特殊的涂层工艺,如 DLC(类金刚石碳膜)PVD (物理气相沉积) 或 CVD (化学气相沉积) 对测量技术提出了挑战。极薄的涂层对测量提出了更高的要求,使得传统的显微硬度计无法对如此薄的涂层/薄膜的机械性能做出正确的测量。

菲希尔(FISCHER)采用仪器化压入测试方法的自动化纳米压痕仪,可以对该类涂层的性能做出快速、准确的测量,十分适用于研发、质量控制、来料检验和过程控制等领域。

方案详情

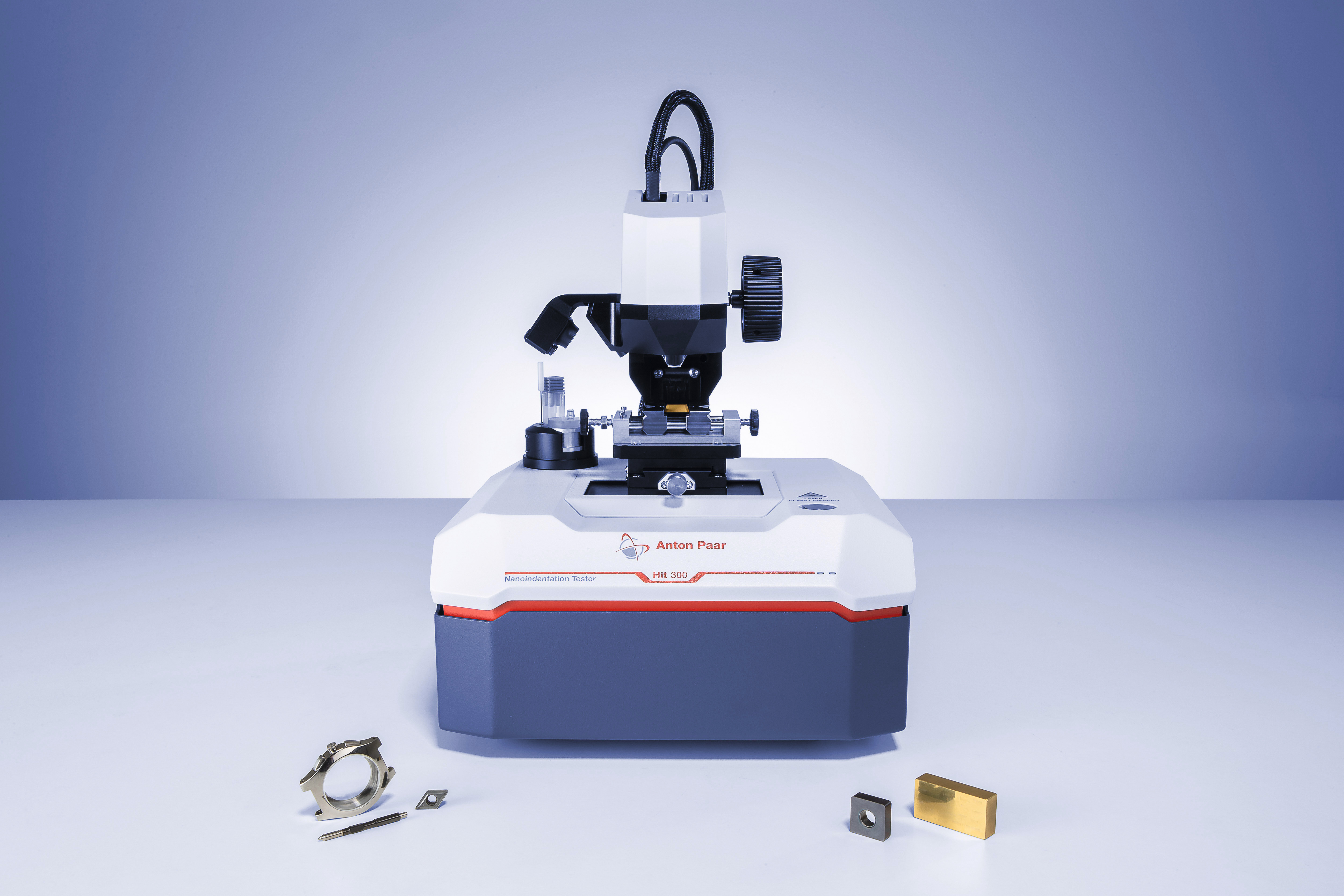

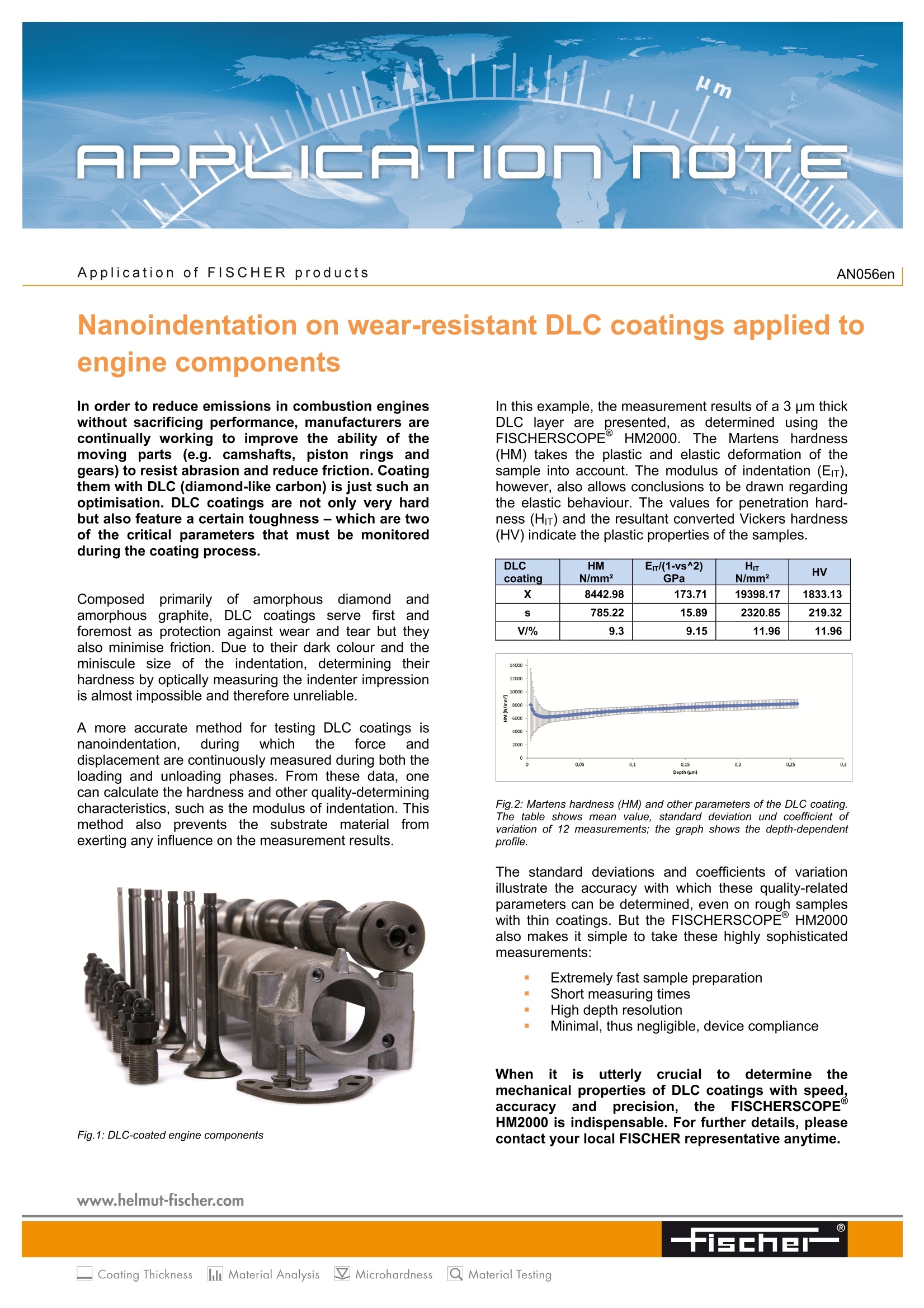

AN056en-Fischel—QCoating Thicknesshh Material AnalysisISMicrohardness QMaterial Testing Application of FISCHER products Nanoindentation on wear-resistant DLC coatings applied toengine components In order to reduce emissions in combustion engineswithout sacrificing performance, manufacturers arecontinually working to improve the ability of themoving parts (e.g. camshafts, piston rings andgears) to resist abrasion and reduce friction. Coatingthem with DLC (diamond-like carbon) is just such anoptimisation. DLC coatings are not only very hardbut also feature a certain toughness - which are twoof the critical parameters that must be monitoredduring the coating process. Composedprimarilyof amorphous diamondandamorphous graphite, DLC coatings serve first andforemost as protection against wear and tear but theyalso minimise friction. Due to their dark colour and theminiscule size of the indentation, determining theirhardness by optically measuring the indenter impressionis almost impossible and therefore unreliable. A more accurate method for testing DLC coatings isnanoindentation.