布鲁克TI系列纳米材料机械性能,压痕,划痕,摩擦磨损具有高精度,结合原位AFM功能,可获得精准数据,排除环境因素,底材因素。

方案详情

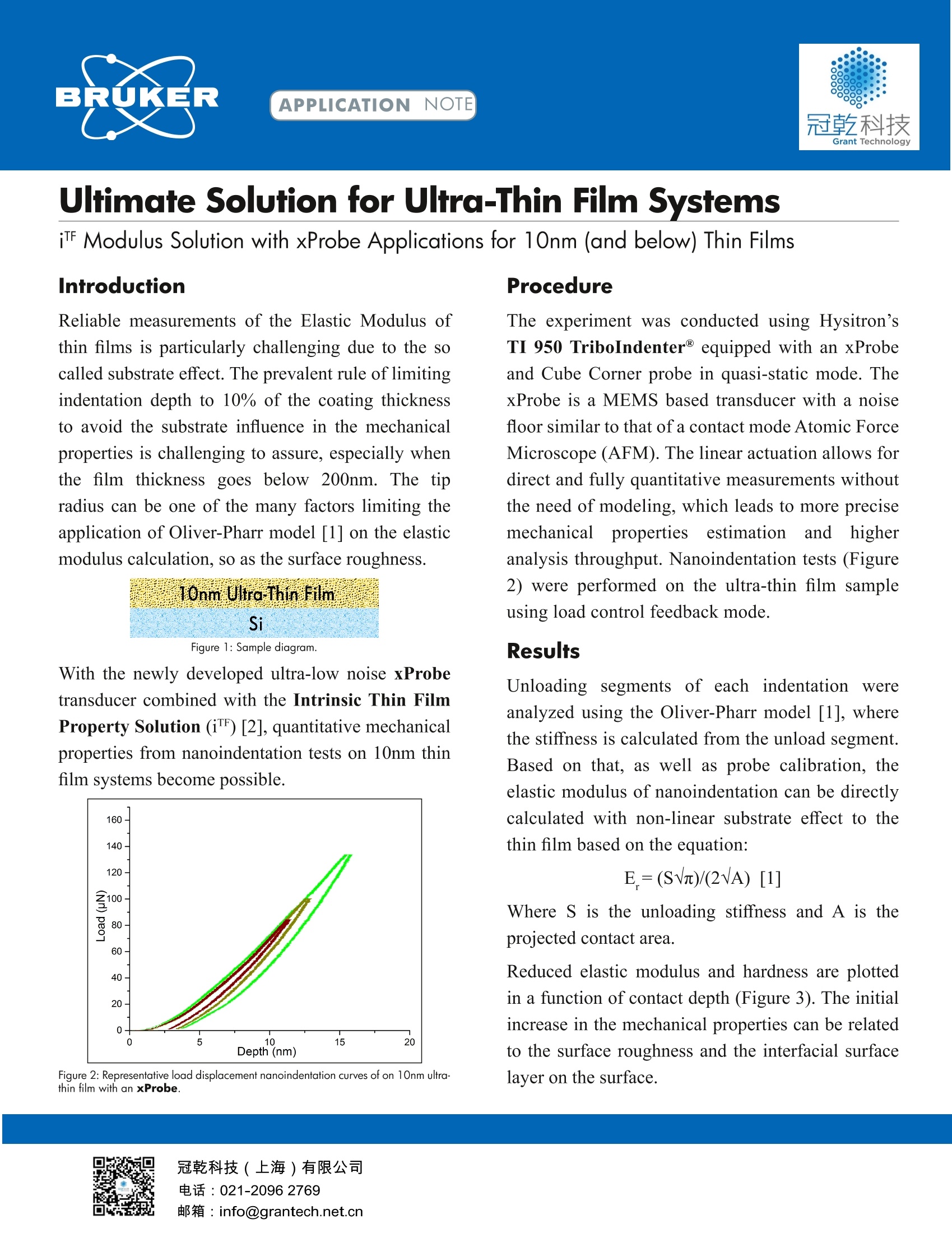

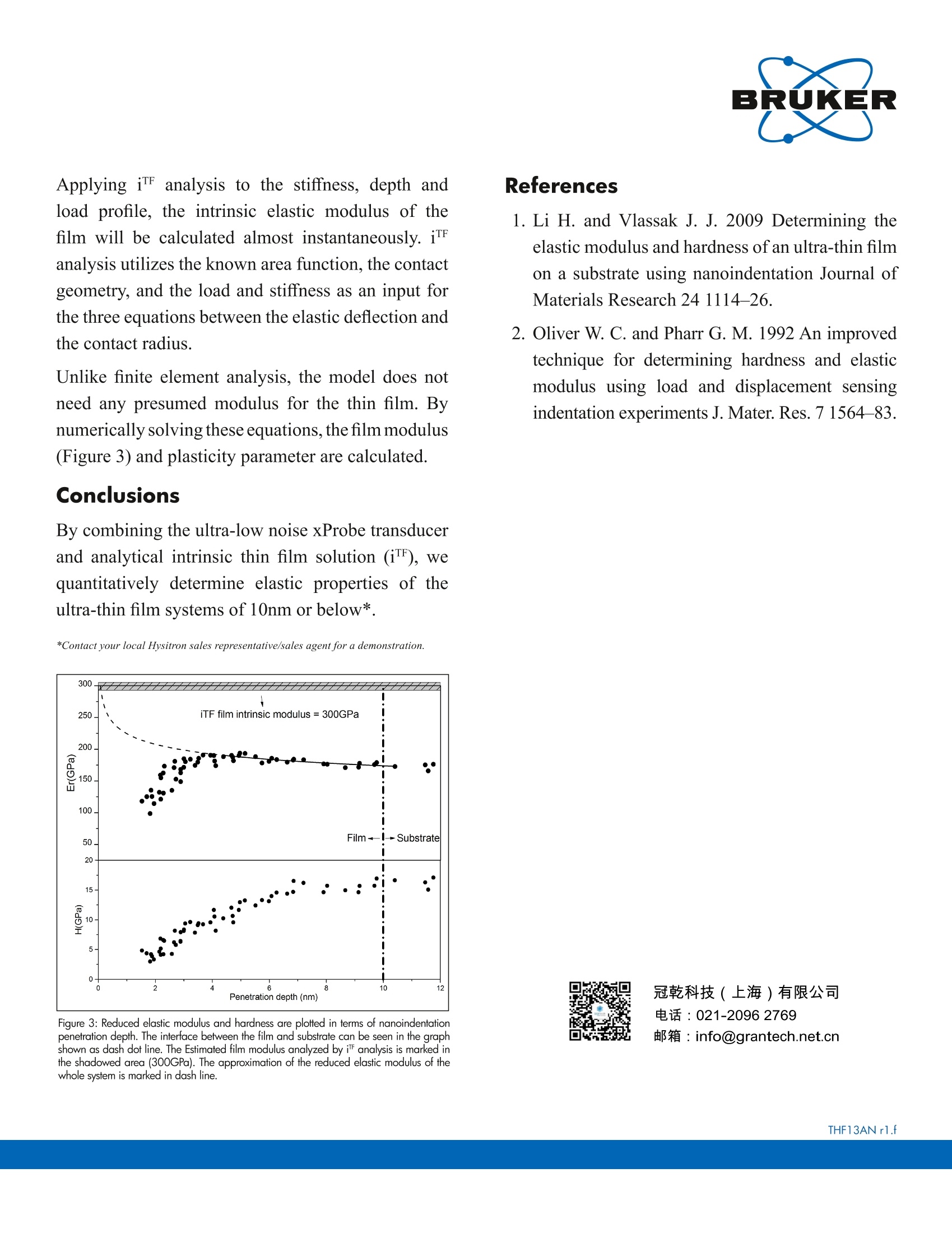

APPLICATIONNOTE Ultimate Solution for Ultra-Thin Film Systems if Modulus Solution with xProbe Applications for 10nm (and below) Thin Films Introduction Reliable measurements of the Elastic Modulus ofthin films is particularly challenging due to the socalled substrate effect. The prevalent rule of limitingindentation depth to 10% of the coating thicknessto avoid the substrate influence in the mechanicalproperties is challenging to assure, especially whenthe film thickness goes below 200nm. The tipradius can be one of the many factors limiting theapplication of Oliver-Pharr model [1] on the elasticmodulus calculation, so as the surface roughness. Figure 1: Sample diagram. With the newly developed ultra-low noise xProbetransducer combined with the Intrinsic Thin FilmProperty Solution (i) [2], quantitative mechanicalproperties from nanoindentation tests on 10nm thinfilm systems become possible. Figure 2: Representative load displacement nanoindentation curves of on 10nm ultra-thin film with an xProbe. Procedure The experiment was conducted using Hysitron’sTI 950 TriboIndenter° equipped with an xProbeand Cube Corner probe in quasi-static mode. ThexProbe is a MEMS based transducer with a noisefloor similar to that of a contact