方案详情

文

无论是小规模还是大的农业应用,优化杀虫剂、除草剂、杀菌剂都要取决于一些基本的表面科学。例如杀虫剂的喷洒不仅要考虑静态表面张力还要考虑其动态表面张力。这同样影响着润湿效果。本文主要分享这种技术而不是促销提到的表面活性剂。

方案详情

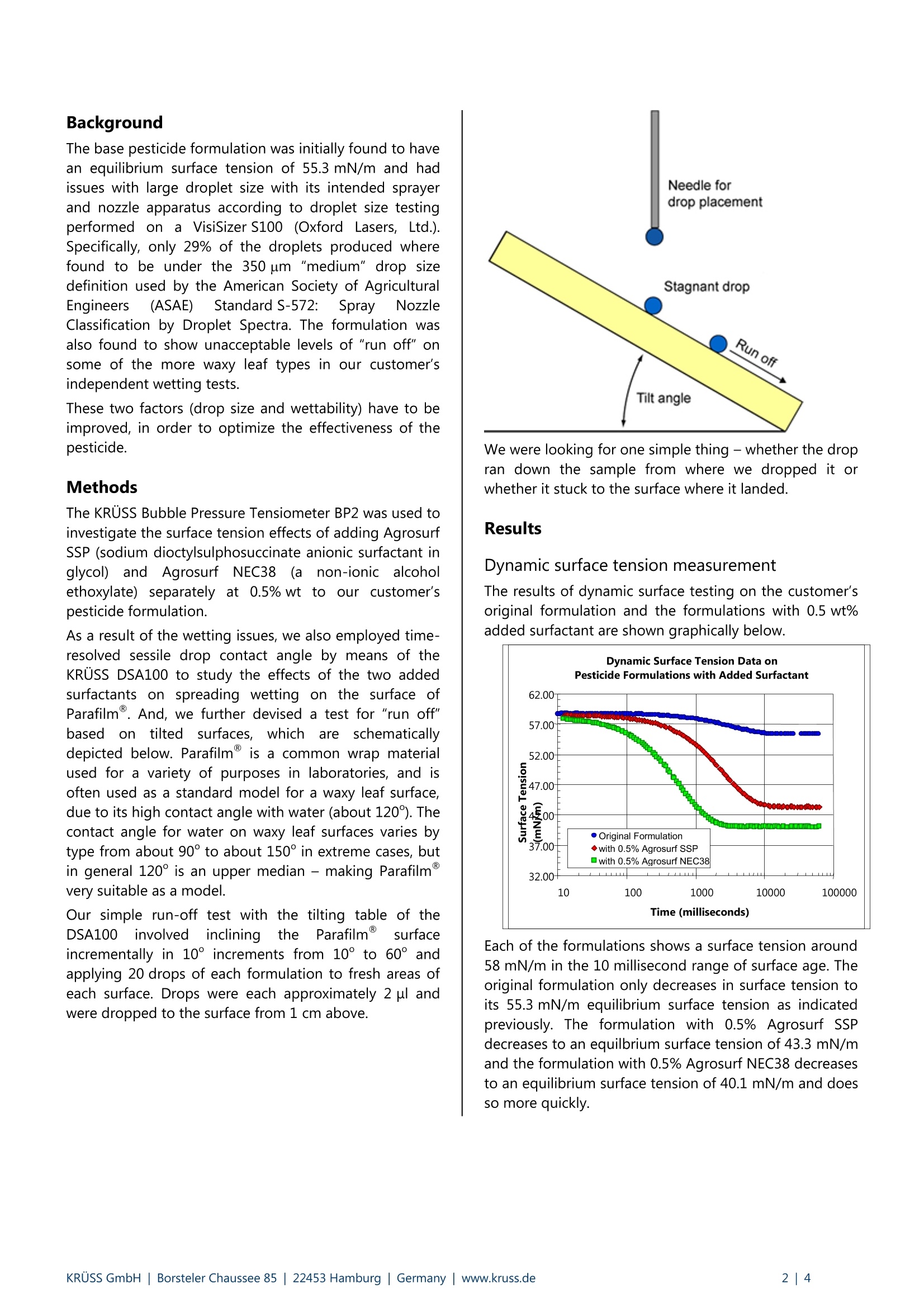

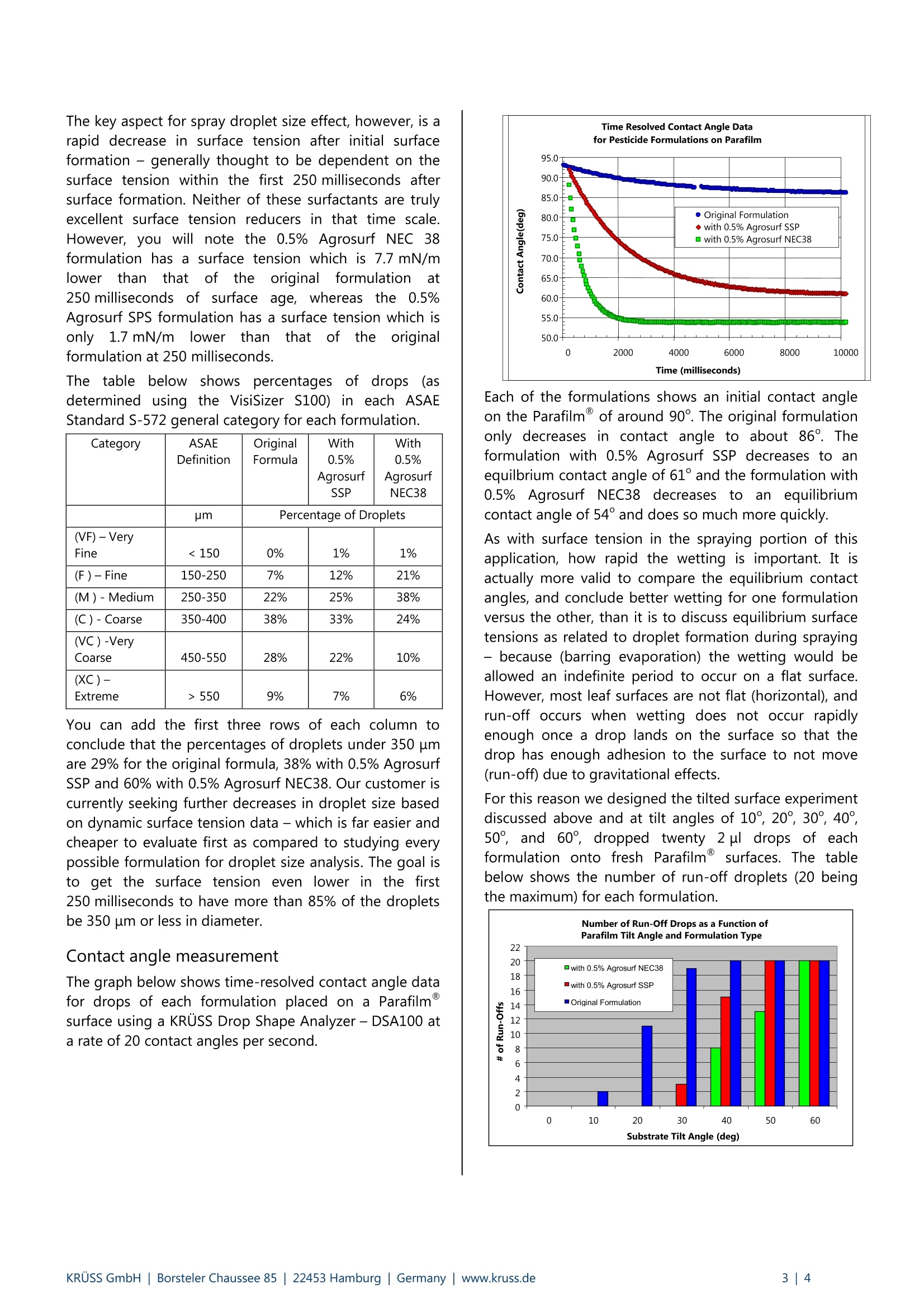

Application Report Surfactant Additives for Pesticide Formulations Application report: AR261e Industry section: Agriculture, Biotechnology Author: Dr. Christopher Rulison Date: 12/2007 Method: Bubble Pressure Tensiometer Drop Shape Analyzer- BP2 DSA100 Keywords: Dynamic Surface Tension, Contact Angle, Atomization, Wettability, Pesticides Surfactant Additives for Pesticide Formulations -Effects on Both SprayAtomization and Substrate Wettability Abstract Optimizing the application of pesticides, herbicides, and fungicides by spraying techniques -either on the small scale orin the case of large agricultural application - depends on some fundamental surface science. For example the interfacialtension determines (for any given amount of pressure and nozzle configuration) the size of the formed droplets ofpesticide. Reducing the size of spray droplets down to a certain point (typically 100 um, wherein spray drift becomes a problem inlarge scale applications) means more uniform application of the pesticide to crops. This means lowering surface tensionthrough the addition of surfactants. To make matters more complicated, it is not just the equilibrium surface tension ofthe formulation that needs to be considered in choosing surfactants to use, because spraying is a dynamic process. Oneneeds to consider not only what surface tension a surfactant can ultimately impart on a formulation, but also how quicklythe surfactant is capable of lowering the surface tension of freshly formed surface. Spray droplets are dynamic surface, not at equilibrium conditions - a fact that also has implications on wetting (thesecond function of surfactants in a pesticide formulation) once the spray hits its target surface (generally the leaves of thecrop). The data and methods we share here are the result of a recent investigation in our labs and others aimed at findinga good surfactant additive for one of our customers pesticide formulations considering both spraying and wettingaspects. The main goal is to share the techniques, not to promote either of the surfactants mentioned in the work, or tonecessarily show an ultimate solution. Background The base pesticide formulation was initially found to havean equilibrium surface tension