德国AOM系统公司名称来源于“AdvanceOptical Measurement Systems“,即先进的光学测量系统,AOM公司作为喷雾监测技术的发明者,为喷雾或粉体颗粒的特性描述提供了创新的探测器和测量系统,并获得了2015年德国工业奖。此系统采用时间漂移技术实时监测喷雾的过程中液滴或粉体颗粒的大小,速度,动量或流量密度等特性,为喷雾或粉体颗粒的监测提供了独有的测量技术。

方案详情

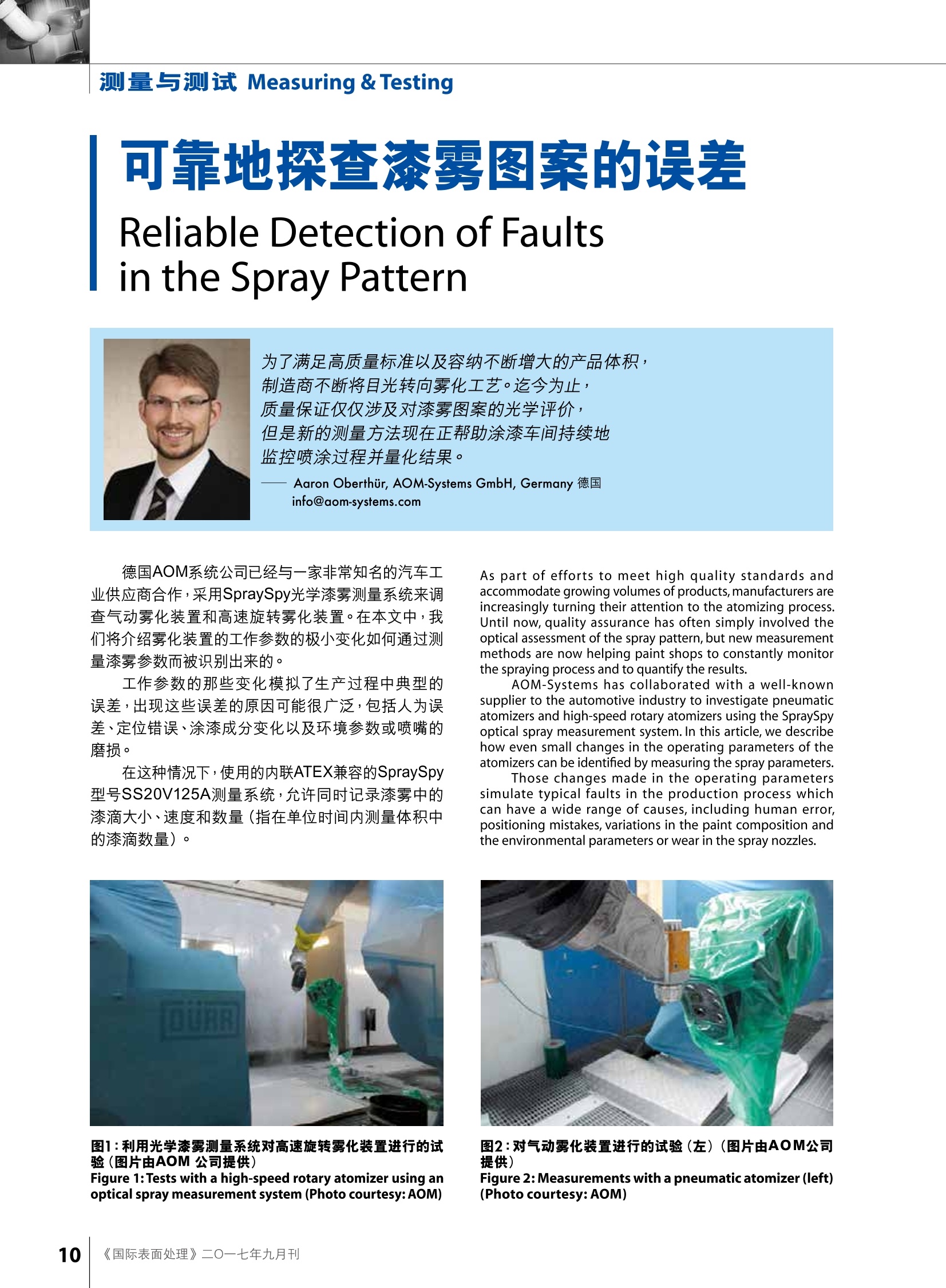

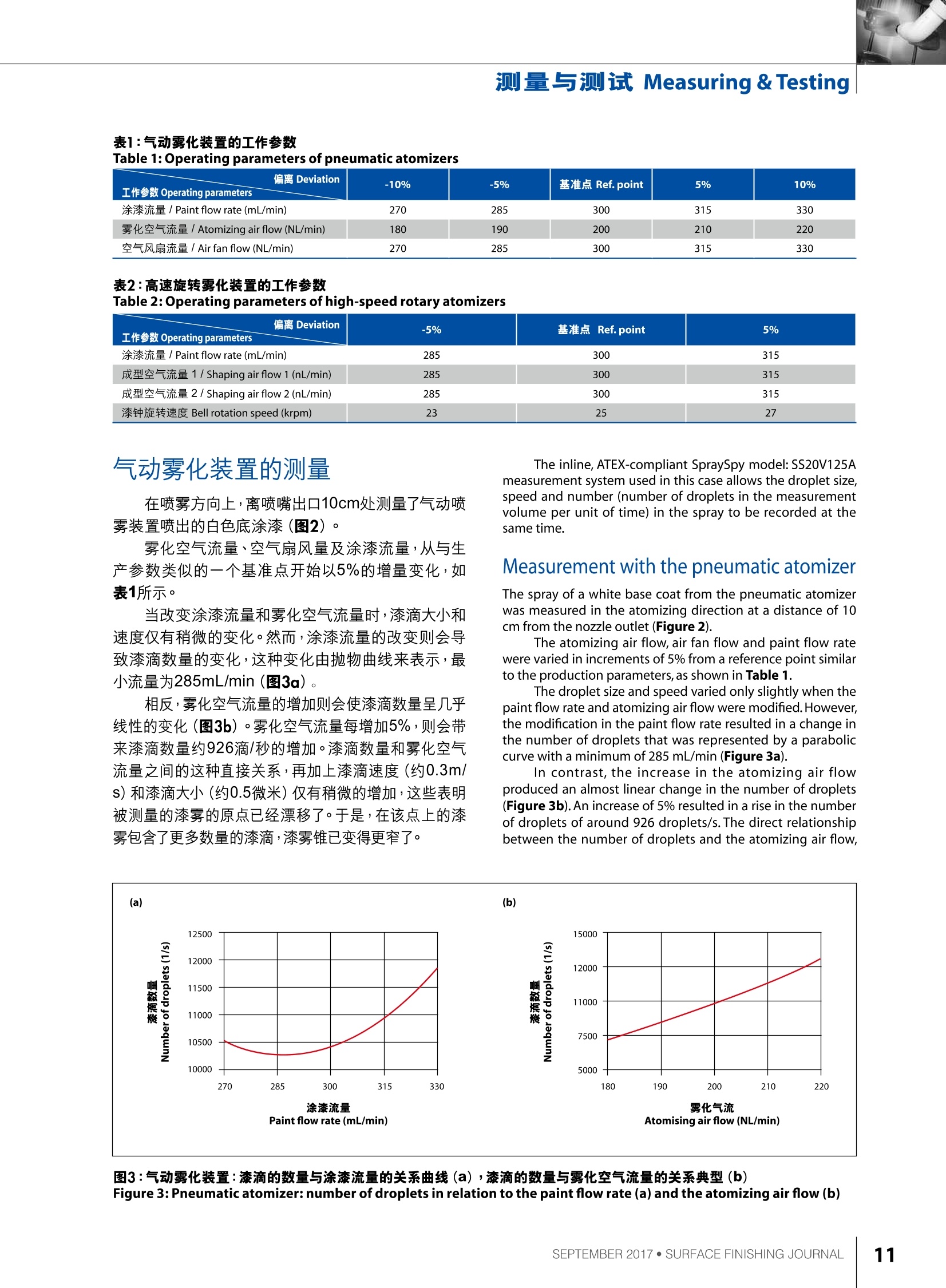

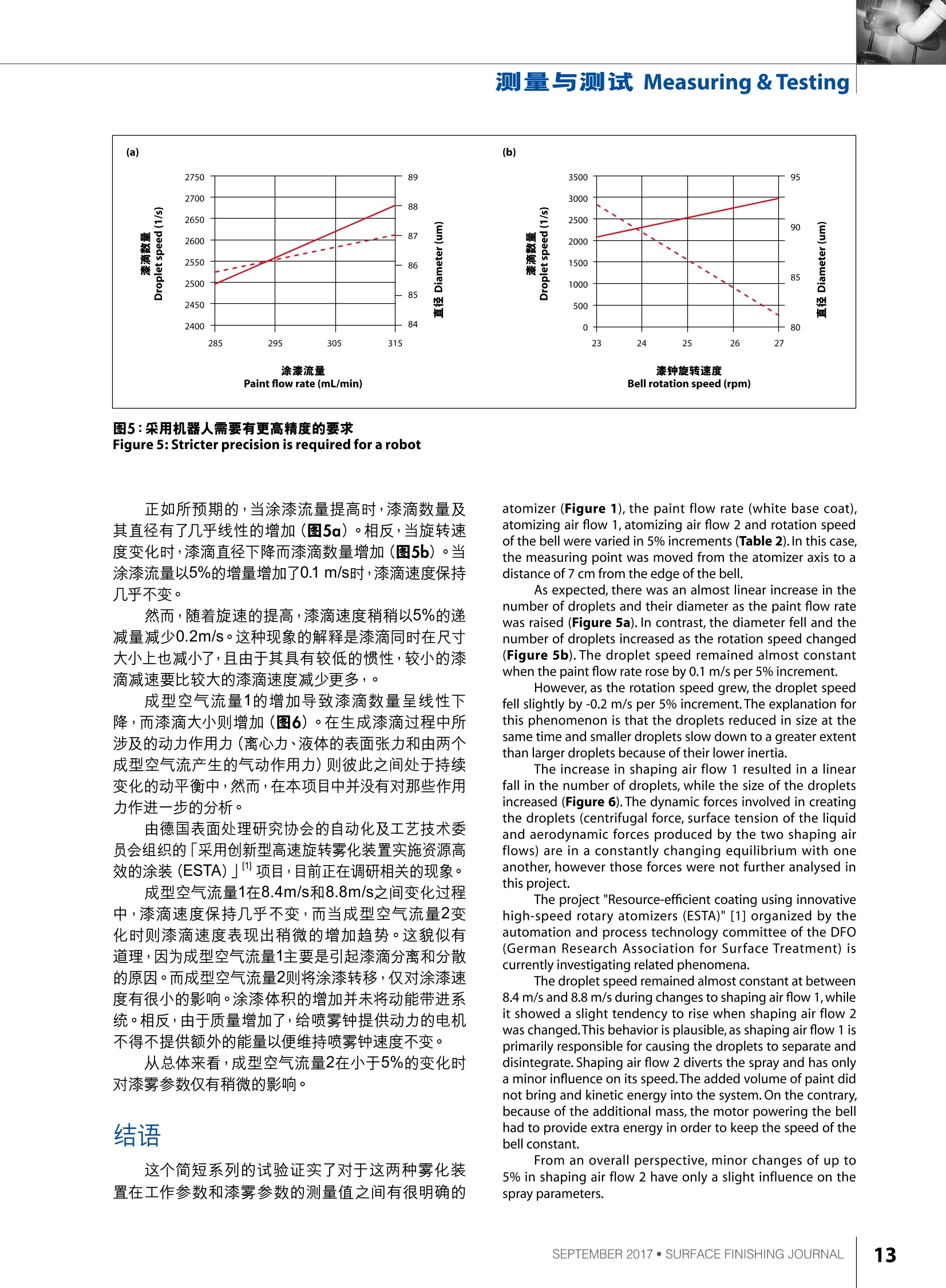

测量与测试 Measuring & Testing 可靠地探查漆雾图案的误差Reliable Detection of Faultsin the Spray Pattern 为了满足高质量标准以及容纳不断增大的产品体积,制造商不断将目光转向雾化工艺。迄今为为·质量保证仅仅涉及对漆雾图案的光学评价,但是新的测量方法现在正帮助涂漆车间持续地监控喷涂过程并量化结果。 — Aaron Oberthur, AOM-Systems GmbH, Germany 德国info@aom-systems.com 德国AOM系统公司已经与一家非常知名的汽车工业供应商合作,采用SpraySpy光学漆雾测量系统来调查气动雾化装置和高速旋转雾化装置。在本文中,我们将介绍雾化装置的工作参数的极小变化如何通过测量漆雾参数而被识别出来的。 工作参数的那些变化模拟了生产过程中典型的误差·出现这些误差的原因可能很广泛,包括人为误差、定位错误、涂漆成分变化以及环境参数或喷嘴的磨损。 在这种情况下,使用的内联ATEX兼容的SpraySpy型号SS20V125A测量系统,允许同时记录漆雾中的漆滴大小、速度和数量(指在单位时间内测量体积中的漆滴数量)。 图1:利用光学漆雾测量系统对高速旋转雾化装置进行的试验(图片由AOM公司提供) Figure 1: Tests with a high-speed rotary atomizer using anoptical spray measurement system (Photo courtesy:AOM) As part of efforts to meet high quality standards andaccommodate growing volumes of products, manufacturers areincreasingly turning their attention to the atomizing process.Until now, quality assurance has often simply involved theoptical assessment of the spray pattern, but new measurementmethods are now helping paint shops to constantly monitorthe spraying process and to quantify the results. AOM-Systems has collaborated with a well-knownsupplier to the automotive industry to investigate pneumaticatomizers and high-speed rotary atomizers using the SpraySpyoptical spray measurement system. In this article, we describehow even small changes in the operating parameters of theatomizers can be identified by measuring the spray parameters. Those changes made in the operating parameterssimulate typical faults in the production process whichcan have a wide range of causes,including human error,positioning mistakes,variations in the paint composition andthe environmental parameters or wear in the spray nozzles. 