安东帕(Anton Paar)是世界上第一家饮料分析的全方位供应商,它将实验室和过程仪器联系在一起,以提供完整和定制的测量解决方案。

高端技术满足了全球服务的要求,可为您提供完美的饮料分析-从进口原材料到易于装瓶的产品,以使消费者持续满意。

方案详情

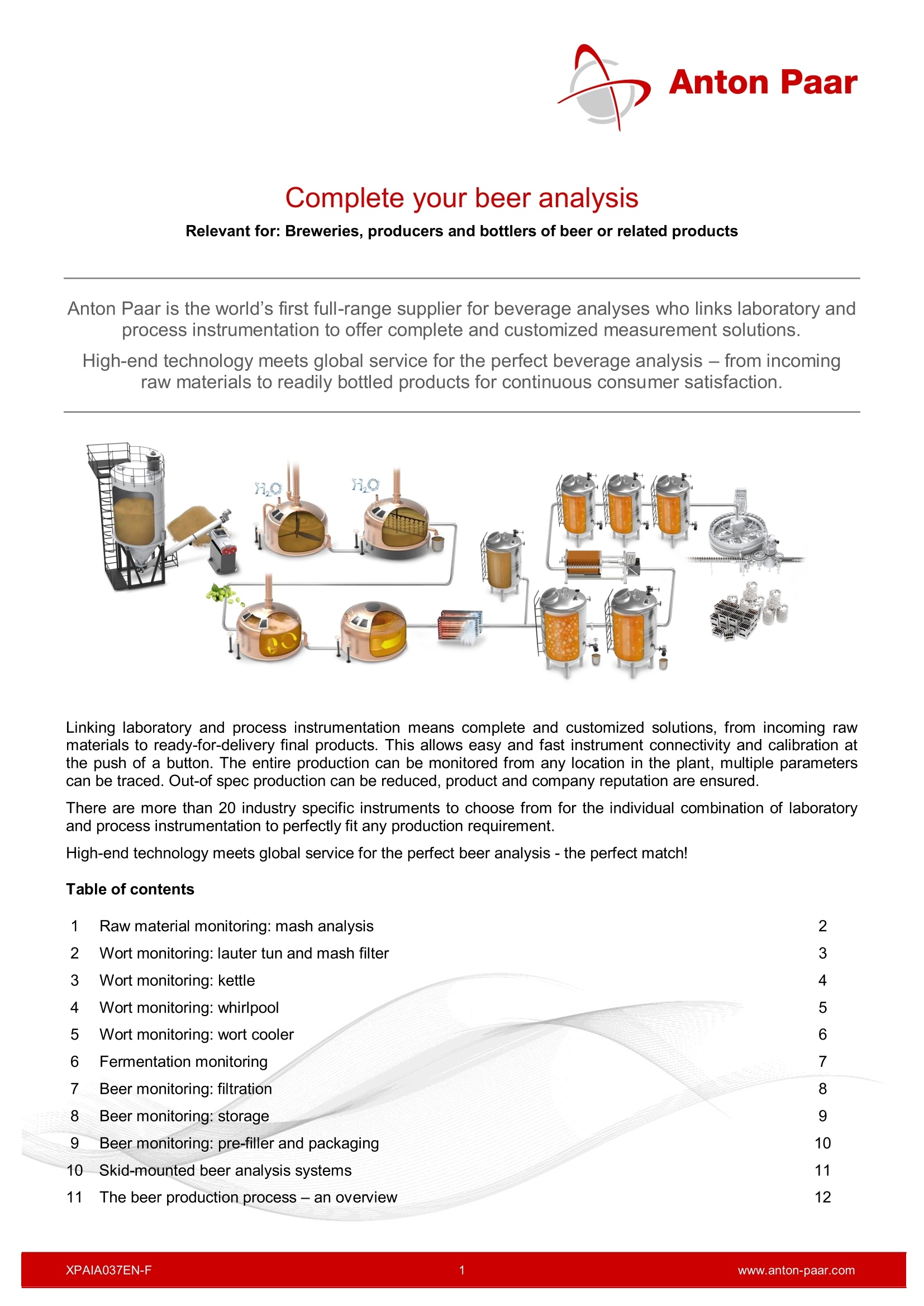

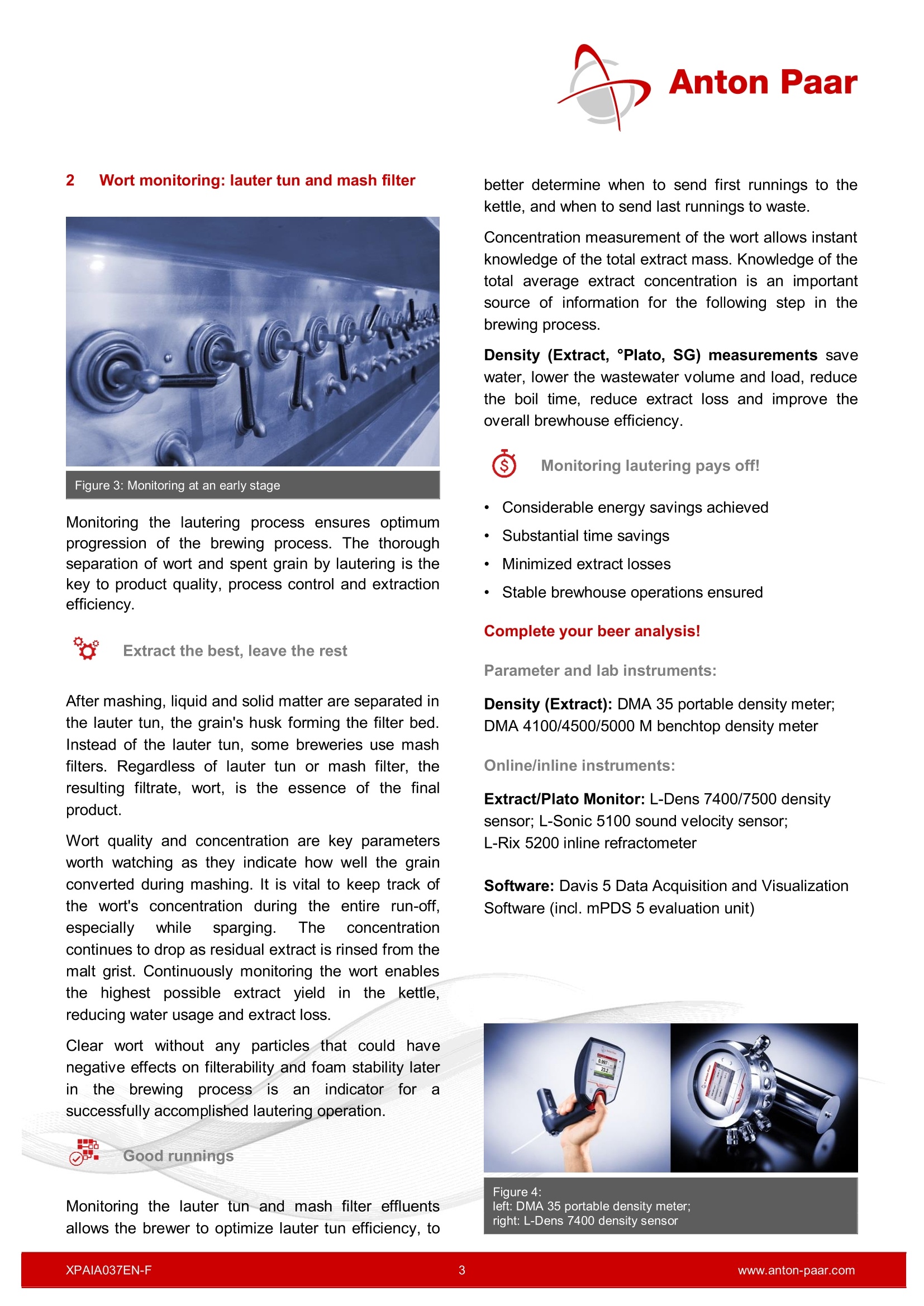

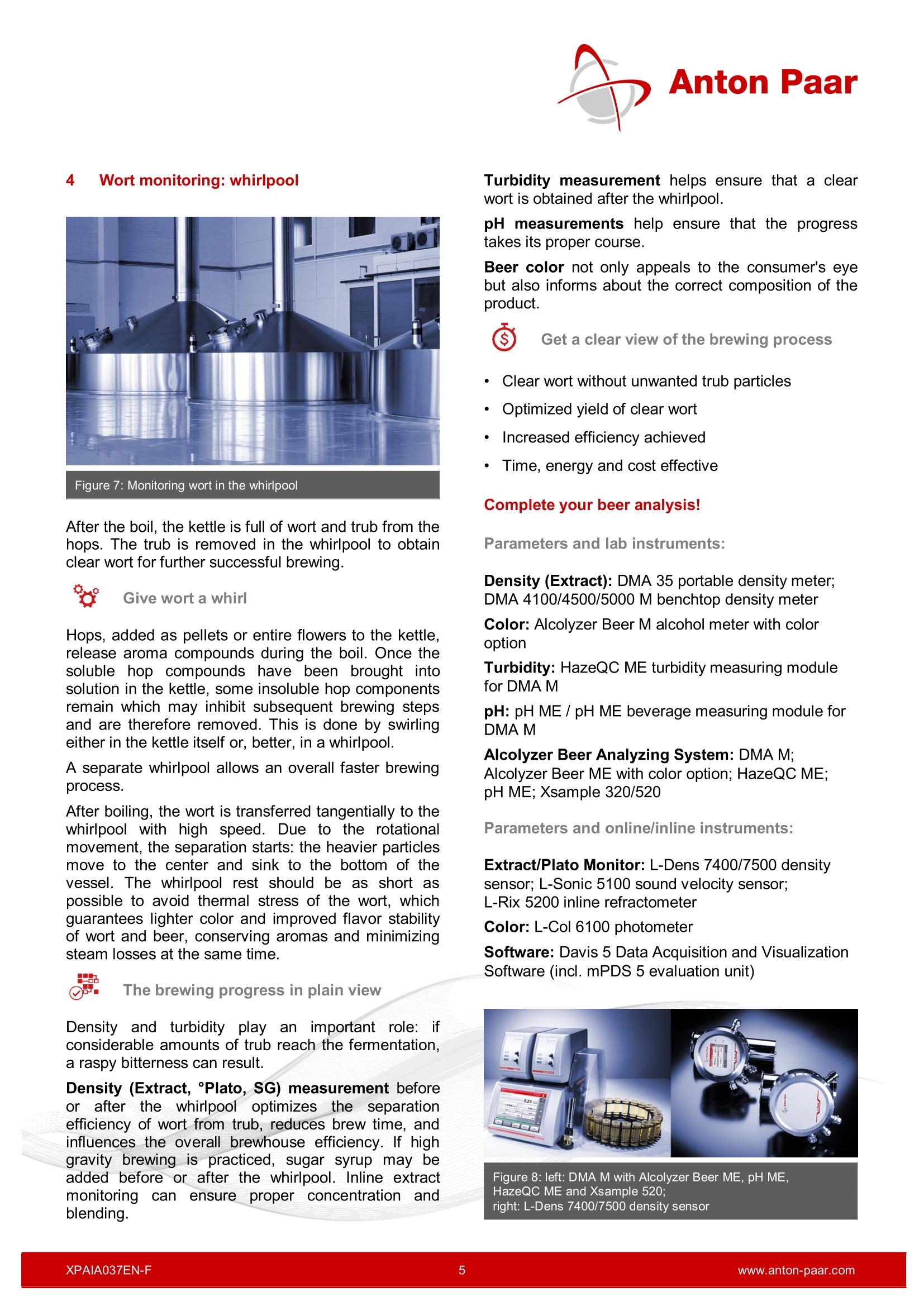

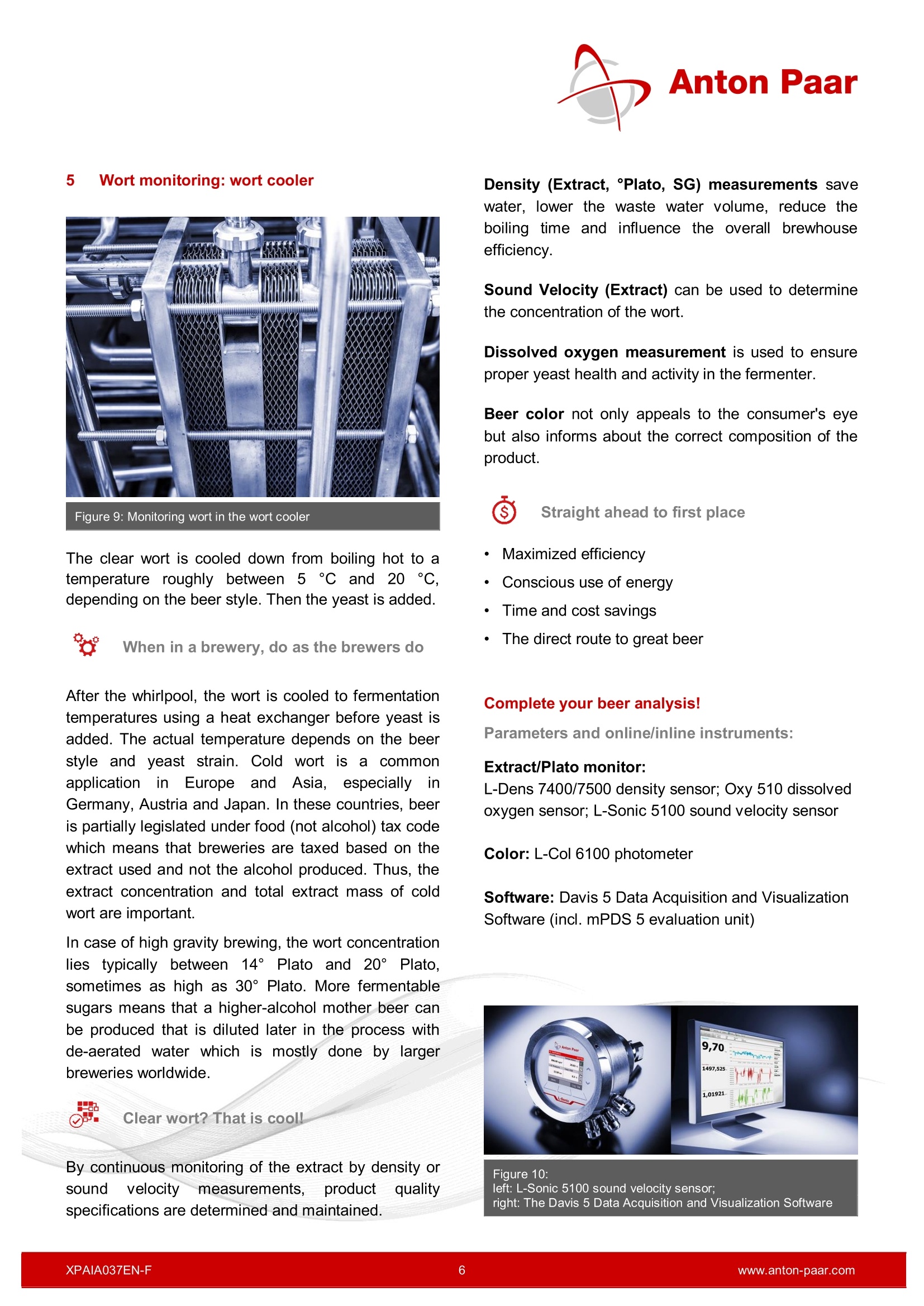

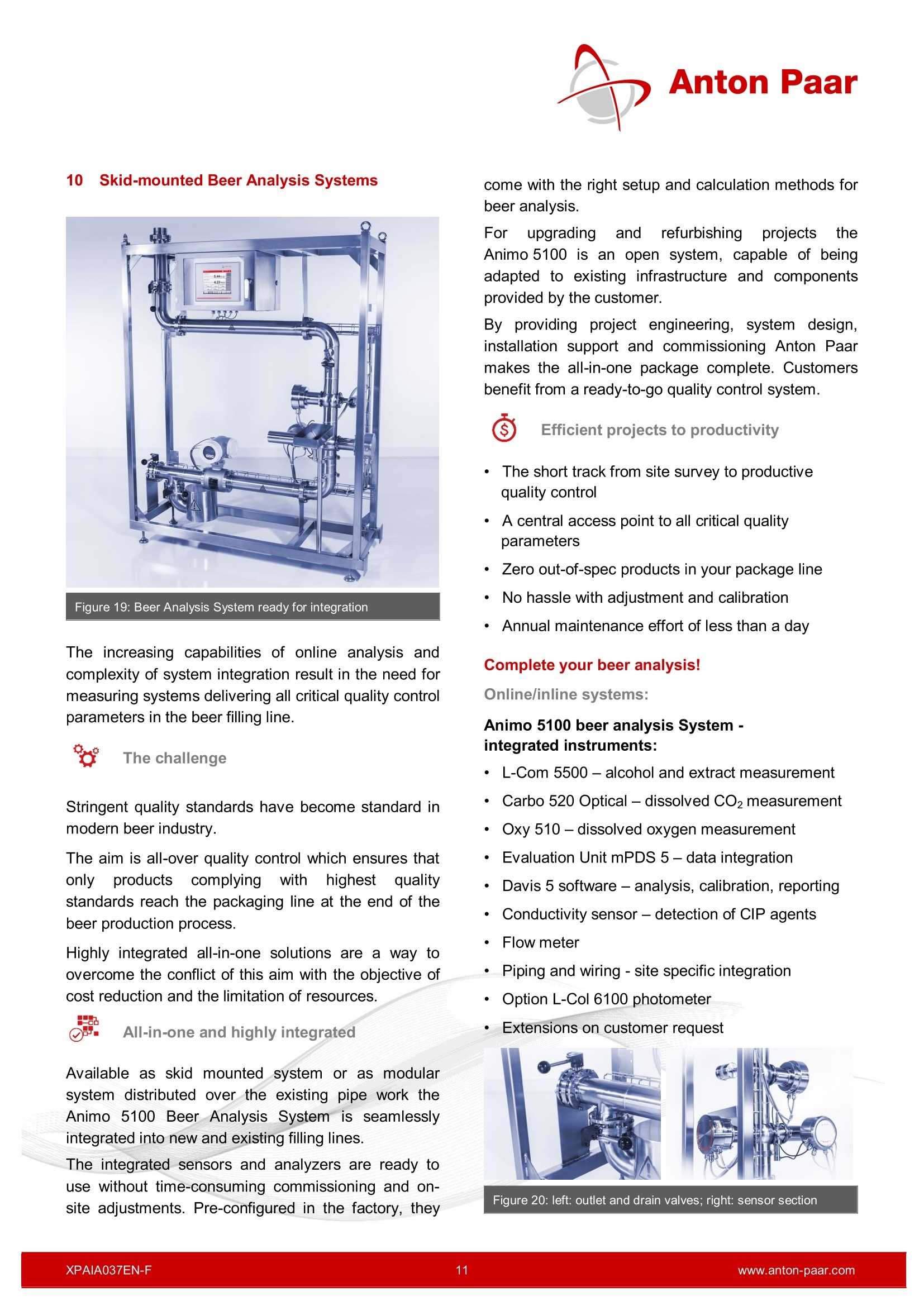

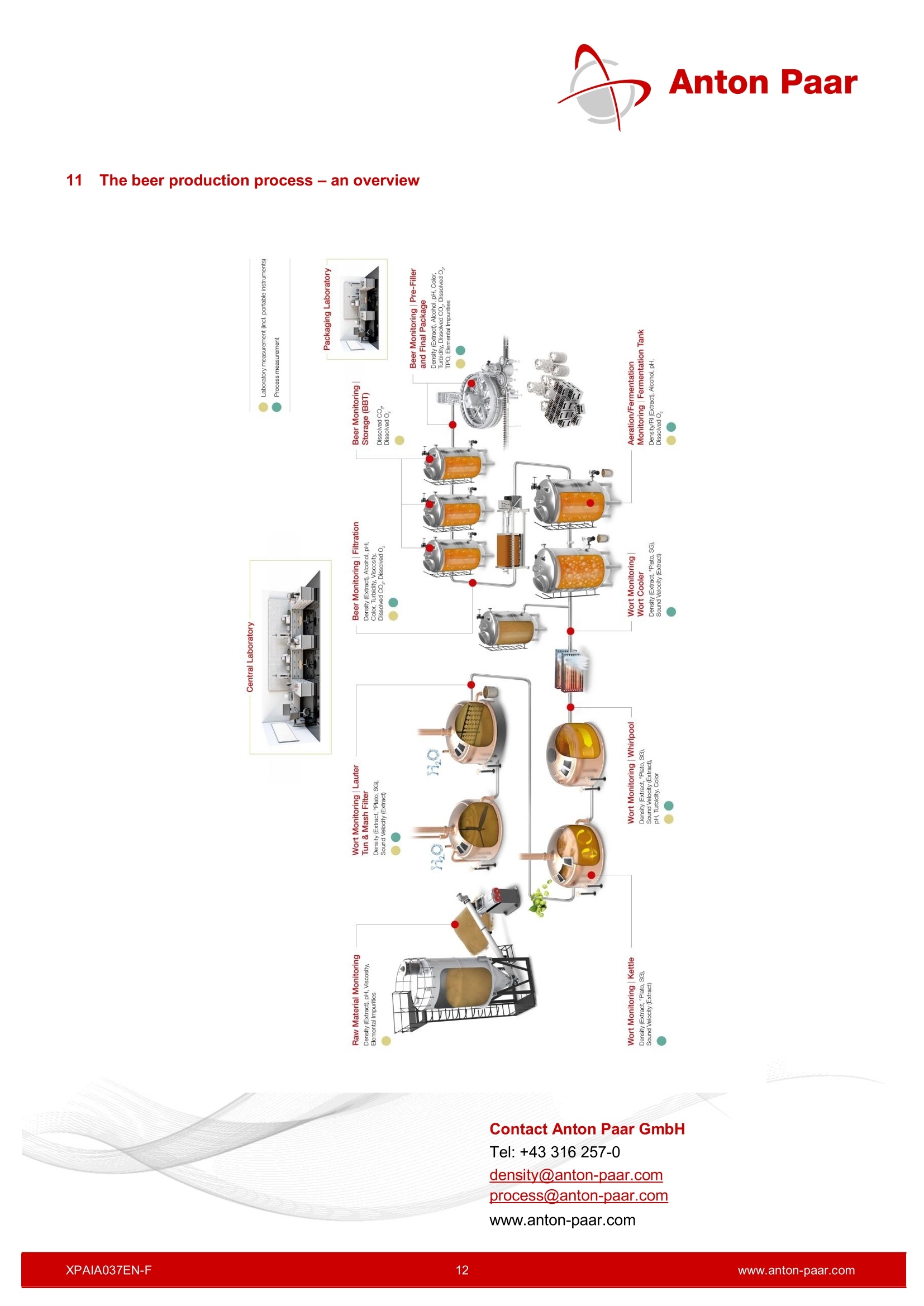

1 7 Complete your beer analysisRelevant for: Breweries, producers and bottlers of beer or related products Anton Paar is the world's first full-range supplier for beverage analyses who links laboratory andprocess instrumentation to offer complete and customized measurement solutions. High-end technology meets global service for the perfect beverage analysis - from incomingraw materials to readily bottled products for continuous consumer satisfaction. Linking laboratory and process instrumentation means complete and customized solutions, from incoming rawmaterials to ready-for-delivery final products. This allows easy and fast instrument connectivity and calibration atthe push of a button. The entire production can be monitored from any location in the plant, multiple parameterscan be traced. Out-of spec production can be reduced, product and company reputation are ensured. There are more than 20 industry specific instruments to choose from for the individual combination of laboratoryand process instrumentation to perfectly fit any production requirement. High-end technology meets global service for the perfect beer analysis - the perfect match! Table of contents 1 Raw material monitoring: mash analysis 2 2 Wort monitoring: lauter tun and mash filter 3 3 Wort monitoring: kettle 4 4 Wort monitoring: whirlpool 5 5 Wort monitoring: wort cooler 6 6 Fermentation monitoring 7 7 Beer monitoring: filtration 8 8 Beer monitoring: storage 9 9 Beer monitoring: pre-filler and packaging 10 10 Skid-mounted beer analysis systems 11 11The beer production process- an overview 12 Raw material monitoring: mash analysis Figure 1: Good products ask for good raw materials Any successful brewing process starts with high-quality starting materials. Having a close look at theingredients at this early stage is essential for superbbeer. Here is where the challenges start As stated in the“Reinheitsgebot", beer is made fromwater, grain, hops and yeast. While this holds true forGermany and many breweries around the world, beercan also be made with rice, corn, or sugar adjuncts.Specialty beers may also contain creative additionssuch as juniper, chocolate, chili or other non-standardingredients to make beers a true delicacy. The most important feature of malt is its behaviorduring the mashing process. The congress mashprocedure isused to create standardizedwortsamples which undergo laboratory tests. Both theEuropean Brewery Convention (EBC) and AmericanSociety of Brewing Chemists (ASBC) have standardmethods to measure the most important criteria ofcongress wort. 