of 55.3 mN/m and hadissues with large droplet size with its intended sprayerand nozzle apparatus according to droplet size testingperformed on a VisiSizer S100 (Oxford Lasers, Ltd.).Specifically, only 29% of the droplets produced wherefound to be under the 350 um "medium" drop sizedefinition used by the American Society of AgriculturalEngineers(ASAE) Standard S-572::Spray NozzleClassification by Droplet Spectra. The formulation wasalso found to show unacceptable levels of "run off" onsome of the more waxy leaf types in our customer'sindependent wetting tests. These two factors (drop size and wettability) have to beimproved, in order to optimize the effectiveness of thepesticide. Methods The KRUSS Bubble Pressure Tensiometer BP2 was used toinvestigate the surface tension effects of adding AgrosurfSSP (sodium dioctylsulphosuccinate anionic surfactant inglycol)andAAgrosurf NEC38(a non-ionic alcoholethoxylate) separately12at 0.5% wt to our customer'spesticide formulation. As a result of the wetting issues, we also employed time-resolved sessile drop contact angle by means of theKRUSS DSA100 to study the effects of the two addedsurfactants on spreading wetting on the surface ofParafilm. And, we further devised a test for "run off"basedl on tilted surfaces, whichare schematicallydepicted below. Parafilmis a common wrap materialused for a variety of purposes in laboratories, and isoften used as a standard model for a waxy leaf surface,due to its high contact angle with water (about 120°). Thecontact angle for water on waxy leaf surfaces varies bytype from about 90° to about 150° in extreme cases, butin general 120° is an upper median - making Parafilmery suitable as a model. Our simple run-off test with the tilting tableR of theDSA100 involved incliningthe Parafilm surfaceincrementally in 10°increments from 10°to 60° andapplying 20 drops of each formulation to fresh areas ofeach surface. Drops were each approximately 2 ul andwere dropped to the surface from 1 cm above. We were looking for one simple thing-whether the dropran down the sample from where we dropped it orwhether it stuck to the surface where it landed. Results Dynamic surface tension measurement The results of dynamic surface testing on the customer'soriginal formulation and the formulations with 0.5 wt%added surfactant are shown graphically below. Each of the formulations shows a surface tension around58 mN/m in the 10 millisecond range of surface