图2:对气动雾化装置进行的试验(左)(图片由AOM公司提供) Figure 2: Measurements with a pneumatic atomizer(left)(Photo courtesy:AOM) 表1:气动雾化装置的工作参数 Table 1:Operating parameters of pneumatic atomizers 一 工作参数Operating parameters 偏离 Deviation -10% -5% 基准点 Ref.point 5% 10% 涂漆流量/ Paint flow rate (mL/min) 270 285 300 315 330 雾化空气流量/ Atomizing air flow (NL/min) 180 190 200 210 220 空气风扇流量/ Air fan flow (NL/min) 270 285 300 315 330 表2:高速旋转雾化装置的工作参数 Table 2:Operating parameters of high-speed rotary atomizers 一 偏离 Deviation -5% 基准点 Ref.point 5% 工作参数 Operating parameters 涂漆流量/Paint flow rate (mL/min) 285 300 315 成型空气流量1/Shaping air flow 1 (nL/min) 285 300 315 成型空气流量2/ Shaping air flow 2 (nL/min) 285 300 315 漆钟旋转速度 Bell rotation speed (krpm) 23 25 27 气动雾化装置的测量 在喷雾方向上,离喷嘴出口10cm处测量了气动喷雾装置喷出的白色底涂漆(图2)。 雾化空气流量、空气扇风量及涂漆流量,从与生产参数类似的一个基准点开始以5%的增量变化,如表1所示。 当改变涂漆流量和雾化空气流量时,漆滴大小和速度仅有稍微的变化。然而·涂漆流量的改变则会导致漆滴数量的变化,这种变化由抛物曲线来表示·最小流量为285mL/min(图3a)。 相反·雾化空气流量的增加则会使漆滴数量呈几乎线性的变化(图3b)。雾化空气流量每增加5%,则会带来漆滴数量约926滴/秒的增加。漆滴数量和雾化空气流量之间的这种直接关系,再加上漆滴速度(约0.3m/s) 和漆滴大小(约0.5微米)仅有稍微的增加,这些表明被测量的漆雾的原点已经漂移了。于是,在该点上的漆雾包含了更多数量的漆滴,漆雾锥已变得更窄了。 The inline, ATEX-compliant SpraySpy model: SS20V125Ameasurement system used in this case allows the droplet size,speed and number (number of droplets in the measurementvolume per unit of time) in the spray to be recorded at thesame time. Measurement with the pneumatic atomizer The spray of a white base coat from the pneumatic atomizerwas measured in the atomizing direction at a distance of 10cm from the nozzle outlet (Figure 2). The atomizing air flow,air fan flow and paint flow ratewere varied in increments of 5% from a reference point similarto the production