Powder coatings are a cost effective and an environmentally friendly alternative to liquid coatings. Traditional coating systems form networks via a thermally activated process. This usually involves placing a powder coated surface into an oven at temperatures between 160°C and 200°C.The powder melts at around 80°C to 120°C and becomes an even film.

At temperatures between 110°C and 140°C the cross linking reaction starts.The curing time typically lasts between 15 and 30 minutes, depending on the temperature and reactivity of the system.

方案详情

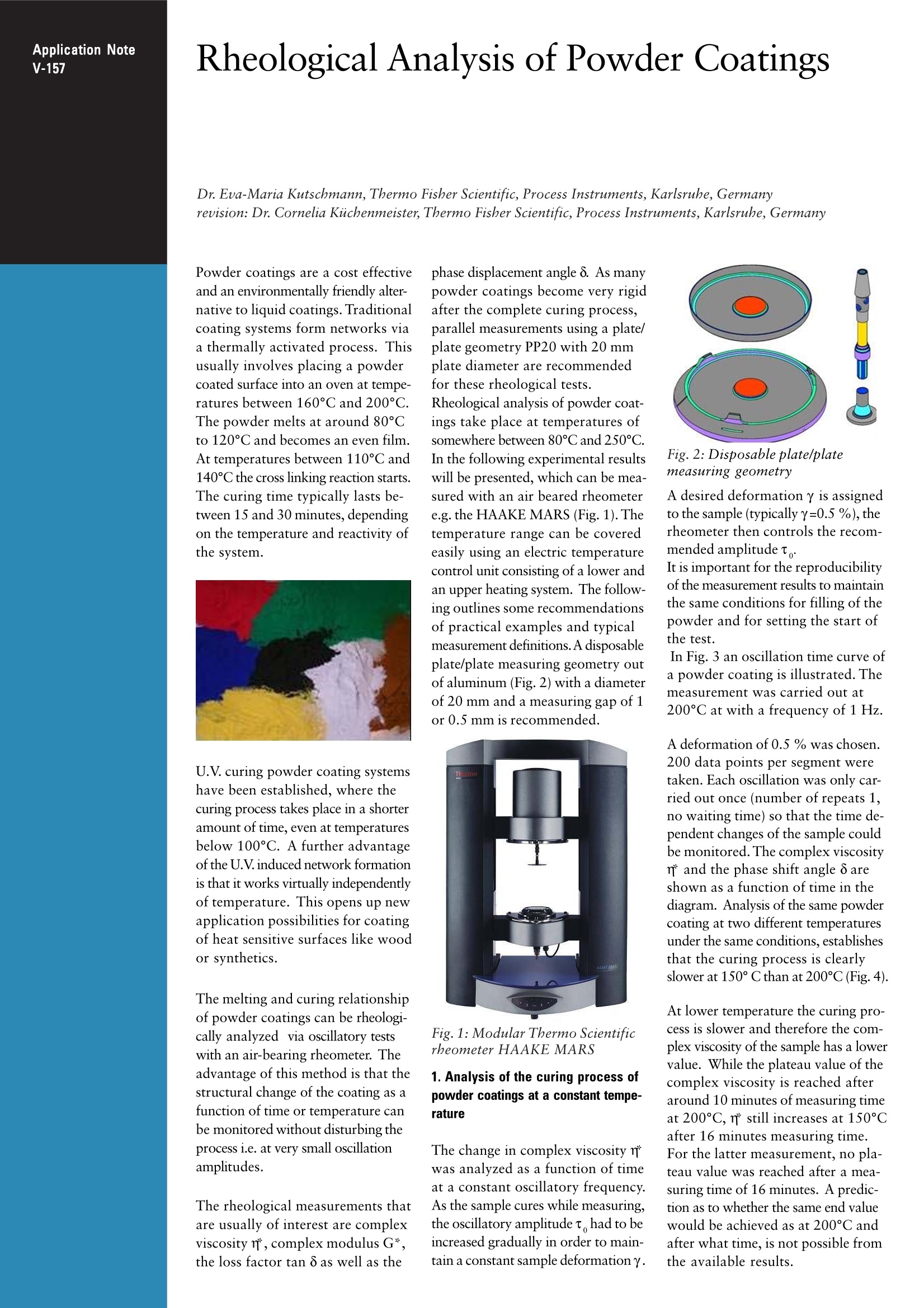

Application NoteV-157Part of Thermo Fisher Scientific Rheological Analysis of Powder Coatings Dr.Eva-Maria Kutschmann, Thermo Fisher Scientific, Process Instruments, Karlsruhe, Germany revision: Dr. Cornelia Kichenmeister, Thermo Fisher Scientific, Process Instruments, Karlsruhe, Germany Powder coatings are a cost effectiveand an environmentally friendly alter-native to liquid coatings. Traditionalcoating systems form networks viaa thermally activated process. Thisusually involves placing a powdercoated surface into an oven at tempe-ratures between 160°C and 200°C.The powder melts at around 80°Cto 120°C and becomes an even film.At temperatures between 110°C and140℃ the cross linking reaction starts.The curing time typically lasts be-tween 15 and 30 minutes, dependingon the temperature and reactivity ofthe system. U.V. curing powder coating systemshave been established, where thecuring process takes place in a shorteramount of time, even at temperaturesbelow 100°C. A further advantageof the U.V.induced network formationis that it works virtually independentlyof temperature. This opens up newapplication possibilities for coatingof heat sensitive surfaces like woodor synthetics. The melting and curing relationshipof powder coatings can be rheologi-cally analyzed via oscillatory testswith an air-bearing rheometer. Theadvantage ofthis method is that thestructural change of the coating as afunction of time or temperature canbe monitored without disturbing theprocess i.e. at very small oscillationamplitudes. The rheological measurements thatare usually of interest are complexviscosityr, complex modulus G**,the loss factor tan 8 as well as the phase displacement angle 8. As many powder coatings become very rigidafter the complete curing process,parallel measurements using a plate/plate geometry PP20 with 20 mmplate diameter are recommendedfor these rheological tests.Rheological analysis of powder coat-ings take place at temperatures ofsomewhere between 80C and 250°C.In the following experimental resultswill be presented, which can be mea-sured with an air beared rheometere.g. the HAAKE MARS (Fig. 1). Thetemperature range can be coveredeasily using an electric