碳纳米管(CNTs)是一种低密度、柔韧、导电的材料,单个碳纳米管具有较高的抗拉强度。Nanocomp Technologies, Inc.生产的碳纳米管形式有薄片、条带、粉末、分散体和线状。Nanocomp的产品用于航空航天、装甲和耐火材料。

方案详情

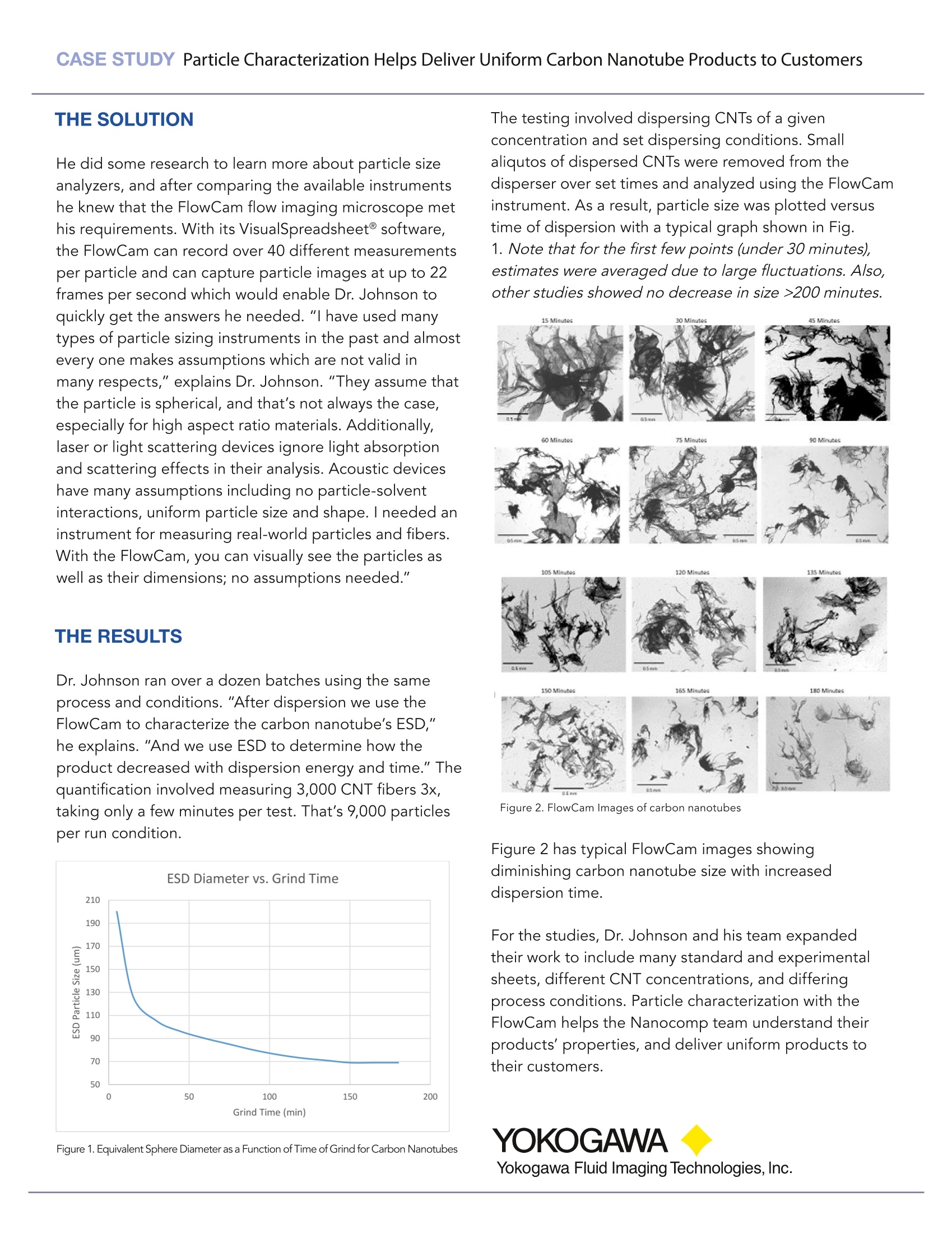

CASE STUDY CASE STUDY Particle Characterization Helps Deliver Uniform Carbon Nanotube Products to CustomersYOKOGAWA FLUID IMAGING TECHNOLOGIESwww.fluidimaging.comCASE STUDY CONTINUED ON REVERSE Particle Characterization Helps Deliver UniformCarbon Nanotube Products to Customers THE CLIENT Carbon nanotubes (CNTs) are low density, flexible, electrically conductivematerials, with individual tubes having relatively high tensile strength.NanocompTechnologies, Inc. produces carbon nanotubes in the form of sheets, tapes,powders, dispersions, and yarns. Nanocomp's products are used for aerospace,aviation, armor, and flame-resistant applications. These hollow, tubular cylinders of aromatic carbon atoms exhibit distinctmechanical, electrical, thermal, and chemical properties. Individual tube diametersare ~10 nm with lengths of ~1 mm. Nanocomp's CNTs have tremendous aspectratios; thousands of times greater than other commercially available carbonnanotubes. Part of producing the carbon nanotube powders and slurries involves a proprietary,surfactant-free dispersion process. The result of this process is bundles of CNTsthat are ~100 um in width and ~1000 um in length. That’s where Joe Johnson, Joe Johnson, Ph.D. Principal Scientist, Nanocomp Ph.D., the Principal Scientist at Nanocomp, comes in. He oversees the dispersion and particle labs, as well as relatedapplications like paints, composites, and polymers. He’s been with the company for three years, but his backgroundincludes over 20 years of experience working with anything involving particles, including synthesis, modification,product development, applications, and characterization. "I needed aninstrument formeasuring real-worldparticles and fibers.With the FlowCam,you can visually seethe particles as wellas their dimensions:no assumptionsneeded" THE CHALLENGE Dr. Johnson wanted an instrument that would help with determining the grindingquantification of carbon nanotubes.Nanocomp's CNT production procedure results innon-woven sheets being made, with the CNTs held together mainly by van der Waal’sforces. An analogy, although using vastly different forces and scale, would be havingmany Velcro@ tapes being pushed together forming a sheet. A grinding device waspreviously identified to "rip" the nanotubes from each other resulting in fibers, or bundlesof CNTs. Previous experiments identified process conditions (e.g. CNT concentration andinstrument conditions). The time of grind to achieve small, uniform fibers was unknown, soa study was planned that would measure particle size vs. grind time. Dr. Johnson needed aquantifying instrument that could accurately measure the width, length, aspect ratio, ESD(equivalent size diameter), and their distributions for dispersed carbon nanotubes. FlowCam° 207-289-3200 contact@fluidimaging.com He did some research to learn more about particle sizeanalyzers, and after comparing the available instrumentshe knew