parameters, as shown in Table 1. The droplet size and speed varied only slightly when thepaint flow rate and atomizing air flow were modified. However,the modification in the paint flow rate resulted in a change inthe number of droplets that was represented by a paraboliccurve with a minimum of 285 mL/min (Figure 3a). In contrast, the increase in the atomizing air flowproduced an almost linear change in the number of droplets(Figure 3b). An increase of 5% resulted in a rise in the numberof droplets of around 926 droplets/s. The direct relationshipbetween the number of droplets and the atomizing air flow, 图3:气动雾化装置:漆滴的数量与涂漆流量的关系曲线(a)·漆滴的数量与雾化空气流量的关系典型(b)Figure 3: Pneumatic atomizer: number of droplets in relation to the paint flow rate (a) and the atomizing air flow (b) 图4:气动雾化装置:漆滴速度和大小与空气扇流量之间的关系曲线(a)·漆滴速度和大小与漆滴数量之间的关系曲线(b)Figure 4:Pneumatic atomizer: droplet speed and size (dotted line) in relation to the air fan flow(a) and the number ofdroplets(b) 空气扇流量的变化导致所有这三个参数都有很大的变化。正如所预期的·漆滴大小和漆滴速度相互之间成反比例(图4a)。然而,尽管定定的涂漆体积和漆滴数量都降低了(图4b)。这种性状,初看起来似乎是矛盾的,但当我们把空气扇流量对喷雾形状有非常大的影响这个因素考虑进去时,这就变得容易理解了。随着空气扇数量的增加,则漆雾被不断地压缩到一个平面上。与此同时,漆雾角在第二个平面中增加。结果,在测量点上漆滴数量极少。 高速旋转的雾化装置的测量 象前面的试验系列一样,对于高速旋转雾化装置(图1)·涂漆流量(白色的底涂)、雾化空气流量1、雾化空气流量2和喷雾钟的旋转速度均以5%的增量变化(表2)。这这种情况中,量量点从雾化装置轴漂移到距离喷雾钟边缘的7cm处。 which was accompanied by only a slight increase in thedroplet speed (by around 0.3 m/s) and droplet size (by around0.5 um), indicates that the original point in the spray wherethe measurements were made had shifted. The spray at thispoint then contained a higher number of droplets and thespray cone had become narrower. Changes in the air fan flow resulted in significant variationsin all three parameters. As expected,the droplet size and dropletspeed were in inverse proportion to one another (Figure 4a).However, despite a constant volume