品Do not miss out to get the picture! Measuring relevantparameters with Anton Paarinstruments helps ensure that only the best rawmaterials find their way into the brewing kettle! Density and pH measurements show how well themalt performs during the mash. Mash pH impactsenzyme activity. Mash extract, derived from itsdensity, is a measure of enzyme activity and the amount of fermentable sugars produced. Mash extractis a quality and enzyme efficiency indicator. Wort viscosity directly correlates with the degree ofmodification. It provides information on malt solubility,expected lauter time, beer filterability, foam stability,taste and influences product quality and processefficiency. Samplepreparationwithhnmicrowavedigestionsystems followed by trace analysis allows you toverify the quality of the raw material and to gaininformation on trace impurities of toxic elements byacid digestion. Osnly the best raw materials find their wayinto the brewing kettle! ·Optimization of the production process · High-quality end products · Required actions possible in time Time and cost effectiveness ensured Complete your beer analysis! Parameters and lab instruments: Density (Extract): DMA 4100/4500/5000 M benchtopdensity meter pH: pH ME /pH ME beverage measuring module forDMA M Viscosity: Lovis 2000 M/ME microviscometer Multiparameter measurements: DMA M; Lovis 2000 ME; pH ME; Xsample 320/520 Sample preparation: Multiwave microwave reactionsystem Figure 2: left: DMA 4100/4500/5000 M benchtop density meter; right: DMA 4500 M and pH ME 2 VWort monitoring: lauter tun and mash filter Figure 3: Monitoring at an early stage Monitoring the lautering process ensures optimumprogression of the brewing process. The thoroughseparation of wort and spent grain by lautering is thekey to product quality, process control and extractionefficiency. Extract the best, leave the rest After mashing, liquid and solid matter are separated inthe lauter tun, the grain's husk forming the filter bed.Instead of the lauter tun, some breweries use mashfilters. Regardless of lauter tun or mash filter, theresulting filtrate, wort, is the essence of the finalproduct. Wort quality and concentration are key parametersworth watching as they indicate how well the grainconverted during mashing. It is vital to keep track ofthe wort’s concentration during the entire run-off,especially while sparging..The concentrationcontinues to drop as residual extract is rinsed from themalt grist. Continuously monitoring the wort enablesthe highestppossible extract yieldinthekettle.reducing water usage and extract loss. Clear wort without any particles that could havenegative effects on filterability and foam stability laterin the brewingprocess iss an indicator for asuccessfully accomplished lautering operation. 品Good runnings Monitoring the lauter tun and mash filter effluentsallows the brewer to optimize lauter tun efficiency, to better determine when to send first runnings to thekettle, and when to send last runnings to waste. Concentration measurement of the wort allows instantknowledge of the total extract mass. Knowledge of thetotal average extract concentration is an importantsource of information for the following step in thebrewing process. Density (Extract, Plato, SG) measurements savewater, lower the wastewater volume and load, reducethe boil time, reduce extract loss and improve theoverall brewhouse efficiency. Monitoring lautering pays off! ·Considerable energy savings achieved · Substantial time savings Minimized extract losses · Stable brewhouse operations ensured Complete your beer analysis! Parameter and lab instruments: Density (Extract): DMA 35 portable density meter;DMA 4100/4500/5000 M benchtop density meter Online/inline instruments: Extract/Plato