that the FlowCam flow imaging microscope methis requirements. With its VisualSpreadsheet@software,the FlowCam can record over 40 different measurementsper particle and can capture particle images at up to 22frames per second which would enable Dr. Johnson toquickly get the answers he needed. "I have used manytypes of particle sizing instruments in the past and almostevery one makes assumptions which are not valid inmany respects," explains Dr. Johnson."They assume thatthe particle is spherical, and that’s not always the case,especially for high aspect ratio materials. Additionally,laser or light scattering devices ignore light absorptionand scattering effects in their analysis. Acoustic deviceshave many assumptions including no particle-solventinteractions, uniform particle size and shape. I needed aninstrument for measuring real-world particles and fibers.With the FlowCam, you can visually see the particles aswell as their dimensions; no assumptions needed." Dr. Johnson ran over a dozen batches using the sameprocess and conditions. "After dispersion we use theFlowCam to characterize the carbon nanotube's ESD,"he explains."And we use ESD to determine how theproduct decreased with dispersion energy and time." Thequantification involved measuring 3,000 CNT fibers 3x,taking only a few minutes per test. That's 9,000 particlesper run condition. Figure 1. Equivalent Sphere Diameter as a Function of Time of Grind for Carbon Nanotubes The testing involved dispersing CNTs of a givenconcentration and set dispersing conditions. Smallaliqutos of dispersed CNTs were removed from thedisperser over set times and analyzed using the FlowCaminstrument. As a result, particle size was plotted versustime of dispersion with a typical graph shown in Fig.1. Note that for the first few points (under 30 minutes),estimates were averaged due to large fluctuations. Also, other studies showed no decrease in size >200 minutes. 15 Minutes Figure 2. FlowCam Images of carbon nanotubes Figure 2 has typical FlowCam images showingdiminishing carbon nanotube size with increaseddispersion time. For the studies, Dr. Johnson and his team expandedtheir work to include many standard and experimentalsheets, different CNT concentrations,and differingprocess conditions. Particle characterization with theFlowCam helps the Nanocomp team understand theirproducts' properties, and deliver uniform products totheir customers. YOKOGAWA 碳纳米管(CNTs)是一种低密度、柔韧、导电的材料,单个碳纳米管具有较高的抗拉强度。Nanocomp Technologies, Inc.生产的碳纳米管形式有薄片、条带、粉末、分散体和线状。Nanocomp的产品用于航空航天、装甲和耐火材料。这些中空的、管状的芳香族碳原子柱表现出独特的机械、电子、热和化学性质。单个碳纳米管的直径约为10nm,长度约为1mm。Nanocomp的碳纳米管具有巨大的长宽比,比其他市场上可获得的碳纳米管大几千倍。碳纳米管粉末和泥浆的生产工艺关系到一种专用的,不含表面活性剂的分散工艺。通过该工艺能够获得的碳纳米管束的宽度为~100μm,长度为~1000μm。这就是Nanocomp首席科学家Joe·Johnson博士的关注点。他管理分散和颗粒实验室,以及相关应用,如油漆,复合材料和聚合物。他在该公司工作了3年,但他有超过20年的任何涉及颗粒的工作经验的背景,包括合成、改性、产品开发、应用和表征。

确定

还剩1页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《碳纳米颗粒中形态对产品质量影响检测方案(图像粒度粒形)》,该方案主要用于其他中形态对产品质量影响检测,参考标准--,《碳纳米颗粒中形态对产品质量影响检测方案(图像粒度粒形)》用到的仪器有纳米流式颗粒成像分析系统 FlowCam® Nano、流式颗粒成像分析系统FlowCam®8100、颗粒成像法+光阻法分析系统 FlowCam® + LO

推荐专场

相关方案

更多

该厂商其他方案

更多