age. Theoriginal formulation only decreases in surface tension toits 55.3 mN/m equilibrium surface tension as indicatedpreviously. The formulation with 0.5% Agrosurf SSPdecreases to an equilbrium surface tension of 43.3 mN/mand the formulation with 0.5% Agrosurf NEC38 decreasesto an equilibrium surface tension of 40.1 mN/m and doesso more quickly. The key aspect for spray droplet size effect, however, is arapid decrease in surface tension after initial surfaceformation - generally thought to be dependent on thesurface tension within the first 250 milliseconds aftersurface formation. Neither of these surfactants are trulyexcellent surface tension reducers in that time scale.However, you will note the 0.5% Agrosurf NEC 38formulation has a surface tension which is 7.7 mN/mlower thanthat of the originallfoformulation at250 milliseconds of surface age, whereas the 0.5%Agrosurf SPS formulation has a surface tension which isonly 1.7 mN/m lower than that of theoriginalformulation at 250 milliseconds. The table below showspercentages of drops (asdetermined using the VisiSizer S100) in each ASAEStandard S-572 general category for each formulation. Category ASAEDefinition OriginalFormula With 0.5%AgrosurfSSP With 0.5%AgrosurtNEC38 um Percentage of Droplets (VF)-VeryFine <150 0% 1% 1% (F)- Fine 150-250 7% 12% 21% (M) - Medium 250-350 22% 25% 38% (C) - Coarse 350-400 38% 33% 24% (VC )-VeryCoarse 450-550 28% 22% 10% (XC)-Extreme > 550 9% 7% 6% You can add the first three rows of each column toconclude that the percentages of droplets under 350 pmare 29% for the original formula, 38% with 0.5% AgrosurfSSP and 60% with 0.5% Agrosurf NEC38. Our customer iscurrently seeking further decreases in droplet size basedon dynamic surface tension data - which is far easier andcheaper to evaluate first as compared to studying everypossible formulation for droplet size analysis. The goal isto get the surface tension even lower in the first250 milliseconds to have more than 85% of the dropletsbe 350 um or less in diameter. Contact angle measurement The graph below shows time-resolved contact angle datafor drops of each formulation placed on a Parafilm"surface using a KRUSS Drop Shape Analyzer- DSA100 ata rate of 20 contact angles per second. Each of the formulations shows an initial contact angleon the Parafilmof around 90°. The original formulationonly decreases in contact angle to about 86°. Theformulation with 0.5% Agrosurf SSP decreases