方案详情

文

Mineral liberation is a critical stage in the production of high quality mineralogical concentrates from their ores. The products

(concentrates) must be of a suitable degree of purity for the downstream processes in which they will be used. The original

mined ore must be processed via comminution (crushing, grinding and classification) to liberate the desired minerals from it and

via concentration (froth flotation, gravity separation, magnetic separation) to enrich the mineral content to the desired level. In

order to design, diagnose, monitor and optimise the process, information is needed on the extent to which the valuable mineral

grains have been released from the accompanying gangue minerals (degree of liberation) and to which form they are lost in

tailings (deportment studies).

方案详情

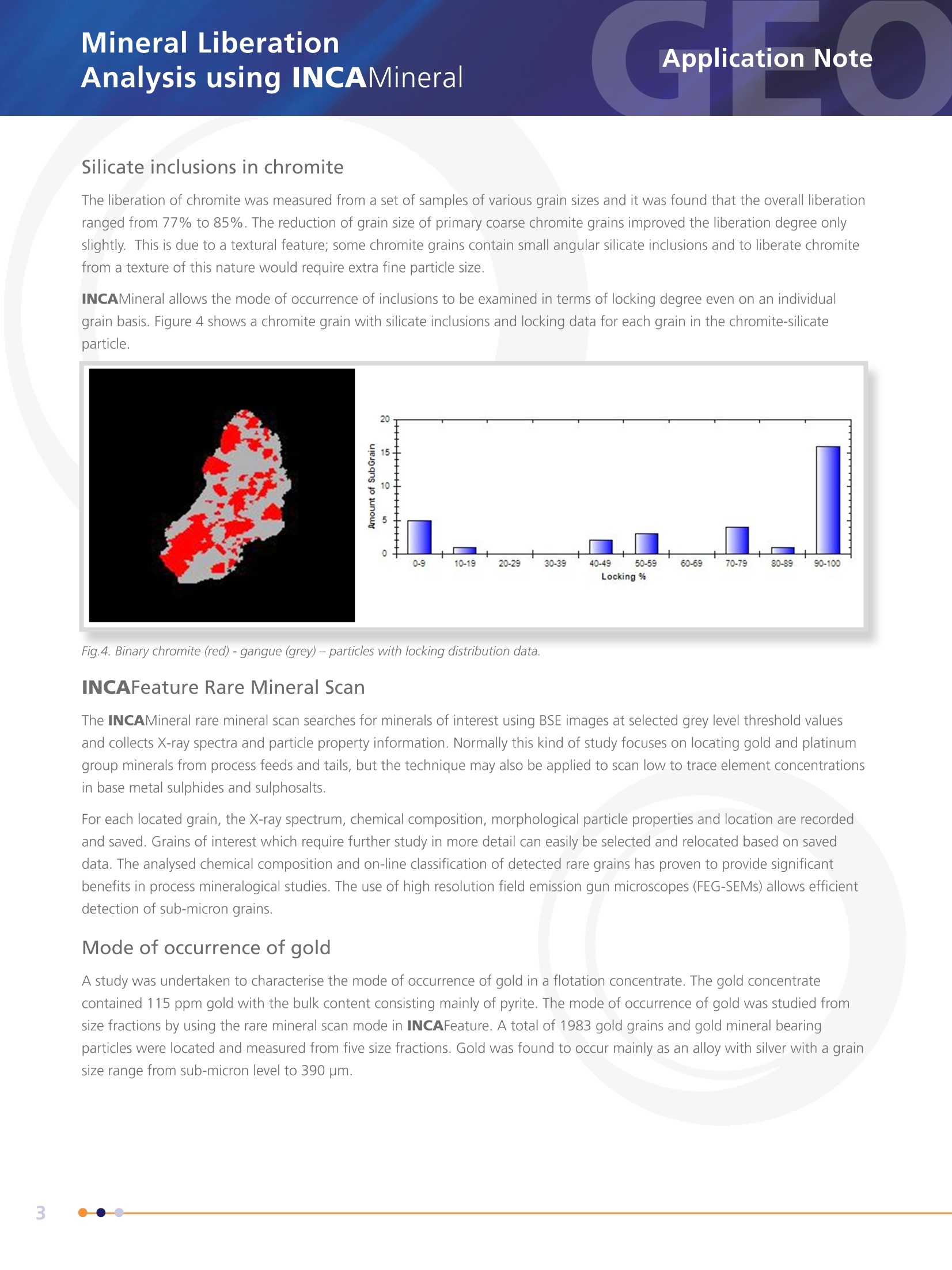

Application Note The Business ofScience@1 Mineral LiberationAnalysis using INCAMineral Introduction Mineral liberation is a critical stage in the production of high quality mineralogical concentrates from their ores. The products(concentrates) must be of a suitable degree of purity for the downstream processes in which they will be used. The originalmined ore must be processed via comminution (crushing, grinding and classification) to liberate the desired minerals from it andvia concentration (froth flotation, gravity separation, magnetic separation) to enrich the mineral content to the desired level. Inorder to design, diagnose, monitor and optimise the process, information is needed on the extent to which the valuable mineralgrains have been released from the accompanying gangue minerals (degree of liberation) and to which form they are lost intailings (deportment studies). INCAMineral INCAMineral is an add-on to the INCAEnergy softwarewhich utilises the functionality of INCAFeature toconduct efficient analysis of mineral liberation degree.INCAMineral combines image analysis of sampleswith X-ray analysis of their chemical composition andpowerful data processing to determine the identity ofgrains and their degree of liberation. The combination of INCAMineral with a large-areaX-Max SDD detector enables a multipurpose SEMto perform mineral liberation analysis to higherperformance and accuracy standards than a dedicatedsystem whilst maintaining the flexibility to perform thefull range of analytical (e.g. WDS, EBSD) and imagingtasks that a SEM is capable of without removing thesample from the chamber. Fig.1. INCAMineral Workflow. INCAMineral introduces a series of recipes and setup parameters to INCAFeature which are dedicated to particle and mineralgrain analysis. Included with the package is the post-processing program GrainAlyzer, which enables in depth analysis ofindividual grains and outputs detailed mineral liberation and association reports. A series of case studies have been completed to demonstrate the capabilities of INCAMineral. The methodology represented inFigure 1 was used in all cases. Mineral LiberationAnalysis using INCAMineral Case Studies Liberation of hematite and goethite The liberation of hematite in a high-gradient SLon magnetic separation concentrate was analysed from a set of size fractions.The feed material for the magnetic separation was hematite rich iron ore with accessory goethite. The amount of magnetite wasless than 1% and quartz was the main gangue mineral. The liberation of hematite and goethite was measured in the ore basedon grey-level image analysis whereas the gangue silicates and accessory sulphides were identified based on