方案详情

文

全自动消解加上全自动蒸馏和滴定系统,减少人工操作,结果准确,重复性高。

意大利设计和生产制造,质量可靠。

方案详情

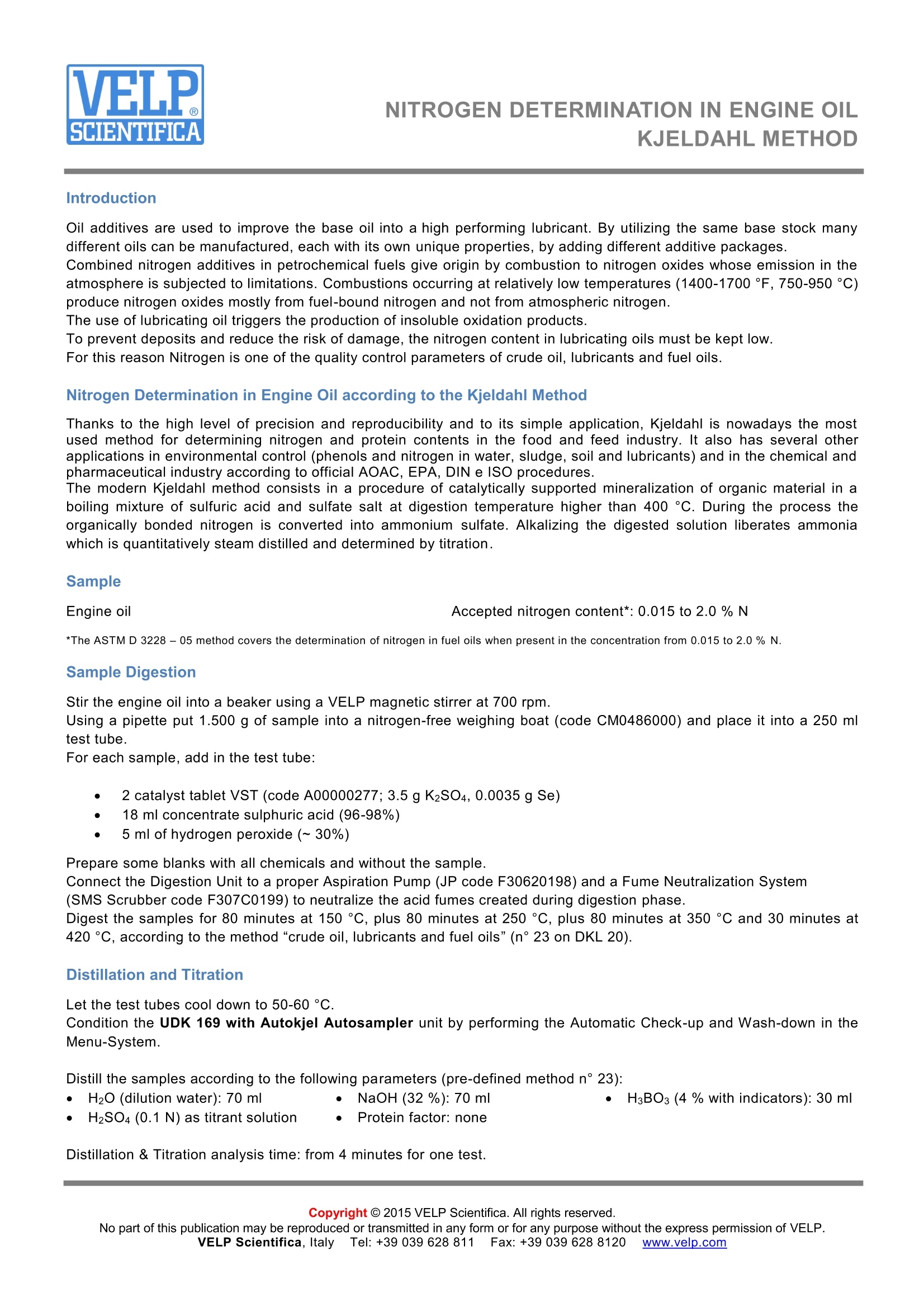

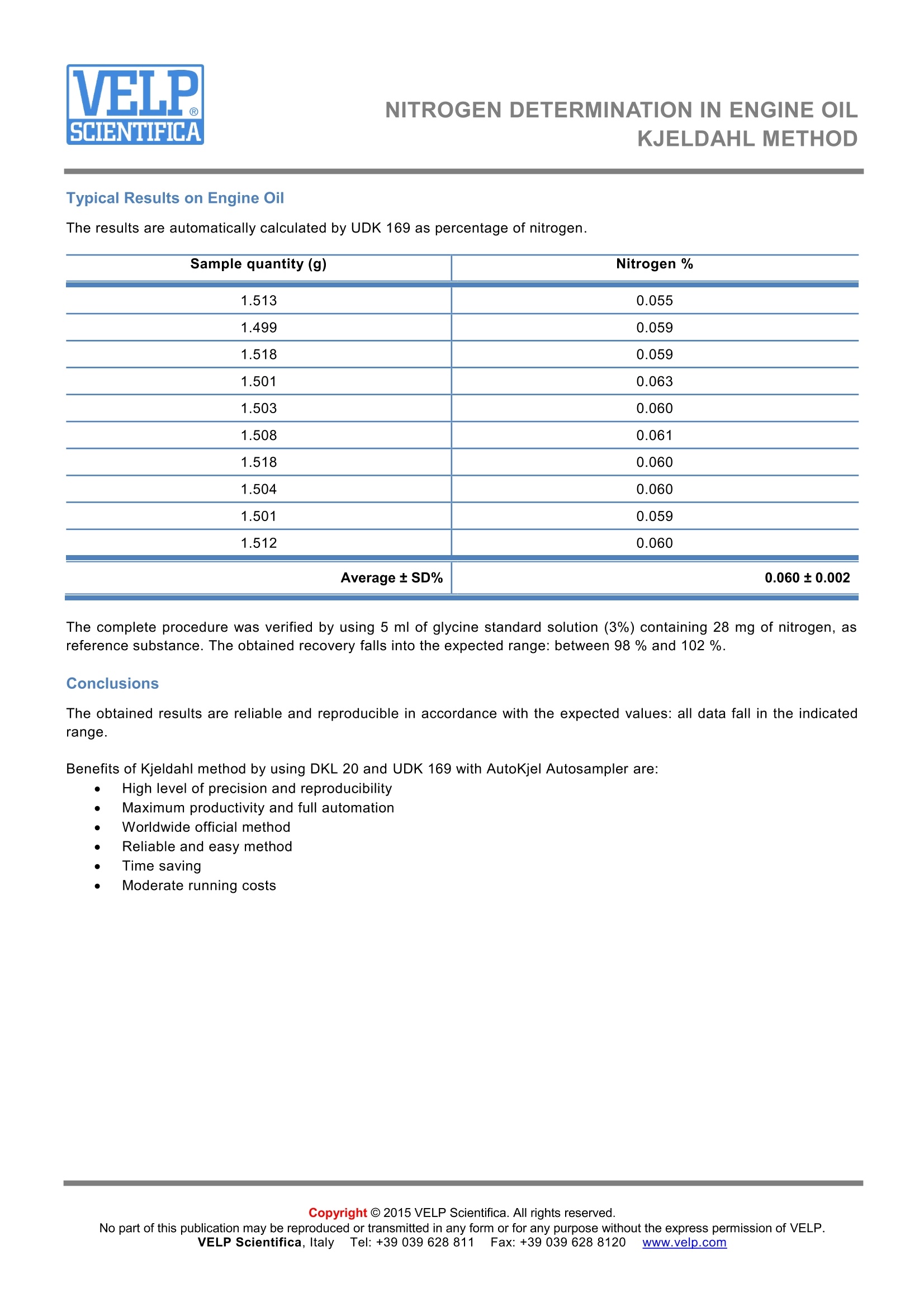

APPLICATION NOTEC-K-001-2015/A1 NITROGEN DETERMINATION IN ENGINE OILKJELDAHL METHOD N Determination in Engine Oilaccording to the Kjeldahl method Reference: ASTM D 3228- 03 Total Nitrogen in Lubricating Oils and Fuel Oils by Modified Kjeldahl Method Tested with VELP Scientifica DKL 20 Automatic Kjeldahl Digestion Unit (Code S30100210) andUDK 169 Automatic Kjeldahl Analyzer with AutoKjel Autosampler (Code S30200160) Introduction Oil additives are used to improve the base oil into a high performing lubricant. By utilizing the same base stock manydifferent oils can be manufactured, each with its own unique properties, by adding different additive packages. Combined nitrogen additives in petrochemical fuels give origin by combustion to nitrogen oxides whose emission in theatmosphere is subjected to limitations. Combustions occurring at relatively low temperatures (1400-1700°F, 750-950°C)produce nitrogen oxides mostly from fuel-bound nitrogen and not from atmospheric nitrogen. The use of lubricating oil triggers the production of insoluble oxidation products. To prevent deposits and reduce the risk of damage, the nitrogen content in lubricating oils must be kept low. For this reason Nitrogen is one of the quality control parameters of crude oil, lubricants and fuel oils. Nitrogen Determination in Engine Oil according to the Kjeldahl Method Thanks to the high level of precision and reproducibility and to its simple application, Kjeldahl is nowadays the mostused method for determining nitrogen and protein