to anequilbrium contact angle of 61° and the formulation with0.5% Agrosurf NEC38 decreases to an equilibriumcontact angle of 54° and does so much more quickly. As with surface tension in the spraying portion of thisapplication, how rapid the wetting is important. It isactually more valid to compare the equilibrium contactangles, and conclude better wetting for one formulationversus the other, than it is to discuss equilibrium surfacetensions as related to droplet formation during spraying- because (barring evaporation) the wetting would beallowed an indefinite period to occur on a flat surface.However, most leaf surfaces are not flat (horizontal), andrun-off occurs when wetting does not occur rapidlyenough once a drop lands on the surface so that thedrop has enough adhesion to the surface to not move(run-off) due to gravitational effects. For this reason we designed the tilted surface experimentdiscussed above and at tilt angles of 10°,20°, 30°, 40°,50°, and 60°, dropped twenty 2 ul drops of eachformulation onto fresh Parafilm surfaces. The tablebelow shows the number of run-off droplets (20 beingthe maximum) foreach formulation. In these data you see that the surfactants tend to preventdrops from running off the tilted model leaf surface.More than half of the drops of the original formulationrun off at a 20° tilt angle and all run off at the 40° tiltangle and above. Agrosurf NEC38 is more effective thanAgrosurf SSP preventing all run offs at the 30° tilt angleand 60% of run offs (12 drops / 20 drops) at the 40° tiltangle. Agrosurf SSP prevents only 85% of the run-offs(17 drops / 20 drops) at the 30° tilt angle and 25% of therun-offs (5 drops / 20 drops) at the 40° tilt angle. Thecustomer plans to use this technique in search of evenbetter surfactant additives for his pesticides. Summary The optimization of pesticide application in terms ofspraying and wetting the surfaces of crops involvesdynamic surface tension, time-dependent contact angle(spreading), and droplet adhesion on non-horizontalsurfaces. Surfactants are commonly added to pesticideformulations to control spray atomization and wetting. Hopefully this brief note, based on using one exampledata set from our own experience, gives you insights intomethods that can be employed to fundamentally studythese important aspects and find the best surfactantadditives for your own formulations. KRUSS GmbH|Borsteler Chaussee Hamburg| Germany|\www.kruss.de|