X-rays. The liberationof both hematite and quartz were 80% and 77%, correspondingly. Goethite occurs intimately with hematite and only 35% ofgoethite reports as liberated grains in the magnetic concentrate. The mode of occurrence and association of hematite with otherminerals is clearly shown in Figure 2. Fig.2. Cumulative liberation yield for hematite, goethite and quartz and association of hematite with other minerals in wt%. Liberation of sphalerite and galena in flotation feed and tails The liberation of sphalerite and galena were measured by size from flotation feed (FF) and flotation tails (FT). These liberationmeasurements were part of a wider mineralogical process assessment. The main object of this process mineralogical study wasto characterise the flotation feed and find reasons for zinc and lead losses in the flotation tails. In the flotation feed, the bulkliberation of sphalerite and galena was at a good level -87% and 77%, respectively. Sphalerite is primarily lost to the flotationtail as liberated grains, while galena is lost mainly as fine grained inclusions in gangue silicates. The bulk liberation of sphaleritein the flotation tails is 67% and that of galena only 15%. Fig.3. Liberation of a) sphalerite and b) galena in flotation feed (circles) and flotation tails (FT) (triangles) respectively. Mineral LiberationAnalysis using INCAMineral Silicate inclusions in chromite The liberation of chromite was measured from a set of samples of various grain sizes and it was found that the overall liberationranged from 77% to 85%. The reduction of grain size of primary coarse chromite grains improved the liberation degree onlyslightly. This is due to a textural feature; some chromite grains contain small angular silicate inclusions and to liberate chromitefrom a texture of this nature would require extra fine particle size. INCAMineral allows the mode of occurrence of inclusions to be examined in terms of locking degree even on an individualgrain basis.Figure 4 shows a chromite grain with silicate inclusions and locking data for each grain in the chromite-silicateparticle. Fig.4. Binary chromite (red)- gangue (grey) - particles with locking distribution data. INCAFeature Rare Mineral Scan The INCAMineral rare mineral scan searches for minerals of interest using BSE images at selected grey level threshold valuesand collects X-ray spectra and particle property information. Normally this kind of study focuses on locating gold and platinumgroup minerals from process feeds and tails, but the technique may also be applied to scan low to trace element concentrationsin base metal sulphides and sulphosalts. For each located grain, the X-ray spectrum, chemical composition, morphological particle properties and location are recordedand saved. Grains of interest which require further study in more detail can easily be selected and relocated based on saveddata. The analysed chemical composition and on-line classification of detected rare grains has proven to provide significantbenefits in process mineralogical studies. The use of high resolution field emission gun microscopes (FEG-SEMs) allows efficientdetection of sub-micron grains. Mode of occurrence of gold A study was undertaken to characterise the mode of occurrence of gold in a flotation concentrate. The gold concentratecontained 115 ppm gold with the bulk content consisting mainly of pyrite. The mode of occurrence of gold was studied fromsize fractions by using the rare mineral scan mode in INCAFeature. A total of 1983 gold grains and gold mineral