Monitor: L-Dens 7400/7500 densitysensor; L-Sonic 5100 sound velocity sensor; L-Rix 5200 inline refractometer Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) 3 VWort monitoring: kettle Figure 5: Monitoring wort in the kettle The kettle is the heart of a brewery. Paying specialattention to the boil by measuring relevant parametersmeans treading the path that leads to optimumproduct quality. Where the essence develops Wort is boiled in the kettle. Hops are added for aroma,flavor, and stability. During the boiling process,various chemical and technical reactions take place,including sterilization of the wort. Hop oils aareisomerized, releasing their flavors and aromas. Theboil on average lasts between 45 and 90 minutes,depending on its intensity, the hop addition schedule,and volume of water expected to evaporate. During evaporation, undesired volatile aromas areremoved. The volume decreases through evaporation,thus dictating the original extract. As a consequence,the desired product characteristics and even legalrequirements are ensured. At the end of the boil, the hopped wort is transferredto a whirlpool, where solid particles such as hops andcoagulated proteins are held back. Culinary beer art Monitoring of the kettle extract, via density or soundvelocity, can increase output quality and quantity. Density (Extract, °Plato, SG) measurement, be it atthe kettle, the external boiler, or the whirlpool,optimizestheieboiling eefficiency,, saves energy, reduces the boiling time and influences the overallbrewhouse efficiency. pH measurement informs about yeast metabolism. s To boil with care · Reduced boil time ·Considerable energy savings 。 Increased brewhouse efficiency · Correct course of the brewing process Complete your beer analysis! Parameters and lab instruments: Density (Extract): DMA 35 portable density meter;DMA 4100/4500/5000 M benchtop density meter pH: pH ME / pH ME beverage measuring module forDMA M Multiparameter measurements: DMA M; pH ME; Xsample 320/520 Online/inline instruments: Extract/Plato Monitor: L-Dens 7400/7500 densitysensor; L-Sonic 5100 sound velocity sensor Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) Figure 6: left: DMA 35 portable density meter;right: L-Dens 7400 density sensor 4 Wort monitoring: whirlpool Figure 7: Monitoring wort in the whirlpool After the boil, the kettle is full of wort and trub from thehops. The trub is removed in the whirlpool to obtainclear wort for further successful brewing. Give wort a whirl Hops, added as pellets or entire flowers to the kettle,release aroma compounds during the boil. Once thesoluble hop compounds have been brought intosolution in the kettle, some insoluble hop componentsremain which may inhibit subsequent brewing stepsand are therefore removed. This is done by swirlingeither in the kettle itself or, better, in a whirlpool. A separate whirlpool allows an overall faster brewingprocess. After boiling, the wort is transferred tangentially to thewhirlpool with high speed. Due to the rotationalmovement, the separation starts: the heavier particlesmove to the center and sink to the bottom of thevessel. The whirlpool rest should be as short aspossible to avoid thermal stress of the wort, whichguarantees lighter color and improved flavor stabilityof wort and beer, conserving aromas and minimizingsteam losses at the same time. The