重复性,低RSD值就是证明。VELP凯氏定氮现代体系使用的是真正的催化剂片KJTabsTM,仍然是食品和饲料领域中一种强有力的蛋白质测定方法。NDA 702 Dumas燃烧装置具有高生产率和不间断性能,确实是理想的高通量,是全自动的,每次分析只需3-4分钟。 综上所述,两种技术都是有效的,能够对大麦样品进行分析,具有较高的准确度和重复性。 VELP为食品和饲料中蛋白质的测定提供了广泛的解决方案。只需要根据实验室的要求找到较好的替代方案

确定

还剩2页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《大麦中N/蛋白质检测方案(氮磷钙测定仪)》,该方案主要用于谷物中N/蛋白质检测,参考标准--,《大麦中N/蛋白质检测方案(氮磷钙测定仪)》用到的仪器有VELP-NDA702杜马斯定氮仪、VELP全自动凯氏定氮仪UDK169 and AutoKjel

推荐专场

相关方案

更多

该厂商其他方案

更多