of paint and number ofdroplets fell (Figure 4b). This behavior, which at first seemedcontradictory, became easier to understand when we took intoconsideration that the air fan flow has a strong influence onthe shape of the spray. As the amount of air fan grew, the spraybecame increasingly compressed into one plane. At the sametime,the spray angle increased in the second plane. As a result,there were fewer droplets at the measuring point. Measurements with the high-speedrotary atomizer As in the previous test series, with the high-speed rotary 表3:工作参数对气动雾化装置和高速旋转雾化装置的漆雾中漆滴动力学的影响 Table 3: Influence of the operating parameters on the droplet dynamics in the spray of a pneumatic atomizer and ahigh-speed rotary atomizer 雾化装置 工作参数 对漆雾中漆滴动力学的影响 Atomizer Operating parameters Influence on the droplet dynamics in the spray 涂漆流量 弱 Paint flow rate Weak 气动雾化装置Pneumatic atomizer 雾化空气流量 中 Atomizing air flow Moderate 空气扇流量 强 Air fan flow Strong 涂漆流量 中 Paint flow rate Moderate 成型空气流量 1 中 Shaping air flow 1 Moderate 高速旋转雾化装置 High-speed rotary atomizer 成型空气流量2 弱 Shaping air flow 2 Weak 漆钟旋转速度 很强 Bell rotation speed Very strong 图5:采用机器人需要有更高精度的要求 正如所预期的,当涂漆流量提高时,漆滴数量及其直径有了几乎线性的增增(图5a)。相反·当旋转速度变化时,漆滴直径下降而漆滴数量增加(图5b)。当涂漆流量以5%的增量增加了0.1m/s时,漆滴速度保持几乎不变。 然而,随着旋速的提高,漆滴速度稍稍以5%的递减量减少0.2m/s。这种现象的解释是漆滴同时在尺寸大小上也减小了,且由于其具有较低的惯性,较小的漆滴减速要比较大的漆滴速度减少更多, o 成型空气流量1的增加导致漆滴数量呈线性下降·而漆滴大小则增加(图6)。在生成漆滴过程中所涉及的动力作用力(离心力、液体的表面张力和由两个成型空气流产生的气动作用力)则彼此之间处于持续变化的动平衡中,然而·在本项目中并没有对那些作用力作进一步的分析。 由德国表面处理研究协会的自动化及工艺技术委员会组织的「采用创新型高速旋转雾化装置实施资源高效的涂装(ESTA)」项目,目前正在调研相关的现象。 成型空气流量1在8.4m/s和8.8m/s之间变化过程中,漆滴速度保持几乎不变·而当成型空气流量2变化时则漆滴速度表现出稍微的增加趋势。这貌似有道理,因为成型空气流量1主要是引起漆滴分离和分散的原因。而成型空气流量2则将涂漆转移,仅对涂漆速度有很小的影响。涂漆体积的增加并未将动能带进系统。相反·由于质量增加了,给喷雾钟提供动力的电机不得不提供额外的能量以便维持喷雾钟速度不变。 从总体来看,成型空气流量2在小于5%的变化时对漆雾参数仅有稍微的影响。 