bearingparticles were located and measured from five size fractions. Gold was found to occur mainly as an alloy with silver with a grainsize range from sub-micron level to 390 um. Fig.5. Grain size distribution and mode of occurrence of gold in flotation concentrate. The liberation of gold is maximized in the coarsest +106 m and in the finest -20 pm size fractions. The bulk liberation is 81%.The rest occurs mainly as locked binary particles with pyrite (16%) and only a small proportion (3%) as inclusions in pyrite. Thecoarsest gold grain that floated to concentrate was 389 um in length. Most likely grinding has produced coarse but flaky goldgrains that were at least partly recovered by flotation. Conclusion INCAMineral enables mineral liberation analysis in a conventional SEM. By utilising the software alongside modern, large areaSDD devices, the conventional instrument is able to equal the throughput and performance of a dedicated system. Here wehave shown a number of applications of the system, demonstrating its efficacy in several scenarios. The advantages of usinga conventional SEM fitted with a large area SDD and INCAMineral for mineral liberation analysis are clear. Many laboratoriesalready possess an SEM. As such, the upgrading of the instrument with software of this nature represents a cost effectiveapproach which maintains flexibility as the equipment may still be used for all of the other functions of which it is capable. Thisgives the user the possibility to apply additional analytical techniques without removing the sample from the chamber. This mayinvolve the WDS analysis of specific minerals, where the highest energy resolution is required, or even analysis of specific grainswith EBSD in order to obtain more detailed crystallographic information. Acknowledgements This application note is based upon work by J Liipo (Outotec Research Center), H Otterstrom & H Person (Ottab Technologies)and P Lamberg (Lulea University of Technology). www.oxford-instruments.com/mineral ( The materials presented here are summary in nature, subject to change, and inten ded for g e n eral information onl y . ) Performances are configuration dependent. Additional details are available. Oxford Instruments NanoAnalysisis certified to ISO9001, ISO14001 and OHSAS 18001. AZtec and Tru-l are Registered Trademarks of Oxford Instruments plc,all other trademarks acknowledged. @ Oxford Instruments plc, 2013. All rights reserved. Document reference: OINA/INCA/AN2013 006/0713. The Business ofScience" INNOVATION 2012 Mineral liberation is a critical stage in the production of high quality mineralogical concentrates from their ores. The products(concentrates) must be of a suitable degree of purity for the downstream processes in which they will be used. The originalmined ore must be processed via comminution (crushing, grinding and classification) to liberate the desired minerals from it andvia concentration (froth flotation, gravity separation, magnetic separation) to enrich the mineral content to the desired level. Inorder to design, diagnose, monitor and optimise the process, information is needed on the extent to which the valuable mineralgrains have been released from the accompanying gangue minerals (degree of liberation) and to which form they are lost intailings (deportment studies).

确定

还剩2页未读,是否继续阅读?

牛津仪器科技(上海)有限公司为您提供《矿物中解离度检测方案(扫描电镜)》,该方案主要用于金属矿产中解离度检测,参考标准--,《矿物中解离度检测方案(扫描电镜)》用到的仪器有电镜专用自动清洁度分析系统---牛津仪器AZtecFeature、牛津仪器Ultim Extreme无窗超级能谱、EBSD探测器Symmetry S3 牛津仪器、牛津仪器Azteclive能谱实时元素成像系统

推荐专场

电子背散射衍射系统(EBSD)

更多

相关方案

更多