temperaturecontrol unit consisting of a lower andan upper heating system. The follow-ing outlines some recommendationsof practical examples and typicalmeasurement definitions.A disposableplate/plate measuring geometry outof aluminum (Fig. 2) with a diameterof 20 mm and a measuring gap of 1or 0.5 mm is recommended. Fig. 1: Modular Thermo Scientificrheometer HAAKE MARS 1. Analysis of the curing process ofpowder coatings at a constant tempe-rature The change in complex viscosity r*was analyzed as a function of timeat a constant oscillatory frequency.As the sample cures while measuring,the oscillatory amplitudet had to beincreased gradually in order to main-tain a constant sample deformation y. Fig. 2: Disposable platelplatemeasuring geometry A desired deformation y is assignedto the sample (typically y=0.5%), therheometer then controls the recom-mended amplitudet· It is important for the reproducibilityof the measurement results to maintainthe same conditions for filling of thepowder and for setting the start ofthe test. In Fig. 3 an oscillation time curve ofa powder coating is illustrated. Themeasurement was carried out at200°C at with a frequency of 1 Hz. A deformation of0.5 % was chosen.200 data points per segment weretaken. Each oscillation was only car-ried out once (number of repeats 1,no waiting time) so that the time de-pendent changes of the sample couldbe monitored. The complex viscosityr and the phase shift angle 8areshown as a function of time in thediagram. Analysis of the same powdercoating at two different temperaturesunder the same conditions, establishesthat the curing process is clearlyslower at 150° C than at 200℃ (Fig. 4). At lower temperature the curing pro-cess is slower and therefore the com-plex viscosity of the sample has a lowervalue. While the plateau value of thecomplex viscosity is reached afteraround 10 minutes of measuring timeat 200°C,r still increases at 150°Cafter 16 minutes measuring time.For the latter measurement, no pla-teau value was reached after a mea-suring time of 16 minutes. A predic-tion as to whether the same end valuewould be achieved as at 200°C andafter what time, is not possible fromthe available results. Fig. 3: Curing ofa powder coating at 200℃(f=1Hz,y=0.5%) Fig. 4: Oszillation time curves at two temperatures(f=1 Hz,y=0.5%, 150 and200°℃) Fig. 5: Comparison oftwo powder coatings(f=1 Hz,y=0.5 %, heating rate 6 K/min) Fig. 6: Influence of the beating rate on the Process Ti(f=1Hz,y=0.5%) 2. Analysis of the melting and curingprocess as a function of temperature The examination of changes in com-plex viscosity as a function of tempe-rature is interesting given that twoinfluences, namely temperature andtime are tracked simultaneously.Firstly the powder is melted and thecomplex viscosity