确定

还剩2页未读,是否继续阅读?

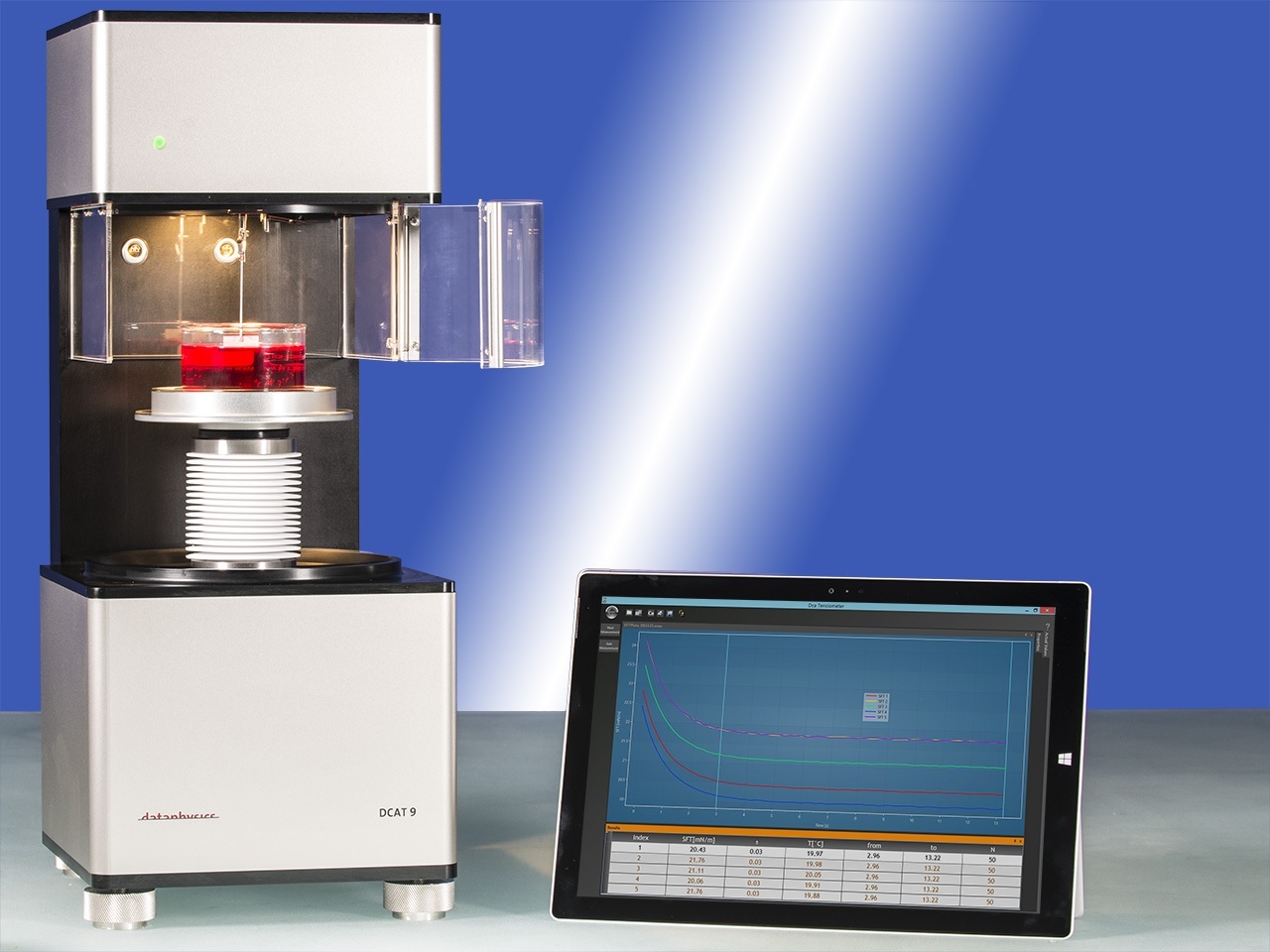

克吕士科学仪器(上海)有限公司为您提供《农药,表面活性剂中润湿性检测方案(表面张力仪)》,该方案主要用于杀虫剂中润湿性检测,参考标准--,《农药,表面活性剂中润湿性检测方案(表面张力仪)》用到的仪器有KRUSS BP100型动态表面张力仪、KRUSS DSA100接触角测量仪

推荐专场

相关方案

更多