(during which the force anddisplacement are continuously measured during both theloading and unloading phases. From these data, onecan calculate the hardness and other quality-determiningcharacteristics, such as the modulus of indentation. Thismethod also prevents the substrate material fromexerting any influence on the measurement results. Fig.1: DLC-coated engine components In this example, the measurement results of a 3 pm thickDLC layer are presented, as determined using theFISCHERSCOPE HM2000. The Martens hardness(HM) takes the plastic and elastic deformation of thesample into account. The modulus of indentation (EiT),however, also allows conclusions to be drawn regardingthe elastic behaviour. The values for penetration hard-ness (Hir) and the resultant converted Vickers hardness(HV) indicate the plastic properties of the samples. DLC coating HMN/mm² E/(1-vs^2)GPa HITN/mm² HV 8442.98 173.71 19398.17 1833.13 S 785.22 15.89 2320.85 219.32 V% 9.3 9.15 11.96 11.96 Fig.2: Martens hardness (HM) and other parameters of the DLC coating.The table shows mean value, standard deviation und coefficient ofvariation of 12 measurements; the graph shows the depth-dependentprofile. The standard deviations and coefficients of variationillustrate the accuracy with which these quality-relatedparameters can be determined, even on rough sampleswith thin coatings. But the FISCHERSCOPEHM2000also makes it simple to take these highly sophisticatedmeasurements: Extremely fast sample preparation Short measuring times High depth resolution Minimal, thus negligible, device compliance When it is utterly crucial to determine themechanical properties of DLC coatings with speed,accuracy and precision, the FISCHERSCOPE:HM2000 is indispensable. For further details, pleasecontact your local FISCHER representative anytime. 工业中各种硬质涂层的产品:对面表强度有很高要求的刀具涂层:特殊的涂层工艺,如 DLC(类金刚石碳膜)PVD (物理气相沉积) 或 CVD (化学气相沉积) 对测量技术提出了挑战。极薄的涂层对测量提出了更高的要求,使得传统的显微硬度计无法对如此薄的涂层/薄膜的机械性能做出正确的测量。菲希尔(FISCHER)采用仪器化压入测试方法的自动化纳米压痕仪,可以对该类涂层的性能做出快速、准确的测量,十分适用于研发、质量控制、来料检验和过程控制等领域。例如,下图中展示了3μm厚的DLC涂层使用HM2000测量的结果:HM(马氏硬度)衡量的涂层的塑性变形和弹性变形,EIT的测量结果同样也能描述涂层的弹性变形性能,HIT(压痕硬度)和HV(维氏硬度)描述了涂层的塑性变形性能。如果您的公司或行业需要快速、精确地测量DLD/PVD/CVD这类硬质涂层的硬度、模量等机械性能,那么菲希尔的HM2000无疑是您最好的选择!

确定

还剩1页未读,是否继续阅读?

菲希尔测试仪器(中国)有限公司为您提供《DLC/PVD/CVD等各类涂层中硬度、模量、蠕变、松弛、弹性功等机械性能检测方案(纳米压痕仪)》,该方案主要用于其他中硬度、模量、蠕变、松弛、弹性功等机械性能检测,参考标准--,《DLC/PVD/CVD等各类涂层中硬度、模量、蠕变、松弛、弹性功等机械性能检测方案(纳米压痕仪)》用到的仪器有菲希尔HM2000微纳米压痕仪

推荐专场

相关方案

更多