这个简短系列的试验证实了对于这两种雾化装置在工作参数和漆雾参数的测量值之间有很明确的 atomizer (Figure 1), the paint flow rate (white base coat),atomizing air flow 1, atomizing air flow 2 and rotation speedof the bell were varied in 5% increments (Table 2). In this case,the measuring point was moved from the atomizer axis to adistance of 7 cm from the edge of the bell. As expected,there was an almost linear increase in thenumber of droplets and their diameter as the paint flow ratewas raised (Figure 5a). In contrast, the diameter fell and thenumber of droplets increased as the rotation speed changed(Figure 5b). The droplet speed remained almost constantwhen the paint flow rate rose by 0.1 m/s per 5% increment. However, as the rotation speed grew, the droplet speedfell slightly by -0.2 m/s per 5% increment. The explanation forthis phenomenon is that the droplets reduced in size at thesame time and smaller droplets slow down to a greater extentthan larger droplets because of their lower inertia. The increase in shaping air flow 1 resulted in a linearfall in the number of droplets, while the size of the dropletsincreased (Figure 6). The dynamic forces involved in creatingthe droplets (centrifugal force, surface tension of the liquidand aerodynamic forces produced by the two shaping airflows) are in a constantly changing equilibrium with oneanother,however those forces were not further analysed inthis project. The project "Resource-efficient coating using innovativehigh-speed rotary atomizers (ESTA)" [1] organized by theautomation and process technology committee of the DFO(German Research Association for Surface Treatment) iscurrently investigating related phenomena. The droplet speed remained almost constant at between8.4 m/s and 8.8 m/s during changes to shaping air flow 1, whileit showed a slight tendency to rise when shaping air flow 2was changed.This behavior is plausible, as shaping air flow 1 isprimarily