brewing progress in plain view Density aanndd turbidity play animportant role: ifconsiderable amounts of trub reach the fermentation.a raspy bitterness can result. Density (Extract, Plato,SG) measurement beforeor after the whirlpool optimizes the separationefficiency of wort from trub, reduces brew time, andinfluences the overall brewhouse efficiency. If highgravity brewing is practiced, sugar syrup may beadded before or after the whirlpool. Inline extractmonitoring cannensure proper concentration andblending. Turbidity measurement helps ensure that a clearwort is obtained after the whirlpool. pH measurements help ensure that the progresstakes its proper course. Beer color not only appeals to the consumer's eyebut also informs about the correct composition of theproduct. s Get a clear view of the brewing process · Clear wort without unwanted trub particles · Optimized yield of clear wort Increased efficiency achieved Time, energy and cost effective Complete your beer analysis! Parameters and lab instruments: Density (Extract): DMA 35 portable density meter;DMA 4100/4500/5000 M benchtop density meter Color: Alcolyzer Beer M alcohol meter with coloroption Turbidity: HazeQC ME turbidity measuring modulefor DMA MpH: pH ME / pH ME beverage measuring module forDMA M Alcolyzer Beer Analyzing System: DMA M;Alcolyzer Beer ME with color option; HazeQC ME;pH ME; Xsample 320/520 Parameters and online/inline instruments: Extract/Plato Monitor: L-Dens 7400/7500 densitysensor; L-Sonic 5100 sound velocity sensor;L-Rix 5200 inline refractometer Color: L-Col 6100 photometer Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) Figure 8: left: DMA M with Alcolyzer Beer ME, pH ME,HazeQC ME and Xsample 520; right: L-Dens 7400/7500 density sensor 5 VWort monitoring: wort cooler Figure 9: Monitoring wort in the wort cooler The clear wort is cooled down from boiling hot to atemperature roughly between55℃and 20 C,depending on the beer style. Then the yeast is added. When in a brewery, do as the brewers do After the whirlpool, the wort is cooled to fermentationtemperatures using a heat exchanger before yeast isadded. The actual temperature depends on the beerstyle and yeast strain. Cold wort is a commonapplicationinn1Europeand Asia, especiallyyinGermany, Austria and Japan. In these countries, beeris partially legislated under food (not alcohol) tax codewhich means that breweries are taxed based on theextract used and not the alcohol produced. Thus, theextract concentration and total extract mass of coldwort are important. In case of high gravity brewing, the wort concentrationlies;ttypically between 14°Plato and 20° Plato,sometimes as high as 30° Plato. More fermentablesugars means that a higher-alcohol mother beer canbe produced that is diluted later in the process withde-aerated water which is mostly done by largerbreweries worldwide By continuous monitoring of the extract by density orsoundvelocitymeasurements.,pproducttqualityspecifications are determined and maintained. Density (Extract,°Plato, SG) measurements savewater, lower the waste water volume, reduce theboiling time and influence the overallbrewhouseefficiency. Sound Velocity (Extract) can be used to determinethe concentration of the wort. Dissolved oxygen measurement is used to ensureproper yeast health and activity in the fermenter. Beer color not only appeals to