contents in the food and feed industry. It also has several otherapplications in environmental control (phenols and nitrogen in water, sludge, soil and lubricants) and in the chemical andpharmaceutical industry according to official AOAC, EPA, DIN e ISO procedures. The modern Kjeldahl method consists in a procedure of catalytically supported mineralization of organic material in aboiling mixture of sulfuric acid and sulfate salt at digestion temperature higher than 400°C. During the process theorganically bonded nitrogen is converted into ammonium sulfate. Alkalizing the digested solution liberates ammoniawhich is quantitatively steam distilled and determined by titration. Sample Engine oil Accepted nitrogen content*: 0.015 to 2.0% N *The ASTM D 3228 -05 method covers the determination of nitrogen in fuel oils when present in the concentration from 0.015 to 2.0 % N. Sample Digestion Stir the engine oil into a beaker using a VELP magnetic stirrer at 700 rpm. Using a pipette put 1.500 g of sample into a nitrogen-free weighing boat (code CM0486000)and place it into a 250 mltest tube. For each sample, add in the test tube: 2 catalyst tablet VST (code A00000277;3.5gK2SO4,0.0035 g Se) ● 18 ml concentrate sulphuric acid (96-98%) ● 5 ml of hydrogen peroxide (~30%) Prepare some blanks with all chemicals and without the sample. Connect the Digestion Unit to a proper Aspiration Pump (JP code F30620198) and a Fume Neutralization System (SMS Scrubber code F307C0199) to neutralize the acid fumes created during digestion phase. Digest the samples for 80 minutes at 150°℃, plus 80 minutes at 250°℃, plus 80 minutes at 350°C and 30 minutes at420°C, according to the