responsible for causing the droplets to separate anddisintegrate. Shaping air flow 2 diverts the spray and has onlya minor influence on its speed.The added volume of paint didnot bring and kinetic energy into the system. On the contrary,because of the additional mass, the motor powering the bellhad to provide extra energy in order to keep the speed of thebell constant. From an overall perspective, minor changes of up to5% in shaping air flow 2 have only a slight influence on thespray parameters. 图6:高速旋转雾化器:相对于成型空气1的液滴数量和尺寸(虚线) Figure 6: High-speed rotaryatomizer: number of droplets and size (dotted line) in relation to the shaping air 1 联系(表3)。在气动雾化装置的情况中,雾化空气流量和漆滴数量之间有线性关系。此外,在这三个漆雾参数和空气扇流量变化之间有明显的关联。我们还证实了,涂漆流量对漆雾仅有极小的影响。正如在高速旋转雾化装置的情况中所预期的,旋转速度对漆滴参数有很强的影响。高旋转速度总是会减小漆滴的大小。此外,还识别出漆滴数量、涂漆流量和成型空气流量1之间的关联。工作参数的变化对漆滴速度产生极小的影响。 AOM系统公司的SS20V125A测量系统能可靠地测量出由小至5%的工作参数变化而引起的漆雾变化,尽管有这样一个事实:对于机器人的总误差率,制造商的数据是2.5%,这并不是很小。系统的高灵敏度以及同时记录多个漆雾参数的能力,能够使漆雾的误差被快速而可靠地探查出来。 ATEX相容及静电相容的SpraySpy产品系列使其能首次使用这种系统用于内联质量监控,并探测出漆雾的出现的小的偏离。这可使喷漆操作向全自动监控和控制回路更近了一步,并代表着向全自动、网络化智能喷涂车间的发展迈进了一大步。 ( 备注 ) [1]1]EESTA是由德国联邦经济事务和能源部资助的IGF(联合性工业研究)项目。 本研究论文是以德国汽车工程大会演讲为基础·并首先以德文在德国JOT杂志上发表(www.jot-oberflaeche.de)。This research paper is based on the presentation inAutomotive Engineering Congress, and was firstlypublished in German in JOT (www.jot-oberflaeche.de). Summarv This short series of tests demonstrated a clear connectionfor both atomizers between the operating parametersand the measurements of the spray parameters (Table 3).In the case of the pneumatic atomizer there was a linearrelationship between the atomizing air flow and the numberof droplets. In addition, there was an obvious correlationbetween the three spray parameters and the variation in theair fan flow. We also demonstrated that the paint flow ratehad only a negligible