the consumer’s eyebut also informs about the correct composition of theproduct. s Straight ahead to first place ●·Maximized efficiencv · Conscious use of energy Time and cost savings The direct route to great beer Complete your beer analysis! Parameters and online/inline instruments: Extract/Plato monitor: L-Dens 7400/7500 density sensor; Oxy 510 dissolvedoxygen sensor; L-Sonic 5100 sound velocity sensor Color: L-Col 6100 photometer Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) Figure 10: left: L-Sonic 5100 sound velocity sensor; right: The Davis 5 Data Acquisition and Visualization Software 6 Fermentation monitoring Figure 11:Monitoring during fermentation In the fermenter, major changes are underway as theyeast converts sugar into alcohol and carbon dioxideand the so far alcohol-free liquid is turned into beer. This evolution deserves special attention. The beer starts here Once yeast is added to the aerated cold wort and allthe oxygen is metabolized by the yeast, fermentationstarts. The conversion of carbohydrates to alcohol andcarbon dioxide is arguably the most important part. What's created here can finally be called“BEER” Careful monitoring is the mother of a goodbeer Certain brewing methods such as high-gravity brewingrequire additives for increasing the yeast activity; insuch cases a concentration measurement by densityproves useful. Laboratory cdensityy measurementaand inlinerefractive index monitoring (extract, SG, apparentextract) allow keeping the overall fermentation curveand speed and enable more proactive productionplanning. Oxygen determination is essential to make sure thatthe addeddyeast has enough air for optimumperformance. pH measurements during fermentation are helpful toensure consistent product quality and taste and allowfor prior planning of batch blending. s It is worth the attention ·Excellent yeast performance maximizes the yield ·Optimized fermentation progress ensured · Consistently high product quality achieved Timely action possible to achieve the desiredoutput Complete your beer analysis! Parameters, lab and At-line instruments: Density (Extract): DMA 35 portable density meter;Alex 500 Alcohol and Extract meter; DMA 4100/4500/5000 M benchtop density meter Dissolved oxygen:OxyQC wide range portableoxygen meter pH: pH ME / pH ME beverage measuring module forDMA M Alcolyzer Beer Analyzing System: DMA M; Alcolyzer Beer ME w/wo color option; pH ME;Xsample 320/520 Parameter and online/inline instruments: Fermentation: Fermentation monitor 5100 Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) - Figure 12:left: DMA M benchtop density meter;right: Fermentation monitor 5100 Beer monitoring: filtration Figure 13: Monitoring the beer during filtration After fermentation, the newly brewed beer is filtered.Only the desired components pass: clear, high-qualitybeer. A cheer for clear beer! Filtration can be carried out in different ways: it can berough, leaving some cloudiness in the beer, fine,removing all the cloudiness for a meticulously clearbeer, or sterile, ensuring all microorganisms areremoved. Filtration is not only performed to obtain a clearer orcompletely clear beer without any suspended particlesin it, but also to stabilize the beer by removing anysubstances that might cause unwanted turbidity. Inmost cases, Kieselguhr (diatomaceous earth) is usedas a filter material. 