method“crude oil, lubricants and fuel oils”(n°23 on DKL 20). Distillation and Titration Let the test tubes cool down to 50-60 °C. Condition the UDK 169 with Autokjel Autosampler unit by performing the Automatic Check-up and Wash-down in theMenu-System. Distill the samples according to the following parameters (pre-defined method n°23): H2O (dilution water):70 ml NaOH (32%): 70 ml H3BO3 (4 % with indicators): 30 ml H2SO4 (0.1 N) as titrant solution FProtein factor: none Distillation & Titration analysis time: from 4 minutes for one test. Typical Results on Engine Oil The results are automatically calculated by UDK 169 as percentage of nitrogen. Sample quantity (g) Nitrogen % 1.513 0.055 1.499 0.059 1.518 0.059 1.501 0.063 1.503 0.060 1.508 0.061 1.518 0.060 1.504 0.060 1.501 0.059 1.512 0.060 Average±SD% 0.060±0.002 The complete procedure was verified by using 5 ml of glycine standard solution (3%) containing 28 mg of nitrogen, asreference substance. The obtained recovery falls into the expected range: between 98%and 102 %. Conclusions The obtained results are reliable and reproducible in accordance with the expected values: all data fall in the indicatedrange. Benefits of Kjeldahl method by using DKL 20 and UDK 169 with AutoKjel Autosampler are: High level of precision and reproducibility Maximum productivity and full automation Worldwide official method Reliable and easy method Time saving Moderate running costs Copyright ◎ VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel:+ Fax: + www.velp.com

确定

还剩1页未读,是否继续阅读?

意大利VELP公司为您提供《机油中N素检测方案(电热消解仪)》,该方案主要用于润滑油中含量分析检测,参考标准--,《机油中N素检测方案(电热消解仪)》用到的仪器有VELP DKL 20 全自动消化炉、VELP唯意朴仪器 全自动凯氏定氮仪UDK 159

推荐专场