mode Atomic ForceMicroscope (AFM). The linear actuation allows fordirect and fully quantitative measurements withoutthe need of modeling, which leads to more precisemechanicalproperties estimation andhigheranalysis throughput. Nanoindentation tests (Figure2) were performed on the ultra-thin film sampleusing load control feedback mode. Results Unloading segments of each indentation wereanalyzed using the Oliver-Pharr model [1], wherethe stiffness is calculated from the unload segment.Based on that, as well as probe calibration, theelastic modulus of nanoindentation can be directlycalculated with non-linear substrate effect to thethin film based on the equation: Where S is the unloading stiffness and A is theprojected contact area. Reduced elastic modulus and hardness are plottedin a function of contact depth (Figure 3). The initialincrease in the mechanical properties can be relatedto the surface roughness and the interfacial surfacelayer on the surface. Applying i analysis to the stiffness, depth andload profile, the intrinsic elastic modulus of thefilm will be calculated almost instantaneously. i analysis utilizes the known area function, the contactgeometry, and the load and stiffness as an input forthe three equations between the elastic deflection andthe contact radius. Unlike finite element analysis, the model does notneed any presumed modulus for the thin film. Bynumerically solving these equations, the film modulus(Figure 3) and plasticity parameter are calculated. Conclusions By combining the ultra-low noise xProbe transducerand analytical intrinsic thin film solution (i), wequantitatively determine elastic properties of theultra-thin film systems of 10nm or below*. *Contact your local Hysitron sales representative/sales agent for a demonstration. Figure 3: Reduced elastic modulus and hardness are plotted in terms of nanoindentationpenetration depth. The interface between the film and substrate can be seen in the graphshown as dash dot line. The Estimated film modulus analyzed by i"f analysis is marked inthe shadowed area (300GPa). The approximation of the reduced elastic modulus of thewhole system is marked in dash line. References 1. Li H. and Vlassak J. J. 2009 Determining theelastic modulus and hardness of an ultra-thin filmon a substrate using nanoindentation Journal ofMaterials Research 24 1114-26. 2. Oliver W. C. and Pharr G. M. 1992 An improvedtechnique for determining hardness and elasticmodulus using load and displacement sensingindentation experiments J. Mater. Res. 7 1564-83. 冠乾科技(上海)有限公司电话: THFN r.f 通过最新研发的 xProbe超低噪音传感探头,可以获得超薄涂层<10nm薄膜的机械性能。避免底材的受到机械力产生的形变数据影响。

确定

还剩1页未读,是否继续阅读?

冠乾科技(上海)有限公司为您提供《硅基上超薄薄膜中弹性模量检测方案(摩擦磨损机)》,该方案主要用于电子元器件产品中弹性模量检测,参考标准--,《硅基上超薄薄膜中弹性模量检测方案(摩擦磨损机)》用到的仪器有布鲁克TI Premier 高精度纳米力学测试系统

推荐专场

相关方案

更多