品 Beer backstage The measurement of all quality parameters is crucialduring thispproductionphase: fHere isthe lastopportunity where these parameters can be measuredand modified! The accurate measurement of alcohol, extract, CO2,O2, color, pH and turbidity in beer provides animmediate, significant insight into product quality,consistency and production efficiency, whether inhigh-gravity blending, carbonation or blending.Beforefiltration, the measurements are carried out in thelaboratory fromthe lager tanks whereas inlinemeasurements are often found pre-installed on larger blending or filter systems.The viscosity of tbeerprovides information on the beer's filterability. Inline instrumentation is also easily added to anexisting system and provides valuable informationduring the filtration process. The beer monitor forinline installations offers itself as the ideal solution forcomprehensivemonitoring offrelevant qualityparameters. Beer color not only appeals to the consumer’s eyebut also informs about the correct composition of theproduct. $ Accurate measurements stand for quality ·Consistently high beer quality · Only product that meets the specifications releasedfor bottlina Timely action possible for desired output quality ·Optimized efficiency during the entire brewingprocess Complete your beer analysis! Parameters, lab and At-line instruments: Density (Extract), Alcohol: Alex 500 Alcohol andExtract Meter Alcohol/Color: Alcolyzer Beer M alcohol meter w/wocolor option Dissolved CO2, O2:CarboQC/CarboQC At-line CO2meter; OxyQC O2 meter; CboxQC/CboxQC At-lineCo2 and O2 meter Multiparameter measurements: DMA M; AlcolyzerBeer ME w/wo color option; HazeQC ME; pH ME;Lovis 2000 ME microviscometer; Xsample 320/520 Parameters and online/inline instruments: Beer monitor: Beer Monitor 5500/5600; L-Com 5500density and sound velocity sensor; Carbo 510,Carbo 520 Optical inline CO2 sensors; Carbo 2100MVE CO2 transducer; Oxy 510 dissolved O2 sensor Color: L-Col 6100 photometer Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) Figure 14: left: Alex 500 Alcohol and Extract meter;right: Oxy 510 dissolved oxygen sensor Beer monitoring: storage Figure 15: Monitoring beer during storage Depending on its style, the beer is left 3 weeks to 3monthsiinnlager tanks,whereits flavor andcharacteristics develop. However, corrections are - ifaccurate measurements showdeviationss--stillpossible. Give taste a chance Accurate measurements of alcohol, extract, CO2, O2,color, pH and turbidity need to be performed to checkproduct specifications before the product is packaged.Whether high gravity brewing, fine tuning or blending,the accurate measurement of these parameters canprovide an immediate, significant improvement toproduct quality, consistency and production efficiency. The bright beer tank is the last step in the beerproduction where these parameters can be measuredand still modified before the product is bottled orcanned. Iltis therefore a matter of course thatcomprehensive investigation of the beer at that stageis essential. 