influence on the spray. As expectedin the case of the high-speed rotary atomizer, the rotationspeed had a strong influence on the droplet parameters.High rotation speeds always reduce the droplet size. Inaddition, a correlation was identified between the numberof droplets, the paint flow rate and shaping air flow 1. Thevariation in the operating parameters had very little impacton the droplet speed. The SS20V125A measurement system from AOM-Systems can reliably measure changes in the paint spraycaused by variations in the operating parameters of as littleas 5%, despite the fact that the manufacturer’s figure for thetotal error rate of the robot is 2.5%, which is not significantlyless. The system’'s high level of sensitivity and ability to recordseveral spray parameters simultaneously allow spray faults tobe detected quickly and reliably. The ATEX-compliant and Electrostatic compatibleSpraySpy product range makes it possible for the first timeto use a system of this kind for inline quality monitoringand to detect small deviations in the spray. This brings thepossibility of a fully automated monitoring and controlcircuit for paint applications one step closer and representsa significant move towards the development of completelyautomated and networked smart paint shops. ( Remark ) ( [1] ESTA is a n IGF (Collective Industrial Research) project funded by the G erman Federal M i nistry for Economic Affairs and Energy. ) 国际表面处理》O刊 EPTEMBER SURFACE FINISHING JOURNAL 德国AOM系统公司名称来源于“AdvanceOptical Measurement Systems“,即先进的光学测量系统,AOM公司作为喷雾监测技术的发明者,为喷雾或粉体颗粒的特性描述提供了创新的探测器和测量系统,并获得了2015年德国工业奖。此系统采用时间漂移技术实时监测喷雾的过程中液滴或粉体颗粒的大小,速度,动量或流量密度等特性,为喷雾或粉体颗粒的监测提供了独有的测量技术。

确定

还剩3页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《塗漆中漆雾工艺评价检测方案(其它)》,该方案主要用于汽车涂层和镀层中涂层和镀层性能检测,参考标准--,《塗漆中漆雾工艺评价检测方案(其它)》用到的仪器有

相关方案

更多