drops to a mini-mum and then increases for the cur-ing process. The position of minimum and also thevalue of viscosity at minimum aredependent on the substance itself aswell as on the chosen heating rate. Fig. 5 shows rin relation to tempe-rature at a heating rate of 6 K/min fortwo different powder coatings. Pow-der A reaches a minimum viscosity ataround 180°C, while the viscosityminimum of sample B is reached at160°C. Examination of the viscosityvalues in the curve minimum however,yield a much lower value for sample Athan for sample B (120 Pas comparedto 400 Pas). For processing purposes coating Ashould result in a more even coatingas the lower viscosity should give abetter development (film formation)on the surface. In Fig. 6 a powder coating sample a-nalysis at three different heating ratesis shown. At a lower heating rate(1 K/min) the complex viscosity runsat a minimum at 110°C after around30 minutes. Afterwards it increasesagain and reaches a plateau valueafter around80 minutes. After thisthe networking formation is virtuallycomplete. At higher heating rates the viscosityminimum shifts to a higher tempera-ture. The effects of two influencescan be seen: the viscosity decreaseswith increasing temperature, the sys-tem simultaneously cross-links andthe viscosity rises again. At higherheating rates the decrease of the vis-cosity predominates momentarilybecause the curing process developsmore slowly. Thereby at the highest heating rate (10 K/min) the viscosityat the curve minimum is somewherearound a factor of 10 lower than atthe lowest heating rate (1 K/min). The viscosity minimum at the highestheating rate is achieved after around7 minutes, at the mid-rate (5 K/min),after around 11 minutes. In Fig. 6the three curves are shown only asa function of temperature, not as afunction of time. This explains whythe complete cross-linking processis only recognizable at one point onthe graph. Thermo Fisher ScientificProcess Instruments International/GermanyDieselstr. 4. 76227 KarlsruheTel.+49(0)721 40 94-444info.mc.de@thermofisher.com Benelux Tel.+31 (0) 76 5 87 98 88info.mc.nl@thermofisher.com China Tel. +86 (21) 68 65 45 88info.china@thermofisher.com France Tel.+33(0) 1 60 92 48 00info.mc.fr@thermofisher.com India Tel.+91 (22) 27 78 11 01info.mc.in@thermofisher.com United Kingdom . Tel. +44 (0) 1785 81 36 48info.mc.uk@thermofisher.com USA Tel. 603 436 9444 info.mc.us@thermofisher.com www.thermo.com/mc V-157_25.04.067 O2007/02 Thermo Fisher Scientific All rights reserved- This document is for informational purposes only and is subjectto change without notice.

确定

还剩1页未读,是否继续阅读?

上海力晶科学仪器有限公司为您提供《粉末涂料中流变性能检测方案(流变仪)》,该方案主要用于涂料中流变性能检测,参考标准--,《粉末涂料中流变性能检测方案(流变仪)》用到的仪器有赛默飞 旋转流变仪HAAKE RotoVisco 1、旋转流变仪 HAAKE MARS iQ AIR

推荐专场

相关方案

更多

该厂商其他方案

更多