品Playing it safe Do not miss the opportunities offered by powerfulmeasuring instruments! Your beer's quality dependson it. Alcohol measurement confirms whether the alcoholconcentration meets the specifications. Dissolved oxygen measurement is a must: anyoxygen in the beer reduces the shelf life and can havedetrimental effects on taste and color. Dissolved carbon dioxide determination ensurescarbonation levels are up to specifications, thusfulfilling taste requirements. Color and turbidity measurements ensure the beerfulfills quality standards and appeals to what meetsthe eye. pH measurements allowmonitoringconsistentproduct quality. If it's on the label, it's in the beer ·Continuous consumer satisfaction · Consistent product quality Timely action possible to achieve the desiredproduct specifications ·Label requirements safeguarded Complete your beer analysis! Parameters, lab and At-line instruments: Alcohol/Color: Alcolyzer Beer M alcohol meter w/wocolor option Turbidity: HazeQC ME turbidity measuring modulefor DMA M Dissolved CO2, O2: CarboQC/CarboQC At-lineportable CO2 meter; CboxQC/CboxQC At-line portableCO2 and O2 meter; OxyQC portable oxygen meter pH: pH ME / pH ME beverage measuring module forDMA M Alcolyzer Beer Analyzing System: DMA M;Alcolyzer Beer ME w/wo color option; HazeQC ME; pH ME; Xsample 320/520 Figure 16: left: CboxQC At-line CO2 and O2 meter; right: DMA Mwith Alcolyzer Beer ME, pH ME, HazeQC ME and Xsample 520 Beer monitoring: pre-filler and packaging Figure 17: Last checks on the finished beer Final quality control before the product leaves theplantfor thelast1ccheckonthe specificationsguarantees continuous consumer satisfaction. Consistent beer quality Final product quality is what the consumers see, tasteand experience every time a package is opened. Thisis the last and final spot check of the packagedproduct before it leaves the plant and ensures thatonly the best product is delivered to be consumed. Modern instrumentation allows analyses in a veryquickmeasurementtime anddensuresthatallspecifications and legal requirements are met thusincreasing overall production efficiency until the veryend of the entire beer production process. 品Beer blendina Careful monitoring of the packaged product beforedelivery puts the brewers’ mind at rest: thesemeasurements assure that only high-quality product isdelivered to its final destination..Powerfulinstrumentation helps: some instruments have alreadyaccompanied the beer during the entire productionprocess right from the start. Dissolved oxygen measurement is a must in thebeer as well as in the head space: any oxygen in thebeer reduces the shelf life and can have detrimentaleffects on taste and color. Dissolved carbon dioxide determination ensurescarbonationlevels are up tospecifications, thusfulfilling taste requirements. Alcohol measurement confirms whether the alcohol concentration meets the specifications. Color and turbidity measurements ensure the beerfulfills quality standards and appeals to what meetsthe eye. pHH rmeasurements allowmonitoringconsistentproduct quality. s The beginning of a long friendship ·Label specifications and legal requirements fulfilled The beer keeps what the label promises The same instruments can accompany the entireproduction process ·Constant quality keeps consumers happy Complete your beer analysis! Parameters, lab and At-line instruments: Dissolved CO2,O2:CarboQC/CarboQC At-lineportable CO2 meter; CboxQC/CboxQC At-line portableCO2 and O2 meter; OxyQC portable oxygen meter;TPO 5000 Total Package Oxygen meter Alcohol, extract, color, turbidity, pH, CO2 and O2:Packaged Beverage Analyzer (PBA-B)M(DMA 4500/5000 M; Alcolyzer Beer ME w/wo coloroption; CarboQC ME w/wo Option O2 (Plus);HazeQC ME; pH ME; PFD/PFD Plus Filling Device) Parameters and online/inline instruments: Beer monitor: Beer Monitor 5500/5600; L-Com 5500density and sound velocity sensor; Carbo 510,Carbo 520 Optical inline CO2 sensors; Carbo 2100MVE CO2 transducer; Oxy 510 dissolved O2 sensor;Color/Turbidity options Color: L-Col 6100 photometer Software: Davis 5 Data Acquisition and VisualizationSoftware (incl. mPDS 5 evaluation unit) Figure 18: left: PBA-B M; right: Beer Monitor 5500 sSkid-mounted Beer Analysis Systems Figure 19: Beer Analysis System ready for integration The increasing capabilities of online analysis andcomplexity of system integration result in the need formeasuring systems delivering all critical quality controlparameters in the beer filling line. The challenge Stringent quality standards have become standard inmodern beer industry. The aim is all-over quality control which ensures thatonly rproductscomplyingwith highest qualitystandards reach the packaging line at the end of thebeer production process. Highly integrated all-in-one solutions are a way toovercome the conflict of this aim with the objective ofcost reduction and the limitation of resources. 品 All-in-one and highly integrated Available as skid mounted system or as modularsystem distributed over the existing pipe work theAnimo 5100 Beer Analysis System is seamlesslyintegrated into new and existing filling lines. The integrated sensors and analyzers are ready touse without time-consuming commissioning and on-site adjustments. Pre-configured in the factory, they come with the right setup and calculation methods forbeer analysis. Forupgrading and refurbishingprojects theAnimo 5100 is an open system, capable of beingadapted to existing infrastructure and componentsprovided by the customer. By providing project engineering, system design,installation support and commissioning Anton Paarmakes the all-in-one package complete. Customersbenefit from a ready-to-go quality control system. s Efficient projects to productivity The short track from site survey to productivequality control · A central access point to all critical qualityparameters Zero out-of-spec products in your package line · No hassle with adjustment and calibration ·Annual maintenance effort of less than a day Complete your beer analysis! Online/inline systems: Animo 5100 beer analysis System-integrated instruments: · L-Com 5500-alcohol and extract measurement · Carbo 520 Optical -dissolved CO2 measurement · Oxy 510 - dissolved oxygen measurement · Evaluation Unit mPDS 5 - data integration · Davis 5 software- analysis, calibration, reporting · Conductivity sensor - detection of CIP agents Flow meter Piping and wiring - site specific integration ·Option L-Col 6100 photometer Extensions on customer request Figure 20: left: outlet and drain valves; right: sensor section Contact Anton Paar GmbH Tel: +43 316 257-0density@anton-paar.comprocess@anton-paar.com www.anton-paar.com XPAIAN-Fwww.anton-paar.com 安东帕(Anton Paar)是世界上第一家饮料分析的全方位供应商,它将实验室和过程仪器联系在一起,以提供完整和定制的测量解决方案。高端技术满足了全球服务的要求,可为您提供完美的饮料分析-从进口原材料到易于装瓶的产品,以使消费者持续满意。

确定

还剩10页未读,是否继续阅读?

安东帕(上海)商贸有限公司为您提供《啤酒中原浓、酒精度等检测方案(其它工程控制)》,该方案主要用于啤酒中理化分析检测,参考标准--,《啤酒中原浓、酒精度等检测方案(其它工程控制)》用到的仪器有安东帕Anton Paar在线啤酒监测仪Beer monitor 5500/5600

推荐专场

相关方案

更多

该厂商其他方案

更多